Dry building mixes with a silica-based modifying additive

Автор: Urkhanova L.A., Lkhasaranov S.A., Bituev A.V., Badmaeva E.V.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Construction materials science

Статья в выпуске: 6 Vol.16, 2024 года.

Бесплатный доступ

Introduction. The use of dry building mixes has broad potential for use in construction due to their stability of properties, the ability to provide a specific set of quality characteristics to the material, and reduced production waste. When developing compositions of floor dry building mixes, it is necessary to ensure high mechanical properties, reduce shrinkage deformations, crack formation, and provide high adhesion to the concrete base. Expanding the range of dry building mixes, using local raw materials and modifying additives for various functional purposes for their production is an urgent task for the construction industry. Materials and methods. To ensure the rheological and technological properties of the dry building mixes, low water demand binders were produced based on Portland cement, volcanic slag, fly ash and dry superplasticizer on a polycarboxylate basis. To regulate the technological properties and increase mechanical properties of dry building mixes, a reinforcing additive in the form of basalt fiber and nanosilica was used. Results and discussion. The compositions of self-leveling dry building mixes were optimized according to the criteria for achieving the highest mechanical properties. The water-holding capacity of the mixes, compressive and flexural strength, water absorption, crack width, abrasion, and adhesion strength to the concrete base were determined. The microstructure of the mortar was studied using scanning electron microscopy. An assessment was made of the influence of modifying additives on changes in the properties of flooring dry building mixes. Conclusion. The resulting compositions of dry building mixes comply with the requirements of state standard for self-leveling flooring building mixes. With the use of a complex of mineral, plasticizing, micro-reinforcing, nano-sized additives, high performance indicators of flooring building mixes have been achieved.

Flooring dry building mixes, Portland cement, low water demand binder, fly ash, volcanic slag, nanosilica, superplasticizer, strength, shrinkage deformation, adhesion, material structure

Короткий адрес: https://sciup.org/142242744

IDR: 142242744 | DOI: 10.15828/2075-8545-2024-16-6-525-532

Текст научной статьи Dry building mixes with a silica-based modifying additive

Original article

Currently, in construction, the practice of using dry mixtures for various purposes is gaining great importance. A wide range of types of dry building mixtures allows them to be used at different stages of the construction of buildings and structures. Dry building mixtures are used when performing concrete, plastering, masonry, tiling, painting, decorative works, and when installing floor coverings [1]. An analysis of the market for dry building mixes (DBM) in Russia for 2019–2023 showed that among dry mixes for construction, mixes for floor coverings have great prospects: lightweight floor mixes, level- ers, self-leveling floor mixes. At the same time, the latter began to be used not only for flooring building mixes, but also for seamless finishing floor coverings for industrial, agricultural and public buildings [2].

Dry building floor mixes must meet stringent requirements for both technological and performance properties. Among the requirements for these mixes are increased resistance to impact loads, low abrasion, and good adhesion to the concrete base [1, 3]. In self-leveling floor mixes, in addition to improving adhesion to the substrate, wear resistance, cohesion and durability are also significantly improved [1, 4, 5]. According to the requirements of Russian national standard 31358-2019, the main in-

CONSTRUCTION MATERIAL SCIENCE dicators of the quality of hardened floor mortars are the flexural strength, the values of which, depending on the application of load, must be at least 2.5 MPa; compressive strength – respectively, not less than 10 MPa; shrinkage deformation – no more than 1.5 mm/m.

In the production of dry building mixes, various types of binders are used. The most widely used mineral binders are cement, gypsum, slaked lime, and it is possible to use mixed and composite binders. The choice of the type of binder is made depending on the purpose, hardening conditions, and the required operational properties of the DBM. Composite binders usually contain fine fillers based on silica- and carbonate-containing rocks. One of the methods for producing composite binders is the joint grinding of Portland cement and active mineral additives. Fine filler grains fill voids in the volume of mortar, which helps to increase the strength of contacts between cement and filler particles. The high dispersion and large specific surface area of such fillers lead to an improvement in rheological properties and an increase in the water-holding capacity of mortars [6]. The author of the work has developed compositions of binders with low water demand with an activity of 40–50 MPa based on a silica-containing component of metamorphogenic and intrusive-magmatic origin using polycarboxylate and melamine-formaldehyde plasticizer and dry self-leveling floor mixes [2].

