Development of antimicrobial packaging materials using rosemary essential oil

Автор: Melesse E.Y., Alkhair A.Y., Shchukina E.A., Кirsh I.A., Zaitseva A.V.

Журнал: Вестник Воронежского государственного университета инженерных технологий @vestnik-vsuet

Рубрика: Химическая технология

Статья в выпуске: 2 (104) т.87, 2025 года.

Бесплатный доступ

In the context of increasing requirements for food safety and quality, it is important to develop effective methods of protection against microbial contamination. One of the innovative solutions is active packaging with natural antimicrobial additives that prevent the growth of microorganisms on the surface of products. These additives must retain their properties both during production and during further use. The main objective of this study was development of an active packaging film made of biopolymer with the introduction of rosemary essential oil in various concentrations, as well as determination of the antimicrobial, physical, mechanical and barrier properties of the resulting polymer material. The starch-based film was prepared by mechanical mixing of the initial reagents with the introduction of rosemary essential oil with a concentration of 0.5%; 1%; 3%; 5%. The antimicrobial properties of the polymer packaging material were determined by the disk-diffusion method in accordance with MUK 4.2.1890–04 in relation to Bacillus subtilis, Escherichia coli, Candida albicans, and Aspergillus niger. To assess the fungal resistance of the materials, the methods of GOST 9.049 (method 1) and GOST 9.048 (method 4) were selected. Determination of vapor permeability using the "PERME W3/030" device according to GOST GВ1037. The method for determining the physical and mechanical properties on a tensile testing machine according to GOST 28840–90. It was found that samples of packaging film based on starch with rosemary essential oil have antimicrobial activity against Candida albicans at concentrations of 3% and 5%, reducing the number of microorganisms on the film surface. In addition, its physical, mechanical and barrier properties are improved. Analysis of existing studies has shown that rosemary essential oil is an effective natural antimicrobial component. Its use in active starch-based packaging not only prevents the growth of microorganisms such as Candida albicans, but also helps improve the physical, mechanical and barrier properties of the packaging film. This makes it a promising solution for ensuring the safety and quality of food products.

Rosemary essential oil, antimicrobial properties, active packaging, starch-based film, physical and mechanical properties, barrier properties

Короткий адрес: https://sciup.org/140312487

IDR: 140312487 | УДК: 640 | DOI: 10.20914/2310-1202-2025-2-177-182

Текст научной статьи Development of antimicrobial packaging materials using rosemary essential oil

The issues of food safety and quality are becoming increasingly important, and therefore the development of new and effective methods for protecting products from microbial contamination is a pressing issue. One of the innovative approaches in this area is the use of active packaging, which is based on the use of natural antimicrobial additives to prevent the growth and reproduction of microorganisms on packaged products [1]. An antimicrobial additive included in the polymer must retain its properties both during production and during subsequent use. The main requirements for such additives include ensuring hygienic safety when interacting with food products and maintaining physical and mechanical characteristics. The packaging material must remain strong, flexible and resistant to external influences, including temperature changes, humidity levels and mechanical stress, even in the presence of antimicrobial components [2].

Currently, much work has been done to impart antimicrobial properties to polymers. The list of substances capable of imparting antimicrobial properties to polymeric materials is quite wide, for example, chitosan; carvacrol; eugenol, geraniol, linalool, terpineol and thymol [3].; However, the

use of natural antimicrobial additives, namely essential oils, is particularly successful. Essential oils attract the attention of researchers due to their antimicrobial properties, which allow them to be considered a safe alternative to synthetic ones. These oils contain active components such as terpenes, which have the ability to destroy or suppress the growth of various microorganisms, including bacteria and fungi. The most popular essential oils include tea tree oil, lemongrass, eucalyptus, thyme, lavender and cloves. The properties of rosemary oil are also being actively studied [4].

One of the significant studies in this area is the work of Nafiseh Mohsenabadi, who developed an active film based on corn starch using benzoic acid and chitosan. By encapsulating rosemary essential oil in the created nanogel (benzoic acid + chitosan) CS-BA, starch-carboxymethyl cellulose (CMC) films with improved physicomechanical and antimicrobial properties were obtained. Films containing nanogel demonstrated higher vapor permeability compared to films containing only rosemary essential oil. Interestingly, samples with nanogel showed a gradual inhibitory effect on Staphylococcus aureus ( S. aureus ), while films with free essential oil had an immediate antimicrobial effect, which proves the ability of the nanogel

to reduce the percentage of rosemary essential oil to achieve the same antimicrobial properties. The use of low concentrations of rosemary essential oil allows to reduce the cost of packaging, as well as the effect of essential oil on the organoleptic properties of the food product [5].

