Development of environmentally friendly PVC compositions

Автор: Albina R. Maskova, Gulnara U. Yarmukhametova, Diana F. Kinzyabulatova, Lyubov Z. Rolnik

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Development of new polymer materials

Статья в выпуске: 5 Vol.14, 2022 года.

Бесплатный доступ

Introduction. Polyvinyl chloride (PVC) is one of the most important polymers in the economy. Due to its versatility, this material is now found in a wide variety of products used in everyday life. A wide range of physical and mechanical properties is given to it by the use of additives, the main of which are plasticizers. The most common in terms of consumption are orthophthalic acid esters, in particular, dibutyl phthalate (DBP), dioctyl phthalate (DOP), diisononyl phthalate (DINP), diisodecyl phthalate (DIDP). Phthalates are well combined with polymers, give them high physical and mechanical properties, therefore plastic compounds based on them are widely used in the construction sector, engineering, as well as in agriculture and in everyday life. Numerous studies of products made from plasticized PVC, conducted in different countries, have established the adverse effects of DOP on human health, which led to the limitation of its areas of application. Legislative bans and growing consumer pressure are forcing PVC compound manufacturers to look for an environmentally friendly replacement for DOP. Methods and materials. In this research work, the possibility of creating more environmentally friendly PVC compounds using a mixture of plasticizers: industrial dioctyl phthalate and diisononyl phthalate and dibutoxyethyl phthalate (DBOEP) developed by us was studied. The choice of the plasticizers is based on the fact that DINP and DBOEP, in contrast to dioctyl phthalate, belong to the 3rd hazard class. Results and discussion. In the course of the correlation-regression analysis, a close functional relationship was obtained between the additives used and the characteristics of PVC, which was confirmed by the calculated coefficient of determination. Using the method of nonlinear programming applied to the constructed third-order polynomial dependencies, it was found that in the basic PVC composition formulation it is promising to replace up to 25 wt.h. DOP on DINP plasticizer. The joint use of industrial plasticizers DOP and DINP, as well as the developed DBOEP in the formulation of PVC compositions, indicates an increase in plasticity and manufacturability. This can probably be explained by the synergistic effect of the studied plasticizers. The dependence of the properties and content of plasticizers DBOEP and DINP in the form of a second-order surface was studied on the basis of the obtained experimental data, the level lines of the constructed function of two variables were studied, as a result of which it was found that the greatest effect is achieved at a dosage of: DOP – 25 wt.h., DINP – 5 wt.h. and DBOEF – 20 wt.h. Conclusion. The obtained research results show that the proposed formulation of the PVC composition makes it possible to reduce the toxicity of the plasticizers used by 50 % and improve the physical, mechanical and technological characteristics of the compounds.

Diisononyl phthalate, dioctyl phthalate, correlation, optimization methods, non-linear programming, elongation at break, PVC compound, plasticizer, melt flow rate, polyvinyl chloride, tear strength, regression, thermal stability, orthophthalic acid ester

Короткий адрес: https://sciup.org/142235383

IDR: 142235383 | DOI: 10.15828/2075-8545-2022-14-5-373-380

Текст научной статьи Development of environmentally friendly PVC compositions

Original article

M odern industry has been constantly requiring improvement of the technical and consumer properties of polymeric materials for the manufacture of a wide range of products. Therefore, research works on the preparation and study of the properties of new polymer composites based on known large-tonnage polymers are relevant [1–5].

One of the most commonly used bulk polymers in industry is polyvinyl chloride (PVC). Both unplasticized and plasticized PVC are used in a variety of ways for the production of building and finishing products, packaging materials for food and pharmaceutical products, plastic compounds for light industry and in many other areas of consumer and industrial goods production [6–12].

When obtaining plasticized PVC, various plasticizers are used, which impart plasticity and elasticity during

DEVELOPMENT OF NEW POLYMER MATERIALS processing and operation. Both the additives simplify the dispersion of the mixture components, lower the temperature of the technological processing of polymer compositions, increase the frost resistance of plastic compounds, but can adversely affect heat resistance. Some types of plasticizers are able to increase the fire, light and heat resistance of polymer composites.

