Development of technology for obtaining anticorrosive nanostructured polyalkenylamide-succinimide coatings in construction

Автор: Evgeny V. Boev, Aigul A. Islamutdinova, Elmira K. Aminova

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Application of nanomaterials and nanotechnologies in construction

Статья в выпуске: 1 Vol.15, 2023 года.

Бесплатный доступ

Introduction. At present, the use of polymer coatings in the protection of metallic materials and structures is becoming popular in the construction industry. It is especially important to obtain nanostructured polymer insulating materials with high anticorrosive properties in order to ensure the service life of the equipment of the fuel and energy complex. Technological equipment during the extraction, transportation, processing of petrochemical raw materials is subject to regular exposure to aggressive environments. Damage to production equipment causes annual environmental damage and human health and material burden on the enterprise. The introduction of heteroatoms into the structure of the polymer molecule helps to improve the physico-chemical characteristics of polymer coatings, in particular, to increase the protective properties, since natural and synthetic polymer compounds represent a large cluster of supramolecular structures located in a certain sequence. Methods and materials. A technology has been developed for obtaining new polymeric nanostructured alkenylsuccinimides with anticorrosive properties, which can be used as part of lubricating coatings in various industries, including construction. Alkenylsuccinimides were tested according to TS 38101147-77 for succinimide additives and showed compliance with their standards TS 38101247-77. Results and discussions. In the course of the research a resource-saving non-waste technology of obtaining a nanostructured polymer additive with polyamines as a nanostructuring base to provide an anticorrosive effect has been developed. Conclusion. The obtained compounds based on triethylenetetramine, tetraethylenepentamine, alkenylsuccinic anhydride can be used as effective polymeric anticorrosion additives in the processing of metal materials and structures in the construction industry.

Polymeric nanostructured additives, construction metal structures, anticorrosive materials and coatings, triethylenetetramine, tetraethylenepentamine, alkenylsuccinic anhydride

Короткий адрес: https://sciup.org/142235801

IDR: 142235801 | DOI: 10.15828/2075-8545-2023-15-1-6-13

Текст научной статьи Development of technology for obtaining anticorrosive nanostructured polyalkenylamide-succinimide coatings in construction

Scientific article

The structure of polymeric compounds has been widely studied and is unusually diverse both in its spatial structure and in the heteroatoms located in the polymer structure. The configuration and conformation of polymer formations, if we consider such structural elements of polymer systems as a ball, pack, globule, crystallite, can form much more complex ordered systems of supramolec-ular level. The presence of heteroatoms in the polymeric structure allows the physical and chemical properties of polymeric materials to change due to the distribution of electron density inside the polymer matrix, thereby forming a nanostructured polymeric protection of metal prod- ucts and structures widely used in construction. Thus, we can conclude that a macroscopic polymeric body is characterized by a complex nanomolecular internal structure with a different arrangement of constituent elements in space and a different nature of interaction between them. These components of the polymer matrix differ in their properties not only due to the different arrangement of the various constituent elements, but also due to the nature of interaction between different groups of atoms.

The Russian Federation consumes 1.6 billion tons of metal per year in the following sectors (Table 1) in 2021 [1].

According to the sources studied, about 40-50% of the production equipment is operated in aggressive en-

APPLICATION OF NANOTECHNOLOGIES AND NANOMATERIALS IN CONSTRUCTION

Table 1

Metal consumption in the Russian Federation by industry

It can be confidently concluded that the technological equipment used at enterprises has long exhausted the planned resource and should be replaced [4–7]. Since failures of industrial equipment are one of the main causes of accidents at operating enterprises, timely replacement and modernization of existing installations and technologies will increase their service life. The following is an analysis of accidents and failures at industrial enterprises (Table 2).

Most of the failures of technological equipment are associated with the stream corrosion, especially the main pipelines are susceptible to this, where about 70% of accidents occur for this reason.

According to the source [4], the length of the pipelines is more than 150 thousand km, they have been in operation since the 1970s. Such a long period of use causes breakouts, fistulas, corrosion. Most industrial and petro- leum equipment has long since exhausted its service life and is still in operation.

Thus, it is relevant to study the processes of corrosion of technological equipment, the selection of ways to protect it in order to reduce the loss of material and energy resources.

