Early medieval jeweler's kit from the Western Amur region

Автор: Nesterov S.P., Savin A.N., Kolmogorov Yu.P.

Журнал: Archaeology, Ethnology & Anthropology of Eurasia @journal-aeae-en

Рубрика: The metal ages and medieval period

Статья в выпуске: 2 т.44, 2016 года.

Бесплатный доступ

A late 9th century jeweler's kit from dwelling 2 at Osinovoye Ozero, a Mohe site on the Middle Amur, is described. Bronze was smelted in a crucible placed on a ceramic support inside a vessel-like furnace. Nine bronze plaques from the same dwelling are compared with negatives of molds in which they were cast. Based on results of the elemental analysis of plaques, these fall into three groups. The fi rst differs from the other two by the source of ore, and plaques of the second group were recast more than once. Most Turkic type plaques were evidently destined for recasting into Mohe ornaments. The latter include one openwork and two fi gured plaques as well as bronze bells found in 2012 in dwelling 3. Because bronze items differing in composition were recast several times, the source of ore cannot be identifi ed. Techniques of manufacturing molds and facing of plaques, used by Central Asian and Mohe artisans, are reconstructed.

Amur region, osinovoye ozero, crucible, bronze metallurgy, bronze plaques, spectral analysis

Короткий адрес: https://sciup.org/145146027

IDR: 145146027 | DOI: 10.17746/1563-0110.2016.44.2.081-090

Текст научной статьи Early medieval jeweler's kit from the Western Amur region

Dwelling 2 at the early medieval settlement of Osinovoye Ozero in the Konstantinovsky District of the Amur Region was investigated in 2009 (Fig. 1). According to 14C-analysis, the settlement functioned from 888– 898 AD (Derevianko A.P. et al., 2010: 149). Some objects were discovered in the dwelling; part of them belonged to the production kit of a jeweler who worked with nonferrous metals (Fig. 2). The kit included a ceramic smelting furnace (vessel No. 8), a crucible, two supports under the crucible, plaques from hanging straps of a belt, an openwork plaque, and whetstones. In addition, metal droplets, slagged fragments of coal, an iron heart-shaped plaque with three holes, and pieces of burned plaster made of a clay/grass mixture were found in the dwelling.

Foundry set

The heating unit consisted of a pot-shaped vessel with a high smooth neck and an everted rim. The bottom of the pot is missing; the edge of the body was processed at the bottom and is at the same horizontal level. The height of the preserved part of the vessel is 19 cm, the diameter of the body is 16.5 cm, that of the neck is 14.5 cm, and that of the rim is 18.8 cm; the diameter of the lower

R- Тот

Troitsky burial ground

100 km

ВигеУа

L50*

of Osinovoye Ozero

Site of Ozero.Dolgoye

100 km

"usks

Ves se

Fig. 1. Mohe sites in the Amur Region.

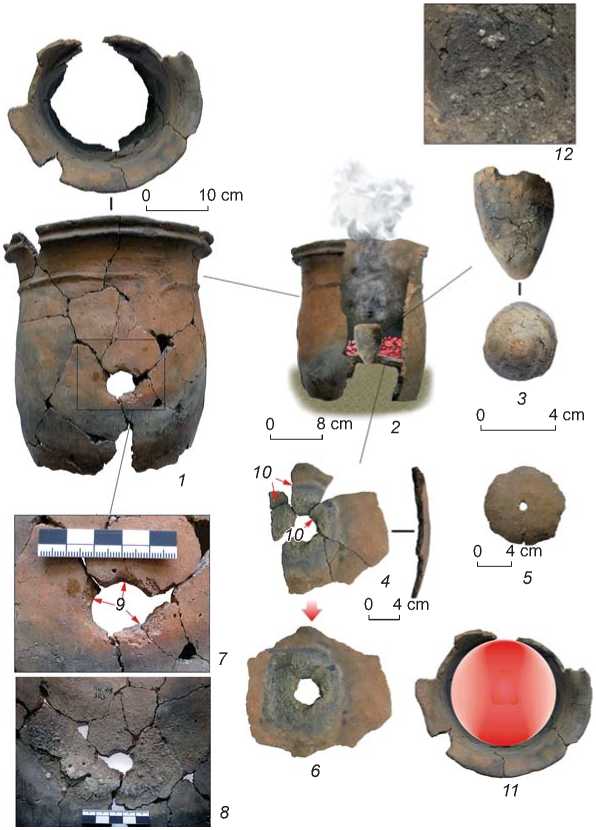

edge (the bottom part) is 14.6 cm. The thickness of the walls is 0.6–0.7 cm. An oval hole (2.20 × 1.85 cm) was drilled and filed 6.8 cm from the bottom edge of the body (Fig. 3, 1 , 7 , 9 ). There are traces of high temperature impact in the form of slagging inside the vessel around the hole and on the opposite wall (Fig. 3, 8 ). Judging by the nature of the work done on the vessel, it was reused as a portable smelting furnace of a simple open design with direct air injection in the bottom part for smelting small portions of non-ferrous metal in a crucible which was placed inside the vessel. Between smelting operations, animal bones were kept in the pot.