About 100 different plasticizers are currently produced worldwide and only 50 of them are commercially important, while 80% of the global market for these additives is accounted for by seven plasticizers. Most of them (100–150 items) are phthalate type plasticizers, and in most cases orthophthalic acid esters are used, such as dibutyl phthalate (DBP), di-(2-ethylhexyl) phthalate (dioctyl phthalate or DOP), diisononyl phthalate (DINP) and diisodecyl phthalate (DIDP), because of the three existing isomeric forms of phthalic acid (orthophthalates, isophthalates, terephthalates), the former are the most popular due to availability, low cost and high modifying properties [13–24]. In this regard, it is not surprising that the interest of researchers in studying the possibilities of expanding the range of orthophthalic acid ester plasticizers does not weaken at the present time.

DOP has optimal plasticizing properties at a low cost and today remains the standard international plasticizer for PVC, the requirements for other plasticizers are consistent with the characteristics of DOP. The leading position of dioctyl phthalate to this day is determined, first of all, by the development of the production of flexible PVC – the largest consumer of DOP [18, 22–24].

However, in contrast to all these advantages, DOP has a significant drawback. According to an examination by European scientists, PVC products plasticized with DOP turned out to be hazardous to health, which led to a ban on the production and sale of certain products in Europe.

In connection with the above, the proportion of DOP consumption tends to gradually decrease. Although the replacement of DOP with other plasticizers is not always possible, since this entails an increase in the cost of the product, and, in addition, such qualities of the final product as flexibility and transparency are not always achieved, nevertheless, tightening requirements are forcing companies producing plasticizers, allocate funds for the search and development of other safe plasticizers for PVC materials.

Therefore, in recent years, the requirements for the operational and technological properties of materials obtained on the basis of polyvinyl chloride have been steadily growing, which, in turn, tightens the quality requirements for the additives used.

An effective method for improving the environmental safety of flexible PVC is to replace toxic dioctyl phthalate with safer phthalates [25, 26]. In this regard, we have studied the possibility of creating more environmentally friendly PVC compounds using a mixture of plasticizers:

industrial dioctyl phthalate and diisononyl phthalate and dibutoxyethyl phthalate (DBOEP) developed by us. The choice of these plasticizers is based on the fact that DINP and DBOEP, in contrast to dioctyl phthalate, belong to the 3rd hazard class.

METHODS AND MATERIALS

When studying the effectiveness of the action of phthalate plasticizers, an industrial formulation was taken as the basis, the composition of which is given in Table 1. PVC compositions were prepared in a laboratory mixer and plasticized on rollers at a temperature of 160оС. As plasticizers, industrial phthalate plasticizers dioctyl phthalate and diisononyl phthalate and dibutoxyethyl phthalate, developed by us earlier, were chosen, the production method and physicochemical properties of which are given in [27, 28].

The plasticizer is suitable for producing films at normal pressure and heating at 160оC for 10 min, if the critical dissolution temperature (Cdt) of the polymer in the plasticizer corresponds to (90–135)оC, and above this temperature the dissolving power of the plasticizer decreases [20, 21].

The fact that the PVC processing temperature depends on the Cdt of the polymer is satisfactorily confirmed in practice. According to the studies, the critical temperature of PVC dissolution in the developed plasticizer was 119оC (for comparison, the value of this indicator for serial DOP is 118оC).