Considering that when grinding composite binders, part of the internal energy of the substance is released, which is implemented in subsequent physical and chemical processes, then a targeted search for thermodynamically unstable initial components of natural and technogenic origin of binder compositions will not only reduce energy costs in their production, but also to improve the properties of composites based on them.

To reduce shrinkage deformations and increase the crack resistance of DBM, dispersed reinforcing components are used, the main function of which is to inhibit the development of microcracks. When improving mechanical properties, it is important to select the correct type of fibers, and the effectiveness of dispersed reinforcement depends on the compatibility of fibers with the mineral matrix, the percentage of reinforcement, the uniform distribution of fibers in the volume of the material and the operating conditions of the material [7].

To produce flooring dry building mixes, the use of basalt fiber is interesting. Basalt fiber is superior in strength to steel, and due to the small diameter of the fibers (9– 12 µm), it has a much larger specific adhesion surface to cement stone. Effective counteraction to the formation of microcracks in the material when using basalt fiber occurs due to the low relative elongation at break compared to steel fiber [8]. To ensure a given set of properties of DBM, chemical additives for various functional purposes are used. This mainly concerns the use of polymer addi- tives, the use of which improves the hydrophysical and mechanical properties of mixes [5–7], for example, selfleveling floor mixes. An alternative to the use of traditional polymer additives are domestically produced mineral additives, the use of which requires studying the properties of the cement-mineral matrix, as well as the structure of the cement stone.

In the last decade, knowledge has been developing about the influence of nano-sized additives in the form of nanosilica, fullerenes, and carbon nanotubes on the properties of concrete [9–13] and other materials. The authors of the works studied the effect of modifying the structure and properties of concrete using nanosilica obtained by evaporating the substance under the action of an electron beam created by an electron accelerator [14], called Tarkosil “Ts” [15, 16].

The purpose of this study is to identify patterns between the standardized quality indicators of hardened mortars for the construction of self-leveling floors from the recipe factors of the composition of mixes using composite binders, modifying additives, such as nanodispersed silica, mineral basalt fiber and surfactants.

MATERIALS AND METHODS

In the research, the following materials were used to obtain low-water-demand binders and dry building mixes for floor coverings: Portland cement (PC) CEM I 42.5 N «TimlyuyCement» LLC; fly ash (FA) from the Gusinooz-ersk thermal power plant, volcanic slag (VS) from the Kh-urai-Tsakir deposit in the Republic of Buryatia, nanosilica (NS) Tarkosil T50 obtained at an electron accelerator; superplasticizer (SP) Sika®ViscoCrete® 225 P in powder form based on polycarboxylate esters; quartz-feldspathic sand. PC and low water demand binders (LWB) were used as binders to produce DBM. LWB was obtained by joint grinding to a specific surface area of 400–450 m2/kg of Portland cement, fly ash or volcanic slag at different ratios of components and dry superplasticizer in a rod vibrating grinder.

Fly ash from the Gusinoozersk thermal power plant is a low-calcium ash, which consists mainly of aluminosilicate glass (66-81%). According to X-ray phase analysis, the main crystalline minerals in low-calcium fly ash are SiO2 in the form of quartz (d/n = 3.356; 1.821; 1.544; 1.376), alumina in the form of mullite (d/n = 1.682), iron oxide in the form of hematite (d/n = 2.702; 2.211; 1.699).

