Development of technological process of cotton cellulose production and evaluation of experimental results

Автор: Kaldybaev R. T., Eldiyar G. K., Zhenisbekova D. A., Takibyeva G. A., Makhmudova M. A., Bekzat A. B.

Журнал: Вестник Алматинского технологического университета @vestnik-atu

Рубрика: Техника и технологии

Статья в выпуске: 2 (132), 2021 года.

Бесплатный доступ

In the course of this study, the technology of bleaching of cotton pulp for various purposes has been improved, which can be used in the production of cotton pulp by "Khlopoprom-Cellulose" LLP and other enterprises to increase the production efficiency and competitiveness of the products obtained. The proposed development makes it possible to obtain cellulose with a high degree of polymerization and whiteness, as well as to solve the problem of stabilization and high decomposition rate of hydrogen peroxide in the technological cycle. The bleached cellulose meets the requirements of GOST (State Standard) 595-79 "Cotton cellulose" and has an average degree of whiteness of 90%, which is 5-6% higher than the samples of cotton cellulose bleached without the use of a hydrogen peroxide stabilizer.

Cotton cellulose, stabilization, hydrogen peroxide, reagents, physical and chemical properties

Короткий адрес: https://sciup.org/140256809

IDR: 140256809 | УДК: 677.024 | DOI: 10.48184/2304-568X-2021-2-43-48

Текст научной статьи Development of technological process of cotton cellulose production and evaluation of experimental results

In this production cotton cellulose is produced on the technological line intended for processing of cotton raw materials into cellulose. The technological process consists of stages of dry mechanical purification of raw materials from mineral and organic waste, chemical purification, which consists in sequential processing of purified cotton raw materials by solutions of alkali and wetting agent in the process of boiling, washing, bleaching with hydrogen peroxide solution, washing, drying and packaging of the finished product.

The equipment of the technological line is located in the opening and cleaning area, in the chemical cleaning area and in the drying and packaging area. The technological line is equipped with equipment and machines of various companies, the characteristics of which are shown in Table 1 of Section 2.

Materials and research methods

All equipment in the continuous opening and cleaning area is connected in series with galvanized air pipes and belt conveyors. In the chemical cleaning and drying section the equipment of periodic action (boilers and bleaching tanks) and continuous action (water pumping unit, aerofontaneous drying unit, packaging press) is installed.

Technical specifications for hydrogen peroxide stabilizer had been developed. Sodium silicate plays a two-way role: as a hydrogen peroxide decomposition stabilizer and as a catalyst in the conditions of bleaching [1,2]. That's its unique property.

These technical specifications apply to the hydrogen peroxide stabilizer, derived from organic and inorganic compounds, intended for use in the bleaching of fibrous materials.

All requirements of these technical specifications are compulsory and suitable for certification.

DTPA 5NA is a known nitrogen-containing chelating agent both in the free form and as salts of alkali metals [3,4,5].

The record of the hydrogen peroxide stabilizer when ordering must consist of the product name with the raw material designation, the number of these technical specifications and the technical description ( TD ) number or a drawing for a specific product type.

«Hydrogen peroxide stabilizer СТ ТОО 40936697-005-2019 (ST TOO 40936697-0052019) ».

According to the physical and chemical indicators, the stabilizer must meet the standards are given in Table 1.

Table 1 - Physical and chemical indicators of the stabilizer

|

Indicator Name |

Characteristics and standards |

Test Methods |

|

Appearance |

Homogeneous and viscous liquid |

|

|

Colour |

From white to slightly yellow according to the reference sample. |

|

|

Relative viscosity, c |

min. 20 |

State standart 8420 |

|

Mass fraction of volatiles, % |

max. 65 |

State standart 17537 |

|

Hydrogen index, aqueous solutionpH of 10 g/l concentration |

9,0-12,0 |

State standart 8433 |

In the production conditions of KMC-2000 LLP "Khlopkoprom-cellulosa" was obtained a pilot batch of stabilizer № 4 in the amount of 500 kg for use in the process of bleaching cotton cellulose.

Results and their discussion

Stabilizer №4 was produced according to the following technological procedure:

[Auxiliary work stages]→ [Prepare facilities and equipment]→[Staff training] → [Prepare the raw materials]→ [Load components]→ [Mixing] → [Filtering] → [Filling] → [Labeling].

