Development of armored products made from multilayer composite plates

Автор: Bokhoeva L.A., Rogov V.E., Bochektueva E.B., Baldanov A.B., Ivanov R.P.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: System solutions for technological problems

Статья в выпуске: 2 Vol.17, 2025 года.

Бесплатный доступ

Introduction. Modern requirements for personal and local armor protection dictate the creation of lightweight, durable, and efficient materials that can withstand a variety of threats, including shrapnel and low-velocity bullets. Conventional metal armor panels, while reliable, have a significant weight that limits their use. At the same time, ceramic materials, although they provide a high level of protection, are prone to the formation of secondary fragments upon impact. In this regard, composite materials such as aramid fibers and ultra-high-molecular-weight polyethylene (UHMWPE), which combine low weight with high strength and resistance to dynamic loads, are of particular interest. The article discusses the development of multilayer plates made from composite materials for personal and light armor protection. Methods and materials. Multilayer structures, including UHMWPE and aramid fabrics, were used to create armor plates. These structures were impregnated with epoxy resin and bioadditives such as collagen. The paper proposes a technology for the production of multilayer plates using aramid fabric and bioadditives. The technological process consisted of several steps: 1) a comprehensive study of the selected polymer materials with experimental determination of rigidity and strength characteristics; 2) cutting the fabric using a laser machine; 3) manufacturing an armor plate depending on the material and the loads subjected to it. Composite plates made from UHMWPE were created through hot molding using a press mold, and they consist of varying numbers of material layers. Multilayer elements (up to 30 layers) were made from aramid fabric with epoxy resin with bioadditives, which impart new elastoplastic properties to the material. Results. The ANSYS software package was used to calculate the strength of a multilayer composite plate under shock loading; field testing of the obtained plates as armor protection were also conducted, demonstrating good agreement with the calculations. Discussion. The obtained combined armor plates are highly effective in absorbing kinetic energy and preventing fragment penetration. Adding bioadditives to the epoxy matrix increased the interlayer defect zone, which contributed to the dissipation of impact energy. According to the authors, when adding bioadditives, the material acquires high fracture toughness. Conclusion (Findings). The developed armor plates offer a combination of low weight, no ricochets, and minimal deformation behind the barrier. This makes them promising for use in personal and local protective equipment. The use of bioadditives has improved the mechanical properties of the composite materials, and the test results confirm that the products comply with the Br3 protection grade, with a weight reduction of 25–30% compared to the analogues. The resulting products (low weight, absence of ricochet and traumatic consequences after impact) make them suitable for use as protection against shrapnel and pistol bullets.

Plate, composite materials, technology, bioadditives, interlayer defects, lightweight armor, mold

Короткий адрес: https://sciup.org/142243957

IDR: 142243957 | DOI: 10.15828/2075-8545-2025-17-2-201-209

Текст научной статьи Development of armored products made from multilayer composite plates

Original article

Бохоева Л.А., Рогов В.Е., Бочектуева Е.Б., Балданов А.Б., Иванов Р.П. Разработка бронированных изделий из многослойных композиционных пластин. Нанотехнологии в строительстве. 2025;17(2):201–209. – EDN: XEBLGZ.

Currently, the development of lightweight and ultrastrong armor products with improved properties and parameters compared to existing analogues is of great

importance. According to world military statistics, 30% of bullet wounds account for 70% of shrapnel injuries among personnel. Therefore, an important role in protecting against shrapnel and low-velocity weapon impacts (pistol bullets) is played by armor. Armor ab-

SYSTEM SOLUTIONS TO TECHNOLOGICAL PROBLEMS sorbs the energy of the impact and prevents shrapnel from penetrating the body. Lightweight armor is used in personal armor protection (bullet-proof vests, armor shields, armored helmets, shoes), as well as for local protection of vehicles and helicopters [1–4]. Polymer armor made from non-impregnated polymer binder fabrics with a specific weave of fibers is used to protect helicopter structures against high-speed impacts.. For many years, metal armor has been used in passenger vehicles, made from special armored steels. However, this type of armor can increase the weight of the car to its maximum. The authors believe that composite armor is the most effective way to protect vehicles. Composite armor has several advantages over other protective structures, such as lower weight and increased comfort for the driver and passengers.