Volcanic slags of the Khurai-Tsakir deposit are loose and clastic rocks of a porous spongy structure made of volcanic glass of basic or intermediate composition with an admixture of other products of volcanic eruptions. In terms of composition, volcanic slag belongs to alkaline aluminosilicate formations. X-ray diffraction patterns of volcanic slag contain lines of quartz (d/n = 3.356),

CONSTRUCTION MATERIAL SCIENCE

Table 1

Fractional composition of sand, providing maximum density of the mortars

Determination of the degree of pozzolanic activity of fly ash and volcanic slag was determined by the amount of absorbed CaO from a saturated solution of calcium hydroxide according to national standard. The rate of absorbed CaO from fly ash, according to the study results, was 35.3 mg/g, which corresponds to active mineral additives with average pozzolanic properties, while volcanic slag was classified as an additive with low pozzolanic properties with an indicator of 15.6 mg/g.

The use of optimal sand granulometry makes it possible to obtain denser mortar mixtures with a reduced consumption of mineral binder (Table 1). In terms of the content of dust, clay and organic impurities, sand meets the requirements of national standard and can be used to produce dry building mixes.

NS Tarkosil was used in the studies as an additive modifying the structure of cement stone. Tarkosil T50 nanosilica was obtained using a facility developed at the Institute of Theoretical and Applied Mechanics of the SB RAS and the Institute of Nuclear Physics of the SB RAS (Novosibirsk). In terms of chemical composition, Tarkosil T50 consists of 99% amorphous silica, conditionally hydrophobic, the concentration of OH group is 0.4-0.5 OH group per square nanometer of surface. The average particle size of NS, according to the Sorbi-M device, is 53 nm.

Basalt fiber (BF), obtained using an electromagnetic technological reactor from basalt rocks of the deposits of the Republic of Buryatia, was used as a reinforcing additive. Basalt fibers have an average fiber diameter of 10 µm, tensile strength – 1350 MPa, temperature resistance – 600 ◦C.

Testing of binding materials and self-leveling floor mixtures was carried out in accordance with the methods of Russian national standards.

RESULTS AND DISCUSSION

The research results showed that the initial activity of pozzolanic additives, their quantity and degree of dispersion, introduction, and amount of nanosilica determine the mechanical properties of LWB. Using volcanic slag at its optimal content (20–30 wt %), the strength of the compositions reaches 55–59 MPa after 28 days of hardening, while the strength of LWB using fly ash as an additive at the same content is 58–62 MPa, which is 5–7% higher than the strength of binders with volcanic slag. With the introduction of NS at a dosage of 0.05% by weight of the binder, the compressive strength of the cement stone at the age of 7 days increased by 35%, and at the age of 28 days – by 25% compared with control samples. The use of polycarboxylate esters in an optimal amount of 0.5% by weight of the binder reduces water consumption by 25%, thereby compensating for the loss of strength of the cement stone associated with a decrease in the amount of cement in the LWB composition. In addition to reducing cement consumption, active finely dispersed additives help bind free portlandite, which ensures the preservation and improvement of the strength of binders. The high mobility and cohesion of binders with low water demand makes them most suitable for use as components of self-leveling flooring dry building mixes [17, 18]. To improve the properties of composite binders and, accordingly, a mortars based on them, it is necessary not only to compact them through the use of finely ground mineral additives and the plasticizing effect of polycarboxylate additives, but also to additionally compact the structure due to the formation of new hydrate phases that have a certain structure, strength and durability. The NS Tarkosil, having increased reactivity compared to volcanic slag and fly ash, reacts with lime, binding it to form additional amounts of calcium hydrosilicates, compacting and strengthening the structure of binders and mortar.

Taking into account the wide range of influencing factors on floor coverings, it was necessary to develop compositions of flooring dry building mixes characterized by high compressive and flexural strength, low shrinkage, abrasion, increased crack resistance and high adhesion to the base. To study the properties of hardened floor mortars, the compositions were selected to ensure a self-leveling effect with a ring flow mobility of at least 230 mm. The ratio between sand and binder in all studied compositions was 3:1.

To ensure a high rate of strength gain and achieve the design strength indicators of flooring dry building mixes, it is necessary to reduce the water-cement ratio as much as possible while maintaining mobility indicators. The introduction of mineral micro-, nano-sized and reinforcing additives led to a change in the water-cement ratio of mortar mixes (Table 2).