Fragments / of vessel No. 7

= < Crush ed Fragments / Ves

vessel No. 6 of vessel No. 7 iSl No. 5

/ Vessel No. 4

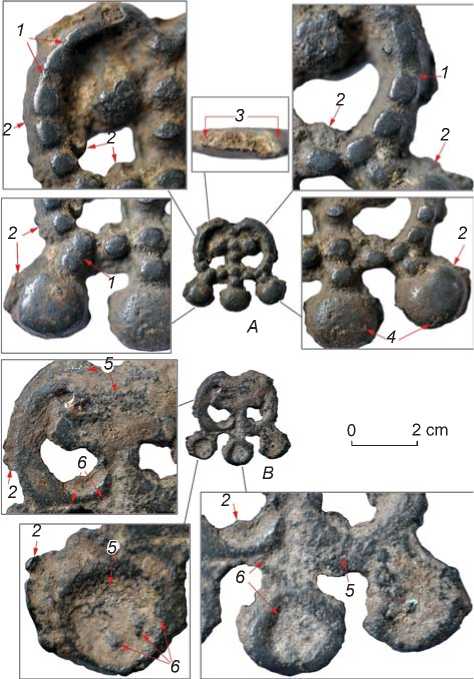

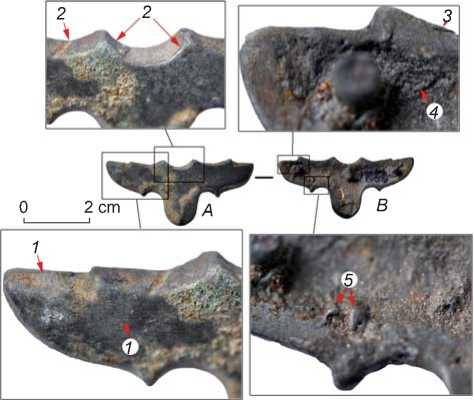

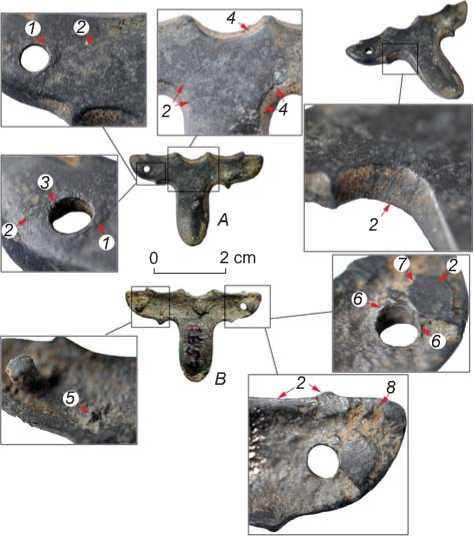

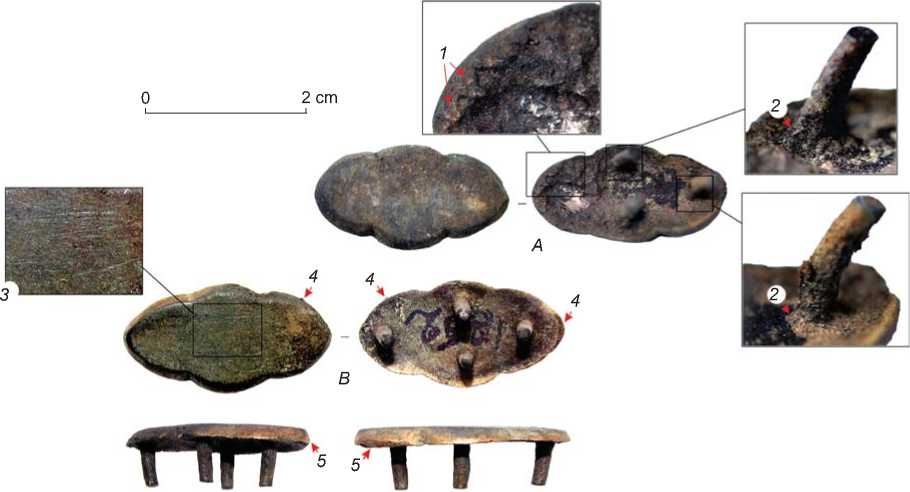

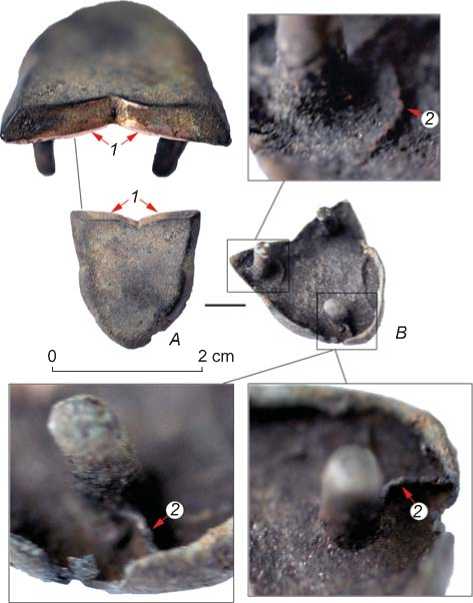

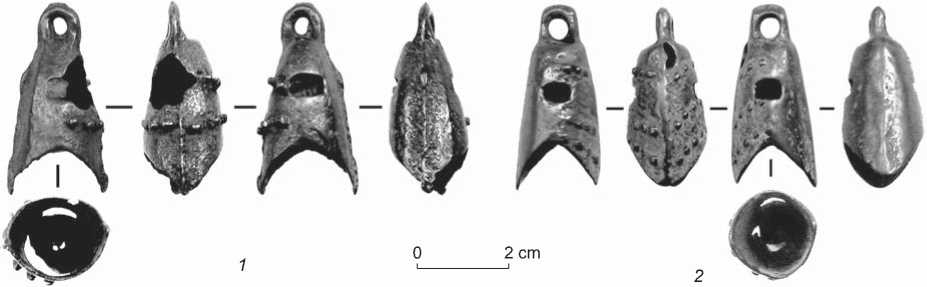

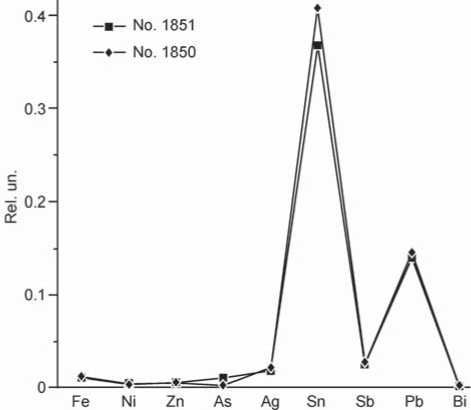

Fragments wheel-made Mam vessel No. 3 dible No. 4 idible No. 3 Vessel No. 1 Mandible Jo. 5 Vessel No. 8 <—Vessel No. 10 Crucible (vessel No. 11) Defective support for the crucit Ie Fragment:' of vessel No. Hearth Stone Mandible No. 2 L Manditle No. 1 1 2 ■ Charred sediment 6 7 8 0 100 cm Fig. 2. Plan of dwelling 2 at the settlement of Osinovoye Ozero. The volume of the interior part of the vessel-like furnace is 3402.49 cm3*. The usable volume of the furnace working chamber is about 40 % of its total volume. Air was injected into the furnace by bellows through a nozzle which was tightly attached to the opening in the wall in order to prevent gas emission from the junction between the nozzle and the edges of the hole. That explains why the furnace walls were slagged only on the inside (Fig. 3, 7, 8). Judging by the distribution of slagged areas, the changes in heat colors (tarnish) on the surface of the vessel, and the level at which the opening for the nozzle of the bellows was located, the furnace was placed into a hearth (Fig. 3, 2). The set of the vessel-like furnace included a ceramic support for the crucible. Two supports made out of the walls of vessels’ bodies were found. One of them is a defective disc, 9.0–9.9 cm in diameter and 0.5 cm thick, with a hole 0.9 cm in the middle. In the process of drilling, the ceramic disc cracked and was discarded in the hearth of the dwelling (Fig. 3, 5). Fragments of another disk were found on the ground to the west of the dwelling. Its maximum diameter is 8 cm; the diameter of the hole is 4 cm (Fig. 3, 4, 6). Traces of high temperature impact and slagging appear on the surface around the hole (Fig. 3, 10). The use of a ceramic support made it possible to place the crucible in the most high-temperature area of the furnace, and to prevent its possible displacement or tipping caused by burning of fuel in the smelting process. The crucible was placed opposite the nozzle. The distribution of slagging on the crucible (Fig. 3, 3) and on the walls of the furnace allowed us to estimate the temperature conditions inside the vessel during smelting for the duration of the entire technological process (Fig. 3, 11). Judging by the uniformity of slagging on the walls of the vessel-like furnace, only one smelting with a single placement of fuel was made in the vessel. The technical ceramics are represented by a crucible of conical shape (vessel No. 11, see Fig. 2) which was made of molding compound with a high content of coarse mineral admixture. The height of the crucible is 5.8 cm; the Fig. 3. Heating implements for nonferrous metal smelting from the settlement of Osinovoye Ozero. 1 – vessel-like furnace; 2 – reconstruction of the smelting furnace unit; 3 – crucible; 4, 5 – supports for the crucible; 6 – reconstruction of the original appearance of the crucible support; 7 – air delivery hole in the wall of the vessel-like furnace (view from the exterior); 8 – air delivery hole in the wall of the vessel-like furnace with traces of slagging (view from the interior); 9 – traces of drilling a hole in the vessel wall; 10 – traces of slagging and color tarnish on the surface of the crucible support; 11 – heat distribution inside the vessel-like furnace at the maximum smelting temperatures (reconstruction); 12 – metal residues on the interior surface of the crucible. maximum diameter along the rim is 4.1 cm. The thickness of its walls is 0.3–0.4 cm at the rim, and 0.9–1.0 cm at the bottom; the thickness