Development of the device for determination of textile permeability to oil

Автор: Ganiyeva G.A., Ryskulova B.R., Amirzhanov B.S., Shambulov E.D.

Журнал: Вестник Алматинского технологического университета @vestnik-atu

Рубрика: Техника и технологии

Статья в выпуске: 3 (108), 2015 года.

Бесплатный доступ

This article presents the description of a new device developed by authors and its operating principle. The developed device refers to the light industry and may be used for determination of textile material permeability to oil in order to produce special clothes for the workers of oil field. Operating principle of the device for the assessment of material permeability to oil is based on the measurement ofsliding friction coefficient.

Special clothing, textile materials, oil permeability, device, sliding friction coefficient

Короткий адрес: https://sciup.org/140205058

IDR: 140205058 | УДК: 67.05

Текст научной статьи Development of the device for determination of textile permeability to oil

Currently special clothes used in oil field do not have the sufficient degree of protection and do not meet the requirements of workers. Main principles of special clothes material properties are not sufficiently studied.

The development of new generation special clothes for workers of oil field shall be based on the study of textile materials’ protective properties. It is known that one of the main features of material protective properties is its permeability to oil.

The authors developed a device to determine textile materials’ permeability to oil [1].

During the conduction of reference-patent search the devices were found developed for determination of fat permeability of materials [2,3,4]. It is noticeable that all known devices have very complex structure. Among them, the device closest in design is the device made to determine material permeability to fats [2], which contain the chamber of test medium delivery and measuring chamber. The device is also equipped with twoelectrodes of capacitance sensor, where the first electrode is located inside the measuring chamber, joined by its lateral surface to the walls, and drawn in to the wall of measurement chamber. It should be noted that at penetration of материалдары, мұнай өткізгіштік, құрылғы, some fats the weight shifts upwards along the vertical plane; that is why it is required to exclude any vibration of the plane at which the device is installed. Unfortunately, this is practically impossible even in a laboratory environment, which leads to the false operation of the device and significantly reduces the reliability of the results obtained. Moreover, the known device uses the springing elements (springs) that are hard to be calculated and reproduced.

Subjects and Methods of the Research

The subject of the research is the device developed by authors. The device consists of a tank with test medium (oil) at the surface of which the test sample is installed and fixed by fixing devices. Weight is connected to the counter-balanced weight by wire; counterbalanced weight is thrown over the roller. Ruler is used as for the determination of liquid level so as for the shift of counter-balanced weight.Theoretical and empirical methods of study were used in this article, combination of which made it possible to study the developed device with more reliability.

Results and their Discussion

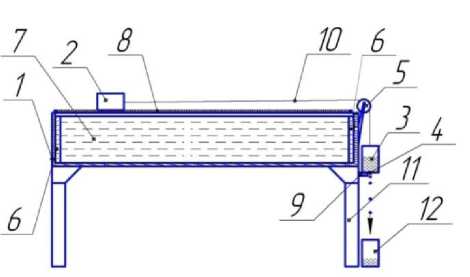

Construction used for determination of textile materials permeability to oil is given in Figure 1.

Device developed by authors operates as follows: the tank 1 is filled with test medium (oil) 7. The rate of delivery should be slow in order to exclude eddying motion. The required level of oil is determined according to the measuring ruler 6 and it shall not be in contact with test material 8.

7 – test medium;

8 – test material;

9 – stopper;

10 – wire;

11 – support;

12 - measuring vessel

-

1 – tank;

-

2 – weight;

-

3 – counter-balanced weight;

-

4 – drain valve;

-

5 – roller;

-

6 – measuring ruler;

Figure 1 – Construction of the Device for Determination of Textile Material Permeability to Oil.

Operating principle of the device for determination of textile material permeability to oil is based on the indirect indicator of friction factor measurement. The weight 2 is installed on the test material in its dry state and after its stretching; weight is connected to the wire 10 with counter-balanced weight 3 over the roller 4. The main feature of the counter-balanced weight is that it can change its mass during shifting, which is achieved by the following: counterbalanced weight 3 is a cylinder filled with liquid and equipped by drain valve 4. At rest drain valve is closed and mass of cylinder 3 with liquid equals to the mass of weight 2 located on the test material 8. In this case, weigh-counterweight system is in the state of static equilibrium.

With penetration of oil products into test material 8,static coefficient of friction is reduced that leads to the shift of weight 2, i.e.equilibrium state of weight-counterweight is broken. It is obvious thatcounter-balanced weight 3 starts moving down. Simultaneously with the beginning of this shift, drain valve of cylinder 4 opens and liquid starts flowing to the measuring vessel 12 reducing its mass. Cylinder mass is going to be reducing up to the moment when weight-counterweight system regains the equilibrium state (resting state) and the drain valve 4 closes.

The opening of drain valve is performed by special stopper 9 installed at the device casing.

The difference between the mass of weight and reduced mass of counter-balanced weight is the force of sliding friction, i.e.

F fr = Р г Р . , (1)

whereF fr is friction force (Newton);

Р п is the weight of counter-balanced weight at the stop time.

Knowing the force of sliding friction, it is possible to calculate friction factor of the system under consideration using Coulomb's law:

F fr = fxQ, (2)

where Q= Р r is the normal reaction of weight to the material surface equal to Q force;

F fr is friction force (Newton);

fis friction factor.

Hence f= Ffr = Р --^ (3)

Conclusion

The device developed for determination of textile material permeability to oil consists of chamber for test medium and system of fixing of test material above the chamber. In order to increase the precision of measurements the device is additionally equipped with weight and counter-balanced weight, measuring rulers for determination of liquid level and shifting of weight and counterweight.Operating principle of the device for determination of material permeability to oil is based on the indirect indicator, which is the measurement of sliding friction coefficient.

Список литературы Development of the device for determination of textile permeability to oil

- Opinion on the issue of innovational patient on invention №12916 from 05.22.2015 on the application of number in 2014/1284.1 from 07.10.2014 "The device for determination of textile materials permeability to oil". Authors: Ganiyeva G.A., Ryskulova B.R., Shambulov E.D.

- Certificate of the authorship №968708, application №3270258/18-25 from 06.04.0981“The device for determination of materials permeability to fat”. Authors: A.N. Sheglov, T.V. Ivanova, V.E. Gul, N.A Tarasova, published on statement № 39 from 23.1082

- Certificate of the authorship № 1122926 А, application №3607600/18-25 from 24.06.0984 “The device for determination of materials permeability to fat”. Authors: A.N. Sheglov, V.V. Lavrientjev, V.A. Muzmacher, N.N. Kubysheva, T.V. Ivanova, V.U.Usanov, V.B.Evseev, published on statement №41 from 07.11.84

- Certificate of the authorship № 1144030 А, application №3636457/24-25 from 30.08.1983 “The device for determination of polymeric materials permeability to fat”. Authors: A.N. Sheglov, V.A. Muzmacher, T.V. Ivanova, V.E. Gul and N.A. Tarasova, published on the statement №9 from 07.03.85.