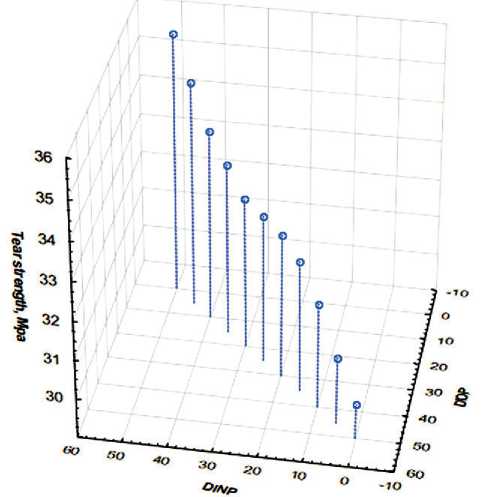

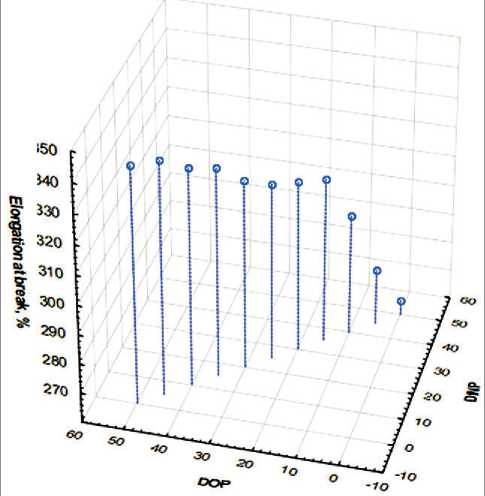

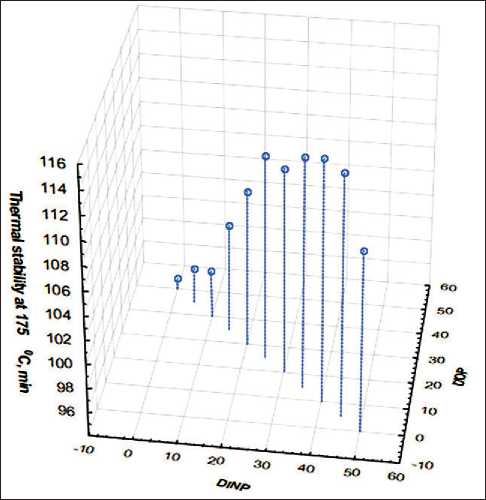

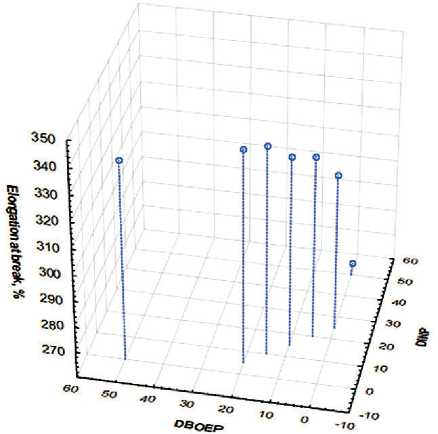

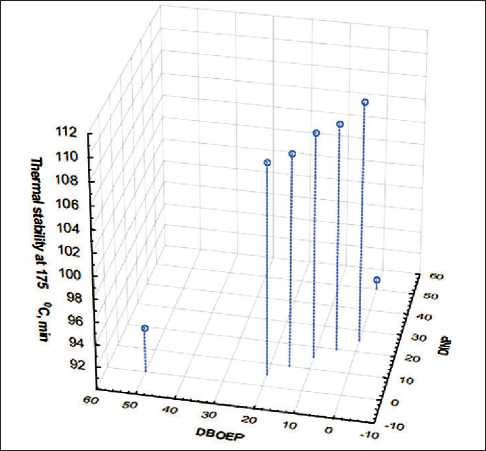

In the first series of tests, film samples plasticized with dioctyl phthalate were made (sample I). Diisononyl phthalate was introduced into the formulation as a partial (samples II–X) and full substituent for DOP (sample XI). At the same time, the total amount of plasticizers in PVC compounds remained constant. The ratio of plasticizers in the formulation is given in Table 2. The physical and mechanical properties of PVC compounds were determined in accordance with GOST 11262, the test results of which are graphically shown in Fig. 1–3.

At the next stage, the functional relationship between the additives used and the characteristics of PVC was

Table 1

The composition of the PVC formulation

|

Component name |

The amount of input component, wt.h. |

|

PVC |

100 |

|

Plasticizer |

50 |

|

Calcium stearate |

1.5 |

|

TOSS |

2.5 |

|

Diphenylolpropane |

0.25 |

DEVELOPMENT OF NEW POLYMER MATERIALS

Table 2

The ratio of dioctyl phthalate and diisononyl phthalate in PVC composition

|

Sample number |

The content of the plasticizer, wt.h./100 wt.h. PVC |

Sample number |

The content of the plasticizer, wt.h./100 wt.h. PVC |

||||

|

General |

DOP |

DINP |

General |

DOP |

DINP |

||

|

I |

50 |

50 |

– |

VI |

50 |

25 |

25 |

|

II |

50 |

45 |

5 |

VII |

50 |

20 |

30 |

|

III |

50 |

40 |

10 |

VIII |

50 |

15 |

35 |

|

IV |

50 |

35 |

15 |

IX |

50 |

10 |

40 |

|

V |

50 |

30 |

20 |

X |

50 |

5 |

45 |

|

XI |

50 |

– |

50 |

||||

Fig. 1. Effect of plasticizer concentration on the tensile strength of PVC composition

Fig. 2. Effect of plasticizer concentration on elongation at break of PVC composition

studied, and the optimal content of DINP and DOP in the PVC composition was determined.