of the bottom is 2 cm. The conical internal cavity is 3.7 cm deep; its maximum diameter is 3.5 cm. The volume of the crucible is 11.86 cm3*. *It was calculated according to the formula of cone volume h г V = —nr , where π = 3.14; r is the inner radius of the rim, and Judging by the traces of oxides on the walls, metal was contained in the conical portion of the crucible; the maximum diameter at this point was 2.5 cm; the height was 2.2 cm, and the volume was 3.6 cm3. Drops of white metal (silver or tin bronze) survived on the walls (see Fig. 3, 12). The weight of the recast silver in the used volume of the crucible (specific weight 10.5 g/cm3) could have reached 37.8 g; the maximum weight could have been 124.53 g; the weight of tin bronze (specific weight 8.8 g/cm3) could have reached 31.68 g and 104.37 g respectively. Bronze objects An openwork plaque was found near dwelling 2. It has an oval shape (2.5 × 2.0 cm, thickness 0.3 cm, weight 10 g); its upper edge in the middle is bent inwardly in a heartshaped manner. There are small hollows on the reverse side which repeat the outline of the object (Fig. 4). The edges of the plaque were left unprocessed after the casting (Fig. 4, 2). The adornment was cast in a bipartite two-sided mold made after the imprint of a wax model, as demonstrated by the negative imprints of trimming the pliable material with a sharp tool, as well as by traces of deformation in the pliable material during the molding process (Fig. 4, 6). The use of a bipartite mold is indicated by casting seams up to 0.06 cm thick, which have been preserved around the outlines of the object (Fig. 4, 2), and by the fragment of a sprue 0.80 × 0.26 cm in cross-section, which is located on the left side of the upper edge, bent in a heart-shaped manner (Fig. 4, 3). The surface of the object clearly shows the imprints of mold walls (Fig. 4, 5), blowholes and caverns in the metal (Fig. 4, 4). The presence of massive, asymmetrical, large metal flashes both along the edge of the object and between individual relief elements of the decoration indicates the destruction of the mold resulting from its repeated use (Fig. 4, 1, 2, 4, 6). Two figured plaques were found on the floor of dwelling 2 (see Fig. 2). The length (between the lateral protrusions) of the first plaque (No. 1858) is 4 cm; the width in the middle part is 1.6 cm. There are three pins for fastening, 0.36–0.40 cm long, on the concave back side of the plaque (Fig. 5, 1). The second plaque (No. 1857) is 3.5 cm long, and 2.5 cm wide in the middle part. A hole with the diameter of 0.2 cm was made on its reverse side to the left next to a pin which was broken and ground away. The middle pin was broken off obliquely down to 0.1–0.2 cm; the right pin—down to 0.2 cm (Fig. 6, A, B). Both plaques weigh 6 g each. These plaques were cast in bipartite two-sided clay (ceramic) molds produced from the imprint of a pliable (wax?) model. The model was sculpted of soft material; its edges were trimmed with a sharp tool (see Fig. 5, 1; 6, 4). For producing a section of the mold with the imprint of the object on the front side, coarse clay molding compound was placed on the pliable model which was set on the molding plate. This compound ensured an even casting seam around the entire outlines of the object (see Fig. 5, 4). At that stage, the system of sprues was formed. After drying and firing of that mold section, its working chamber was filled with molten wax in which the cavity of the future casting would be formed. After creating an intermediate wax model, the parts of the mold were made with the imprint of the object on the reverse side. Holes were pierced in the formed part for casting the pin-rivets. The reverse section was made of molding compound with high content of fine sand for providing a sufficient gas-generation value to the mold and plasticity to the linear deformations of