Development of a concrete mixture composition utilizing a nanostructuring additive for 3D printing of small architectural forms

Автор: Zhegera K.V., Dasaeva N.A.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Construction materials science

Статья в выпуске: 1 Vol.17, 2025 года.

Бесплатный доступ

Introduction. Currently, additive technologies are widely used across various fields. Their application in construction addresses several critical challenges. In the 3D printing process of small architectural forms, it is very important to choose the right composition of the materials from which they will be made. Materials and methods. We used for composition development: synthesized aluminosilicates as a nanomodifying additive, Portland cement without additives 52.5N as a binder, fine filler quartz sand from the Ukhtinsky and Chaadaevsky deposits, complex additive Sika Antifreeze N9, and superplasticizers Axton and C-3. The water retention capacity of formulations using a nanomodifying additive was determined by the amount of water in the test composition before and after the tests. The kinetics of water absorption of the compositions was determined in accordance with the methodology presented in GOST 5802. Porosity was determined by the content of free and chemically bound water in the cement stone. The change in the normal density and setting time was determined using the Vic device. The intergranular voidness of the sand was calculated from the values of the true and bulk densities of the fine aggregate. The true density was determined using the Le Chatelier device. The bulk density of materials was determined using the methodology established by GOST 9758. Results and discussion. It was revealed that the presence of a nanomodifying additive in the composition, with a dispersion of Sud = 0.69 m2/g and Sud = 1.03 m2/g, increases the strength of the compositions compared with the control ones (without additives) from 7% to 17.8%, respectively. That is, there is an inverse relationship between the dispersion of the introduced additive and the change in the strength of the samples. The high dispersion value of the introduced additive ensures optimal conditions for the hardening of compounds, which is confirmed by studies on the water absorption of compounds. During the research, the influence of the amount of the studied additive on the setting time of cement, changes in the normal density of cement dough and porosity of cement systems were evaluated. In order to reduce cement consumption and increase the mobility of the mixture composition, a fine filler is introduced – sand with a mixed grain composition. In the process of selecting the composition of the concrete mix for 3D printing of small architectural forms, their technological properties were taken into account. Four compositions of a concrete mix for 3D printing with different amounts of nanostructuring additive, sand, and cement were studied. Conclusion. Compositions with optimal characteristics have been identified for further research in the field of selection and development of concrete mixtures for 3D printing of small architectural forms.

3D printing, composition, concrete mix, nanostructuring additive, mobility, shrinkage, strength

Короткий адрес: https://sciup.org/142243353

IDR: 142243353 | DOI: 10.15828/2075-8545-2025-17-1-14-22

Текст научной статьи Development of a concrete mixture composition utilizing a nanostructuring additive for 3D printing of small architectural forms

Original article

In recent years, additive technologies have become an important tool in construction, including the creation of small architectural forms, opening up new horizons for design and implementation [1–9]. To create small architectural forms, building mixes are used on various types of binder, but products made with cement binder are considered the most durable and durable. Construction 3D printing using concrete mixes allows you to create complex and unique objects, not limited to traditional methods. This approach not only reduces construction time, but also significantly reduces material costs.

The development of compositions for concrete mixtures used in construction 3D printing is an exciting and promising area of modern construction technologies. Depending on the requirements of the project, the concrete composition must provide the necessary mechanical properties, solidification rate and resistance to external influences.

The key role is played by the choice of binders, additives and fillers, which affect the fluidity of the mixture and its adhesion to the 3D printer. An important aspect is the optimization of the formulation to ensure the uniformity and stability of the material flow, which is critical for the output layers of the structure.

Currently, many studies are focused on the creation of modifying additives that improve the characteristics of building mixes, as well as on the development of optimal formulations for 3D printing used in construction. In this regard, the process of selecting components for a building mix designed for 3D printing of small architectural objects is relevant [10–22].

METHODS AND MATERIALS

The following materials were used in the research:

– nanostructuring additive;

– additive-free Portland cement 52.5N;

– complex concrete additive Sika Antifreeze N9;

– the sand of the Ukhta deposit;

– sand of the Chapaevsky deposit;

– Axton superplasticizer;

– superplasticizer C-3.