A mathematical model was compiled, on the basis of which a polynomial dependence of the third degree was established in the form [29]:

Н = а1х3 + а2х2 + а3х + а4 , (1)

where H – is a physical-mechanical or technological indicator; а1, а2, а3, а4 – parameters of the polynomial regression model (1) calculated by the least squares method; х – is the content of DINP plasticizer, parts by mass.

The results of correlation and regression analysis for the data obtained as a result of the experiment are given in Table 3.

According to the results of statistical analysis, the parameters of the model (1) and the coefficient of determination were determined, which amounted to 0.98–0.99, which indicates a very high relationship between the content of the plasticizer DINP and the properties of the samples under consideration.

Regression models (1) are applicable both for predicting properties and for calculating the optimal content of the plasticizer in the formulation. To implement the optimization problem, we used nonlinear programming based on numerical methods for determining the extremum of a certain objective function under given constraints. Any property represented as a model (1) can act as an objective function. The mathematical expectations (mean values) of each of the considered properties are chosen

DEVELOPMENT OF NEW POLYMER MATERIALS

Fig. 3. Effect of plasticizer concentration on thermal stability PVC compositions as limitations. The problem statement for this study was formulated as follows:

Н = а11х3 + а12х2 + а13х + а14 →max (tensile strength, MPa)

Restrictions:

а21х3 + а22х2 + а23х + а24 ≥ 315

(Elongation at break, %)

а31х3 + а32х2 + а33х + а34 ≥ 107

(Thermal stability at 175оС, min)

The solution of the nonlinear programming problem was carried out using the tool “Search for a solution”. This tool is an additional add-on for the spreadsheet processor MS Excel 2010. As a result of solving the problem, it was found that the most optimal content of DINP is 25 mass.h. A decrease in the content of DOP in the mixture leads to a decrease in the plasticity of PVC, which can be judged from the values of relative elongation and tensile strength of the studied samples. With an increase in the dosage of DINP more than 25 mass.h, a deterioration in the physico-mechanical characteristics of the plastic compound is observed in comparison with the composite containing DOP. Comparison of samples I and VI shows that with partial replacement of DOP with DINP, the strength increases from 29.9 MPa to 32.8 MPa, and the relative elongation at break decreases from 340% to 320%, the thermal stability of the studied samples increases from 95 min to 111 min. But, nevertheless, the complete replacement of DOP by DINP (sample XI) leads to an increase in strength to 35.7 MPa and a significant decrease in elongation at break to 265%, while thermal stability increases slightly. Thus, replacing 50% of dioctyl phthalate with diisononyl phthalate makes it possible to obtain more environmentally friendly plastic compounds with physical, mechanical and technological characteristics that meet the requirements of regulatory standards.