the casting (see Fig. 6, 8). In the process of heating, the pliable model was melted out of the finished mold, and its cavity was filled with molten metal through the system of sprues. Distinctive metal flashes (see Fig. 5, 5), formed during the casting, manifest the defect caused by cracking and partial destruction of the mold (veining, casting defect No. 1114) (Durakov, 2014: 78). After the object was taken out of the mold, casting sprues and channels were removed; casting seams and the surface of the object were processed. Since all plaques were subjected to a thorough secondary treatment, and became polished after long use, many sprue-joining areas cannot be clearly seen. The location of sprues in some areas is indicated by the thickened lateral faces of the objects. The sprues of the objects under study, ranging from 0.20 × 0.16 to 0.80 × 0.27 cm in size, were of subsquare or oval shape. The sprue-joining area was carefully filed and polished. Some objects were finished by polishing the entire surface. Five plaques with scalloped edges from the northwestern corner of dwelling 2 (see Fig. 2) are almost identical; they were probably made from the imprint of a pliable model or from a rigid model, made from a pliable matrix based on an original object. The practically identical linear dimensions and weight (3 g) of the objects can serve as an indirect proof that a single matrix was used (Table 1; Fig. 7). The plaques were attached to the base with four pins cast simultaneously with the body (Fig. 7, 2). Their ends were slightly unriveted, which determined the difference in length. The differences of plaques in thickness were caused by the amount of metal poured into the mold, the degree of wear of the mold, as well as precision in assembling the bipartite mold, since misalignments of its elements resulted in changed sizes of the cast. Thus, for example, in one object there was a slight shift and, consequently, an asymmetry of the casting seams was observed (Fig. 7, 4). On the Fig. 4. Bronze openwork plaque No. 1845 from the front (A) and reverse (B) sides. 1 – traces of mold destruction; 2 – casting seams; 3 – traces of sprue-joining; 4 – surface blowholes; 5 – imprints of coarse-grained structure of the mold; 6 – signs of treatment of the pliable modeling material. Fig. 5. Bronze profiled plaque No. 1858 from the front (A) and reverse (B) sides. 1 – traces of abrasive treatment of the object’s surface; 2 – traces of processing the pliable model with a narrow-bladed tool; 3 – fragment of a casting seam; 4 – imprint of the coarse-grained structure of the mold; 5 – metal flashes on the interior surface of the object. reverse side of one of the plaques, one can see the signs of destruction in the mold’s working chamber and formation of multiple surface casting defects (Fig. 7, 1). Low quality of casting of the scalloped plaques is manifested by the traces of extensive abrasive treatment of the front surface (Fig. 7, 3), which appear on almost all objects of that group. A belt tip with a scalloped edge (length 1.67 cm, width 1.57 cm, thickness 0.1 cm, and weight 3 g) was made in a bipartite two-sided casting mold; this is indicated by the remains of a casting seam up to 0.16 cm thick which follows the outline of the object. Traces of flashes on the reverse side of the object (Fig. 8, 2) suggest the casting defect No. 1114. Three pins 0.18 cm in diameter made in a single casting process together with the main part, have survived on the reverse side of the object (Fig. 8, B). The pins are axially deformed, and their top edge is somewhat thickened from unriveting. An area with amalgam gilding has survived on the upper edge of the plaque (Fig. 8, 1). Fig. 6. Bronze figured plaque No. 1857 from the front (A) and reverse (B) sides. 