The main advantage of polymeric materials is their great resistance to both chemical and environmental influences. This explains the use of polymeric materials in almost all areas of science and technology. Due to its high chemical resistance, polymer materials are widely used for anticorrosive protection of building structures and products made of metal, reinforced concrete, lime and cement-lime plaster, etc.

The most common method of preventing corrosion of building structures is to treat the protected surface by spraying or coating of polymer compositions. For the most stable adhesion to the metal surface polymeric additives are often added to various paint materials. Thus, nanostructuring polymeric additives create so-called film-forming polymeric dispersions, where water acts as a dispersion medium, an example of such systems can be latex paints [8, 9].

Emulsion (latex) paints are especially recommended for covering lime or lime-cement plaster, particle board and fiberboard in the premises of cinemas, train stations, clubs and other premises of civil buildings. Such colorful compositions, in addition to the main film-forming component, contain additives of plasticizers, stabilizer and pigment. The polymer is mostly applied to the surface to be treated with either a brush or a spray gun. To protect equipment from corrosion at petrochemical plants a primer is used as a base and then coated with emulsion paints, polymer paints and others based on polychlorvinyl resin. [10, 11].

The main area of the Russian Federation is located in a temperate climate zone, which is characterized by a high percentage of humidity. Protecting the exterior walls of industrial and civil buildings from moisture is of great

Table 2

Causes of equipment failure of chemical and oil and gas systems

|

System |

Cause of accidents, % |

||||

|

Corrosion |

Marriage of construction and installation works, % |

Marriage of materials |

Mechanical damage |

Violation of the operating mode |

|

|

Petrochemical, oil refining industry and oil transportation |

70 |

15 |

2 |

10 |

3 |

|

Oil and Gas Industry |

36.7 |

10 |

13.3 |

13.9 |

26.1 |

|

In-field pipelines |

95 |

2.8 |

0.8 |

0.6 |

0.8 |

APPLICATION OF NANOTECHNOLOGIES AND NANOMATERIALS IN CONSTRUCTION importance to increase their durability. In this regard, the treatment of the exterior walls of buildings with silicone substances largely solves this problem. For example, the treatment of brick and plastered walls with silicone materials gives the masonry hydrophobic properties, protects it from corrosion and at the same time preserves their ability to “breathe”.

Most silicone materials are used by dissolving in organic solvents as compounds such as alkylsiliconates of alkali metals. The process of protecting equipment in terms of physical and chemical processes involves the interaction of alkylsiliconate salts with carbon dioxide in the air. This reaction is characterized by the formation of sodium and potassium carbonates and insoluble polymeric compounds based on alkylsiliconates that can exhibit hydrophobic properties on the surface of the treated metalwork.

A very effective way to protect building structures and structures from corrosion is to cover them with polymer materials. The high chemical resistance of such cladding significantly increases the durability of tanks, baths and pipelines operating in aggressive environments. For this purpose, mainly sheets and films made of polyvinyl chloride and polyethylene are used. Polypropylene compositions are also used, which are applied with a spray gun. Fiberglass in the form of smooth or wavy sheets is also used as facing polymer materials for corrosion protection.

Penetration of aggressive medium molecules into the metal structure is explained by diffusion processes, causing unwanted processes of swelling, rusting, formation of ulcers, cracks and other damages. These damages have a synergistic effect, causing a simultaneous combination of processes of physical and mechanical effects on the protected surface. Formed microcracks, ruptures and ulcers over the period of operation increase and lead to the destruction of technological equipment and, thus, to additional significant material costs.

During the operation of polymer anticorrosive coatings, processes of diffusion of aggressive media, swelling to dissolution and chemical reactions can occur in them. These destruction processes occur, as a rule, simultaneously in various combinations and lead to changes in the physical and mechanical properties of polymer coatings. A significant influence on the change in the properties of polymer materials and their aging has the effect of aggression in the stressed state of the protective coating. It has been established, for example, that microcracks occur on the surface of polymer materials under conditions of simultaneous exposure to an aggressive environment and mechanical stress, which then gradually increase. At the same time, polymer coatings have proven themselves positively in construction as anticorrosive materials.