Another significant work is the research of Shabanova and Borisova, who studied films based on polylactic acid with the addition of rosemary oil. Their work demonstrated that the addition of essential oil leads to a decrease in the transparency of films, an increase in their humidity and a significant decrease in vapor permeability, which emphasizes its effect on the physical and mechanical properties of materials [6]. This article examines the development of an antimicrobial film based on starch with the addition of rosemary essential oil. The purpose of the work is to evaluate the antimicrobial properties and analyze changes in the physical, mechanical and barrier properties of the films.

Rosemary – belongs to the Lamiaceae family. It is known for its antimicrobial and antioxidant properties, used in medicine to treat various diseases [7]. Rosemary extracts are used in the treatment of Alzheimer's disease, as well as to protect the liver [8, 9]. Analysis of rosemary essential oil using gas chromatography revealed 22 compounds, of which 1,8 – cineole (38.5%), camphor (17.1%), α-pinene (12.3%), limonene (6.23%), camphene (6.00%) and linalool (5.70%) predominate. These compounds make up 97.41% of the total oil composition [10]. Antimicrobial studies have confirmed that rosemary essential oil has antimicrobial properties against microorganisms such as E. coli, Bacillus cereus, Staphylococcus aureus, Clostridium perfringens, Aeromonas hydrophila, and Salmonella cholerae-suis [11]. Several experiments involving the treatment of beef and pork with rosemary essential oil have shown that this oil can inhibit bacterial activity and increase the shelf life of meat [12–14].

The antimicrobial properties of rosemary essential oil are largely due to its active components, such as 1,8-cineole, camphor, and α-pinene. These compounds can disrupt the membranes of microbial cells by interacting with proteins, which leads to the leakage of their internal components. As a result of such changes in cells, the destruction of genetic material occurs, which ultimately causes the death of microorganisms [15–17]. The European Food Safety Authority has approved the daily intake of carnosic and carnosolic acids: 0.09 mg/kg for the elderly and 0.81 mg/kg for children. In food production, rosemary extracts can contain up to 400 mg/kg of these acids [18].

Material and methods

The objects of the study were examination of an antimicrobial additive – rosemary essential oil produced by LLC “PK ASPERA” of the Russian Federation.

The following components were used to develop antimicrobial films with different concentrations (0.5%; 1%; 3%; 5%): starch, glycerin, vinegar and an antimicrobial additive in the form of essential oil. Preparation of the mixture: Preparation of a starch-based composition with the addition of rosemary and the mixture of components was subjected to heat treatment at a temperature of 98 ± 1 °C until a homogeneous state was achieved. Besides, the resulting mass was poured into glass frames, where it hardened. Further, the films were left to completely harden for 3 days at room temperature, after which they were ready for further use. The antimicrobial activity of rosemary essential oil included in the film was assessed using the disk method in accordance with the guidelines MUK 4.2.1890–04. The study was conducted with respect to the following microorganisms: Bacillus subtilis, Escherichia coli and Candida albicans . This method allows determining the ability of essential oil to inhibit the growth and development of various pathogenic microorganisms, which is an important indicator for assessing the effectiveness of the developed material. To assess the fungal resistance of materials, the methods of GOST 9.049 (method 1) and GOST 9.048 (method 4) were selected. Method 1 checks the resistance of the material in conditions unfavorable for the development of spores, assessing the germination of fungi on the surface. Method 4 assesses how moisture and fungi affect the physical and mechanical properties of the material. The studies were conducted using the fungus Aspergillus niger . The samples were cleaned of external contaminants and placed in sterile Petri dishes. According to method 1, the samples were sprayed with an aqueous suspension of spores, according to method 4 – they were placed in dishes with an agar medium and also infected with a suspension. Additionally, the method for determining the vapor permeability of materials consists of measuring the amount of water vapor passing through a sample in a certain time, carried out using the PERME W3/030 device according to GOST GВ1037. Furthermore, the method for determining the physical and mechanical properties on a tensile testing machine according to GOST 28840–90. Consists of preparing a material sample, testing it on a tensile testing machine, which gradually increases the load. During the test, the maximum load and the corresponding deformations of the sample are recorded. Based on these data, parameters such as temporary resistance and relative elongation are calculated, which allows determining the behavior of the material under load. Finally, Structural and morphological properties of a polymer film. Consists of studying the film surface using an electron microscope.

