Development of the concept of a reusable liquid rocket engine with three-component fuel

Автор: Belyakov V. A., Vasilevsky D. O., Ermashkevich A. A., Kolomentsev A. I., Farizanov I. R.

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Aviation and spacecraft engineering

Статья в выпуске: 1 vol.22, 2021 года.

Бесплатный доступ

The article considers a promising direction for the development of liquid-propellant rocket engines (LPRE) – the use of three-component propulsion systems. The interest in this topic is based on a number of advantages that can be obtained by using this LPRE concept, namely: saving the mass of the launch vehicle (LV) by using a denser hydrocarbon fuel at the initial launch site; high specific impulse values at high-altitude launch sites due to the use of a more efficient pair of fuel components (FC): liquid oxygen + liquid hydrogen; reducing the cost of removing the payload, due to the use of a single propulsion system for both launch sites. An analytical review of implemented three-component LPRE schemes developed in Russia and abroad has been conducted, and their main advantages and disadvantages have been highlighted. Based on a detailed study of a number of circuit solutions for liquid-propellant rocket engines running on three-component fuel, the concept of a two-mode single-chamber three-component engine made according to a closed circuit with afterburning of generator gas is proposed. The oxidizer is liquid oxygen, the fuel is RG-1 kerosene and liquid hydrogen. In the first mode, the engine runs on three components, the share of liquid hydrogen in the fuel mixture is 4% of the total consumption of components. In the second mode, the engine runs on FC liquid oxygen + liquid hydrogen. The results of a computational and analytical study of the optimal design parameters of the engine are presented. The aim of the study was to understand the qualitative picture of the influence of various fuel parameters on the thermodynamic properties of the combustion products of the fuel mixture and the engine efficiency. Based on the results of the study, the optimal percentage of fuel components was determined. A mathematical model for calculating a three-component LPRE has been developed. The results of calculation of energy coupling are presented. A comparative analysis of the mass characteristics of the designed propulsion system is carried out.

LPRE on three-component fuel, mathematical model of LPRE, PHS, mass characteristics, gas dynamic parameters.

Короткий адрес: https://sciup.org/148321792

IDR: 148321792 | УДК: 629.7.036.54 | DOI: 10.31772/2712-8970-2021-22-1-121-136

Текст научной статьи Development of the concept of a reusable liquid rocket engine with three-component fuel

Introduction. In recent years, the space launch market has expanded with the emergence of numerous new aerospace private companies in Japan, China, Brazil and other countries, but the cost of launching a payload remains quite high. This is due, among other things, due to the one-time use of the most expensive component of the launch vehicle (LV) - the engine, which is lost when the stage is thrown away (except for the returned LV stages by SpaceX, Blue Origin).

One of the options for reducing the cost of launching the payload is the use of one propulsion system (PS) for two stages. To implement this concept, it is advisable to use three-component liquid-propellant rocket engines (LPRE). In the first injection section, these engines operate on fuel components (FC) - liquid oxygen

+ hydrocarbon fuel, and in the subsequent injection sections, they use a more energetically efficient fuel pair - liquid oxygen + liquid hydrogen.

The advantages of LPREs operating on three-component fuel include: economy of the launch vehicle mass due to the use of a denser hydrocarbon fuel at the initial stage of launching; high values of specific impulse in further launch phases due to operation on a highly efficient pair of FC - liquid oxygen + liquid hydrogen; reduction in the cost of launching the payload, which is possible due to a single PS for two stages of the LV.

The disadvantages of these PSs are: lack of infrastructure for testing and operation of LVs with LPREs operating on three-component fuel; complication of the design of the control system; relative efficiency losses due to the need to maintain two modes of engine operation.

Description of the implemented circuits of three-component LPREs. In the world practice, several concepts of LPREs operating on two fuels have been considered in relation to a single-stage LV.

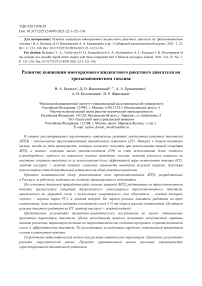

In [1] the PHS of a two-mode propulsion engine with thrust of 3160 kN is presented (Fig. 1). Liquid hydrogen and RJ – 5 (synthetic fuel with a density 35% higher than that of kerosene) are used as fuels. The main feature of this engine is the presence of 4 gas generators (GG), which makes it possible to simplify the propulsion control and divide the flight into two modes: the first mode is the operation of the engine on the components liquid oxygen + RJ-5, the second mode is the operation of the engine on the components liquid oxygen + liquid hydrogen. Another distinctive feature of this engine is the cooling of the chamber with an oxidizer – liquid oxygen, throughout the entire active phase of the flight.

Fig. 1. Pneumohydraulic scheme of an oxygen-hydrocarbon LPRE with an additional hydrogen subsystem

Рис. 1. Пневмогидравлическая схема ЖРД на кислород-углеводородном топливе с дополнительной водородной подсистемой

The supply of fuel components to the combustion chamber (CC) and gas generators (GG) is carried out using three booster pump units (BPU) and three main turbo pump units (TPU). RJ-5 and hydrogen are fed directly to the GG. The oxidant taken after the first stage of the oxidizer pump cools the engine chamber, after which it is bypassed into the oxidizing GG [2]. The oxidant entering the second stage of the oxidizer pump (the second stage of the pump is not shown in the diagram) is supplied to the reducing GG. The working fluid of the turbine of hydrocarbon fuel and hydrogen TPU is a reducing generator gas. The oxygen turbine TPU operates on an oxidizing generator gas.

Disadvantages of this propulsion system concept:

-

– decrease in the reliability of LPRE due to the large number of units that make up the engine;

– difficulties in organizing reliable cooling of the chamber with an oxidizer [3].