The developed samples of nano-containing polymeric alkyl succinimides can also be used as an effective additive to lubricating coatings in various industries, including construction. Alkenylsuccinimides were tested according to TS 38101147-77 for succinimide additives and showed compliance with their standards TS 38101247-77. Also, succinimide additives can be used to create nanostuctur-ated polymer coatings as an anticorrosive protection of metal structures in construction.

Most additives of the succinimide type, while possessing detergent and dispersant properties, do not improve the anti-corrosion properties of lubricating oils. Therefore, it is quite often necessary to use these additives in compositions with anticorrosive materials and it is recommended to use antimony dialkyl dithiocarbamates, 2,2'-diphenylcarboxylic acid, zinc dialkyl dithiophosphates or introduce phosphorus, boron, sulfur atoms into the succinimide additive [12].

The preparation of alkenylsuccinimides by the reaction of alkenyl-substituted succinic acid or its anhydride (>90% of the С10–30 alkyl substituent with a mixture of amines in a molar ratio of 1:0.8–1.5 at a temperature of 125–135оC in the presence of an aromatic solvent for 3.5 hours with subsequent filtration of the product. At the first stage, the alkylation of maleic anhydride (MA) with polyalphaolefins is carried out at 150–250оC for 15 hours.Up to 10% (per alkenylsuccinimide) polyglycol alkyl phenol formaldehyde resin is added to prevent haze. As amines, a mixture containing 5–70% amino-ethyl-ethanolamine, 5–30% aminoethylpiperazine, 0–25% triethylenetetramine (TETA), 0–20% hydroxyethylpiperazine, 0–10% diethylenetriamine (DETA), 10–15% oligomers of these amines are used [13–14].

Succinimide additives, having an effective detergent and dispersing force, and, as noted above, exhibit an anticorrosion effect. These additives are usually used in compositions with anticorrosion agents [15–22].

METHODS AND MATERIALS

The reaction of formation of ASA (alkenylsuccinic anhydride) from MA (maleic anhydride) and olefin is carried out in the environment of aromatic hydrocarbons (toluene, etc.). The regeneration of aromatic hydrocarbons requires the use of additional equipment, the process is lengthy and environmentally unsafe. In this work, toluene is used as a solvent. The obtained alkenyl-anthalic anhydride is a viscous transparent light yellow liquid with the concentration of the main substance up to 85%. Products produced on the basis of alkenylan-thalic anhydride are excellent dispersants in motor oils, emulsifiers of industrial explosive emulsions, corrosion inhibitors, etc.

Practical significance of the research lies in the development of modern demanded nanostructured additive with the aim of import substitution. The developed technology of polymeric additive production on the basis of alkisuccinimides will increase the line of anticorrosive

APPLICATION OF NANOTECHNOLOGIES AND NANOMATERIALS IN CONSTRUCTION lubricating polymeric materials of domestic production and exclude the dependence on foreign supplies.

The substituted succinic anhydride described in the patent document is used as the alkenyl succinic anhydride [19].

When studying the protective anti-corrosion properties of the compounds under study, three main methods are used. The most objective is gravimetric or weight method, which consists in changing the weight of the studied object (steel samples) before and after exposure to aggressive medium at different temperatures. In practice, this method consists in direct immersion of the studied object in technological equipment.

The express method is electrochemical, which consists in the use of laboratory equipment to measure the rate of corrosion in electrolyte solutions.

The resistometric method consists in the study of the dependence of the reduction of the cross-section of the equipment and the increase of electrical resistance. The advantage of the method is the possibility of continuous monitoring of metal corrosion processes in time not only in electrolyte solutions, but also in organic solutions, in air, gases and soil.

RESULTS

In the scientific work an analytical review of succinimide-based inhibitory compositions was carried out. Analysis of the literature data confirms the assumption that polymeric nanostructured additives containing such groups as carboxyl, succinimide, various heteroatoms (nitrogen, oxygen) can exhibit high adhesive properties, increase the chemical resistance and durability of the system.