The thickness of woven armor packages produced by different manufacturers varies from 6–7 mm for the first protection class to 18–20 mm for the second protection class. These protective structures may include shock absorbers designed to reduce the risk of human injury.

To withstand multiple high-speed, high-energy impacts of varying intensity and flying fragments, armor plates made from various materials are used. These include special metal alloys, which are used to create metal armor panels. Additionally, ultra-high molecular weight polyethylene and ceramic materials made from various metal oxide powders are also used [7–16].

Advantages of metal armor panels include: low cost, small thickness, high survivability, and operational durability. Their main disadvantage is high ricochet ability and weight. Ceramic panels have a high protection class and a relatively low weight, but they form multiple damaging fragments upon impact. The lightest available armor option is composite plates made from UHMWPE, which have low weight and no ricochet, but may cause significant deformations behind the armor and injure a person.

The disadvantages of the presented materials do not always allow creating the necessary anti-fragmentation protection; therefore, armor plates are produced as a combination of several different materials (sandwich package). Practice has shown that the first component of the protection takes on a high-speed impact and ensures maximum energy extraction of the striker. The rear elements of the armor plate must be sufficiently rigid and not subject to large deformations.

Optimum performance characteristics of armor can be achieved by using the potential of existing types of composites, as well as by combining properties that correspond to the maximum capabilities for minimum weight and strength of a particular composite material or structures made from this material.

This article discusses the development of multilayer plates made from composite materials that are used for personal and local lightweight armor protection.

SELECTING MATERIAL FOR LIGHTWEIGHT ARMOR PROTECTION

Fabrics based on aramid and UHMWPE fibers have been considered as promising materials for armored products.

Aramid fibers, made from polyparaphenylene tere-phthalamide, are an extremely strong material that has five times the strength of steel. At the same time, they are relatively lightweight, with a density of only 1.44 grams per cubic centimeter.

UHMWPE exhibits unique mechanical properties, has high wear resistance, impact resistance, abrasion and abrasive wear, surpassing other polymers and many steel grades in these qualities (density is 0.95 g/cm³). It is known [7, 17] that UHMWPE fibers have a specific fibrillar structure, which is formed by fibrillar proteins. Fibrillous proteins give tissues and structures rigidity, strength, elasticity. Some of the main structural proteins – animal connective tissues include collagen and elastin, as well as keratins in hair and horn formations and fibroin in natural silk, etc. Fibrils in UHMWPE fibers have a “shish-kebab” structure that is 50–70 nanometers long. This “shish-kebab” – like structure is a unique structure to polymers that resembles disks or plates strung on a common rod. The ability of polymer fibers with this fibrillar structure to resist high-speed impacts is ensured by a complex mechanism that inhibits crack growth:

-

• The splitting off microfibrils from the surface of the fibers during deformation and the accumulation of defects create barriers in the path of cracks;

-

• The rounding off of the crack tip due to multiple stages of relaxation processes and the forced damping of vibrations;

-

• Low sensitivity of fibers to stress concentrators.

PLATE MANUFACTURING TECHNOLOGIES

A technology for manufacturing multilayer plates used for personal and local lightweight armor protection has been developed [3, 18–22]. At the first step, a comprehensive study of the selected polymeric materials was conducted. The mechanical properties of the individual layers of selected materials were obtained in order to calculate the strength of the multilayer plate. The samples used were strips of UHMWPE films, Kevlar fabric, and aramid fabric.