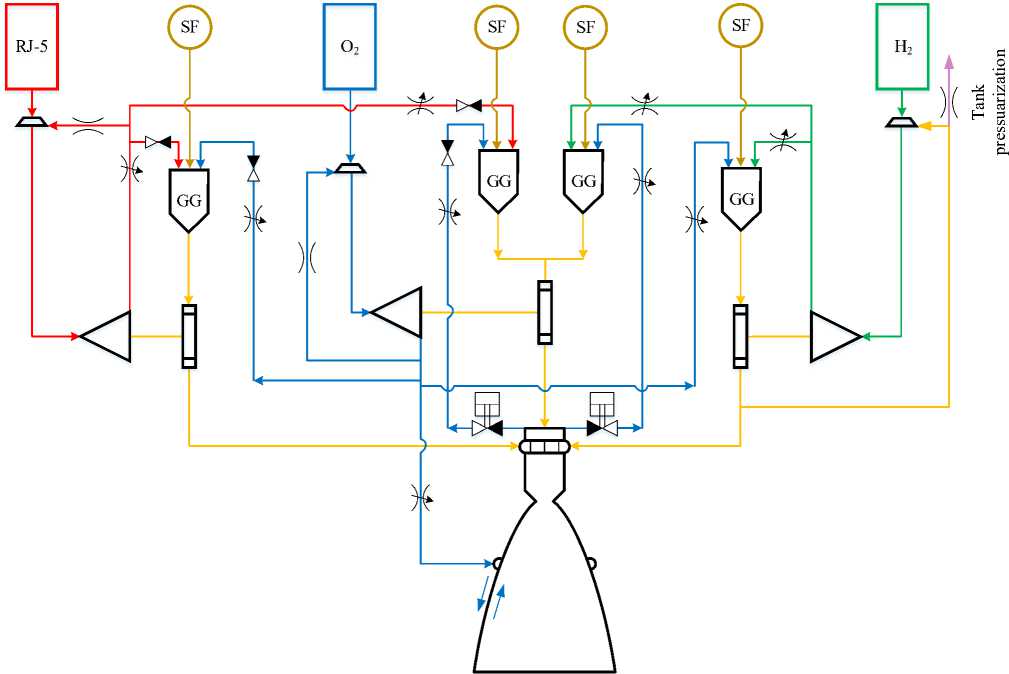

In [4], the PHS of the domestic two-mode three-component LPRE – RD-701, developed by NPO “Energomash” as part of a project to develop a multipurpose aerospace system (MAKS) is presented. The engine thrust in the first mode is 4000 kN, in the second mode – 1590 kN (Fig. 2). Liquid hydrogen (throughout the entire active phase of the flight) and RG-1 kerosene (in the first mode of engine operation) are used as fuels. The main feature of this engine is the presence of two separate TPU circuits, which allows the use of autonomous development of individual elements.

Fig. 2. Pneumohydraulic scheme of a two-mode LPRE – RD - 701, running on three-component fuel

Рис. 2. Пневмогидравлическая схема двухрежимного ЖРД - РД – 701, работающего на трёхкомпонентном топливе

The fuel components are fed into the chamber and the gas generator by means of three BPU and two main TPU. The oxidant is fed directly to the GG. Kerosene is fed directly to the mixing unit (MU). Liquid hydrogen, taken after the first stage of the hydrogen pump, cools the engine chamber and is supplied to the MU. The remaining liquid hydrogen (the second stage of the pump is not shown in the diagram) is taken after the second stage of the hydrogen pump and supplied to the GG. Turbines of two TPUs run on oxidizing generator gas.

Disadvantages of this PS concept:

– the presence of a three-component injector head;

– the need for a kerosene pump to operate to drive the BPU hydrogen turbine throughout the entire active phase of the flight.

There are other concepts of three-component engines, the most interesting are the concepts [5–7].

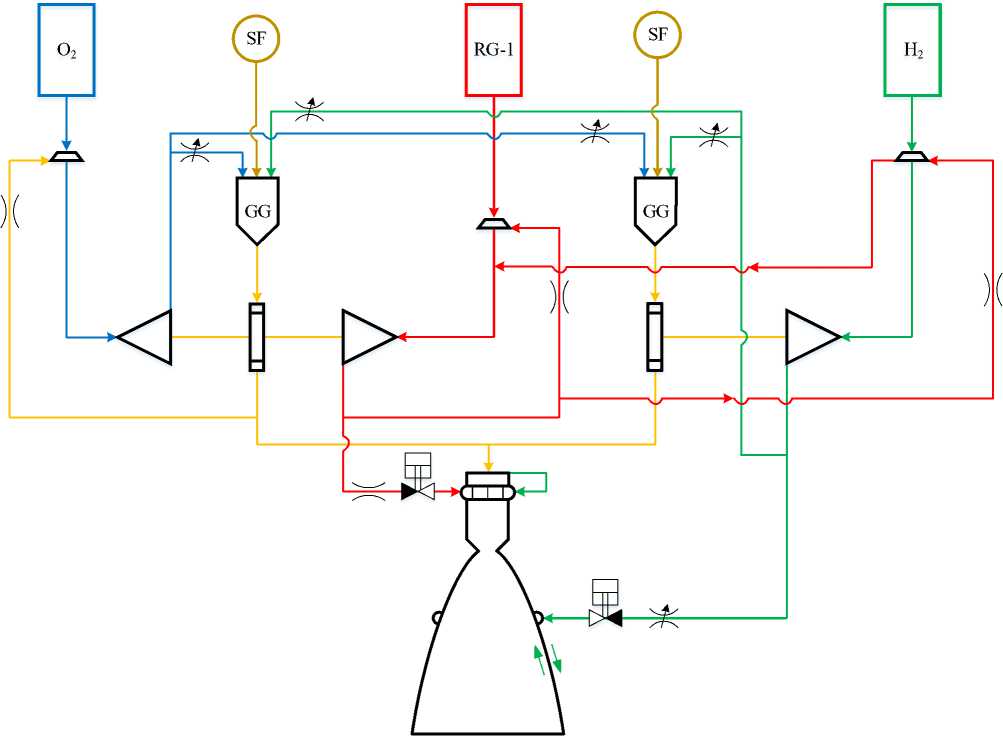

The proposed scheme for the implementation of a three-component LPRE. The engine is a two-mode LPRE operating on a three-component fuel, having 3 BPU located on each component supply line (hydrogen, oxygen and kerosene), 2 three-component GG (oxidizing gas generator (OGG) and a reducing gas generator (RGG)) with pre-ignition of the working fluid from the starting fuel (SF), 2 TPU, a chamber representing a Laval nozzle, consisting of a cylindrical, subsonic and supersonic parts, an intensive multicircuit regenerative - flow cooling system (CS).

Based on the analysis of the existing circuit solutions of three-component LPREs, taking into account their advantages and disadvantages, an PHS is proposed for a two-mode LPRE operating on three-component fuel (Fig. 3): in the first mode, the engine operates on the components - liquid oxygen + kerosene + liquid hydrogen (the proportion of hydrogen in fuel mixture - 4% of the total mass of fuel consumption), in the second mode - on the components - liquid oxygen + liquid hydrogen.