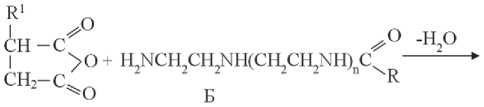

H2NCH2CH2NH(CH2CH2NH)nH RC00H> A -H2°

/O

H2NCH2CH2NH(CH2CH2NH) СГ n XRБ where R = (CH2)2CH3, CH(CH3)2, C17H33, C17H35

or

H^NCH CH^N NCHAHNHC

^ \ / 2 2

xК

R*-CH-C/ ^°

^H_C>NCH2CH2NH(CH2CH№

1-9, 13-15

or

R ?H C>N(CHAN^N(CHANHC^

CH2- 10-12, (B) Compound 2, R = CH(CH3)2, n =1 [AI based on DETA, IBA and ASA]; Compound 3, R = C17H33, n = 1 [AI based on DETA, OA and ASA]; Compound 4, R = (CH2)2CH3, n = 2 [AI based on TETA, BA and ASA]; APPLICATION OF NANOTECHNOLOGIES AND NANOMATERIALS IN CONSTRUCTION Compound 5, R = CH(CH3)2, n = 2 [AI based on TETA, IBA and ASA]; Compound 6, R = C17H33, n = 2 [AI based on TETA, OA and ASA]; Compound 7, R = (CH2)2CH3, n = 3 [AI based on TEPA, BA and ASA]; Compound 8, R = C17H33, n = 3 [AI based on TEPA, OA and ASA]; Compound 9, R = C17H35, n = 3 [AI based on TEPA, SA and ASA]; Compound 10, R = (CH2)2CH3, n = 3 [AI based on bis-AEP, BA and ASA]; Compound11, R = C17H33, n = 3 [AI based on bis-AEP, OA and ASA]; Compound 12, R = C17H35 + C19H31 (1:1), n = 3 [AI based on bis-AEP, SA, PA and ASA]; Compound 13, R = (СН2)2СН3, n = 0 [AI based on EDA, OA and ASA]; Compound 14, R = СН(CН3)2, n = 0 [AI based on EDA, IBA and ASA]; Compound 15, R = CН(СН3)2, n = 1–3 [AI based on PEPA, EPA and ASA]; DISCUSSION The obtained nanostructured polyalkylsuccinimide compounds can be used as effective additives with high protective anti-corrosion properties in paint and varnish materials, construction mixtures used for internal and external coating of construction materials subjected to corrosion damage. The positive point of this work is that in the process of obtaining the final product aromatic hydrocarbons (toluene, benzene, etc.) are not used as solvents, but lubricating synthetic oils are used. This helps to reduce the cost of the final product and exclude the stage of solvent recycling from the process chain, which reduces the environmental burden of production. The obtained samples were examined on the basis of physico-chemical characteristics of the compounds obtained (1–15), according to which the amine number varies from 21–24 mg HC1 per 1 g, which can be used Table 3 "В. s (Z> Parameters Amine number, mg HC1 per 1 g of additive, not less than 20 Acid number, mg KOH per 1 g of additive, not more than 4.0 Mass fraction of nitrogen in additive, %, not less than 2.4 Mass fraction of mechanical impurities, %, no more than 0.06 Mass fraction of water, %, no more than 0.1 Mass fraction of active substance, %, not less than 40.0 Mass fraction of free polyamines, %, not more than 0.2 Flash point determined in an open crucible, оC, not less than 160 1 2 3 4 5 6 7 8 9 1 24.2 2.3 2.6 0.02 0.02 44.2 0.1 172 2 24.8 2.9 3.3 0.04 0.03 45.9 0.16 185 3 22.1 2.9 2.8 0.04 0.08 42.2 0.1 170 4 21.0 3.2 2.7 0.03 0.02 46.3 0.14 182 5 26.8 2.8 2.5 0.04 0.05 46.6 0.08 185 6 22.4 2.8 2.7 0.04 0.06 43.3 0.09 173 7 22.5 3.0 3.0 0.05 0.05 45.1 0.08 175 8 24.6 3.1 2.8 0.06 0.08 46.4 0.07 180 9 22.0 3.6 2.5 0.02 0.07 42.6 1.12 166 10 25.7 2.2 3.2 0.01 0.08 48.2 1.11 177 11 25.3 2.9 3.1 0.02 0.06 46.6 0.18 176 12 24.9 2.7 3.2 0.04 0.09 46.7 0.16 170 13 21.2 2.9 2.5 0.01 0.03 41.0 0.15 163 14 21.4 2.8 2.4 0.03 0.04 42.0 0.16 162 15 24.6 8.8 2.8 0.02 0.04 46.2 0.13 174 APPLICATION OF NANOTECHNOLOGIES AND NANOMATERIALS IN CONSTRUCTION as roofing and corrosion-resistant materials and coatings (Tables 3 and 4). According to the table, the physico-chemical parameters of the compounds obtained differ slightly. During the study of the corrosion resistance properties of the synthesized compounds in acid medium in the absence of application of nanostructured polymer system to the metal surface