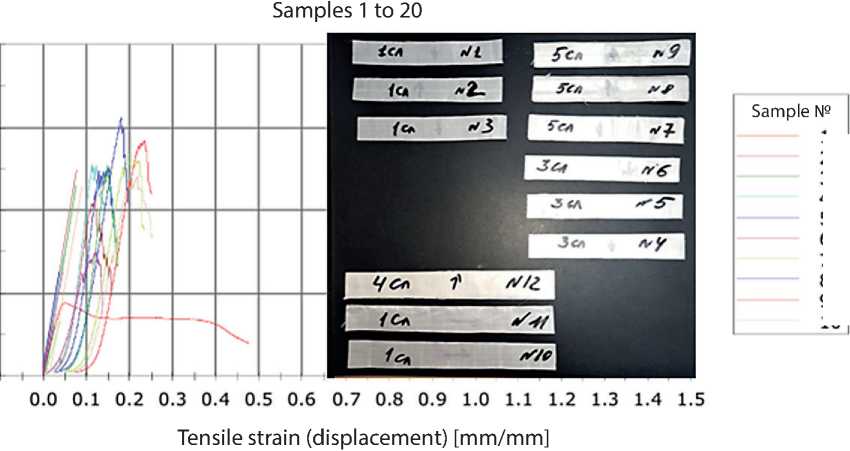

Tensile testing of 150×20 mm samples was conducted in accordance with GOST 11262 using an INSTRON 3368 testing machine (Figure 1), with a gripping speed of 10 mm/min. Figures 2 and 3 show the graphs of the dependence of the load on deformation during sample stretching; the values of the material stiffness properties were obtained: for one, two, and three layers.

SYSTEM SOLUTIONS TO TECHNOLOGICAL PROBLEMS

Fig. 1. Electromechanical tensile testing machine INSTRON 3368

Cutting of the material fabric is the second step in the process of manufacturing armor plates. The fabric for the plates is cut into pieces of a specific size using a stencil. It is important to avoid the formation of folds and overlaps when laying the fabric in the mold.

The fabric was cut using a Kamach laser cutting machine, where geometric parameters of the plate were set. During the cutting process of aramid fabric or oriented polyethylene, some issues arise that are common to most fabrics and specific to aramid fibers. If the fabric is not symmetrical, the bending of the warp and weft threads is different, these differences must be taken into consideration when cutting. Additionally, the direction of warp orientation must also be considered when laying out layers of fabric.

The third step of the process is the production of an armor plate. This plate consists of two main components: a multilayer material made from UHMWPE and aramid fabric package impregnated with epoxy resin containing bioadditives. The initial components of the armor plates take on a high-speed impact and ensure maximum extraction of the kinetic energy of the impactor and break through the “crushing” mechanism. Such elements require fabric with a structure that effectively converts the local impact of the striker into a deformation cone distributed over the volume. UHMWPE-made fabrics have such a structure. The first elements of the composite plates are created through hot molding process and consist of a varying numbers of layers of UHMWPE material with a thickness of 0.3 mm (up to 100 layers).

Samples 1 to 20

]apM[ sserts elisneT

Kevlar fabric, thickness 0.3 mm

Kevlar fabric, thickness 0.2 mm

0・0 0.2 0・4 0.6 0.8 1.0 1.2 1.4 1.6 1.8

Tensile strain (displacement) [mm/mm]

Fig. 2. Graphs of the dependence of the load on the deformation during the stretching of samples made from aramid fabrics and Kevlar fabrics

SYSTEM SOLUTIONS TO TECHNOLOGICAL PROBLEMS

о

ОО 40

00 300

00 200

о 1234567891

Fig. 3. Graphs of the dependence of load on deformation during the stretching of UHMWPE samples

]apM[ sserts elisneT

The layers are a film of a set of aligned filaments connected to each other. To produce UHMWPE plate elements, we developed a heated high-pressure mold made of aluminum and steel, which was modeled and manufactured (see Figure 4). Using 3D modeling software products NX10 and ANSYS, we modeled a high-pressure mold for working with polymer materials. Hot forming at temperatures up to 150 °C allows us to obtain high-quality blanks that accurately reproduce the desired shape. The finished products are cooled with the mold. The entire process takes between 10 and 24 hours to complete, depending on the temperature and thickness of the multilayer elements being produced.