Results and discussion

Biodegradable starch-based films are shown in Figure 1.

А В C D E

Figure 1. Appearance of experimental samples of obtained materials based on starch with rosemary essential oil. A) K; B) K + P 0.5%; C) K + P 1%; D) K + P 3%; E) K + P 5%

The results of the study showed that rosemary oil does not have antimicrobial properties against Bacillus subtilis . When testing this oil, no zone of inhibition was observed around the material, indicating a lack of antimicrobial activity.

The results of the study showed that rosemary oil does not have an antimicrobial effect on Escherichia coli (Fig. 3). During testing of the oil, no inhibition zone was observed around the material, indicating a lack of effectiveness in relation to this type of bacteria. This indicates that the components of the oil do not prevent the growth and reproduction of Escherichia coli.

The materials in Figure 1 show a homogeneous structure of the films, which indicates good compatibility of the components used. With an increase in the concentration of rosemary oil, the film darkens and loses transparency, which deteriorates the appearance of the film. Antimicrobial activity was assessed by measuring the inhibition zone, which made it possible to assess the growth level of the test cultures.

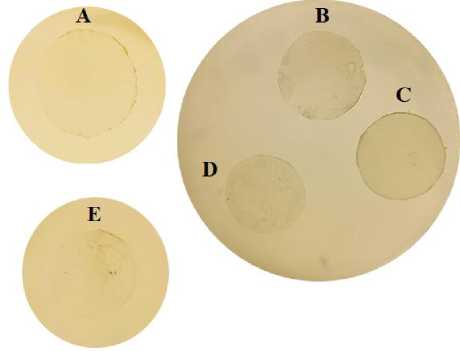

Figure 2 shows the results of studies to determine the antimicrobial properties of the obtained materials in relation to Bacillus subtilis.

Figure 2. Results of studies to determine the antimicrobial properties of the obtained materials in relation to Bacillus subtilis after 2 days A) K; B) K + P 0.5%; C) K + P 1%; D) K + P 3%; E) K + P 5%

Figure 3. Results of studies to determine the antimicrobial properties of the obtained materials in relation to Escherichia coli after 2 days A) K; B) K + R 0.5%; C) K + R 1%; D) K + R 3%; E) K + R 5%

Figure 4 shows the results of the experiment to determine the antimicrobial properties of the obtained materials in relation to Candida albicans .

Figure 4. Results of studies to determine the antimicrobial properties of the obtained materials against Candida albicans after 4 days A) K; B) K + R 0.5%; C) K + R 1%; D) K + R 3%; E) K + R 5%

The highest concentration of oil demonstrates the largest inhibition zone for the tested Candida albicans microorganisms. At an oil concentration of 3%, the inhibition zone is 0.5 mm, and with an increase in concentration to 5%, it increases to 1 mm. These results confirm that with an increase in the concentration of antimicrobial oil, the inhibition zone around the package also increases. Thus, the use of higher concentrations of oil can improve the efficiency of protecting the surface of food products from microbial damage.

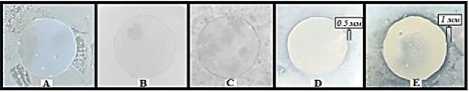

Figure 5. Fungus resistance tests of materials according to Method 1: samples obtained based on starch with different concentrations of rosemary essential oil (0.5; 1; 3; 5%)

Melesse E.Y. et al. Proceedings of VSUET, 2025, vol. 87, no. 2, pp. 177-182 post@vestnik-vsuet. ru

Table 1.

Fungus resistance of materials: Results of tests according to Method 1

|

соntrоl sample |

The development of fungi covering more than 25% of the test surface is clearly visible to the naked eye |

5 |

|

starch film with the addition of rosemary essential oil 0.5% |

The development of fungi covering more than 25% of the test surface is clearly visible to the naked eye |

5 |

|

starch film with the addition of rosemary essential oil 1% |

The development of fungi covering more than 25% of the test surface is clearly visible to the naked eye |

5 |

|

starch film with the addition of rosemary essential oil 3% |

The development of fungi covering more than 25% of the test surface is clearly visible to the naked eye |

5 |

|

starch film with the addition of rosemary essential oil 5% |

Fungal growth covering less than 25% of the test surface is clearly visible to the naked eye |

4 |

Table 3.

