Development of a human-machine interface for cascade control mills in obtaining nepheline ore charge

Автор: Ivanov R.D., Danykina G.B., Piskazhova T.V., Kolmakova L.P.

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Technological processes and material science

Статья в выпуске: 3 vol.23, 2022 года.

Бесплатный доступ

Aluminum and alloys based on it are the main materials for space engineering, both in the production of vehicle parts, and in the organization of power supply and electronics. The raw material for producing aluminum is alumina. Alumina production is a multi-stage process that includes the processing of raw materials in various ways: mechanically, thermally, chemically. Mechanical processing of raw materials is the first stage of production, it includes a crushing department and a batch preparation department. The preparation of the charge from nepheline ore for further stages of production takes place in mills with the addition of limestone and recycled solution. The ratio of the components entering the mills directly affects the composition of the charge and the quality of the final product. At the same time, the required quality of the charge is not always ensured, since the costs of the components are set by a person based on the re-sults of a rare chemical analysis performed by the laboratory with a delay. The aim of the work is to improve the control of the mill when receiving a mixture of nepheline ore. A virtual mill control program and a mnemonic diagram were developed in the TIA Portal software environ-ment using the S7-1500 microprocessor controller. A system for automatic control of the lime and alkaline modules of the raw charge has been developed. The control program is built on the basis of calculating the moisture content of the charge, as well as the al-kaline and limestone modules, depending on the composition of the ore, limestone, as well as the feed rates of circulating water, ore and limestone to the mill. The mnemonic diagram includes an indication of important process parameters, trends in input and output characteristics, and tools for setting control actions.

Batch preparation, nepheline ore grinding, virtual control, mnemonic diagram

Короткий адрес: https://sciup.org/148329649

IDR: 148329649 | УДК: 004.5:62-52:669 | DOI: 10.31772/2712-8970-2022-23-3-542-550

Текст научной статьи Development of a human-machine interface for cascade control mills in obtaining nepheline ore charge

Alumina (Al 2 O 3 ) is the main source material used in the production of primary aluminum, which, in turn, is the main material for space engineering, both in the production of vehicle parts and in the organization of power supply and electronics. In most cases, bauxite acts as an ore base when creating alumina, but nepheline and other ores containing alumina are also used. One of the most common methods of alumina production is the alkaline method by sintering. The essence of this method consists in binding Al 2 O 3 to sodium aluminate by sintering and subsequent leaching of the resulting sinter [1-7]. This method of alumina production is used at the Achinsk Alumina Plant (AGP), the largest enterprise in the aluminum industry in Russia [8].

The preparation of raw materials for sintering is handled by the charge preparation department. The process of preparing the charge of nepheline ore is one of the most important stages of obtaining alumina, and with the improvement of the control scheme, a significant economic effect can be achieved by reducing energy and material costs [9; 10].

This effect can be achieved by solving some problems of the automated control system of technological process (ACS TP):

-

– lack of automatic monitoring and indication of the operation of the main technological equipment (on/off mode, emergency status indication);

-

– lack of output to the ACS TP of important parameters of operational control of equipment operation (bearing temperature, oil pressure, etc.);

-

– monitoring of parameters only in place;

-

– the absence of an automatic control system for lime and alkali modules of the raw charge;

-

– implementation of the output to the target parameters of the charge in manual mode based on the results of chemical laboratory analysis.

Description of the technological process

The charge preparation department is designed for the preparation of a charge from nepheline ore and limestone with specified characteristics. The composition of the charge is characterized by:

-

– limestone modulus – the molar ratio of the sum of calcium oxide to silicon dioxide ( M izv = 1.07 - (CaO/SiO 2 ));

-

– alkaline modulus – molar ratio of the sum of sodium and potassium oxides in terms of Na 2 O to aluminum oxide ( M gap = 1.645 -[ (Na 2 O + 0.659K 2 O) / Al 2 O 3 ] );

-

– fineness of grinding, fraction content +0.08 mm, %;

-

– humidity ( W ), %;

-

– consistency of the composition.

The grinding of nepheline ore and limestone with the addition of a circulating solution is carried out in tubular ball mills.