The simultaneous introduction of a micro-sized additive (fly ash, volcanic slag), nanosilica and a superplasticizer helps reduce the water-cement ratio of mortar mixes compared to control non-additive compositions by 10–12% while maintaining mobility along the ring spread of 240 mm. The introduction of basalt fiber has

CONSTRUCTION MATERIAL SCIENCE

Table 2

Technological indicators of flooring dry building mixes

The process of forming the structure and properties of dry building mixes is somewhat different from the structure formation of mineral concrete with coarse aggregate. The structural features of mortars obtained from dry building mixes with additives are largely determined by the degree of their impact [1, 19, 20]. As shown by the results of a study of various compositions of dry building mixes with targeted mineral additives, the introduction of a small amount of nanosilica increases the compressive strength of the mortar (Table 3) – by 30–35% compared to a mortar based on PC. An increase in the strength of a mortar based on LWB using the NS additive occurs due to the compaction of the structure caused by the interaction of silica of slag or ash and NS with the products of cement hydration and the formation of an additional volume of low-basic calcium hydrosilicates. A study of the kinetics of hardening of the mortar showed that strength gain occurs intensively within 7–14 days, after which the process of strength growth levels off. Optimization of the composition made it possible to reduce the cracking of the hardened mortar due to the introduction of a nanoad- ditive and a micro-reinforcing component.

The introduction of basalt fiber, in addition to increasing the compressive strength of the material, increases the flexural strength by 1.5–1.8 times. The introduction of a reinforcing component reduces the development of microcracks in the flooring dry building mixes under loading and increases the adhesion strength of the fiber to Portland cement due to their chemical affinity, and the introduction of NS increases the corrosion resistance of basalt fiber. The pozzolanic reaction occurring between nanosilica and portlandite leads to additional formation of calcium hydrosilicates and a change in the alkalinity of the environment, preventing corrosion of the basalt fiber. The content of fiber in an optimal amount (4 wt. %) ensures maximum crack resistance of the mortar and abrasion resistance of the flooring dry building mixes.

Considering the fact that the properties of a hardened mortar largely depend on its porous structure, which in turn can be assessed by the amount of water absorption, comprehensive studies were carried out to determine water absorption and the influence of formulation factors on these indicators. Figure 1 shows the dependence curves of water absorption on the composition of a mortar made

Table 3

Mechanical parameters of floor mixtures after 28 days of hardening

|

Binder composition of flooring building mixes |

Compressive strength, MPa |

Flexural strength, MPa |

Crack opening width, mm |

Abrasion, g/cm2 |

Strength of adhesion to concrete base, MPa |

|

PC |

24.1 |

5.1 |

0.6 |

0.9 |

0.7 |

|

LWB-70 (FA) |

27.2 |

5.8 |

0.5 |

0.75 |

0.8 |

|

LWB-70 (FA)+NS |

32.8 |

7.5 |

0.2 |

0.55 |

1.0 |

|

LWB-70 (FA)+BF+NS |

36.5 |

9.1 |

– |

0.3 |

1.1 |

|

LWB-70 (VS) |

26.5 |

5.4 |

0.45 |

0.8 |

0.75 |

|

LWB-70 (VS)+NS |

28.8 |

7.1 |

0.25 |

0.65 |

0.9 |

|

LWB-70 (VS)+BF+NS |

33.6 |

8.2 |

– |

0.34 |

1.0 |

CONSTRUCTION MATERIAL SCIENCE

万 a

* .? -uoKJosqe JSBM

о

2 乙

8,

PC+fly ash

PC

-

■ without additives

PC+volcanic slag

-

■ SP ・SP+NS ・SP+NS+BF

Fig. 1. Effect of mortar composition on water absorption from a dry mix with various mineral and nanodispersed additives. It has been shown that compositions with LWB with the simultaneous introduction of reinforcing and nanodispersed additives have minimal water absorption.