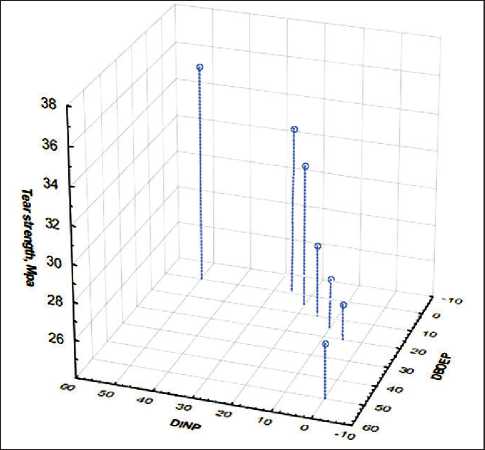

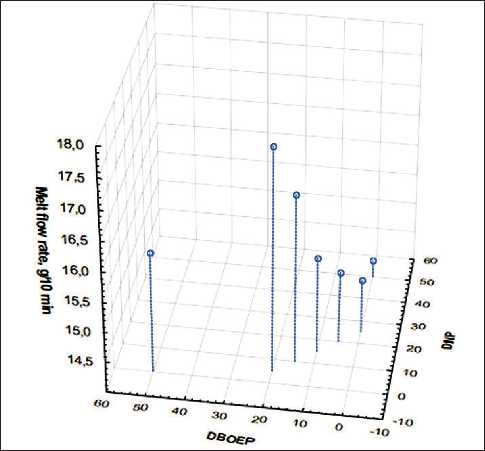

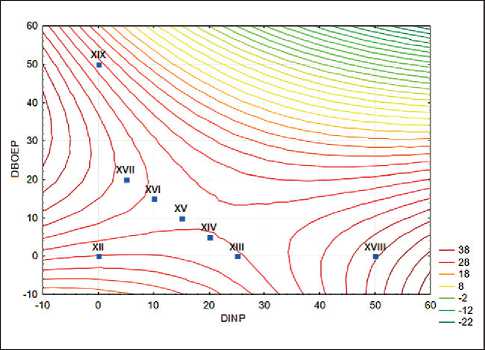

In the next series of tests, we prepared film samples modified separately with individual plasticizers (XII, plasticized with DOP; XVIII with DINP; XIX with DBOEP) and with a mixture of DOP and DINP with the addition of dibutoxyethyl phthalate (XIII–XVII). In order to further reduce the content of industrial phthalate plasticizers in the basic formulation of the initial composition, the influence of the concentration of additives on the physical, mechanical and technological characteristics was studied. The content of plasticizers in the formulation is given in Table. 4, the test results are graphically depicted in Fig. 4–7.

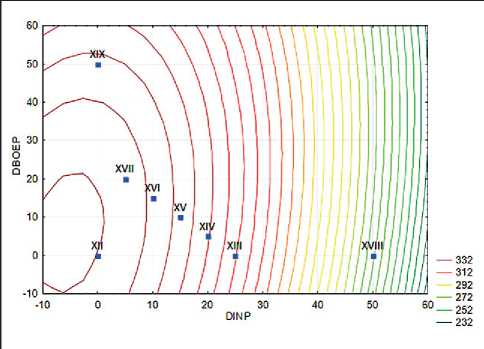

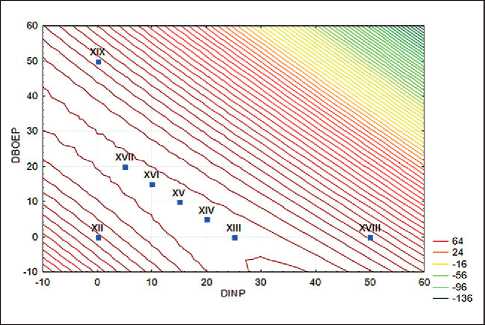

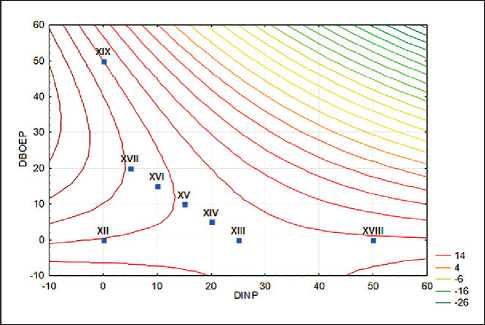

We have studied the dependence of the properties and content of plasticizers DBOEP and DINP in the form of a second-order surface based on the analysis of the experimental data obtained (Table 4 and Fig. 4–7) using factor analysis methods [30]:

Н = b1 + b2x + b3y + b4xy + b5х2 + b6y2 , (2)

where H – is a physical and mechanical property or technological indicator; b1, b2, b3, b4, b5, b6 – parameters

Table 3

Results of statistical analysis

|

Name of indicator |

Model parameters |

Determination coefficient |

|||

|

а1 |

а2 |

а3 |

а4 |

||

|

Tensile strength, MPa |

0.0001 |

–0.0088 |

0.2699 |

29.788 |

0.99 |

|

Elongation at break, % |

–0.0011 |

0.0525 |

–1.3373 |

341.970 |

0.98 |

|

Thermal stability at 175оС, min |

–0.0005 |

0.0255 |

0.2628 |

94.797 |

0.98 |

DEVELOPMENT OF NEW POLYMER MATERIALS

Table 4

The content of plasticizers in the PVC composition

|

Sample number |

The content of the plasticizer, wt.h./100 wt.h. PVC |

Sample number |

The content of the plasticizer, wt.h./100 wt.h. PVC |

||||||

|

General |

DOP |

DINP |

DBOEP |

General |

DOP |

DINP |

DBOEP |

||

|

XII |

50 |

50 |

– |

– |

XVI |

50 |

25 |

10 |

15 |

|

XIII |

50 |

25 |

25 |

– |

XVII |

50 |

25 |

5 |

20 |

|

XIV |

50 |

25 |

20 |

5 |

XVIII |

50 |

– |

50 |

– |

|

XV |

50 |

25 |

15 |

10 |

XIX |

50 |

– |

– |

50 |

Fig. 4. Effect of the concentration of plasticizers on the tensile strength of the PVC composition

