Development of an experimental recoater to study the technology of layer-by-layer application of sand mixture

Бесплатный доступ

The article is devoted to solving one of the problems of research and design of robotic complexes for production of foundry molds using 3D printing. The article describes the development of an experimental recoater unit for automated production of foundry molds using the technology of layer-by-layer application of sand mixture. Experimental studies of the quality of sand distribution using the developed unit are carried out. Methods of laying the sand mixture are described. The evaluation of the speed of pouring sand into the hopper, the evaluation of sand distribution depending on the time of pouring out of the hole area. The efficiency of the experimental recoater for sand mixture application, which consists of an auger conveyor and slide gate, was analyzed and the main technical characteristics of its work were evaluated. The conclusions drawn according to the results of the experiments pointed to the positive technical constructive solutions of the developed unit for the application of the sand mixture. Recommendations for its improvement are offered.

Additive technologies, casting mold, 3D-printing, sand mixture, experimental recoater, gate valve, screw

Короткий адрес: https://sciup.org/14130664

IDR: 14130664

Текст научной статьи Development of an experimental recoater to study the technology of layer-by-layer application of sand mixture

At the present stage, 3D printing technology is used in various areas of industry. For foundries, the use of additive manufacturing allows to obtain molds of different configurations without loss of material, which expands the possibilities for manufacturers. But not every material can be used for 3D printing. Therefore, instead of manufacturing a part, a 3D print casting mold is often made, where the material is subsequently poured. The sequence of operation of the 3D printer is as follows: a layer of mixture consisting of a filler (quartz sand) and a catalyst necessary to ensure the reaction of curing the mold is applied to the build surface. Next, a binder is printed onto the layer, forming a solid pattern, and layers of patterns form the finished casting mold [1-3].

These modern technologies require an increase in the number of printing devices. When creating new robotic units for 3D printing sand casting molds, there is a need for research on each unit of the unit, conducting preliminary studies and tests [4-10].

The research work was carried out within the framework of the contract on "Creation of scalable direct digital production of casting molds to increase the productivity of high-tech casting production lines".

-

2 MATERIAL AND METHODS

The purpose of this paper is to conduct experimental studies of the quality of sand distribution using the developed recoater unit, and to analyze the performance of the unit.

The important parts of a casting mold 3D printer are the sand mixture and binder application devices. 3D printing technologies for casting sand molds consist of layer-by-layer application of sand, followed by bonding of the sand mixture with a binder. Two basic operations form the two basic devices:

-

- a sand mixture application device (recoater);

-

- a device for binder jetting.

Sand application methods can be executed in different ways:

-

- from a single small hole, while guiding it along a desired trajectory;

-

- from a linear slot, directing it in one direction;

-

- from the entire area of the slot;

-

- different combination of the previous methods.

There are two main dependencies in these methods:

-

- The longer the trajectory, the longer the operation will take;

-

- The smaller the hole, the more accurately sand can be applied (dosed).

Both parameters (time and accuracy) are critical, so the intermediate option with a linear slot is preferable. However, the final precision of layer application must be achieved with an additional mechanism, since sand is a loose material that usually forms slides. Two designs of such a mechanism can be distinguished:

-

- In the form of a single blade;

-

- a combination of blades.

The scheme with a combination of knives is used if there is a need to level a large amount of sand, a single knife is used when there is a small amount of sand to be leveled.

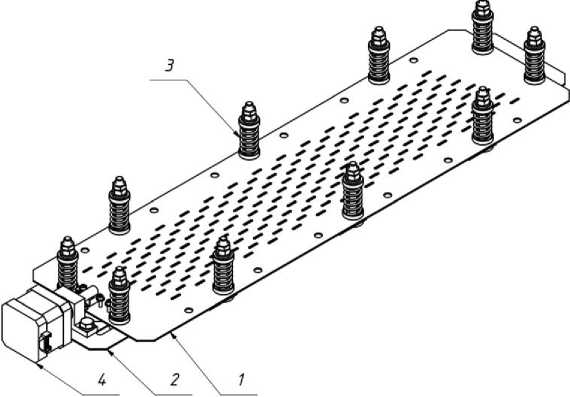

In accordance with the above-mentioned methods of applying sand, an experimental device for applying the mixture, shown in Figure 1, is developed to determine the characteristics of the resulting layer of the mixture and the study of the technology of dosing the mixture [2,3]. The basis of the experimental recoater device is a metal hopper 1 with holes at the bottom, which open and close. The hopper is attached to the articulated robot 6. Under the action of gravity acting on the sand, it falls from the holes when they are open, for distribution of sand inside the hopper is used auger conveyor 2. Slide gate 3 is installed at the bottom of the hopper. A leveling blade 4 is used to level the material.