Microstructural studies of mortar samples (JEOL-JSM-6510LV, ESSUTM) with additives, presented in Figure 2, show a change in the microstructure associated with the effect of the additives – basalt fiber and NS. The addition of NS not only increases the corrosion resistance of mineral fiber, but also promotes the uniform distribution of the composite binder on the surface of the mineral filler, and this, in turn, indicates the reinforcing role of additives and the ordering of the microstructure of mortar from a dry mix. In addition, dispersed reinforcement together with the NS additive helps strengthen the conglomerate, which ensures high performance characteristics of the material and long-term operation in buildings and structures.

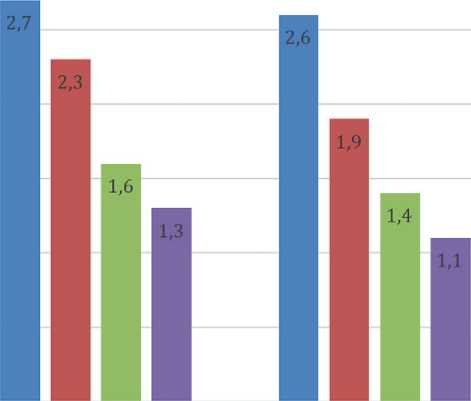

In addition, the introduction of micro-reinforcing additives, reinforcing the structure of the hardening material, leads to a decrease in shrinkage deformations of the mortar in all directions (Fig. 3).

Fig. 2. Microstructure of mortar ( × 1000): a – without additives; b – with basalt fiber and NS

CONSTRUCTION MATERIAL SCIENCE

PC+volcanic slag

PC+flyash

■ without additives

Л25 647О

■ SP ・SP+NS eSP+BF+NS

Fig. 3. Shrinkage deformations of flooring building mixes

The amount of reduction in shrinkage deformations depends on the amount of the fibrous component, mineral filler, and type of binder. A mineral filler in the form of volcanic slag or fly ash, and the addition of NS reduce porosity and shrinkage deformations, and also increase the abrasion of the mortar. The effect of increasing crack resistance is significantly enhanced, by 20–30%, with the introduction of basalt fiber. Optimization of DBM compositions made it possible to reduce the cracking of hardened mortar due to the introduction of targeted mineral additives with minimal consumption of cement binder. In order to ensure long-term joint work, as a rule, of a concrete base and mortar from a dry mix, it is necessary to introduce dispersed powders into the compositions, usually redispersible polymer powders [5, 21, 22] or additives with good penetrating action [1], which improve adhesion strength and adhesive bond with the base. It should be especially noted that adhesive strength depends on the strength of not only the mortar itself, prepared from a dry mix, but also the cement concrete base, the quality of the surface, its cleanliness and humidity [1]. When developing the composition of a dry mix, in our opinion, the use of nanodispersed silica not only modifies the structure of the composite and creates a denser packing of the hardened solution, but also enhances the adhesion of the solution to the concrete base. Due to the reaction between it and Ca(OH)2

formed during the hydration of cement, the adhesion strength in the “dry mix mortar – concrete base” system increases. In the case of the presence of CaCO3 on the surface of concrete, formed during the interaction of portlandite with carbon dioxide of the surrounding air, the phase composition of lamellar crystalline formations, based on the results of additional microscopic studies, corresponds to mixed type hydrosilicates.

CONCLUSION

Thus, the compositions of dry building mixes have been optimized for their intended use and ways to increase the technological, mechanical and operational performance of the flooring dry building mixes using a complex of additives for various functional purposes have been shown.

Based on the conducted research, we can conclude that the performance indicators of mortars made from dry mixes for self-leveling flooring building mixes based on composite binders with directional additives are quite high compared to compositions without additives. The noted high indicators of water-holding capacity, strength, crack resistance, adhesive ability and other indicators are achieved due to pozzolanic activity, the hydrophobizing, plasticizing effect of the addition of nanosilica and the micro-reinforcing effect of basalt fiber.

CONSTRUCTION MATERIAL SCIENCE

Список литературы Dry building mixes with a silica-based modifying additive

- Pichugin A.P., Khritankov V.F., Belan V.I. Dry building mixes with increased performance characteristics. Novosibirsk: IC “Zolotoy Kolos”; 2014.