With an increase in the oil concentration, a decrease in fungal growth on the test surface is observed. In the groups with a concentration of 0.5%, 1% and 3%, there is a clear development of fungi covering more than 25% of the surface (score 5). However, with an increase in the concentration to 5%, fungal growth decreases, since fungal damage is less than 25% of the surface (score 4). An increase in the oil concentration helps to reduce fungal growth, which indicates its antifungal properties. For effective fungal control, it is recommended to use higher concentrations of oil.

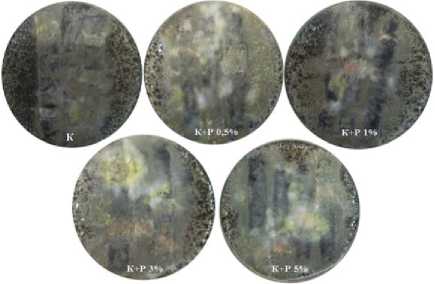

Figure 6. Fungus resistance tests of materials using method 4: samples obtained based on starch with different concentrations of rosemary essential oil (0.5; 1; 3; 5%)

The film completely dissolved due to the activity of fungal cultures, as well as due to the humidity of the nutrient medium. The study of the effect of antimicrobial additives on the physical and mechanical properties of polymeric materials is presented in Table 2

Table 2.

Data on the physical and mechanical properties of films

|

Composition of starch-based compositions |

Breaking stress, σр, МРа |

Relative elongation at break, εр, % |

|

соntrоl sample |

1,63 ± 1 |

31,70 ± 1 |

|

starch film with the addition of rosemary essential oil 0.5% |

1,31 ± 1 |

31,85 ± 1 |

|

starch film with the addition of rosemary essential oil 1% |

0,8 ± 1 |

37,84 ± 1 |

|

starch film with the addition of rosemary essential oil 3% |

0,72 ± 2 |

53,21 ± 1 |

|

starch film with the addition of rosemary essential oil 5% |

0,54 ± 1 |

56,63 ± 1 |

With an increase in the concentration of rosemary essential oil, the breaking stress undergoes a significant decrease of ~ 3 times, but the relative elongation increases ~ 2 times.

Comparative table of vapor permeability of materials

|

Composition of compositions based on PE, PP, starch and gelatin |

Vapor permeability of polymeric materials 24h, g/сm2 |

|

соntrоl sample |

3293,5094 |

|

starch film with the addition of rosemary essential oil 0.5% |

3241,8457 |

|

starch film with the addition of rosemary essential oil 1% |

3054,9756 |

|

starch film with the addition of rosemary essential oil 3% |

2775,2578 |

|

starch film with the addition of rosemary essential oil 5% |

2484,7368 |

An increase in the concentration of rosemary essential oil leads to a decrease in the vapor permeability of the films. At a concentration of 0.5% rosemary essential oil, vapor permeability decreased by 20%, and at a concentration of 1% rosemary essential oil – by 25%, 3% – 36%, 5% – 50%. When adding essential oil, a significant decrease in vapor permeability is observed, which indicates that the essential oil performs a barrier function, reducing the possibility of water vapor passing through the film.

Conclusion

A comprehensive study was conducted to research and develop antimicrobial coatings based on starch with the addition of an antimicrobial additive of rosemary essential oil for use in food packaging. In the context of increasing requirements for the safety and quality of food products, the use of antimicrobial technologies is becoming especially relevant, which determines the importance of this work. As a result of the studies, it was found that rosemary oil has fungistatic activity. The film demonstrated effectiveness against Candida albicans . However, despite the manifestation of antimicrobial activity against Candida albicans , effectiveness against other studied microorganisms, such as Bacillus subtilis and Escherichia coli , was not detected. The obtained data on the physical and mechanical properties of the films showed that with an increase in the concentration of essential oil, a decrease in the strength of the film is observed, but at the same time, its elasticity improves. It is also worth noting that the addition of rosemary oil leads to a decrease in the vapor permeability of the film, which has a positive effect on its ability to protect the contents from moisture and external factors. Analysis of existing studies confirmed the relevance of using rosemary essential oil as a natural antimicrobial component.