1 – signs of drilling in the casting, metal flashing around the hole on the front side of the object; 2 – traces of abrasive treatment of the object’s surface; 3 – slip marks of the cutting edge of the drill; 4 – traces of processing the pliable model with a narrow-bladed tool; 5 – metal flash (veining) on the reverse side of the casting; 6 – signs of drilling in the casting, metal flashing around the hole on the reverse side of the object; 7 – base of pin fastening processed with abrasive; 8 – imprint of coarsegrained structure of the mold. Table 1. Summary description of scalloped plaques from hanging straps of the belt No. of the plaque Length, cm Width, cm Thickness, mm Fastening pins Location of the amalgam gilding on the plaque Amount, pieces Diameter, mm Length, mm 1849 2.43 1.3 1.4 3 1.8 6.6 On the edge 1850 2.42 1.27 1.8 3 2 5.5 On the front side 1851 2.4 1.26 1.2 2 1.8 6 On the edge 1852 2.5 1.32 2 4 1.9 5.8 On the edge and on the front side 1856 2.43 1.29 1.6 4 1.7 6 On the edge Fig. 7. Bronze scalloped plaques No. 1849 (A) and 1852 (B). 1 – casting defects: metal swelling, veining; 2 – thickening at the base of the pin fastening; 3 – traces of abrasive treatment of the object’s surface; 4 – casting seams; 5 – cutting marks in the sprue-joining area. A belt tip with an oval shield and a direct cut at the top (height 1.56 cm, width 1.52, thickness 0.2 cm, and weight 4 g) is covered with fine-grained black patina (Fig. 9, A). Traces of abrasive treatment can be seen on the surface along the outline and on the front part of the shield (Fig. 9, 1). Three pins up to 0.2 cm in diameter are located on the reverse side. The object was made in a bipartite two-sided mold, as indicated by the casting seam along the outline (Fig. 9, 2). Most of the seam was removed by filing with an abrasive tool with a fine-grained structure (Fig. 9, 3). A small part of the casting seam 0.1 cm thick has survived on the lower part of the shield. The sprue was also removed by an abrasive tool, leaving a small oval area 0.80 cm long and 0.27 wide. Some objects show very thorough polishing of the front surface. The figured plaques stand out in the collection (Fig. 5, A; 6, A). They show traces of abrasive treatment, but these traces are minimal. These are the only quality objects in the collection, without the evidence of repeated use of the mold (traces of its destruction) and of rigid models or ready objects used as models, though these plaques underwent some repairs. The place where a pin was broken off of the figured plaque (No. 1858) was abraded (see Fig. 6, 2, 7) and a hole was drilled next to this place; traces of drilling can be observed on the interior surface of the hole in the form of long parallel scratches (see. Fig. 6, 3), while the excess of the metal which was “squeezed out” in the process (flashing) is visible on both the front and reverse side of the object (see Fig. 6, 1, 6). Traces of amalgam gilding of their front surfaces can be attributed to secondary treatment of the plaques. Chemical composition of the plaques The elemental chemical composition of the bronze which was used for casting the adornments, was determined for one openwork plaque, two figured plaques, four scalloped plaques, and two end plaques*. A “tablet” of shavings, drilled at the location of a hole in the object, was placed in the measuring chamber of the unit in such a way that a 33.5 keV monochromatic synchrotron radiation beam would fall on its surface. The secondary radiation from the samples (emission spectrum) was recorded by a ARTAX-400 energy dispersive spectrometer and was processed using AXIL software. The External Standard method was used for calculating the concentration of chemical elements in the samples. The standard for bronze which was included in the spectrometer set, had the following reference chemical content (%): P – 0.01, S – 0.03, Fe – 0.02, Ni – 1.5, Cu – 76.8, Zn – 1.1, As – 0.02, Sn – 8.0, Sb – 0.5, Pb – 12.0, Bi – 0.01. The spectra