- Bondarenko A.V. Dry building mixes for self-leveling floors based on composite binder: dissertation for competition.... candidate of technical sciences. Sciences. Belgorod; 2012.

- Bezborodov V.A., Parikova E.V., Pichugin A.P. Dry building mixes and technology of their application. Novosibirsk; 2010.

- Meshkov P.I., Mokin V.A. Ways to optimize the composition of dry building mixes. Building materials. 2000; 5: 26–27.

- Nesvetaev G.V., Osipov V.V. On the effect of redispersible polymer powders on the modulus of elasticity and adhesion strength of building mortars. Engineering Bulletin of the Don. 2022; 7: 493-505.

- Gorshkova A.V. Dry building mixes with a modifying additive based on peat: dissertation for the competition... Candidate of Technical Sciences. Tomsk; 2015.

- Batalin B.S. Studies of the effectiveness of additives used for the production of dry building mixes. Successes of modern natural science. 2007; 7: 60-62.

- Borovskikh I.V. High-strength fine-grained basalt fiber concrete: abstract of the dissertation for the competition... candidate of technical sciences. Sciences. Kazan; 2009.

- Lesovik V.S., Strokova V.V. On the issue of the development of the scientific direction “Nanosystems in building materials science”. Building materials. 2006; 9: 18-20.

- Lukuttsova N.P., Matveeva E.G., Fokin D.E. Investigation of fine-grained concrete modified with a nanodisperse additive. Bulletin of the V.G.Shukhov BSTU. D.E. 2010;4: 6-11.

- Pukharenko Yu.V., Ryzhov D.I., Staroverov V.D. Features of the structure formation of cement composites in the presence of carbon nanoparticles of the fulleroid type. Vestnik MGSU. 2017;7:718-723.

- Korolev E.V., Bazhenov Yu.M., Beregovoy V.A. Modification of building materials with nanocarbon tubes and fullerenes. Building materials. 2006; 8: 2-4.

- Yakovlev G.I., Pervushin G.N., Korzhenko A.[et al.] Modification of cement concretes with multilayer carbon nanotubes. Building Materials. 2011; 2: 47-51.

- Bardakhanov S.P., Korchagin A.I., Kuksanov N.K. [et al.] Production of nanopowders by evaporation of starting materials on an electron accelerator at atmospheric pressure. Reports of the Academy of Sciences. 2006; 409(3): 320-323.

- Urkhanova L.A., Lkhasaranov S.A. Fine-grained cement concrete with a nanodisperse modifier. Scientific Online Journal “Nanotechnology in construction”. 2010; 4: 42-52.

- Demyanenko O.V., Kopanitsa N.O., Sarkisov Yu.S. The influence of nanoscale silicon on the properties of cement stone. 2nd Intern. sciences. The conference “Youth, Science, technology: new ideas and prospects”. Tomsk: TGUAB Publishing House; 2015.

- Khokhryakov O.V. Composite cements of low water demand. Possibilities and prospects of application in building materials. Building materials. 2022; 1-2: 123-133. http://doi.org/10.31659/0585-430X-2022-799-1-2-123-133

- Khokhryakov O.V., Khozin V.G., Valieva A.I. Dry organomineral additive for the device of non-shrinkable industrial floors. Izvestiya Kazan State University of Architecture and Civil Engineering. 2017; 4(42): 328-334.

- Shatalova N.P. Modified cement mortars for sealing filter concrete of industrial structures: abstract.... candidate of Technical Sciences. Saratov; 1991.

- Bazhenov Yu.M. Betonopolymers. M.: Stroyizdat; 1983.

- Ilyina L.V., Tulyaganov A.K. The use of mineral fibers in plaster cement mixtures to improve the performance characteristics of the solution. Regional architecture and construction. 2020; 3(44): 5-11.

- Nesvetaev GV., Osipov V.V. Influence of redispersible polymer powders and retention conditions on the shrinkage of building mortars. Engineering Bulletin of the Don. 2023;11(107): 581-597