The nanostructuring additive was obtained from an aluminosilicate precipitate, which is dried and ground to a powder with the required specific surface area [23].

The specific surface area of bulk materials was measured using the PSX-9 device [24].

To determine the water retention capacity, an installation consisting of a glass plate with a thickness of 5mm and a size of (150×150) mm; blotting paper with a size of (150×150) mm; a metal ring with a wall thickness of 5 mm, a height of 12 mm and a diameter of 100 mm and a gauze cloth gasket (250×350) mm was

used [25]. The calculation was carried out according to the formula:

, -(1 。。 тп^—тп^ 1 。。) , (1)

where m 1 – the weight of the blotting paper size (150×150) mm before testing, g;

m 2 – the weight of the blotting paper after the test, g;

m 3 – installation weight without mortar mixture, g;

m 4 – the mass of the installation with a mortar mixture, g.

The kinetics of water absorption of the composition was determined by the method specified in GOST 5802 [25]. To do this, the samples were pre-dried to a constant mass and placed in a vessel filled with water t = (20 ± 2) °C. The mass of the samples was measured on a scale every hour, the results were recorded with an accuracy of ±0.1%. The tests continued until the difference between two consecutive weighings did not exceed 0.1%.

Water absorption by weight (Wm) as a percentage was determined using the formula:

И4n =

叫一 2 I00 ,

人

where md – mass of the dried sample, g;

mw – mass of the water–saturated sample, g.

The compressive strength of the samples (MPa) was determined in accordance with GOST 5802 [25]. To determine the strength, samples with a size of 100×100×100 mm and an IR 5057-50 testing machine were used. The load rate on the test sample was set to 10 mm/min. Calculations were carried out according to the formula:

Rс = P / F ,

where P – destructive load, N;

F – sample surface area, m2.

Capillary ( Pcap ), contractional ( Pcon ) and gel ( Pgel ) porosities of the compositions were calculated as a percentage in accordance with the methodology [26] and formulas:

%=絵鳶.1°°,(4)

Р"詳訖・1。。,(5)

p2=面鼻.1°°,(6)

where W/C – water-cement ratio;

The hydration of cement (α) was calculated from the value of chemically bound water ( Wn ) in the studied samples [26]:

CONSTRUCTION MATERIALS SCIENCE

α = 4· Wn . (7)

The open porosity ( Po ), taking into account the natural volume of the material ( Vn, m3 ), was calculated using the formula [26]:

2 - [^ ' 1000 * ]0 。% , (8)

where ms and md is the mass of the material in a saturated state and mass of the material in a dry state, kg.

The total porosity ( Pg ) as a percentage was calculated using the formula [26]:

P = //C-°'216. 100, (9)

g W//C+0,32

The change in the normal density and setting time of the cement dough was determined using the Vika device [27]. The test solution was placed in the bowl, leveled, then the pestle of the Vika device was brought into contact with the solution, the initial value on the scale of the device was fixed and the locking mechanism was removed. After 5 minutes, the final value was measured on the scale of the device. The difference between the initial and final values, equal to (5–7) mm, was considered the normal density of the solution.

The change in the setting time of the composition was measured by the Vika device using a needle. The solution was placed in the bowl of the device and evenly distributed. The needle of the device was brought to the surface of the solution and the locking mechanism was released. The beginning of the setting process was considered to be the moment when the needle did not reach the bottom of the bowl by 1–2 mm, and the end was the moment when the needle did not go deeper into the solution by more than 1–2 mm.

The intergranular voidness of a fine filler in an uncompacted state ( Vi.v. ) was calculated [28]:

%.=аү ) .іоо%, (10)

where ρ b and ρ t – bulk density and true density of the material, g/cm3.

The true density ( сt ) was determined using the Le Chatelier device [29] and the formula:

сt = ( m 1– m 2)/ V , (11)

where V – volume of the poured powder, cm3;

m 1 is the initial mass of the powder with a cup, g;

m 2 – mass of the remaining powder with a cup, g;

The bulk density ( сb ) was determined according to GOST 9758 [30] using the formula:

сb = m / V , (12)

where m is the mass of the material, g;

V –volume of the vessel, cm3.