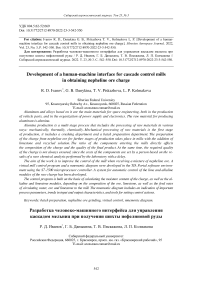

There are four stages of charge preparation at AGP (Fig. 1):

Stage I – grinding of nepheline ore with the addition of circulating solution (mills No. 15-22);

Stage II – re-grinding of nepheline pulp (mills No. 11-14);

Stage III – limestone grinding together with nepheline pulp (mills No. 1-8);

Stage IV – re-grinding of nepheline charge, limestone (mills No. 9-10, 23-28, 31-35).

Fig. 1. Stage of the mixing processes

Рис. 1. Стадии приготовления шихты

After the re-grinding mills of the fourth stage, the charge is collected in a prefabricated agitator and moved by pumps into flow averaging schemes of the charge in the correction pools.

From the flow averaging schemes, the charge is pumped into the flow pools, from where it is pumped to the sintering furnaces. The excess charge through the ring pipelines is returned to the flow pools.

Cascade of mills as an object of automation

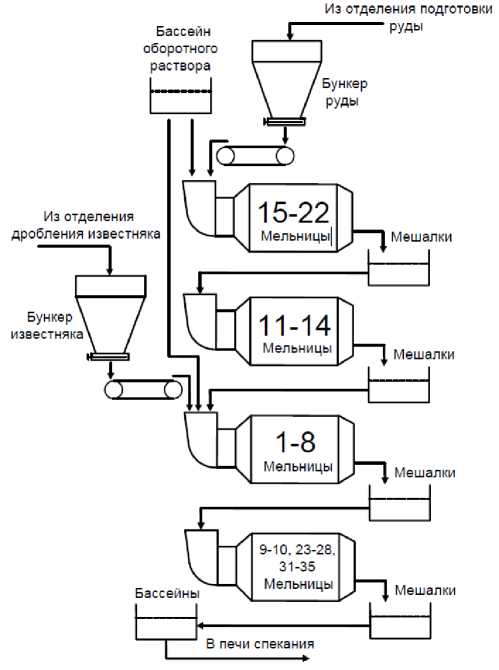

In Fig. 2 shows a cascade of mills as an automation object, where X ( t ) is a vector of control actions; F ( t ) and M ( t ) are vectors of controlled and uncontrolled disturbances, respectively; Y ( t ) is a vector of output parameters. The table contains vector variables of the cascade of mills.

After the fourth stage, the charge enters the correction pools, where the main output parameters of the alkaline and limestone modulus cascade are measured by laboratory analysis:

M gap - alkaline modulus, 1.12 ± 0.02 units.;

M izv - limestone module, 2.04 ± 0.02 units.

The adjustment of these parameters consists in regulating the input parameters of the mills in the cascade (changes in the consumption of ore, mortar, etc.). This gives additional complexity for automated control, since the modules depend not only on the consumption of input indicators, but also on the composition of the components. Therefore, in order to achieve the necessary indicators of the alkaline and limestone module, it is possible to have variations in the humidity index in the range of 30-35%.

Vector variables of a four-stage cascade

Fig. 2. Cascade as automation object

Рис. 2. Каскад как объект автоматизации

|

СЛ о ед Й |

Vector variables |

|||

|

Control actions X ( t ) |

Output parameters Y(t) |

Controlled disturbances F ( t ) |

Uncontrolled disturbances M ( t ) |

|

|

о ед й |

x 1.1 – feed of nepheline ore, 0-160 t/h; x 1.2 – feed of circulating solution, 0-63 m3/h |

y 1.1 – charge humidity, 28-35 %; y 1.2 – charge level in the agitator, 1.5–4.5 m; y 1.3 – pulp at the outlet of the agitator, 0-200 t/h |

f 1 – overheating of the bearings of the drive and gearbox of the mill, up to 75 ° ; f 2 – overheating of mill axle bearings, up to 65 ° ; |

m 1 – sensor failure; m 2 – equipment wear and tear |

|

сч о ед л й |

x 2 – pulp feed from the first stage of grinding, 0200 t/h |

y 2.1 – charge humidity, 30-35 %; y 2.2 – charge level in the mixer, 1.5–4.5 m; y 2.3 – pulp at the outlet of the agitator, 0-125 t/h |

||

|

ед Й |

x 3.1 – supply of nepheline pulp, 0-125 t/h; x 3.2 – limestone feed, 0160 t/h; x 3.3 – feed of circulating solution, 0-63 m3/h |

y 3.1 – charge humidity, 26.5–27 %; y 3.2 – charge level in agitators, 1.5–4.5 m; y 3.3 – pulp at the outlet of the agitator, 0-200 t/h |

f 3 – clogging of the mill loading funnel, up to 3 m; f 4 – lack of material in the ore bunker; f 5 – oil filter clogging (pressure increase) |

|

|

ед й |

x 4 – pulp feed from the third stage of grinding, 0200 t/h; |

y 4.1 – charge humidity, 30-35 %; y 4.2 – charge level in agitators, 1.5–4.5 m; y 4.3 – pulp at the outlet of the agitator, 0-200 t/h |