The rear multilayer armor plates should not undergo significant deformation, which helps minimize human injuries. Therefore, they are made from dense aramid fabrics. The multilayer elements, which can be up to 30 layers thick, were made from aramid fabric combined with epoxy resin (ED-20 GOST 10587-84) with bioadditives. As a bioadditive, we used a bioactive material – collagen (dried or in the form of a gel), obtained in VSGUTU from animal skin waste. The bioactive material has a sour-milk composition or lactic acid and belongs to fibrillar proteins. Therefore, the bioadditives introduced into the brittle epoxy resin impart new elastic-plastic properties to the material [17, 23–24]. When

Fig. 4. The process of installing and configuring the high-pressure mold

SYSTEM SOLUTIONS TO TECHNOLOGICAL PROBLEMS using bioadditives, both empirically and theoretically, we encounter the problem of uncertainty in the distribution of particles by volume in the matrix. A method for introducing bioadditives with varying mass concentrations (between 5–15% by weight) has been developed and a new approach for their evenly distribution in the polymer matrix of the composite has been proposed [25]. The introduction of bioadditives into the matrix of the polymer composite material allows changing the physical and mechanical properties. However, there is a problem with their evenly distribution on the surface of the epoxy resin. There are several main methods for incorporating bioadditives into composite materials. One of these methods is by mixing the bioadditives with epoxy resin using a mixing machine that rotates the platform and the container. For better processing, zirconium oxide (ZnO2) balls can be added to the suspension with ED-20 epoxy resin with bioadditives, the total mass is equal to the mass of the mixture. As a result of rotation in the container, the balls create shear forces that promote the destruction of agglomerates and evenly distribution of bioadditives in the epoxy resin.

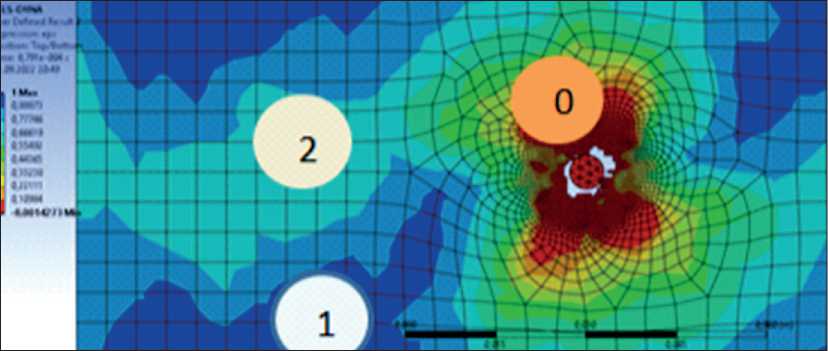

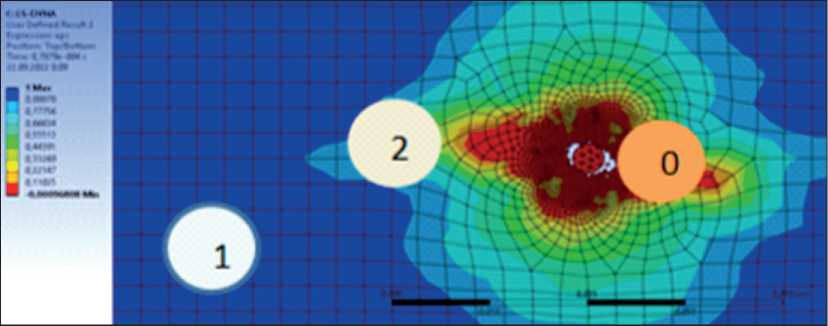

It can also be used an AG SONIC TC-150B ultrasonic bath with water heated to 45 °C for evenly distribution of bioadditives in the epoxy resin. An ultrasonic bath reduces the occurrence of air bubbles formed during mechanical mixing and promotes evenly distribution of particles. In this research for evenly distribution of bioadditives in the epoxy resin, authors used an AG SONIC TC-150B ultrasonic bath with water heated to 45 °C. According to the authors, kinetic energy dissipation during a low-velocity impact in multilayer composite structures is observed due to an increase in the interlayer defect zone. Studies of defects in the plate after testing have shown that the impactor velocity decreased by 30–45%, while the interlayer defect zone increased, the material had high fracture toughness. The analysis of plate damage was made in the ANSYS software package. In the ANSYS/LS-DYNA finite element system, with additional modules, we have developed dynamic models of the destruction of multilayer plates and the appearance of defects or holes due to a high-speed impact from a striker. 3D models of the striker and multilayer plate have been created, which correspond to the experimental samples.