A characteristic feature of the proposed PHS is complete gasification of the components. This solution has a number of following advantages: it allows to obtain high pressures in the СС in two modes of operation; due to the passage of a larger mass through the turbines, the thermal load on the TPU drive is reduced; the rate of passage of chemical reactions in the combustion chamber increases, which in some cases increases the specific impulse of the LPRE. Also, in order to maintain a constant pressure drop across the turbine of oxygen-kerosene TPU, in the second operating mode of the engine, part of the generator gas is discharged in front of the turbine directly into the gas tube.

O 2

RG-1

H 2

Fig. 3. The proposed PHS for LPRE operating on three-component fuel

Рис. 3. Предлагаемая ПГС для ЖРД, работающего на трёхкомпонентном топливе

The fuel components are supplied to the CC and the GG by means of three BPU and two main TPU, one of which supplies liquid hydrogen, the other - liquid oxygen and kerosene. The turbine oxygen - kerosene TPU is fed by oxidizing generator gas produced in the oxidizing gas generator. The turbine of the hydrogen TPU operates on a reducing generator gas produced in a reducing gas generator. The total consumption of liquid oxygen and kerosene is fed directly to the gas generator. In turn, the full flow rate of liquid hydrogen is supplied to the engine regenerative cooling lining, after which it is transferred to the drive of the BPU hydrogen turbine, and then to the GG.

The disadvantage of the proposed LPRE scheme on three-component fuel is the need to develop a three-component GG.

A more detailed design of a three-component OGG and RGG and their cooling systems will be carried out at further stages of the engine development. It is planned that both single-zone, two-zone and multi-zone GG designs with and without the use of a ballasting component will be considered, such GGs are used both in the domestic engine building and in the petrochemical industry. The working process in the GG is more complicated and complex than in the combustion chamber of a liquid-propellant engine.

Extremely important in the development of GG of any concepts and standard sizes is:

– the associated task of cooling;

– heat and mass transfer processes of growth and evaporation of droplets in a gaseous medium;

-

– taking into account thermodynamic nonequilibrium for complex chemical compounds of fuel component (FC) reaction;

-

– design of a highly efficient mixture formation system using a gas component or spreading of fine droplets with ignition from an ignition system;

-

– taking into account the delay rate and relaxation times of individual reagents during chemical reactions of FC combustion;

-

– obtaining a stable working process at the outflow after the MU with a high completeness of the combustion of FC;

-

– the intensity of the flow of the working process with the FC presence times of short and average duration in the entire volume of the GG;

-

– relative consumption of GG;

-

– the task of ballasting with the involvement of an additional excess or main component of the fuel;

-

– regulation and maintenance of a stable PC ratio for a multi-mode engine;

-

– obtaining a reduced temperature of the generator gas to drive the turbine for the purpose of thermal protection of the nozzle guide vanes and turbine blades;

-

– obtaining the expected operability of the generator gas to provide the built-in in the processes of the design and coordination turbine power;

-

– the issue of reliability with reusable GG;

-

– increasing efficiency by complicating the design of the GG and the use of active heat and mass transfer physical methods of flow control (flow recirculation, additional turbulence, local and heterogeneous systems of vortices that improve efficiency, forced deceleration of the gas-dynamic flow by obstacles of various profiles in order to increase the residence time and the rate of achievement of a chemical reaction, injection or insertion of long-range jets into a gas wake (wall, boundary layer, or main stream) ) or forced mixing of the mixture with the installation of wall-mounted intensifiers, turbulators and developed surfaces.

Formation of a mathematical model using thermodynamic equilibrium and frozen approximations and models describing all of the above features is extremely important for modeling work processes in GG.

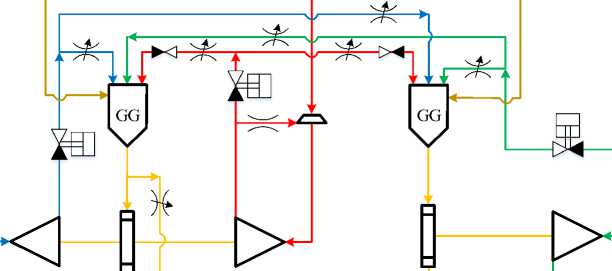

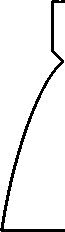

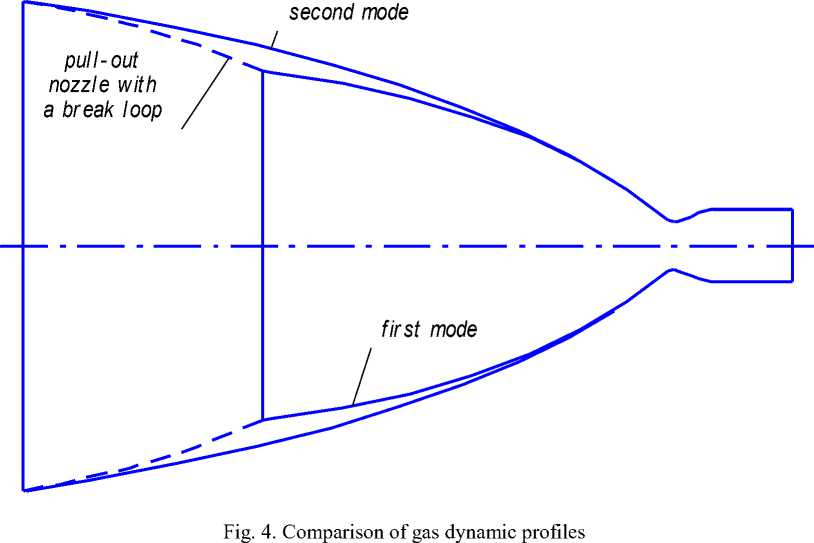

Design features of three-component LPREs. When carrying out thermogasdynamic calculation of the combustor and nozzle for two modes of engine operation, a significant difference in gas-dynamic profiles was obtained (Fig. 4). The profiling of the nozzle only along the gas-dynamic profile of the first operating mode leads to a significant increase in losses and a decrease in the specific impulse in the second operating mode of the engine. In turn, the profiling of the nozzle along the gas-dynamic profile of the second operating mode leads to an increase in the total mass of the propulsion system.