In order to meet the requirements of the process for several indicators at once and at the same time do it automatically, it is necessary to develop a control program containing a circuit for automatic regulation of the chemical composition of the charge, and a mnemonic circuit based on modern software. WinCC was chosen from a number of different SCADA systems, as it has a powerful set of tools for any automation tasks. The simulation capabilities of WinCC software allow real-time monitoring of changes in the technological process described using software and functional blocks, as well as influencing output variables during the process [11; 12].

Development of a mnemonic circuit for cascade control

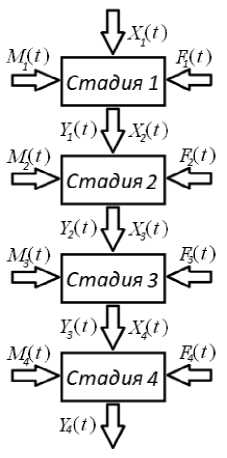

A virtual control project has been developed, which includes several screens.

The screen "Mill 1" (Fig. 3) is the main control screen of the mill of the first stage of charge preparation. The upper part of the screen is the general control panel. It includes toggle switches for controlling mills, selecting the operating modes of mills of stage 1 and 3, and setting the consumption of materials at the entrance to the mills and exit from the agitators [13].

Fig. 3. Screen «Mill 1»

Рис. 3. Экран «Мельница 1»

On the left side of the screen "Mill 1" shows a mill, an ore hopper, a conveyor, a pipeline with a solution, an agitator and a pump at the exit of the mill. The current sensor readings are also located here. At the bottom there is a navigation bar. On the right are the trends showing the current and preset material costs, as well as the trend of the pulp level in the agitator.

Imitation of the mill operation

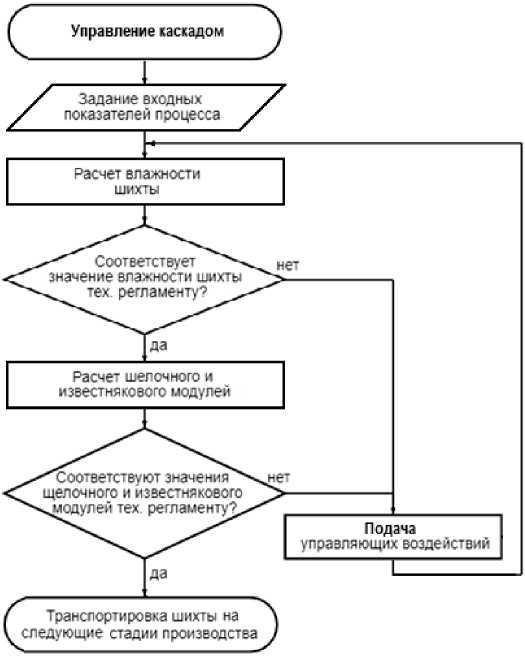

The mill cascade is controlled in several stages, which can be repeated during operation. Figure 4 shows the order of operation of the control program blocks. Input indicators on the flowchart include control actions and the composition of raw materials.

Simulation of sensor readings is implemented using scripts in the VBS language.

Changing the values of the flow of materials into the mill can also change the humidity of the incoming mixture. To show this on the mnemonic scheme, a script was developed. The operation of the script is that the equality between the current humidity in the agitator and the humidity of the incoming mixture is continuously checked, and if the equality is violated, then the current humidity value decreases or increases to the required value [14].