of the studied object, the corrosion rate was 0.8 mm/year. It should be noted that when the inhibiting material was applied to the metal plate, it was possible to reduce the corrosion rate over time to 0.01 mm/year. Thus, the average protection rate was 97.3% (Table 4). The gravimetric method for determining the corrosion rate was carried out in a cell filled with the medium under study. The samples (metal plates St3) were in a suspended state at the same time. The weights of the samples were measured before and after the test, which made it possible to determine the rate of corrosion by weight loss. The tests were conducted for 2 hours: the average corrosion rate in the environment without the addition of the sample alkylsuccinimide nanostructuring additive was 4.35 mm/year, in the presence of IR with a dosage of 0, 5, 10, 20, 30, 40, 50 mg/l – 0.108 mm / year. The protective effect of corrosion inhibitor determined by weight loss of control samples in the absence and in the presence of corrosion inhibitor. Also the degree of protection of the samples obtained was studied at the temperatures of aggressive environment at 20оC and 40оC. Table 4 Results of studies of the obtained samples for inhibitory capacity Ser. No. The composition of the corrosion inhibitor Mole ratio Inhibitor dosage, mg/l Degree of protection, % 1 2 3 4 5 1 diethylene triamine: butyric acid:amide: alkenylanthalic anhydride 1:1:1,1:1 50 98.8 2 diethylene triamine: isobutyric acid:amide: alkenylanthalic anhydride 1,05:1:1:1 50 99.3 3 diethylene triamine:oleic acid:amide: alkenylanthalic anhydride 1,1:1:1:1 30 98.5 4 triethylenetetramine: butyric acid:amide: alkenylanthalic anhydride 1:1:1:1 50 99.2 5 triethylenetetramine: isobutyric acid:amide: alkenylanthalic anhydride 1:1:1,4:1 50 99.1 6 triethylenetetramine:oleic acid:amide: alkenylanthalic anhydride 1:1:1:1 50 99.1 7 triethylene polyamine: butyric acid:amide: alkenylanthalic anhydride 1:1:1:1 50 99.3 8 triethylene polyamine: oleic acid:amide: alkenylanthalic anhydride 1:1:1:1 50 98.3 9 triethylenpolyamine:stearic acid:amide: alkenylanthalic anhydride 1:1:1:1 30 97.2 10 di-aminoethylpiperazine: butyric acid:amide: alkenylanthalic anhydride 1:1:1,3:1 30 99.4 11 di-aminoethylpiperazine:oleic acid:amide: alkenylanthalic anhydride 1:1:1:1 50 99.5 12 di-aminoethylpiperazine: stearic acid:amide: alkenylanthalic anhydride 1:1:1:1 50 98.2 13 ethylenediamine: butyric acid:amide: alkenylanthalic anhydride 1:1:1:1 50 95.4 14 ethylenediamine: isobutyric acid:amide: alkenylanthalic anhydride 1:1:1:1 50 95.3 15 polyethylene polyamine: isobutyric acid:amide: alkenylanthalic anhydride 1:1:1:1 50 99.15 APPLICATION OF NANOTECHNOLOGIES AND NANOMATERIALS IN CONSTRUCTION At 25оC the corrosion rate is 4.35 mm/year, at 20оC it is 4.81 mm/year, at 40оC it is 4.4 mm/year. Thus, there is an increase in the corrosion rate with increasing temperature. The results of studies of the obtained samples for inhibitory capacity are presented in Table 4. CONCLUSION As a result of scientific research polyalkylsuccinimide compounds were synthesized, physical and chemical properties and anticorrosive activity were studied. The advantage of the method is the most environmentally friendly way of producing succinimide additives without the use of aromatic solvents. The obtained compounds have polymer-binding characteristics, this property will increase the degree of adhesion of the coating with the surface of the metal structure. The obtained fifteen samples of polymeric nanostructured alkylsuccinimide additives exhibit high corrosion activity and can be used to protect industrial equipment and metal building structures from corrosion.