To minimize losses due to maintaining two modes of operation of the propulsion system, it is proposed to profile the nozzle along the gas-dynamic profile for the first mode of operation, and in the second mode of operation to use an uncooled retractable nozzle attachment with a break in the contour [8] or a similar profiled nozzle attachment repeating the geometry of the supersonic part of the profile. This solution will allow obtaining the maximum efficiency of the starting mode, high values of specific impulse at high-altitude operation, and will also lead to a decrease in the dimensions of the product and a decrease in the mass of the engine chamber due to the use of a carbon-carbon composite [9] (CCC) retractable nozzle attachment.

Рис. 4. Сравнение газодинамических профилей

Analysis of the effect of different admixtures of hydrogen and kerosene on a chemical compound of the form: liquid oxygen + m 1 ·kerosene + m 2 ·liquid hydrogen, energy parameters of the fuel mixture and engine efficiency. An urgent direction in the study of jet propulsion is the study of the parameters of known propellant pairs of rocket fuel with various small additions of another component to the fuel or oxidizer. Moreover, chemical kinetics [10; 11] of rocket fuel, which occurs during the combustion reaction in the LPRE chamber with the use of such mixed additives, can significantly increase the efficiency of the engine by changing the thermodynamic parameters of combustion products. Taking into account all of the above and using modern methods of mathematical modeling or modern applied programs, the calculation of dissociated chemical equilibrium reactions of the form m 1 * G + m 2 * G, where m 1 and m 2 are mass or mole fractions of substances, is an easy task. It is undeniable that this statement is valid only for dissociated equilibrium chemical reactions, with non-dissociated nonequilibrium chemical reactions [12], the situation is more complicated.

To assess the optimal design parameters, an analytical study was carried out. The aim of the study is to understand the qualitative picture of the influence of distributed fuel parameters on the thermodynamic parameters of the fuel mixture and engine efficiency. As a result of technical study, the optimal design parameters for a three-component fuel mixture were selected.

In all calculations, it is assumed that the engine thrust, pressure in the combustion chamber, the relative area of the combustion chamber and nozzle, temperature and pressure at the inlet to the combustion chamber of liquid oxygen, liquid hydrogen and kerosene are fixed parameters that do not change during the analysis.

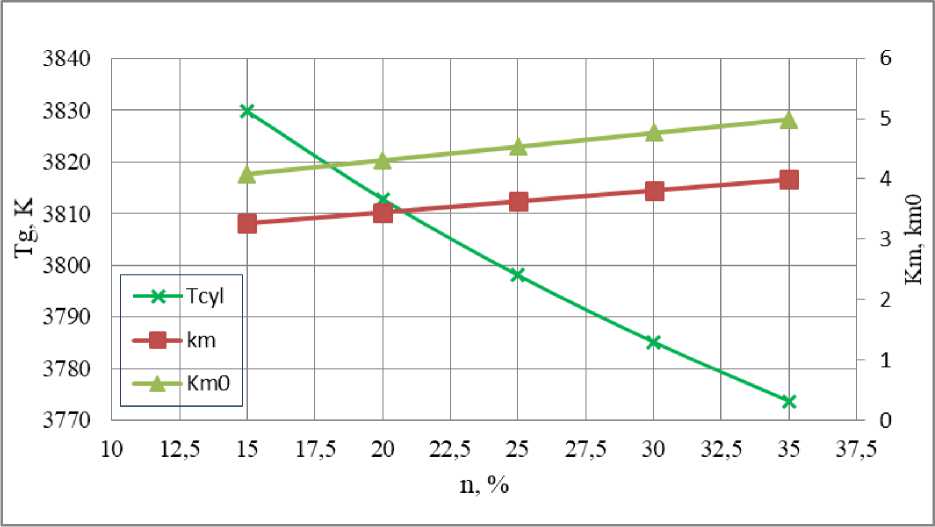

Table 1 and fig. 5 show the changes in the ratio of FCs, stoichiometric ratio of FCs and the chemical formula of the gross reaction of fuel combustion with a different admixture of liquid hydrogen to RG1 kerosene. The temperature T cyl is given in table 1 corresponds to the design section in the cylindrical part of the chamber near the mixing unit.

Table 1

Influence of the chemical compound m 1 · RG1 + m 2 · H 2 on the chemical reaction of fuel combustion, the ratio of FC, stoichiometric ratio of FC

|

m 1 , % |

m 2 , % |

T cyl , K |

K m |

K m0 |

Chemical formula for the gross reaction of fuel combustion |

|

85 |

15 |

3829.786 |

3.267 |

4.083 |

O 0.860 H 1.125 C 0.256 |

|

80 |

20 |

3812.777 |

3.448 |

4.31 |

O 0.816 H 1.172 C 0.217 |

|

75 |

25 |

3798.047 |

3.629 |

4.537 |

O 0.779 H 1.210 C 0.184 |

|

70 |

30 |

3785.133 |

3.811 |

4.763 |

O 0.749 H 1.242 C 0.158 |

|

65 |

35 |

3773.702 |

3.992 |

4.99 |

O 0.723 H 1.269 C 0.135 |

Fig. 5. Changes in the temperature in the cross section of the mixing unit, the ratio of FCs and the stoichiometric ratio of FCs at different percentages of liquid hydrogen admixture in kerosene RG1

Рис. 5. Изменение температуры в сечении смесительной головки, соотношения КТ и стехиометрического соотношения КТ при разном проценте примеси жидкого водорода в керосине РГ1

Based on the presented dependences, it can be concluded that with a larger admixture of liquid hydrogen in kerosene, the ratio of FCs and stoichiometric ratio of FCs increases, and the temperature in the CC decreases.

Analysis of the chemical formula of the gross – reaction of fuel combustion shows that with a different admixture of liquid hydrogen to liquid kerosene, the number of atoms in the oxygen molecule decreases from 0.86 to 0.723, hydrogen increases from 1.125 to 1.269, carbon decreases from 0.256 to 0.135. Accordingly, it can be concluded that it is 85% of kerosene and 15% of hydrogen in fuel that are most interesting from the point of view of chemical kinetics and energy of rocket fuel, because the number of reacting atoms in the chemical reaction of the composite fuel prevails over the rest of the considered mixture combinations. Consequently, from the point of view of chemical kinetics and energy of rocket fuel, the option with 85% kerosene and 15% hydrogen in fuel is of greatest interest.