of the tested sample and the reference sample were measured and compared. According to the chemical composition, the collection of objects was divided into three main groups: First group, two figured plaques of tin-lead bronze (Cu, Sn, Pb). Compared to other objects, they were distinguished by extremely low levels of arsenic (As) – up to 0.26 %, antimony (Sb) – up to 0.08 %, and iron (Fe) – up to 0.02 %; Second group, six objects of lead-tin-arsenic bronze (Cu, Pb, Sn, As). They shared a high content of lead (Pb) – from 4.6 to 10.1 %, and tin (Sn) – from 1.32 to 5.5 %. A specific feature of this group was a high share of arsenic (As) – up to 1.69 %, and bismuth (Bi) – up to 0.19 %. Such a wide range of values of components suggests that the metal of plaques belonging to the second group was recast several times with the addition of arsenic and lead. A high content of bismuth in almost all objects of this group may indicate that the sources of ore for the production of this metal were located near the smelting; Third group, a belt tip with a scalloped edge (see Fig. 8, A) of tin-lead-arsenic-antimony bronze (Cu, Sn, Pb, As, Sb). The find from this group, as well as objects from the second chemical group, is distinguished by a significant amount of bismuth (Bi) – up to 0.15 %. The main difference was high content of antimony (Sb) – up to 2.27 %, probably indicating its intentional addition and few recasting operations which involved the metal of this object. Fig. 8. Bronze belt tip No. 1855 with scalloped edges from the front (A) and reverse (B) sides. 1 – part covered with amalgam gilding; 2 – traces of metal flashes. Fig. 9. Bronze belt tip No. 1853 with an oval shield from the front (A) and reverse (B) sides. 1 – traces of abrasive treatment of the object’s surface; 2 – fragment of the casting seam; 3 – traces of abrasive filings of the casting seam. Thus, in terms of the elemental composition, the objects of the first group differ from artifacts of the second and third groups, which are close according to the feature mentioned above. The plaques of the second group were recast several times. Conclusions The jeweler’s casting kit described in this article was used for domestic production of small amounts of nonferrous metal. Typical adornments of the Mohe culture were made of this metal. Only one such object (an openwork plaque) was found during the excavation of dwelling 2. The absence of finishing marks on the object suggests that the plaque was lost when it was left to cool in the open air outside the dwelling. An object similar to two figured plaques appears only among the plaques discovered at the Troitsky burial ground in the Amur Region (Derevianko E.I., 1975: 237, pl. XXXIX, 61). In terms of manufacturing technique, figured plaques Table 2. Elemental composition of the plaques on the basis of spectrum analysis, % No. of the plaque Ni Fe Zn As Ag Cd Sn Sb Pb Bi 1858 0.089 0.029 0.068 0.261 0.321 0.011 5.88 0.08 5.46 0.092 1851 0.069 0.122 0.061 0.857 0.073 0.002 1.32 0.189 5.16 0.094 1850 0.134 0.226 0.121 1.51 0.152 0.004 2.73 0.379 9.4 0.167 1845 0.054 0.129 0.05 0.418 0.048 0.009 3.94 0.188 6.32 0.107 1849 0.101 0.056 0.095 1.13 0.091 0.004 2.63 0.507 4.65 0.06 1852 0.078 0.138 0.072 1.06 0.064 0.004 1.79 0.299 6.17 0.087 1853 0.101 0.132 0.089 1.69 0.089 0.01 5.53 0.647 10.1 0.197 1857 0.055 0.028 0.052 0.148 0.201 0.007 3.61 0.047 4.16 0.066 1855 0.092 0.219 0.141 5.85 0.37 0.012 13.3 2.27 6.65 0.152 2 cm Fig. 10. Mohe bells from dwelling 3 of the settlement of Osinovoye Ozero. Table 3. Share of chemical elements in the samples relative to copper (Cu), % No. of the plaque Cu Ni Fe Zn As Ag Sn Sb Pb Bi 1858 1 0.0025 0.0017 0.004 N/D 0.067 1.23 0.0081 0.114 0.0018 1851 1 0.0026 0.0096 0.0048 0.01 0.02 0.37 0.025 0.142 0.0024 1850 1 0.0027 0.0096 0.0052 0.0021 0.023 0.41 0.028 0.148 0.0023 1845 1 0.0023 0.011 0.0044 