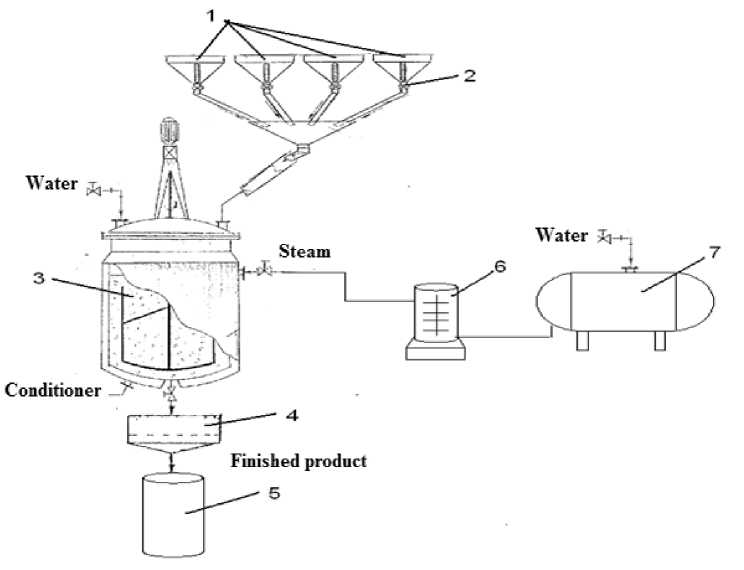

The equipment scheme of the low silicate stabilizer №4production is given below:

Figure 1- Equipment scheme of the low silicate stabilizer №4production.

1.–tank for components; 2 - dozers; 3 -reactor; 4 - mesh filter; 5 - vessel for finished products; 6 - steam boiler; 7 - water tank.

The obtained hydrogen peroxide stabilizer meets the requirements of ST ТОО 40936697005-2019 "Hydrogen Peroxide Stabilizer" and has the following characteristics:

Table 2 - Physical and chemical indicators of stabilizer №4

|

№ |

Indicator Name |

According to ST TOO 40936697005-2019 |

Experimental batch |

|

1 |

Appearance |

Homogeneous and viscous liquid |

complies with standard |

|

2 |

Colour |

From white to slightly yellow. |

complies with standard |

|

3 |

Relative viscosity, с |

min 20 |

34 |

|

4 |

Mass fraction of volatiles, % |

max 65 |

55 |

|

5 |

Hydrogen index, aqueous solution pH of 10 g/l concentration |

9,0-12,0 |

11,2 |

Ten pilot batches and 10 tons of cotton cellulose have been produced. Cotton cellulose bleaching processes were carried out within the framework of technological regulations for bleached cotton cellulose production.

Bleached cotton cellulose obtained by using a new hydrogen peroxide stabilizer meets the requirements of state standart 595-79 "Cotton cellulose" according to its quality characteristics.

The results of physical-mechanical and chemical experiments are given in Table 3.

Table 3 - Results of physical-mechanical and chemical experiments

|

Indicators |

GOST (State Standard) 595-79. |

Actual results |

|

1st grade |

||

|

Appearance |

The loose mass of white color, not containing foreign particles in the form of pluck, sand, pieces of rubber, metal impurities and other impurities of noncellulose character. |

complies with standard |

|

Mass fraction of alpha cellulose, % |

min.98,0 |

98,9 |

|

Mass fraction of water, % |

max. 10,0 |

8,2 |

|

Mass fraction of ash, % |

max. 0,2 |

0,18 |

|

Mass fraction of insoluble residue in sulfuric acid, % |

max. 0,30 |

0,20 |

|

Wettability, g |

min. 140 |

135 |

|

Whiteness, % |

min.85 |

90 |

|

Mass fraction of fibrous dust % max |

max 2 0 |

12 |

|

Dynamic viscosity mPa.s. |

(21-30) |

23 |

Conclusions

The results of the conducted experiments showed that:

-

1. Bleached cotton cellulose obtained by using a new hydrogen peroxide stabilizer is in accordance with the physical, mechanical and chemical indicators of the standard technical document for the produced products.

-

2. The obtained new hydrogen peroxide stabilizer can be used in production of cotton cellulose and hygroscopic mats without interrupting the stable operation of production.

Список литературы Development of technological process of cotton cellulose production and evaluation of experimental results

- Krichevsky G.E. and other Chemical technology of textile materials / Krichevsky G.E., Korchagin M.V., Senakhov A.V. - M.: Legprombytizdat, 1985.- 159 p. (in Russian)

- Raskina I.Kh., Sadov F.I., Bogdanov G.A. To the question of the mechanism of stabilization of hydrogen peroxide by sodium silicate under bleaching conditions // Journal of Applied Chemistry.-1966.- №1.- P.35-39 (in Russian)

- Kaldybaev R. T., Nabiev D. S., Kaldybaeva G. Yu., Zhunisbekova D. A., Takibaeva G. A., Temirshikov K. M., Zholaeva N. Study of the possibility of stabilization and reduction of the rate of decomposition of hydrogen peroxide in the process of bleaching cotton pulp // Izvestiya vysshikh uchebnykh zavedenii. Tekhnologiya tekstilnoy promyshlennosti 2018. - №2 (374). - PP. 233-237 (in Russian)

- Koukkari P., Salminen J. Therochemistry and reaction kinetics of PO-bleaching // Proc. 9th Int. Symp Wood Pulp. Chem. June 9-12, 1997. - Montreal, 1997. - PP. 191-195

- Soini P., Jäkärä J., Koljonen J., Gullichsen J. Effect of transition metals on oxygen delignification and peroxide bleaching // Pap. japuu. - 1998. -V. 80.-No. 2. - PP. 116-121.