RESULTS AND DISCUSSIONS

To optimize the composition of the concrete mix for a 3D printer, it is necessary to investigate the effect of each component on the system and determine its optimal content in the formulation.

In order to identify the optimal size of the specific surface of the additive for its use in the composition of the concrete mixture, an assessment of the hardening change was carried out (Fig. 1) and water absorption (Fig. 2) of a cement composite using a synthesized additive of different dispersion in the formulation.

The analysis of Fig. 1 showed that the value of the specific surface of the nanostructuring additive has an effect on the structure formation of cement compositions. It was revealed that a nanostructuring additive with a surface of Sud = 1.03 m2/g and Sud = 0.69 m2/g in the studied compositions favorably affects an increase in compressive strength by 7% and 17.8%, but an increase in the specific surface of the additive leads to a decrease in strength by 35% and 31% compared with the additive-free composition. Thus, a nanomodifying additive with a high dispersion value contributes to the creation of favorable conditions for the strength gain of the composition using cement.

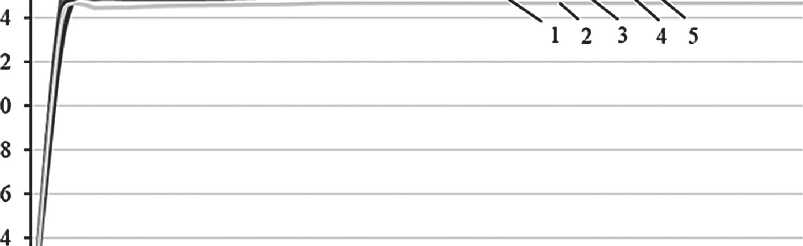

Analysis of the data presented in Fig. 2 showed that samples with an additive with a specific surface area of Sud = 0.69 m2/g, compared with samples with Sud = 0.1 m2/g, have 9.6% lower water absorption. That is, it is possible to identify a pattern that the higher the dispersion value of the additive, the lower the water absorption of the studied compositions.

Thus, for subsequent tests, the optimal surface size of the nanostructuring additive is Sud = 1.03 m2/g.

The results of the effect of the amount of nanostructuring additive, depending on the mass of cement in the cement system, on the setting time and the normal density of the cement dough are shown in Table 1.

It was found that the compositions in the presence of a nanostructuring additive have a higher value of the normal density of the cement paste and a shorter setting time. At the same time, an increase in the percentage of the nanomodifying additive in the cement binder accelerates the setting time of the compositions.

Also, there is a decrease in capillary porosity by 11–52% and total porosity by 2–10%, an increase in gel porosity by 5–23% and contractional porosity by 4–23% compared with the control sample (without additives). Thus, it can be said that the introduction of a nanostructuring additive helps to increase the durability of the composition using cement.

CONSTRUCTION MATERIALS SCIENCE

0 • • I I i I i i I I i к I I I I I I I i i i i i I i i i i i i

0 6 12 18 24 30 36 42 48 54 60 66 72 78 84 90

Curing time, day

Fig. 1. Strength set of compounds with a nanostructuring additive: 1 – sample without additive (control); 2 – specific surface area of the additive Ssp = 1.03 m2/g; 3 – Ssp = 0.69 m2/g; 4 – Ssp = 0.31 m2/g; 5 – Ssp = 0.1 m2/g

18 I

0,. 一一一 I 一一一,I 一一 ■,一

О 2 4 6 8 10 12 14 16 18 20 22 24

Time, hour

Fig. 2. Changing the water absorption of compounds: 1 – control sample; 2 – nanomodifying additive with specific surface area Ssp = 1.03 m2/g; 3 – nanomodifying additive with Ssp = 0.69 m2/g; 4 – nanomodifying additive with Ssp = 0.31 m2/g; 5 – nanomodifying additive with Ssp = 0.1 m2/g

In order to reduce cement consumption and increase the mobility of the mixture, a fine filler sand is introduced. Sand with the lowest intergranular voidness should be used in the composition being developed. In this regard, sands with a mixed grain composition were studied (Table 2). Table 2 shows the granulometric compositions of the sands of the Ukhtinsky and Chaadaevsky deposits.