Fig. 4. Block-diagram of the cascade control

Рис. 4. Блок-схема управления каскадом

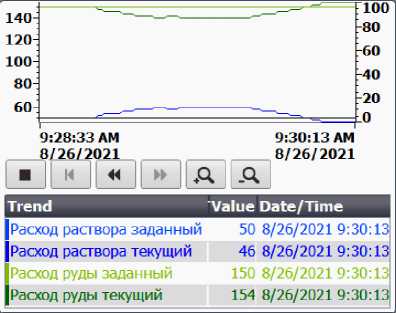

The automatic mode of operation of the mill assumes that the deviation of the current humidity value from the set one will lead to a change in the values of the consumption of mate- rials entering the mill. For example, if the value of the current humidity is less than the set value, it is necessary to increase the consumption of the solution, but at the same time reduce the consumption of ore so that the overall productivity of the mill does not change. The trend bar below shows such a case (Fig. 5) [15].

Fig. 5. Bar of the flow trends

Рис. 5. Панель трендов расхода

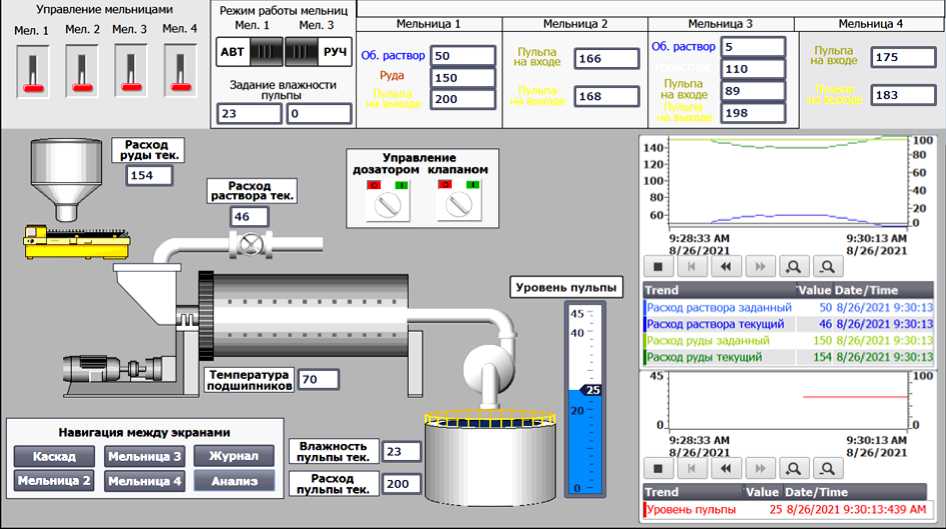

Figure 6 shows the bar specifying the composition of raw materials and calculating modules. You can go to it through the navigation panel – the "Analysis" tab. To simulate the operation of laboratory analyzers, a program for calculating alkaline and limestone modules in FBD was developed. Thanks to the program, you can change the composition of raw materials and see the change in the value of modules in real time. Limestone and alkaline modules are calculated on the basis of calculation formulas according to the technological regulations described above.

|

Состав руды |

||

|

Текущий, % Регламент, % |

||

|

AI2O3 |

+26 |

25,5-27,5 |

|

SiO2 |

+ 40 |

39-41 |

|

СаО |

+ 8 |

7-9 |

|

Na2O |

+ 10 |

10-11,5 |

|

К2О |

+ 3 |

2,5-3 |

|

Модуль известняковый |

||

|

|+2.379 |

||

|

Состав известняка Текущий, % Регламент, % |

||

|

AI2O3 |

+ 1 |

0,1-1 |

|

SiO2 |

+3 |

1-5 |

|

СаО |

+53 |

50-55 |

|

Состав раствора Текущий, % Регламент, % |

||

|

Na2O |

+ 9 |

8-9 |

|

Модуль щелочной |

||

|

1 + 1.705 |

||

Fig. 6. Bar for specifying the raw material composition and module calculation

Рис. 6. Панель задания состава входного сырья и расчета модулей

Conclusion

Automation of the charge preparation process in the production of alumina has some problems that were described above. The developed mnemonic scheme and programs in the WinCC SCADA system allow to partially solve these problems, namely: to monitor technological parameters, output their values to the automated process control system and display the operation of equipment; to implement automatic cascade control based on data collection in the automated process control system; to calculate the output charge indicators based on data on the composition of input raw materials and the volume of input flows to the cascade of mills. The latter allows you to set and adjust the ratio of the supply of ore, limestone and water to ensure the desired quality of the charge.