Список литературы Development of technology for obtaining anticorrosive nanostructured polyalkenylamide-succinimide coatings in construction

- Semenova I.V, Florianovich G.M., Khoroshilov A.V. Corrosion and corrosion protection. Moscow: Fizmatlit; 2002.

- Burlov V.V., Parputs I.V. Features and types of corrosion destruction of metal equipment of primary oil refining plants. Protection of metals. 2005;41(1): 1-6.

- Mamulova N.S., Sukhotin M., Sukhotina L.P., Florianovich G.M., Yakovlev A.D. All about corrosion: handbook. St. Petersburg: Himizdat; 2000.

- Burlov V.V., Altsybeeva A.I., Parputs I.V. Corrosion protection of refinery equipment. St. Petersburg: Chemical Publishing House; 2005.

- Burlov V.V., Parputs T.P., Parputs I.V. Corrosion cracking of austenitic welds of oil refining equipment made with a cladding layer of 08X13 steel. Corrosion: materials, protection. 2004; 7: 22-25.

- Burlov V.V., Parputs I.V. Features and types of corrosion destruction of metal equipment of primary oil refining plants. Protection of metals. 2005; 41(1):1-6.

- Kotlyarevsky V.A., Shatalov A.A., Khanukhov H.M. Safety of tanks and pipelines. Moscow: Publishing House Economics and Informatics; 2000.

- Boev E.V., Islamutdinova A.A., Aminova E.K. Method of acquiring calcium silicate for construction. Nanotechnologies in Construction. 2021; 13(6):350-357.

- Boev E.V., Islamutdinova A.A., Aminova E.K. Acquiring the retainer for waterproofing road bitumen. Nanotechnologies in Construction. 2021; 13(6): 319-327.

- Ildarkhanova F.I., Bogoslovsky K.G. Choice of paint coatings for long-term anticorrosion protection of metal structures in the oil and gas industry. Territory of Neftegaz. 2013; 6: 85.

- Semenova I.V. et al. Corrosion and corrosion protection. M.: Fizmatlit; 2002.

- 12 Bazhenov S.L. et al. Polymer composite materials: strength and technology. Dolgoprudny: Intellect; 2010.

- Fomin G.S. Corrosion and corrosion protection. Encyclopedia of International Standards. Moscow: Protekor; 2013.

- Kuliyev A.M. Chemistry and technology of additives to oils and fuels. M.: Chemistry; 1985.

- US Patent No. 4863487. MKISIOL 1/22; RZHX 16P213P. 1990.

- Ostroverkhov V.G., Glavati O.L., Chermenin P.L. Succinimide additives based on the C18-C40 fraction of products of high-temperature oligomerization of ethylene. Chemistry and technology of fuels and oils.1982; 5: 24-27.

- Harun Ya.E., GlavatiO.L., Glavati E.V., Turchin G. V., Bugai B. I., Puchkovskaya G. A., Gavrilko T. A. The influence of the structure of oligobutenes on the high-temperature dispersing properties of succinimide additives // Chemistry and technology of fuels and oils. 1979; 2: 14-17.

- Application 433079 FRG 1993. Additive to lubricating oils and motor fuels based on the reaction products of copolymers with amines. RathHansPeter.

- RF Patent No. 2502748. A method for obtaining amidoimidovalkenylantaric acid. Zagidullin R.N., Mustafin A.G., Dmitrieva T.G., Zagidullina G.R., Bul. No. 36, 2013.

- RF Patent No. 2502747. A method for obtaining amidoimidovalkenylantaric acid. Zagidullin R.N., Mustafin A.G., Zagidullina G.R. Byull. No. 36, 2013.

- Copyright certificate of the USSR No. 455142. A method for obtaining alkenylsuccinimides. Gorunya.E., Sklyar V.T., Glavati O.L., Byull. No. 48, 1974.

- RF Patent No. 2296134. A method for obtaining alkenylantaric acid imides. Zagidullin R.N., Dmitriev Yu.K., Lyakumovich A.G., Pub. 27.03.2007.