Due to the fact that in the future the CS of an engine operating on three-component fuel will be considered, a detailed analysis of the thermophysical, thermodynamic and gas-dynamic parameters affecting fuel heating, convective mass transfer, thermal protection and cooling of the engine was carried out, brief conclusions of which are given below.

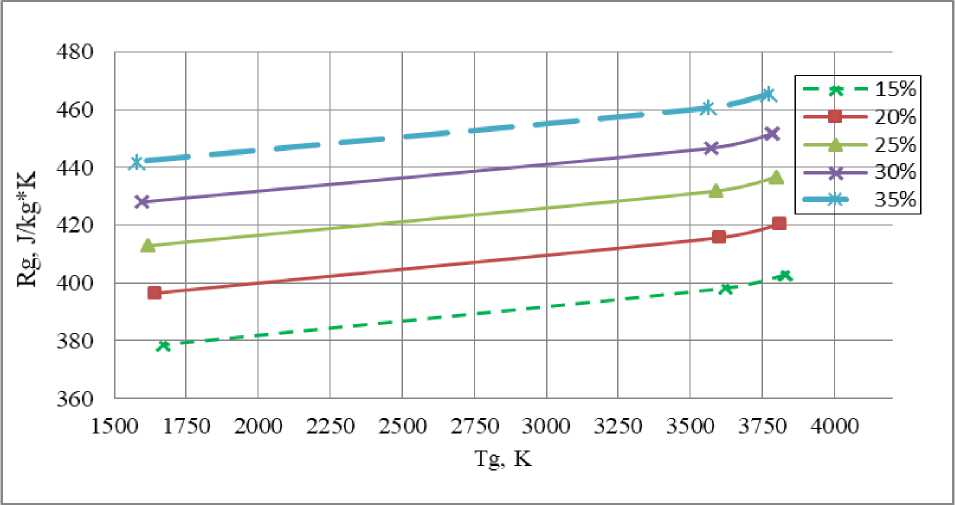

Fig. 6 shows a graphical dependence of the gas constant on the temperature of the combustion product (CP) with a different admixture of liquid hydrogen in kerosene.

Fig. 6. Dependence of the gas constant on the CP temperature for different percentages of liquid hydrogen admixture in kerosene

Рис. 6. Зависимость газовой постоянной от температуры ПС при разном проценте примеси жидкого водорода в керосине

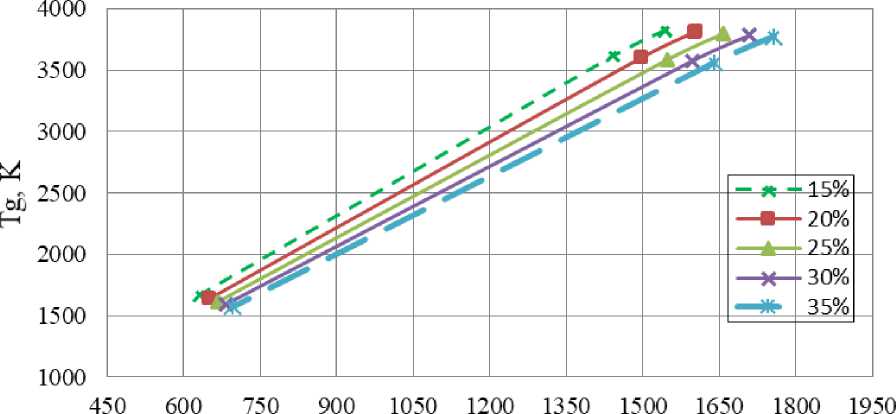

Fig. 7 shows the dependence of the temperature of the CP on the performance of the gas with a different admixture of liquid hydrogen in kerosene.

Lg, kJ/kg

Fig. 7. Dependence of gas efficiency on the CP temperature at different percentages of liquid hydrogen admixture in kerosene

Рис. 7. Зависимость работоспособности газа от температуры ПС при разном проценте примеси жидкого водорода в керосине

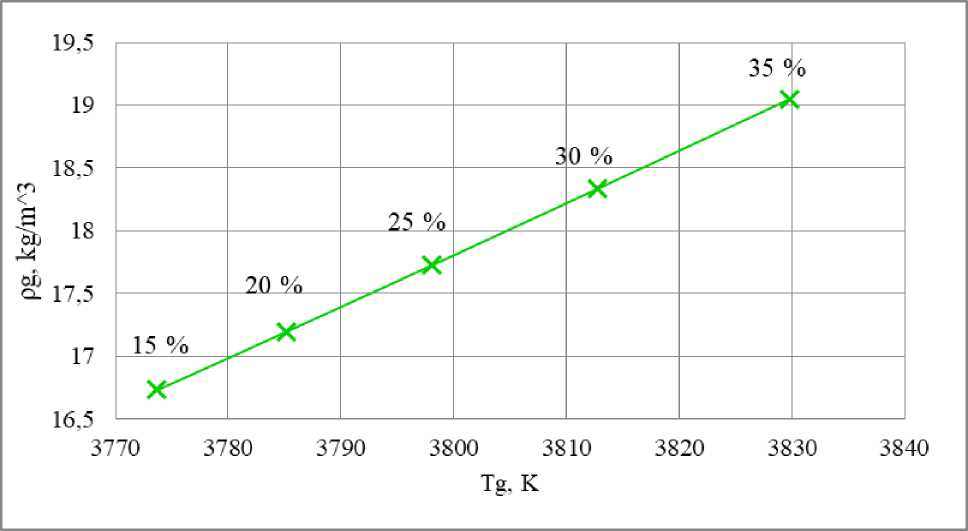

Fig. 8 shows the dependence of the gas density on the temperature of the CP with different admixtures of liquid hydrogen in kerosene.

Fig. 8. Dependence of the gas density on the CP temperature at different percentages of liquid hydrogen admixture in kerosene

Рис. 8. Зависимость плотности газа от температуры ПС при разном проценте примеси жидкого водорода в керосине

A detailed analysis of the results obtained showed that the gas constant, although it increases with a larger admixture of liquid hydrogen in kerosene, the largest complex Lf, which characterizes the performance of the gas, corresponds to 15% of the admixture of liquid hydrogen in kerosene.