0.0068 0.015 1.22 0.028 0.183 0.0031 1849 1 0.0021 0.0024 0.004 0.0088 0.014 0.4 0.038 0.072 0.0009 1852 1 0.0027 0.0098 0.0052 0.016 0.016 0.45 0.037 0.15 0.002 1853 1 0.0024 0.0064 0.0044 N/D 0.015 0.95 0.054 0.186 0.0031 1857 1 0.0022 0.0023 0.0043 N/D 0.059 1.05 0.0066 0.113 0.0018 1855 1 0.002 0.01 0.0065 0.014 0.06 2.15 0.18 0.17 0.0023 are the closest to openwork plaques: they all show distinct features of model molding. The comparison of spectral analysis data of the three plaques showed similar elemental composition (Cu, Sn, Pb; Table 2), also comparable to the chemical composition of the Mohe bronze adornments from the Troitsky burial ground. According to L.V. Konkova, a large amount of lead in the multi-component alloy of the objects was associated with metal engraving (1989: 59, 96). Figured plaques probably served as Mohe adornments. This set of adornments can be supplemented with two bells from dwelling 3 of the settlement on the shore of Lake Osinovoye, excavated in 2012. One of the bells was discarded due to a casting defect (Fig. 10, 1), and another one underwent secondary processing for receiving a “marketable” condition (Fig. 10, 2). As far as the five plaques with scalloped edges and two tips of hanging belt straps are concerned, they probably represent the casting practice of the medieval population of Central Asia (the Turkic peoples, the Uyghurs). In their metal, similar and even identical shares of chemical elements relative to copper (which was taken as the unit of comparison) have been identified (Table 3). Thus, metal samples of plaques No. 1850 and 1851 showed almost the same share composition of chemical elements, which may indicate their simultaneous manufacturing in the same workshop (Fig. 11). Turkic and Uyghur belts were widespread in Eurasia, including the areas of the Mohe culture (Derevianko E.I., 1974; 1975: 237; Nesterov, Maksimov, 1990). A significant number of belt plaques of the Turkic type were found in the tombs of the Korsakovsky burial ground on the Bolshoy Ussuriysky Island in the Eastern Amur region (Medvedev, 1982, 1991). In the Western Amur region, they came to be widely used with the arrival of the Bohai Sumo Mohe people from the basin of the Second Sungari River in the 8th century (Nesterov, Alkin, 1999). In the Amur region, such belts were apparently highly valued; thus, many plaques which used to decorate them are polished from long wear, bear traces of repair in the form of drilled holes for attaching to the belt, have broken pins and edges, cracks, and worn gilding. When belt onlays would completely fall into disrepair, the Mohe jewelers would recast the plaques, and out of this metal they would make adornments typical for their culture. Replicas of the Central Asian plaques are not yet known in the Western Amur region. Bronze objects, different in elemental composition, were repeatedly recast; thus, it is not possible to reliably determine the origin of the metal. However, we have managed to reconstruct the techniques of manufacturing molds and processing of finished objects, used by the Central Asian and Mohe artisans. The use of ceramic vessels as furnaces for smelting iron is known from the materials of a medieval dwelling Fig. 11. Share of chemical elements in samples No. 1850 and 1851 relative to copper (Cu). which was excavated in 1965 on the shore of Lake Osinovoye, 400 meters from dwelling 2 (Derevianko E.I., 1975: 44–45, 203, pl. V); a fragment of a vessel-like furnace of the Mohe Troitsky group with a hole for a nozzle in the body was found at the site of Ozero Dolgoye (Nesterov et al., 2014). A similar process of iron smelting in vessel-like furnaces was used in the Early Iron Age in the Middle Angara region (Gladilin, 1985: 168). This demonstrates the effectiveness of using vessel-like furnaces for smelting both nonferrous and ferrous metals in the household.