Fig. 5. Effect of plasticizer concentration on elongation at break of PVC composition

Fig. 6. Effect of plasticizer concentration on thermal stability PVC compositions

Fig. 7. Influence of the concentration of plasticizers on the melt flow index of the PVC composition

DEVELOPMENT OF NEW POLYMER MATERIALS

Fig. 8. Line map of the level of dependency of tensile strength from the content of DBOEP and DINP

Fig. 9. Map of lines of the level of dependence of relative elongation at a break from the content of DBOEP and DINP

Fig. 10. Map of lines of the level of dependence of thermal stability from the content of DBOEP and DINP

Fig. 11. Map of the lines of the level of dependence of the melt flow index from the content of DBOEP and DINP

of the second order model (2) calculated by the least squares method; x – is the content of DINP plasticizer, mass parts; y – is the content of DBOEP plasticizer, parts by mass.

As is known, level lines are widely used to study second-order surfaces, which clearly show the behavior of a function in space, thereby making it possible to estimate its optimal values.

On fig. 8–11 shows maps of the lines of the level of dependence of the physical, mechanical and technological characteristics of samples XII–XIX.

As can be seen from fig. 8–11, sample XVII show the best indicators of strength and relative elongation at break, has a significantly higher MFI value compared to the original plastic compound, samples XIII–XVII show high thermal stability values. Thus, the most promising for further research is sample XVII containing 25 wt.h. dioctyl phthalate, 5 wt.h. diisononyl phthalate and 20 wt.h. dibutoxyethyl phthalate per 100 wt.h. PVC.

RESULTS AND DISCUSSION

The data obtained show that the combined use of industrial plasticizers DOP and DINP, as well as the developed DBOEP in the formulation of PVC compositions (samples XIII–XVII) leads to a decrease in tensile strength and an increase in relative elongation, which indicates an increase in plasticity. This can probably be explained by the synergistic effect of the studied plasticizers. With an increase in the content of the plasticizer dibutoxyethyl phthalate in the mixture, which is characterized by a higher specific gravity in comparison with DINP, there is a natural increase in the melt flow index of the PVC compound (from 15.2 to 17.7 g/10 min), which indicates an increase in the processability of PVC composites made according to the developed recipes. The greatest effect is achieved at a dosage of: DOP – 25 wt.h., DINP – 5 wt.h. and DBOEP – 20 wt.h. per 100 wt.h. PVC.

DEVELOPMENT OF NEW POLYMER MATERIALS

CONCLUSION:

the use of the developed PVC compound formulation based on a synergistic mixture of plasticizers: dioctyl phthalate (25 mass parts), diisononyl phthalate (5 mass parts) and dibutoxyethyl phthalate (20 mass parts) – allows to improve the strength and relative elongation at break, thermal stability and melt flow index;

- the use of dibutoxyethyl phthalate in place of dioctyl phthalate makes it possible to reduce the ecological burden on the environment.

Thus, the proposed formulation of the PVC composition makes it possible to reduce the toxicity of the plasticizers used by 50% and improve the physical, mechanical and technological characteristics of the compounds.

Список литературы Development of environmentally friendly PVC compositions

- Malbiev S.A., Gorshkov V.K., Conversations P.B. Polymers in construction. M.: Higher school; 2008.

- Polymers / Gowariker V.R., Viswanathan N.V., Sridhar J.; translat. from English. M.: Nauka; 1990.

- Ogrel L.D. Russian market of polymeric materials and products from them: state and prospects. Polymeric materials. 2019; 2: 46–51.

- Volkova A.V. Large-tonnage polymer market-2020.pdf. Higher School of Economics, Development Center, 2020. https://dcenter.hse.ru/data/2020/07/07/1595325171/Market%20large-tonnage%20polymers-2020.pdf

- Speranskaya O.A., Ponizova O.A., Gursky Ya.G., Tsitzer O.Yu. Russian market of plastic and plastic waste. Polymeric materials. 2022; 2: 30–38. https://polymerbranch.com/f51238cd02c93b89d8fbee5667d077fc/cab4c0a-5036fa3aba3ba0c021ca5da8c/magazineclause.pdf

- Market Reviews INVENTRA: Polyvinyl Chloride (PVC-C). Results of the year 2018. URL: https://plastinfo.ru/information/articles/671/

- Fadina Yu.I. Analysis of the Russian polymer market and further ways of its development. Business education in the knowledge economy. 2017; 1: 99–101.