It is this option that is most interesting both from the point of view of the chemical kinetics of the rocket fuel, the energy parameters of the CPs, and from the point of view of the growth of the complex, which characterizes the operability of the gas.

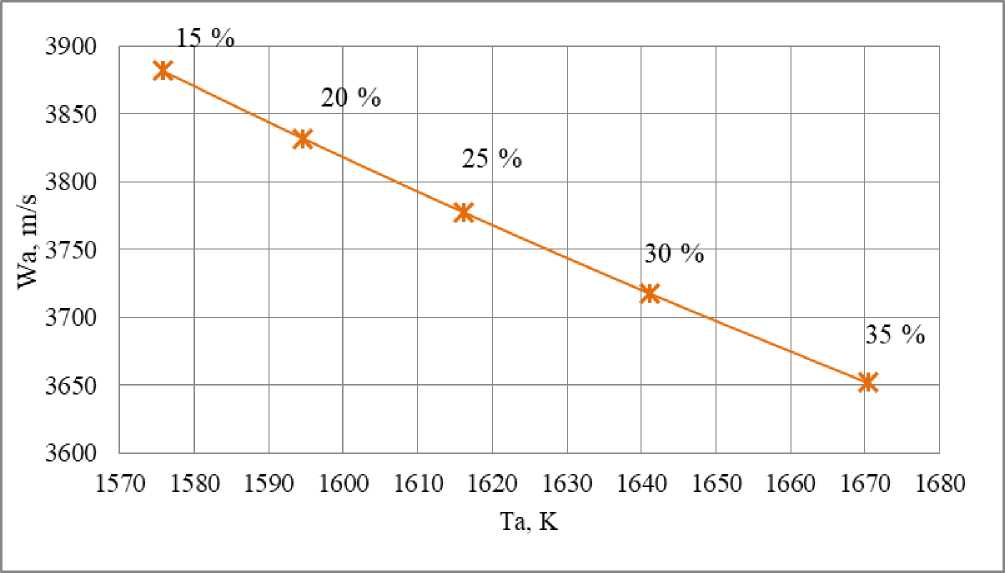

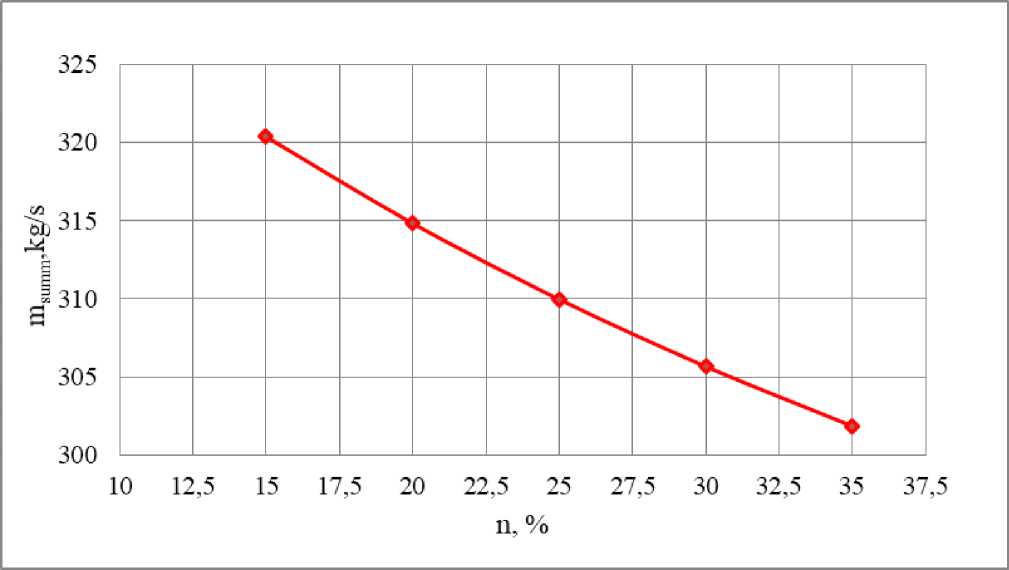

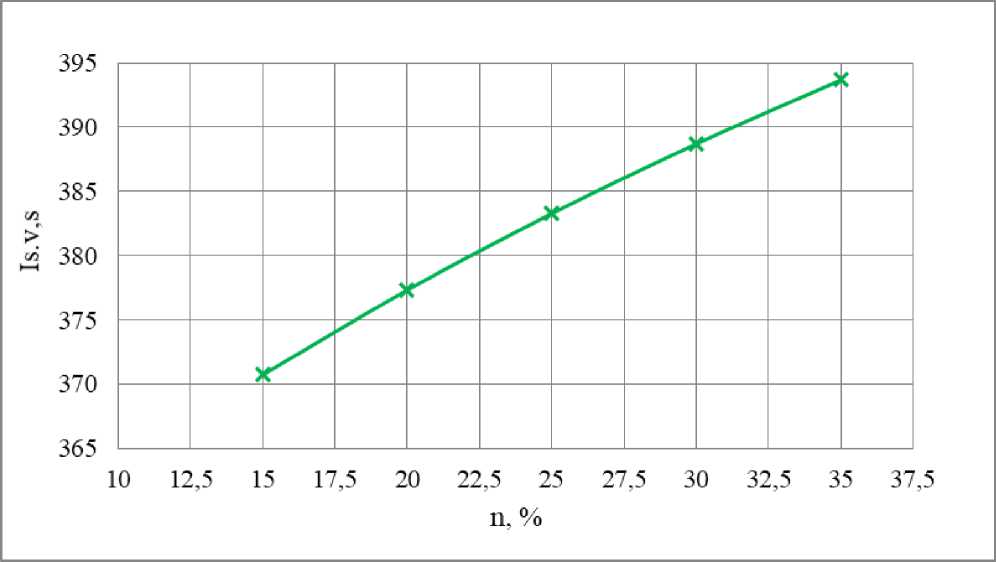

Analysis of the influence of the parameters of the fuel mixture on the efficiency of the engine. Fig. 9–11 show the dependences characterizing the efficiency [13] of the engine. These dependencies can be used as a "tool" for small complex assessments of the efficiency of such mixed fuels at the previously considered circuit solutions, thrust and pressures in the combustion chamber. Dependences for other ranges of distributed parameters of the technical system (pressure in the chamber, draughts, heating in cooling system, etc.) give quantitatively different results, but are approximately and qualitatively similar.