Thus, the analysis of the data in Table 2–3 showed that for further development of the composition of the

CONSTRUCTION MATERIALS SCIENCE

3D construction mixture, sand from the Ukhtinskoye deposit should be used.

To find the optimal ratio between the three main sand fractions (0.16–0.315mm; 0.315–0.63mm; 0.63– 1.25mm), the value of the bulk density of fine aggregate was estimated using the method of mathematical description of physical adsorption (Table 4).

It has been found that the use of sand with a fraction ratio of 0.63–0.315:0.315–0.16 (mm) of 80% to 20% leads to an increase in the value of the coefficient of angularity (K u), which contributes to the strong adhesion of sand particles to the cement matrix.

In the process of selecting the composition of the concrete mix for 3D printing of small architectural forms, their technological properties were taken into account. Four compositions of a concrete mix for 3D printing with different amounts of nanostructuring additive, sand, and cement were studied. Table 5 shows the basic

requirements for mixtures and the results of the tests performed.

Thus, in the course of the conducted research, it was found that despite the mobility of compositions 3 and 4 cannot be used in 3D printing technology of small architectural forms, since the long-term setting speed of the mixture does not make it possible to apply the mixture in layers. Therefore, formulations 1 and 2 will be used for further research. In the future, a plasticizer will be introduced into the composition to increase the mobility of the mixture.

CONCLUSION

As a result of the study, it was found that the addition of a nanostructuring additive to cement compositions increases their density, shortens the setting time and reduces capillary porosity. To optimize the composition

Table 1. The change in the properties of the composition from the percentage of the nanostructuring additive

|

The amount of nanomodified additive |

||||

|

– |

10% |

20% |

30% |

|

|

The normal density of the cement paste, % |

28 |

34 |

41 |

43 |

|

Setting time |

Beginning 2 h 30min End of 5 h |

Beginning 50 min End 1 h 40 min |

Beginning 40 min End 1 h 30 min |

Beginning 20 min End 1 h 15 min |

|

Total porosity, % |

41.1 |

40.3 |

38.3 |

36.9 |

|

Capillary porosity, % |

18.7 |

16.7 |

12 |

9 |

|

Gel porosity, % |

15.5 |

16.3 |

18.1 |

19.5 |

|

Contractional porosity, % |

7.0 |

7.3 |

8.2 |

8.8 |

Table 2. Granulometric composition of fine aggregate

|

The content of fractions, % |

Sand fraction, mm |

|||||

|

More 2.5 |

2.5–1.25 |

1.25–0.63 |

0.63–0.315 |

0.315–0.16 |

Less 0.16 |

|

|

The sand of the Ukhta deposit |

1.0 |

2.1 |

9.8 |

39.5 |

44.0 |

3.8 |

|

Sand of the Chapaevsky deposit |

– |

0.3 |

12.1 |

58.1 |

26.6 |

2.9 |

Table 3. Density and intergranular voidness of fine filler

|

Fraction size, mm |

Chaadaevsky sand |

Ukhtinsky sand |

||

|

Bulk density, kg/m3 |

Intergranular voidness, % |

Bulk density, kg/m3 |

Intergranular voidness, % |

|

|

0.315–0.16 |

1418.2 |

46.5 |

1460.1 |

44.9 |

|

0.63–0.315 |

1529.9 |

42.3 |

1522.3 |

42.6 |

|

1.25–0.63 |

1599.3 |

39.6 |

1530.3 |

42.3 |

CONSTRUCTION MATERIALS SCIENCE of the 3D construction mix, it is recommended to use sand from the Ukhtinskoye deposit with a fraction ratio of 0.63–0.315:0.315–0.16 (mm) 80%:20%, which provides better mobility and adhesion to cement.

Formulations with long setting times are not suitable for 3D construction printing, so further research will be aimed at reducing the setting time of the formulations and increasing their mobility.