Models of plates up to 100 layers made from UHMWPE and up to 30 layers made from aramid fabrics have been built. The calculation of each computer experiment takes from 6 to 8 hours. In the modeling, we used the mechanical properties of the composite materials, which were determined using both calculated analytical formulas and experimental methods [20, 24, 26]. The samples were subjected to impact tests at an impact speed of 380–500 m/sec. Fig. 5 shows the damage area to a plate made from aramid fabric with the addition of bioadditives to the epoxy matrix up to 10%. Fig. 6 shows the damage area to a plate made from aramid fabric with the addition of bioadditives to the epoxy matrix up to 1%. The strength calculation of the multilayer composite plate under the action of an impact load has been performed.

The following damage areas have been identified: 1 – no damage (blue indicator); 2 – interlayer defects (yellow, green indicator); 0 – complete destruction (red indicator). Fig. 5 shows the area of damage to the plate (interlayer defects) – 32% of the total area of the plate. Fig. 6 presents the damage area of the plates – 18%. Each layer reduces the impact, while an increase in the interlayer defect zone is observed, which corresponds to the area of interlayer destruction is significantly higher in results of experimental studies.

modified layered composite materials with bioadditives [26]. It was found that after testing for impact load, the

The back multilayer elements of the plate were obtained by molding in a low-pressure mold. To manufac-

10%

Fig. 5. Damage area of a plate made from aramid fabric with the addition of bioadditives to the epoxy matrix up to

SYSTEM SOLUTIONS TO TECHNOLOGICAL PROBLEMS

Fig. 6. Damage area of a plate made from aramid fabric with the addition of bioadditives to the epoxy matrix up to 1%

Fig. 7. Low pressure mold made from polymeric materials

At the final stage of armor plate production, multilayer plates are bonded and sheathed. The resulting armor plate and elements are weighed, their thickness and dimensions measured, and recorded in the armor plate production protocol. Armor plates with a protection class of Br3 weigh 1300 ± 5% grams, which is 25–30% less than existing counterparts.

TESTING THE LIGHTWEIGHT ARMOR PROTECTION

The development of a composite material for lightweight armor is guided mainly by the results of experimental testing, due to the complex nature of the processes that occur at dynamic loading rates [27, 28]. Field tests were conducted using an impactor with a speed ranging from 390 to 410 meters per second. The test temperature was up to ±40 degrees Celsius, and the humidity was up to 100 percent. All test results were recorded in the test protocol.

ture the plate elements from aramid fabrics, a low-pressure mold made of unreinforced polymers was designed, modeled and manufactured. A low-pressure mold made from polymer materials was developed and modeled using 3D modeling software products in NX10 and ANSYS (Figure 7).

When molding in a press, the cut prepreg (aramid material and uncured resin with bioadditives) is placed in a mold (matrix), clamped with the mold’s counterpart (punch), and an external pressure of 15 tons is applied so that the product acquires the required shape. The pressure is maintained until the resin has hardened. The manufacturing process for one multilayer element can take up to 24 hours.

CONCLUSION

The main advantage of the new armor plates is their lightweight design, which eliminates the risk of ricochets and recoil on the wearer’s chest, thereby reducing the likelihood of traumatic injuries after impact. Additionally, these plates do not produce any fragments. A technology for manufacturing multilayer plates from aramid fibers with bioadditives has been developed. Field testing of the obtained plates as armor protection has been conducted. The obtained products provide the possibility of using them as protection against fragments and pistol bullets. The results of these tests have shown that the plates are able to withstand both shrapnel and pistol bullets.

SYSTEM SOLUTIONS TO TECHNOLOGICAL PROBLEMS