A similar efficiency assessment was carried out in [14] for the mass fraction of liquid hydrogen that occupies the entire fuel mixture.

It is assumed that the hydrogen impurity does not occupy the entire fuel mixture, but only a part of the fuel compound. In terms of percentages for the entire fuel mixture, 15 % of the liquid hydrogen in the fuel mixture corresponds to 4 %, and 35 % corresponds to 7 % of the liquid hydrogen in the fuel mixture.

Fig. 9. Dependence of the flow rate from the Laval nozzle on the temperature of the CPs on the nozzle section at different percentages of liquid hydrogen admixture in kerosene

Рис. 9. Зависимость скорости истечения из сопла Лаваля от температуры ПС на срезе сопла при разном проценте примеси жидкого водорода в керосине

Fig. 10. Dependence of the total fuel consumption in an LPRE operating on three-component fuel with different percentages of liquid hydrogen admixture in kerosene

Рис.10. Зависимость суммарного расхода топлива в ЖРД, работающего на трёхкомпонентном топливе, при разном проценте примеси жидкого водорода в керосине

Fig. 11. Dependence of the specific impulse in the void of an LPRE operating on three-component fuel at different percentages of liquid hydrogen admixture in kerosene

Рис. 11. Зависимость удельного импульса в пустоте ЖРД, работающего на трёхкомпонентном топливе, при разном проценте примеси жидкого водорода в керосине

Therefore, although the specific impulse in the void increases with a larger admixture of liquid hydrogen, the mass fuel consumption and the exhaust velocity decrease. Also significant is the fact that with a greater admixture of liquid hydrogen, the mass of fuel in the tanks increases.

Energy characteristics of the proposed PHS. Energy coordination of the parameters of a LPRE operating on three-component fuel was carried out according to the methodology [15]. Thermodynamic calculations of oxidizing and reducing gas generators were carried out based on the recommendations [16].

Table 2 shows the results of calculations of the energy correlation of the parameters of the proposed PHS of a two-mode LPRE operating on three-component fuel.

Table 2

The results of calculations of the energy coupling of the parameters of LPRE operating on three-component fuel

|

Parameter |

I mode |

II mode |

|

|

Engine thrust in vacuum, kN |

1060 |

420 |

|

|

Combustion chamber pressure, MPa |

29.4 |

14.8 |

|

|

Specific impulse in the void, s |

386 |

473 |

|

|

Temperature in the combustion chamber, K |

3858 |

3617 |

|

|

The ratio of the components in the combustion chamber |

3.45 |

6.349 |

|

|

Pump heads, J/kg |

RG-1 |

67507 |

- |

|

H 2 |

821659 |

386400 |

|

|

О 2 |

48411 |

23850 |

|

|

Turbine pressure ratio |

TPU RG-1+О2 |

1.762 |

1.762 |

|

TPU H2 |

1.31 |

1.236 |

|

|

TPU speed, rpm |

TPU RG-1+О2 |

35224 |

35723 |

|

TPU H2 |

150400 |

71065 |

|

|

Gas temperature in the gas generator, К |

GG oxidising |

893 |

898 |

|

GG reducing |

1100 |

802 |

|

|

The ratio of the components in the gas generator |

GG oxidising |

52 |

96 |

|

GG reducing |

0.16 |

0.89 |

|

Calculation of the mass characteristics of a propulsion system running on three-component fuel. Evaluation of the perfection of the LPRE design is carried out by calculating the mass characteristics, which are widely used when choosing the optimal parameters of aircraft, propulsion systems and individual units. To determine the mass characteristics of an engine running on three-component fuel, a mathematical model was created, which is based on the dependences taken from [17]. Tab. 3 contains the results of calculating the mass characteristics of a LPRE operating on three-component fuel.

Table 3

Results of calculating the mass characteristics of a LPRE operating on three-component fuel

|

Unit name |

Mass, kg |

|

Mixing unit |

4 |

|

Blast tube |

26 |

|

Combustion chamber and nozzle with a nozzle attachment and extension mechanism |

644 |

|

TPU RG-1+О2 |

252 |

|

Unit name |

Mass, kg |

|

TPU H2 |

118 |

|

BPU RG-1 |

11 |

|

BPU H2 |

14 |

|

BPU О2 |

27 |

|

Other engine units (valves and control units, gas generators, pipelines, frame, parts of the general assembly) |

347 |

|

Total dry weight of a three-component engine |

1443 |

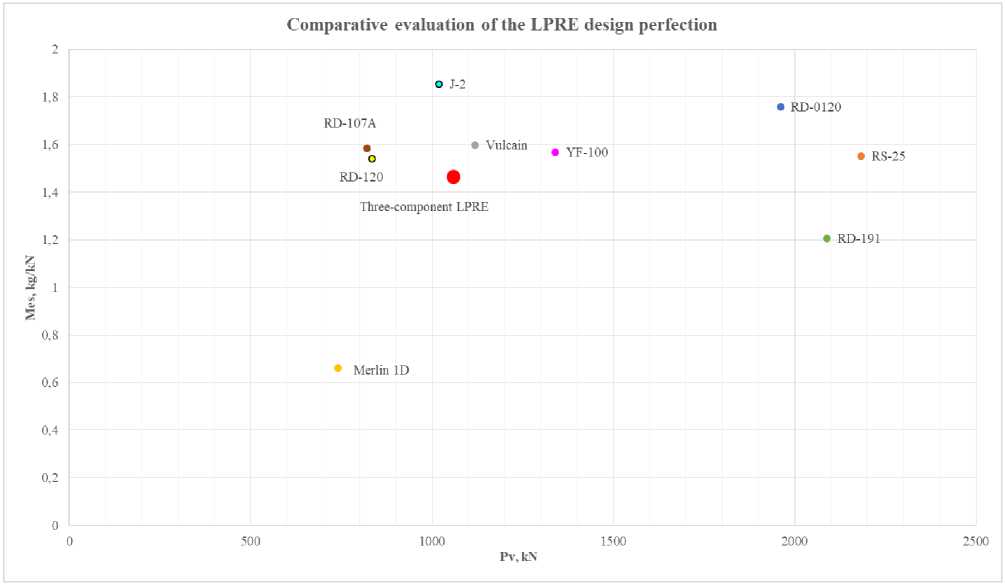

To confirm the efficiency of using a LPRE on three-component fuel, a comparative assessment of the design perfection of the propulsion system was carried out.