Table 4. The coefficient of angularity for the Ukhta sand deposit

|

Name of the material |

Sf according to the BET method, m2/kg |

Sт , m2/kg |

К u |

|

Sand without sifting |

800 |

776.35 |

1.03 |

|

Sand fractions of 0.16 – 0.315; 0.315 – 0.63; 0.63 – 1.25 (mm) in a ratio of 70%:20%:10% |

789 |

750.4 |

1.05 |

|

Sand fractions 0.63–0.315:0.315–0.16 (mm) in a ratio of 70%:30% |

756 |

652.3 |

1.09 |

|

Sand fractions 0.63–0.315:0.315–0.16 (mm) in a ratio of 75%:25% |

720 |

621.7 |

1.12 |

|

Sand fractions 0,63–0,315:0,315–0,16 (mm) in the ratio 80%:20% |

700 |

582.39 |

1.20 |

Table 5. Technical requirements for a concrete mix solution for 3D printing

|

Requirements |

The value of the indicator |

Composition 1 |

Composition 2 |

Composition 3 |

Composition 4 |

|

Mobility, mm |

no more 7 |

4.4 |

3.8 |

6.7 |

5.4 |

|

Delamination, % |

no more 10 |

2.5 |

1.9 |

7.8 |

8.8 |

|

Water retention capacity |

no less 97 |

97.72 |

98.86 |

96.92 |

9.25 |

|

Plastic strength, Pa |

no less 80 |

81.3 |

86.9 |

31.1 |

75.8 |

|

Setting speed of the mixture, min |

no more 20 min after extrusion |

Beginning 12 min, end – 30 min |

Beginning 15 min, end – 20 min |

Beginning 20 min, end – 67 min |

Beginning 45 min, end – 90 min |

Список литературы Development of a concrete mixture composition utilizing a nanostructuring additive for 3D printing of small architectural forms

- Torshin A.O., Borovikova S.O., Korchunov I.V., Potapova E.N. Development of construction mix for 3D printing. Advances in chemistry and chemical technology. 2018;32(2):164-166.

- Suvash Ch.P., Yi Wei D.T., Biranchi P., Ming J.T. Fresh and hardened properties of 3D printable cementitious materials for building and construction. Archives of Civil and Mechanical Engineering. 2018;311-319.

- Elistratkin M.Yu., Lesovik V.S., Alfimova N.I., Glagolev E.S. On the development of building printing technologies. Bulletin of the Belgorod State Technological University named after V. G. Shukhov. 2018;5:11-19.

- Mukhametrakhimov R.H., Ziganshina L.V. Technology and quality control of construction 3D printing. Proceedings of the Kazan State University of Architecture and Civil Engineering. 2022;1(59):64-79.

- Korolev E.V., Zuong T.K., Inozemtsev A.S. A method for providing internal care for cement hydration in 3D printing formulations. Bulletin of the MGSU. 2020;6(15)6:834-846. https://doi.org/10.22227/1997-0935.2020.6.834-846

- Slavcheva G.S., Artamonova O.V. Rheological behavior of dispersed systems for construction 3D printing: a control problem based on the capabilities of the Nano arsenal. Nanotechnologies in construction. 2018;3(10):107-122. https://doi.org/10.15828/2075-8545-2018-10-3-107-122

- Myradov R., Guldzhanova D., Nazarlieva O. 3D printing in construction: a revolution in construction technologies. Bulletin of Science. 2024;3-9(78):464-467.

- Zagorodnyuk L.H., Elistratkin M.Y., Podgorny D.S., Al Mamuri Saad Khalil Shadid. Composite binders for 3D additive technologies. Bulletin of the Siberian State Automobile and Road Academy. 2021;18-4 (80):428-439.

- Mukhametrakhimov R.H., Ziganshina L.V. Improving the technology of additive construction production by regulating the duration of breaks in the 3D printing process. Engineering Bulletin of the Don. 2024;4(112):21.

- Bondarev B.A., Bayazov V.A., Korneev O.O., Vostrikov I.A., Meshcheryakov A.A., Korneeva A.O. Selection of mixtures for 3D printing. Bulletin of Eurasian Science. 2021;13(3):25.