The slide, shown in Figure 2, consists of two plates 1 and 2 with a group of overlapping holes arranged in sequence to minimize subsequent leveling of the sand. Plate 1 is attached to the hopper. To adjust the size of the holes, plate 2 is moved longitudinally, by means of a screw gear 4, relative to plate 1. Grooves cut in the plate 2 are used as guides, spring-loaded bolt connections 3 are inserted into them.

The auger is driven by a brushless DC motor connected by a coupling.

The assembled experimental design for the application of the mixture is shown in Fig. 3.

To control the installation, a control system has been developed that controls the screw drive motors and the slide gate drive.

During the study of the developed unit, the following tasks were set:

-

- Evaluate the performance of the auger conveyor;

-

- Determine the speed of pouring out of the sand at different positions of the slide gate;

-

- determine the quality of sand distribution;

-

- evaluate the performance of the slide gate;

-

- assess the tightness of moving parts.

1 - Hopper; 2 – Auger conveyor; 3 - Slide gate; 4 - Leveling blade;

5 - Robotic mounting; 6 - Articulated robot Figure 1. Experimental installation of mixture application

Figure 2. Slide gate

Figure 3. Assembled recoater

-

3 RESULTS AND DICCUSSION

Installation calculation is based on the parameters of carrying capacity of articulated robot no more than 10 kg and a layer width of 500 mm.

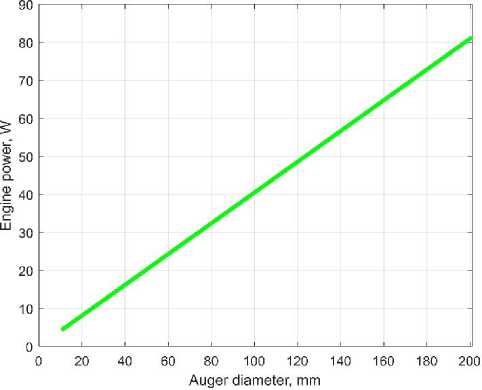

The optimum diameter and motor power for the auger was selected. Dependence of motor power on the diameter of the auger is shown in Fig. 4.

Figure 4. Dependence of motor power on auger diameter

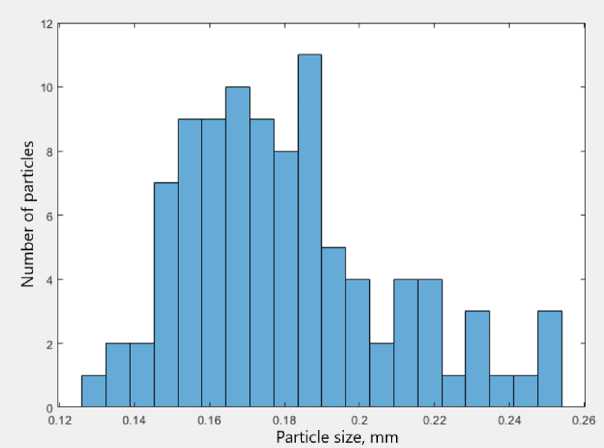

Mixture applied consists of silica sand mixed with sulfonic acids. The particle size distribution of the sand is shown in figure 5.

Figure 5. Particle size distribution

The experiment involves testing the workability of the mechanisms of the experimental installation of the mixture, as well as examining the quality of the resulting layer.

To assess the performance of the auger conveyor from the edge of the hopper poured sand in an amount of 4 kg. During operation, the auger moved the sand relatively evenly throughout the hopper and rotated at a speed of 100 rpm. As a result of the experiment the calculations of the auger were confirmed, which was able to fully distribute the sand over the entire surface of the hopper.

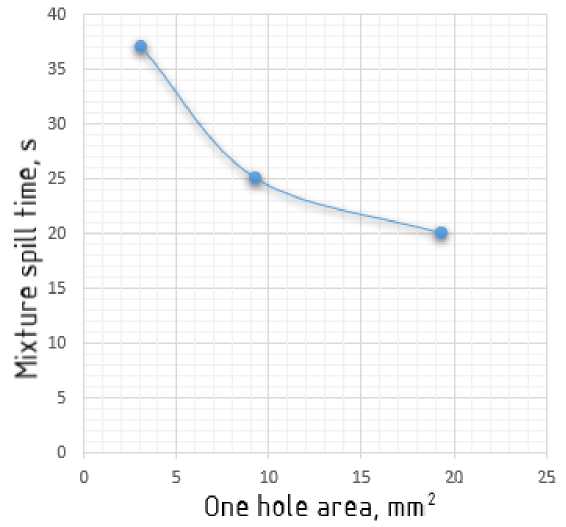

To estimate the rate of sand pouring into the hopper, 4 kg of sand was poured into the hopper and distributed. The results are shown in Figure 3 for different hole areas. You can see from the figure that the graph is a non-linear, which eventually leads to a more complicated control of the sand flow rate.