Список литературы Early medieval jeweler's kit from the Western Amur region

- Derevianko A.P., Kim Yeongwon, Nesterov S.P., Yu Gwangjin, Lee Gyuhun, Han Jiseon, Mylnikova L.N., Loskutova Y.Y., Shelomikhin O.A., Park Jongseong, Lee Gyeonha. 2010 Materialy i issledovaniya Rossiysko-Koreiskoi arkheologicheskoi ekspeditsii v Zapadnom Priamurye. Iss. III: Raskopki rannesrednevekovogo poseleniya Osinovoye Ozero v 2009 godu. Daejeon: Izd. Gos. Issl. Inst. kulturnogo naslediya Respubliki Korei.

- Derevianko E.I. 1974 Nabornyi poyas mokhestsev kak odno iz svidetelstv kontaktov s tyurkami. Izvestiya SO AN SSSR. No. 6: Ser. gum. nauk, iss. 2: 95–102.

- Derevianko E.I. 1975 Mokheskiye pamyatniki na Srednem Amure. Novosibirsk: Nauka.

- Durakov I.A. 2014 Metodika izucheniya drevnikh izdeliy iz tsvetnogo metalla. Ucheb. spravochnik. Novosibirsk: Izd. Novosib. Gos. Ped. Univ.

- Gladilin A.V. 1985 Metallurgiya Sredneangariya. In Arkheologicheskiye issledovaniya v rayonakh novostroyek Sibiri. Novosibirsk: Nauka, pp. 167–180.

- Konkova L.V. 1989 Bronzoliteinoye proizvodstvo na yuge Dalnego Vostoka SSSR (rubezh II–I tys. do n.e. – XIII vek n.e.). Leningrad: Nauka.

- Medvedev V.E. 1982 Srednevekovye pamyatniki ostrova Ussuriyskogo. Novosibirsk: Nauka.

- Medvedev V.E. 1991 Korsakovskiy mogilnik: Khronologiya i materialy. Novosibirsk: Nauka.

- Nesterov S.P., Alkin S.V. 1999 Rannesrednevekovyi mogilnik Chaliba na r. 2-ya Sungari. In Traditsionnaya kultura vostoka Azii, iss. 2. Blagoveshchensk: Izd. Amur. Gos. Univ., pp. 153–176.

- Nesterov S.P., Maksimov S.M. 1990 Srednevekovyi klad s r. Selemdzhi. In Voyennoye delo drevnego i srednevekovogo naseleniya Severnoi i Tsentralnoi Azii. Novosibirsk: Poligraf, pp. 121–128.

- Nesterov S.P., Mylnikov V.P., Shelomikhin O.A., Mamul Y.M., Yakovlev A.V. 2014 Issledovaniye pamyatnika Ozero Dolgoye v Amurskoi oblasti v 2014 godu. In Problemy arkheologii, etnografi i, antropologii Sibiri i sopredelnykh territorii, vol. XX. Novosibirsk: Izd. IAE SO RAN, pp. 247–250.