Список литературы Development of a human-machine interface for cascade control mills in obtaining nepheline ore charge

- Anikeev V. I. Sposob pererabotki nefelinovoy rudy s dozirovkoy boksita [Method for processing nepheline ore with bauxite dosage]. Patent RF, No. 2006112505, 2006.

- Anushenkov A. N., Shepelev I. I., Golovnyh N. V., Chudiyenko K. V. Sposob upravleniy prigotovleniem shihty pr ipererabotke nefelinovogo cyrya s polucheniem glinozema I sodoproduktov [Method for controlling the charge preparation during the processing of nepheline raw material with the production of alumina and soda products]. Patent RF, No. 2725228, 2019.

- Ogol V. G., Yagin V. P. Sposob pererabotki nefelinovoy rudy dly polucheniy glinozema I sodoproduktov [Method for processing nepheline ores for producing alumina and soda products]. Patent RF, No. 2450066, 2011.

- Shepelev I. I., Sakhachev A. Y., Anushenkov A. N., Aleksandrov A. V. Sposob pererabotki ne-felinovoy rudy [Method of processing nepheline ore]. Patent RF, No. 2606821 C, 2017.

- Algebraistova N. K., Shepelev I. I., Sakhachev A. Y., Zhukov E. I., Zhizhaev A. M., Aleksan-drov A. V., Sviridov L. I. Sposob pererabotki nefelinovoy rudy I koncentratov [Processing method of nepheline ores and concentrates]. Patent RF, No. 2702590 C2, 2019.

- Shepelev I. I., Algebraistova N. K., Sakhachev A. Y., Zhyzhaev A. M., Prokopiev I. V. [Grinda-bility study of nepheline ore and ferrotitanium production slag for their processing by sintering tech-nology]. VestnikIrGTU. 2017, Vol. 21, No. 11 (130), P. 167–178 (In Russ.).

- Kozlov A. A, Kolmakova L. P., Kovtun O. N. [Analysis of technologies of preparation of the charge for sintering of nepheline ore at RUSAL Achinsk]. EvraziskiSouzYchenyh. 2018, No. 11 (56), P. 22–22 (In Russ.).

- Achinsky Glinozemny Kombinat. RUSAL [Achinsky Alumina Plant. RUSAL] (In Russ.). Availa-ble at: https://rusal.ru/about/geography/achinskiy-glinozemnyy-kombinat/ (accessed 24.03.2022).

- Liner A. I. Proizvodstvoglinozema [Alumina production]. Moscow, Metallurgizdat Publ., 1961, 619 p.

- Pivnev A. I. Razrabotka I vnedreniye novoy tekhnologii prigotovleniya glinozemsoderzhashchey shikhty pri kompleksnoy pererabotke nefelinov. Kand. Dis. [Development and introduction of a new technology for the preparation of alumina-containing charge. Cand. Dis.]. Krasnoyarsk, KICM Publ., 1994.

- Programmnoye obespecheniye konfigurirovaniya SIMATIC WinCC (TIA Portal): catalog In-dustry Mall [Software for configuration of the SIMATIC WinCC (TIA Portal): catalogueIndustry Mall]. (In Russ.). Available at: https://mall.industry.siemens.com/mall/ru/RU/catalog/products/ 10090965 (accessed 24.03.2022).

- Piskazhova T. V., Sidelnikov S. B., Belolipetskii V. M., Yakivyuk P. N., Sidelnikov A. S. [Virtual CC&RP – a mathematical model for the control of the unit CC&RP and its visualization by means software products WinCC 7.0 and Step 7]. Vestnik SibGAU. 2015, No. 2(54), P. 140–144 (In Russ.).

- Sverchkov D. [Human-machine interface development and application in control systems]. Transactfons of the Kryfov State Research Centre. 2018, No. 1, P. 184–190 (In Russ.).

- Rukovodstvo po programmirovaniyu kontrollerov S7-1200/S7-1500: bazovoye sistemnoye rukovodstvo [Guide to programming controllers S7-1200/S7-1500: base system guide]. Available at: https://assets.new.siemens.com/siemens/assets/api/uuid:6f74436a53942bf8f1c7b6ed34d2ae72e92ed8a8/programming-guideline-v14-rus.pdf (accessed 02.05.2022).

- Kayukov I. Yu. [Creation process trends in the WINCC development environment]. Mezhdunarodny studencheskiy nauchny vestnik. 2021, No. 6, P. 44–50 (In Russ.).