- Akhsyanov A.N., Gataullina I.I., Gabbasov D.A., Zakirova K.I., Khantimirov A.G., Khuziakhmetova K.R. Polyvinyl chloride building materials and products. Polymers in construction: scientific online journal. 2021; 1 (9): 10–66.

- Sharavara A.M., Khristoforova I.A. Modern building materials based on PVC. International Academic Bulletin. 2019; 10 (42): 107–109.

- Guidelines for the development of compositions based on PVC / Ed.F. Grossman, translat. from English. ed. V.V. Guzeev. SPb.: Scientific foundations and technologies; 2009.

- Wilkie Ch., Summers J., Daniels Ch. Polyvinylchloride. SPb.: Professiya; 2007.

- Ulyanov V.M., Rybkin E.P., Gudkovich A.D., Pishin G.A. Polyvinylchloride. M.: Chemistry; 1992.

- Müller Н. Plastics Additives Handbook: Stabilizers, Processing AIDS, Plasticizers, Fillers, Reinforcements, Colorants for Thermoplastics. Published by Hanser Gardner Publications; 1988.

- Charles A. Handbook of Plastics, Elastomers, and Composites. The McGraw Hill: Harper Editor-in-Chief.; 2002.

- Schiller M. PVC Additives. Composition, properties, application / Tr. from English lang. ed. N.N. Tikhonova. SPb.: CEE Professiya; 2017.

- Additives to polymers. Directory. Zweifel H., Maer R.D., Schiller M. Translated from English 6th ed. (Plastic Additives Handbook), under ed. V.B. Uzdensky, A.O. Grigorov. Profi-Inform; 2010.

- Maslova I.P. Chemical additives to polymers. Directory. M.: Chemistry; 1981.

- Barshtein R.S., Kirillovich V.I., Nosovsky Yu.E. Plasticizers for polymers. M.: Chemistry; 1982.

- Kozlov P.V., Popkov S.P. Physic-chemical bases of plasticization of polymers. M.: Chemistry; 1982.

- Shtarkman B.P. PVC plasticization. M.: Chemistry; 1975.

- Tinius K. Plasticizers. M.: Chemistry; 1964.

- Vikhareva I.N. Synthesis and study of the properties of adipates of ethoxylated alcohols, promising plasticizers for polyvinyl chloride: dis. … cand. chem. Sciences. Ufa; 2021.

- Aleksandrov A.Yu. Development of scientific and technological bases for obtaining a plasticizer for PVC polymers based on trimethylolpropane: dis. … cand. chem. Sciences. Samara: 2019; 105.

- Mazitova A.K., Nafikova R.F., Aminova G.K. Polyvinylchloride plasticizers. In: Kirikov O.I. (ed.) Science and the era: monograph. Voronezh; 2011.

- Mitro S.D. Phthalate metabolite exposures among immigrants living in the United States: findings from NHANES, 1999–2014. Journal of Exposure Science. Environmental Epidemiology. 2019; 29: 71–82.

- Shkaeva I.E., Solntseva S.A., Nikulina O.S., Nikolaev A.I., Dulov S.A., Zemlyanoy A.V. Toxicity and danger of phthalates. Toxicological Bulletin. 2019; 6: 3–9.

- Maskova A.R., Aminova G.K., Rolnik L.Z., Faizullina G.F., Mazitova A.K. Oxyalkylated alcohols phthalates. Nanotehnologii v stroitel’stve = Nanotechnologies in Construction. 2019; Vol. 11, no. 1: 52–71. https://doi.org/10.15828/2075-8545-2019-11-1-52-71.

- Aminova G.K., Stepanova L.B., Maskova A.R., Efimova E.V., Mazitova A.K. Symmetric and asymmetric phthalates of oxyalkylated alcohols. Bashkir Chemical Journal. 2011; 18(1): 147–151.

- Math modeling. Theoretical basis. Materials for practical classes and independent work of students. Methodical instructions: educational and methodical complex / UGNTU, department. PED; comp. G.U. Yarmukhametova. Ufa: UGNTU; 2018.

- Middleton M.R. Analyzing statistical data using Microsoft Excel для Office XP. М.: BINOM: Knowledge Lab; 2005.