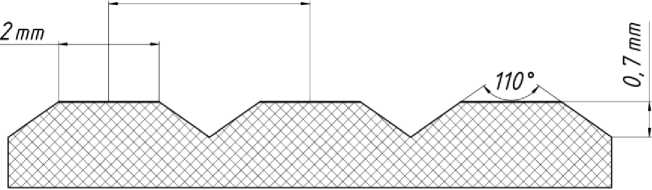

To estimate the distribution of sand, we obtained the dependence of the dumping time on the hole area, which is shown in Figure 6. The resulting difference of 0.7 mm shown in Figure 7 must be swept away with a blade, though not completely, but most of it. Also, mixture spread angle gives the friction coefficient of sand against sand, which is 0.7.

The tightness was evaluated at the end of all other experiments.

Conclusions drawn from the results of the experiments:

-

1. During the experiment, lumps were formed, clogging the gate orifices, which led to a stoppage in the flow of the mixture.

-

2. This installation does not sufficiently ensure the uniformity of the layer.

-

3. Unevenness of the layer appears due to the application of large heaps of sand, which do not fall into the empty space after leveling.

-

4. Due to the insufficient tightness of the slide gate, the space between the gates is clogged, which affects the performance of the device and the wear of parts.

-

5. Reinforced sleeves ensure sufficient sealing of the auger bearings against sand clogging.

Figure 6. Dependence of the sweeping time on hole area

4 mm

Figure 7. Approximate distribution of sand

-

4 CONCLUSION

Conclusions drawn from the results of experiments:

-

- the developed design of the unit ensures the distribution of sand;

-

- the sand flow rate is not proportional to the cross-sectional area, which complicates control;

-

- large overspending of sand is expected due to the high difference in layers;

-

- fine sand is comparable to dust, so serious sealing of moving elements is required;

-

- auger is an excellent way to move bulk materials.

Based on the results of experimental studies of the mixture application unit, the following recommendations for improvement of the unit were obtained:

-

1. the resulting lumps of mixture should be broken up or filtered;

-

2. the distance between the holes in the chute should be kept to a minimum, sufficient to level out the mixture to prevent the formation of empty areas;

-

3. mechanisms in contact with sand should be carefully sealed.

-

4. to pass the sand through the cells, it is rational to apply a certain force to the sand particles, achieved through the use of vibration mechanisms.

Список литературы Development of an experimental recoater to study the technology of layer-by-layer application of sand mixture

- Gibson Ya., Rosen D., Stacker B. Additive manufacturing technologies. Three-dimensional printing, rapid prototyping and direct digital production. Moscow: TECHNOSPHERE, 2020. 648 p.

- Efimov P.A., Sych A.A., Baranchugov I.A., Morozova N.T., Notkin B.S. Operation of service robots. Saint Petersburg, 2021. p. 140.

- Zlenko M.A. Additive technologies in mechanical engineering. Moscow: SSC RF FSUE "NAMI", 2017. 220 p.

- Zmeu K.V., Morozova N. T., Pleshakov F. A. Experimental installation of applying a mixture for automated production of molds. Automation in industry. 2023. No. 2. pp. 62-64.

- Ilyin A.A. Mathematical modeling of elements of a cable robot for three-dimensional large-size printing. In the collection: Integration of science in the era of crisis: problems, solutions. Materials of the IX All-Russian Scientific and Practical Conference. Rostov-on-Don, 2022. pp. 162-165.

- Kozyrev Yu.G. Industrial robots: basic types and technical characteristics: textbook. - M.: KNORUS, 2015. - 560 p.

- Pleshakov F.A., Zmeu K.V., Morozova N.T. Development and research of a device for applying a mixture using a mesh dispenser. Prospects of Science. 2023. No. 1(160), pp. 66-72.

- Turaev N.S., Brus I.D., Kantaev A.S. Calculation of a screw conveyor. Tomsk: Tomsk Polytechnic University Press, 2015. 18 с.

- Bin Zhang, Jinke Gong, Wenhua Yuan, Jun Fu, Yi Huang. Intelligent Prediction of Sieving Efficiency in Vibrating Screens // Shock and Vibration. 2016. P. 7.

- Helio A. Navarro, Meire P. de Souza Braun. Linear And Nonlinear Hertizian Contact Models For Materials In Multibody Dynamics // 22nd International Congress of Mechanical Engineering (COBEM 2013). São Paulo. 2013. pp. 159-170