The specific gravity was compared – the ratio of the mass of the filled LPRE to its void thrust in the main mode, of various engines with the proposed three-component LPRE. The comparative evaluation involved liquid propellant rocket engines close in thrust to the considered prototype of a LPRE operating on three-component fuel. The results are shown in Fig. 12.

Fig. 12. Comparative evaluation of LPRE design perfection

Рис. 12. Сравнительная оценка совершенства конструкции ЖРД

As can be seen from the graph, LPREs operating on three-component fuel are superior in their specific mass to LPREs based on “liquid oxygen + liquid hydrogen” components and are slightly inferior to some LPREs based on “liquid oxygen + kerosene” components.

Conclusion. Various schemes and design options for LPREs operating on three-component fuel are considered, their advantages and disadvantages are revealed. A PHS is proposed for a LPRE operating on three-component fuel, with full gasification of the components (the “gas-gas” scheme). Calculations are performed: thermogasdynamic, combustion chambers and gas generator, nozzle geometry with a break in the contour, energy coupling of parameters, mass characteristics of the investigated LPRE.

Based on the results of the calculations, it can be concluded that propulsion systems operating on three-component fuel, in terms of their energy and mass efficiency, are not inferior to propulsion systems running on two-component fuel. Taking into account the unification of the engine for the first and second stages of the LV, the use of three-component LPREs is more economically feasible. However, the development and testing of a three-component LPRE and a specialized LV require a large amount of work [18], which requires large financial investments. Nethertheless, research in the field of LPREs operating on three-component fuel, and the creation of a LV in the future can significantly reduce the cost of launching the payload.

Список литературы Development of the concept of a reusable liquid rocket engine with three-component fuel

- Salked R., Beichel R. Reusable one-stage-to orbit shuttles: bright energy propects. Astronaut. Aeronaut. 11, 1973. P. 6–48.

- Belyaev E. N., Vorob’yev А. G. [Influence of filling processes of gas generator mixing heads on the dynamics of a non-starter launch of a liquid rocket engine]. Siberian Journal of Science and Tech-nology. 2018, Vol. 19, No. 3, P. 469–481. Doi: 10.31772/2587-6066-2018-19-3-469-481. (In Russ.)

- Belyakov V.A., Vasilevskiy D. O. [Perspective circuit solutions of liquid rocket engine by expanded cycle]. Vestnik PNIPU. Aerospace science. 2019, Vol. 58, P. 69–86. Doi: 10.15593/2224-9982/2019-58-06. (In Russ.)

- Gusev V. N., Semenov V. I., Storozhenko I. G. [Three-Component two-mode main engine for aerospace systems and new-generation launch vehicles]. Alternative energy and technology. 2008, No. 3 (59), P. 36–41. (In Russ.)

- Goncharov G. I., Goncharov N. With., Replevy I. V. et al. Experimental’nyj Zhidkostnoj raketnij dvigatel’ s dozhiganiem [Experimental liquid-propellant rocket engine with afterburning]. Pat RF. No. 2065068, 1994.

- Goncharov G. I., Replevy I. V., Orlov V. A. et al. Trekh komponentnyj Zhidkostnoj raketnij dvigatel’ [Three-component liquid propellant rocket engine]. Pat RF. No. 2065985, 1994.

- Gorokhov V. D., Milovanov A. G. Trekh komponentnyj Zhidkostnoj raketnij dvigatel’ [Three-component liquid propellant rocket engine]. Pat RF. No. 2575238, 2014.

- Semenov V. V., Ivanov I. E., Sorokin V. A. et al. Vysotnoe Soplo Lavalya [High-altitude Laval nozzle]. Pat RF. No. 125262, 2013.

- Abashev V. M., Demidov A. S., Eremkin I. V. et al. [Temperature stresses in cylindrical shells made of carbon fibers and the contact problem of heat exchange]. Vestnik MAI. 2017, Vol. 24, No. 4, P. 7–13. (In Russ.)

- Girshfelder D., Curtis Ch., Byrd R. Molekularnaya teoria gazov i zhidkostej [Molecular theory of gases and liquids]. Moscow, Foreign literature publ., 1961, 931 p.

- Bretschneider S. Svojstva gazov i zhidkostej [Properties of gases and liquids]. Moscow, Chemistry publ., 1936, 536 p.

- Gidaspov V. Yu. [Numerical simulation of a chemically nonequilibrium flow in a liquid rocket engine nozzle]. Vestnik MAI. 2013, Vol. 20, No. 2, P. 90–95. (In Russ.)

- Piunov V. Yu., Nazarov V. P., Kolomentsev A. I. [Improving the energy characteristics of oxygen-hydrogen liquid-propellant rocket engines of upper stages of methods for optimizing design schemes]. Vestnik MAI. 2017, Vol. 24, No. 3, P. 23–33. (In Russ.)

- Orlin S. A., Orlov A.V. [Increasing the specific impulse of liquid rocket engines running on oxygen + kerosene fuel by adding hydrogen to the combustion chamber]. Engineering journal: science and innovation. 2019, No. 11, P. 23–33. Doi: http://dx.doi. org/10.18698/2308-6033-2019-11-1935. (In Russ.)

- Belyaev E. N., Vorob’yev A. G. Energeticheskaya uvyazka parametrov zhidkostnogo raketnogo dvigatelya [Energy coupling of parameters of a liquid rocket engine]. Moscow, MAI publ., 2016, 68 p.

- Belyaev E. N., Vorob’yev A. G., Nascimento L. B. et al. [Problematic issues of energy coupling of parameters of liquid rocket engines]. Trudy' MAI. 2013, Vol. 71 Available at: https://mai.ru/ upload/iblock/382/382669ab36066d251d57dd531a45cd9f.pdf (accessed: 06.03.2020). (In Russ.)

- Kozlov A. A., Novikov V. N., Soloviev E. V. Sistema pitaniya I upravleniya zhidkostych raketnyh dvigatelnyh ustanovok [Power supply and control systems for liquid rocket propulsion systems]. Moscow, Mashinostroenie publ., 1988, 347 p.

- Nesterov V. E., Rudakov V. B., Makarov V. I. [Analysis of the main tasks of experimental testing of a reusable rocket and space system]. Vestnik MAI. 2013, Vol. 20, No. 5, P. 77–85. (In Russ.).