- Zhegera K.V., Lavrov I.Yu., Troshchev D.V. Optimization of the synthesis of a nanostructuring additive for use in the working mixture of a 3D printer. Regional architecture and construction. 2024;2(59):60-65. https://doi.org/10.54734/20722958_2024_2_60

- Patent CN 105753404A, B33Y70/00. Cement-based material used for building 3D (three-dimensional) printing, claimed. 13.02.2016, publ. 13.07.2016.

- Lavrov, I.Y., Zhegera, K.V., Troshchev, D.V. Designing a Construction 3-D Printer and Choosing a Kinematic Scheme for Moving the Printhead. Lecture Notes in Mechanical Engineering. 2024. https://doi.org/10.1007/978-3-031-65870-9_2

- Patent CN 108715531A, C04B28/02. A kind of high thixotropic 3D printing concrete and preparation method therefor, claimed. 06.12.2018, publ. 08.28.2020.

- Trebukhin A.F., Parry D.E. Modern three-dimensional printers for additive construction production. Engineering Bulletin of the Don. 2019;8(59):8.

- Yemelyanov R.T., Prokopyev A.P., Yakshina A.A., Pindur S.V. Modeling of 3D printing of small architectural forms. Bulletin of Eurasian Science. 2020;12(2):8.

- Patent RU 2729086, C04B 28/04. Two-phase cement-based mixture for composites in construction 3D printing technology, claimed. 21.10.2019, publ. 04.08.2020.

- Klyuev S.V., Klyuev A.V., Shorstova E.S. Composite binders for fiber-reinforced concrete used for 3-D printing. System technologies. 2019;1(30):47-51.

- Demyanenko O.V., Kopanitsa N.O., Sorokina E.A. The effect of the addition of thermomodified peat on the technological properties of building mixes for 3D printing. Bulletin of the Tomsk State University of Architecture and Civil Engineering. 2018;20(4):122-134.

- Baykhodzhaeva Zh.I., Estemesova A.S. Fine-grained concrete for 3D (additive) printing. Endless light in science. 2024;2:416-420.

- Beznogova O.Yu., Potapova E.N. Materials for additive construction production. Advances in chemistry and chemical technology. 2022;36(3)-(252):16-18.

- Slavcheva G.S., Artamonova O.V., Babenko D.S., Shvedova M.A. Investigation of the effect of modifying additives on the structure formation and hardening of cement composites for 3D printing. Condensed media and interphase boundaries. 2023;25(1):112-124.

- Zhegera K.V., Ryzhov A.D., Sokolova Yu.A., Shestakov N.I. Patterns of structure formation of calcareous composites with an additive based on amorphous aluminosilicates. Nanotechnologies in construction. 2023;15(3):220–227. https://doi.org/10.15828/2075-8545-2023-15-3-220-227

- Khaliullin M.I., Rakhimov R.Z., Gaifullin A.R. Pozzolanic activity of expanded clay dust and its dependence on specific surface area. Proceedings of the Kazan State University of Architecture and Civil Engineering. 2013;3(25):98-104.

- Electronic Fund of legal and regulatory documents [Electronic resource]. https://docs.cntd.ru/document/901710699 (11.15.2024).

- Zhegera K.V. Development of an adhesive dry building mix using an additive based on amorphous aluminosilicates: dissertation... Candidate of Technical Sciences: 05.23.05 Penza 2016. [Electronic resource]. https://viewer.rsl.ru/ru/rsl01008558930 (11/15/2024).

- Electronic fund of legal and regulatory documents [Electronic resource]. https://docs.cntd.ru/document/871001226 (11.15.2024).

- Electronic Fund of legal and regulatory and technical documents [Electronic resource]. https://docs.cntd.ru/document/1200003348 (11.15.2024).

- Electronic Fund of legal and regulatory documents [Electronic resource]. https://docs.cntd.ru/document/1200113456 (accessed: 11.15.2024).

- Electronic Fund of legal and regulatory documents [Electronic resource]. https://docs.cntd.ru/document/1200100905 (11.15.2024).