Economic efficiency of innovation production of removable building structures

Автор: Dokunikhin Nikolay Ivanovich

Журнал: Economic and Social Changes: Facts, Trends, Forecast @volnc-esc-en

Рубрика: Business sectors

Статья в выпуске: 2 (10) т.3, 2010 года.

Бесплатный доступ

Open joint stock company «Vologda building designs and road machines factory» realized the innovative program 454.3 million roubles worth of mobile buildings manufacturing in 2007 - 2009. That madepossible to double productivity of block-containers, increase sales volume from 1731.2 to 2183.9 million roubles, increase profit from 260 to 399.4 million roubles and keep personnel size in crisis years 2008 - 2009.

Innovation, mobile buildings, manufacturing, economics

Короткий адрес: https://sciup.org/147223193

IDR: 147223193 | УДК: 65.011(470.12)

Текст научной статьи Economic efficiency of innovation production of removable building structures

Under the market economy conditions the reliability of enterprise activity is determined by the level of innovation activity – capacity to produce high competitive product. Foreign and domestic experience shows that the most stable enterprises at the market are those enterprises which are based in their development on their own scientific and technical potential ensuring the production output of high consumer properties. In the Vologda region one of such enterprises is PlC “Vologda building structures and road machines plant” (till 2007 “Vologda machine-building plant”). The plant was established on the basis of auto repair workshops and in 1917 it was reoriented to the production of road-building machinery: heavy-duty trailers, scrapers and removable buildings for personal services of road builders. In 1990-s in connection with elimination of plan-distribution system of management and country’s transition to market economy there was a sharp drop in plant’s product. The way out of the protracted crisis started with expansion of block-containers production. Since 2002 having taken the experience and the market conditions into account the plant reoriented its activity to the production of fast-erected buildings of various functionalities.

At present PlC “Vologda building structures and road machines plant” produces one-, two-, three-stored buildings of panel and rack-mount structure under the trademark of “Voldom” and three kinds of block-containers under the trademark of “MobiKon”: welded box blocks (BCS-700), prefabricated demountable structures (BCS-600) and movable blocks with their own undercarriage. Their manufacturing features are given in table 1 . Over 70% of total production is the share of bloc-containers.

The marketing research established that some buildings are in keen demand at the market. These buildings have such design, technical and performance characteristics which ensure comfort, environmental safety of dwelling in various climatic zones, performance reliability under static and dynamic load, possibility to construct the rooms of different planning, multitasking functionality of use and short terms of building with reasonable prices [1, 2, 3].

Table 1. The technical characteristics of block-containers

|

Marking |

Overall dimensions, m (width x iength height) |

Internal height, m |

Mass, kg at the most |

|

BCS600 |

2.438 x 6.058 x 2.590 |

2.2 |

3,000 |

|

BCS601 |

3.000 x 9.125 x 2.810 |

2.4 |

5,000 |

|

BCS602 |

3.000 x 6.058 x 2.810 |

2.4 |

4,000 |

|

BCS700 |

2.438 x 6.058 x 2.590 |

2.2 |

3,000 |

|

BCS701 |

3.000 x 9.125 x 2.810 |

2.4 |

5,000 |

|

BCS702 |

3.000 x 6.058 x 2.810 |

2.4 |

4,000 |

|

BCM-4 |

2.500 x 6.600 x 3.768 |

2.2 |

7,500 |

|

BCM-4.1 |

2.500 x 8.000 x 3.988 |

2.4 |

8,500 |

|

BCM-5 |

2.800 x 8.000 x 3.988 |

2.4 |

9,000 |

When the competition being intensified in order to extend the product market in 2007 – 2009 plc “Vologda building structures and road machines plant” worked out and realized the innovation-and-investment program for technical reequipment and production of new generation of removable prefabricated demountable block-containers as well as construction of buildings of various functionalities on their basis. The fulfillment of this program made it possible to create cyclic-line production technology, to improve the existing structures of block-containers and to work out new ones in the main as well as to create new planning solutions concerning the erection of panel and rack-mount structure buildings.

The plant has performed high volume of engineering developments, 11 of which have been protected by patents for inventions and useful models in Russia and Germany. The most important engineering developments of the plant are new building elements and their joints ensuring production of removable prefabricated demountable buildings of various planning and different number of storeys [4, 5, 6, 7].

The production has new technological equipment and rigging for the processes of metal blanking, stamping, welding, metal machine working and woodworking.

The most important new technological solutions are the following: reduction of heat conductivity of covering panels by overlaying foamed polyurethane onto the internal elements of the panel metal structure; improvement of corrosion resistance of the external metal boarding of the containers by powder paint spraying; increase in durability of wooden elements of structure thanks to wood preservative and fire retardant; improvement of quality of coating and product design owing to the use of paint-and-lacquer materials with acid hardening. The execution of the modernization program made it possible to increase productivity and labour safety as well as to improve the industrial processing control.

The produced removable structures are characterized by high seismic stability (up to 9 points on the Richter scale) and they can be used under the atmospheric temperature from +45°С to -55°С, they are hard to snow load up to 320 kg per sq. m and wind load up to 85 kg per sq m. The prefabricated building structures ensure the opportunity to transport them knocked-down (packaged) by using different kinds of transport and the block-container buildings can be redeployed many times.

The block-containers can be used both in a detached way and a semidetached way with different spatial planning and different number of storeys. Such structures are equipped with heating utility, water supply and sewerage, ventilation and electrical equipment conditioning.

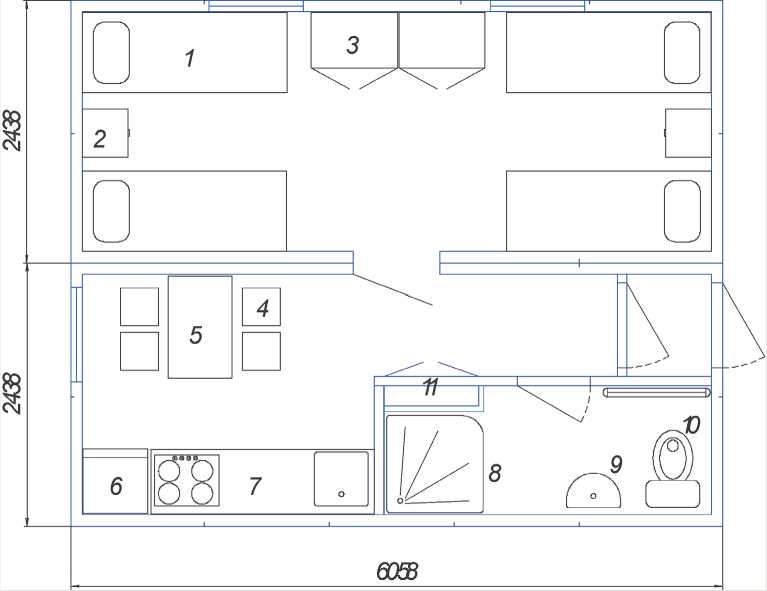

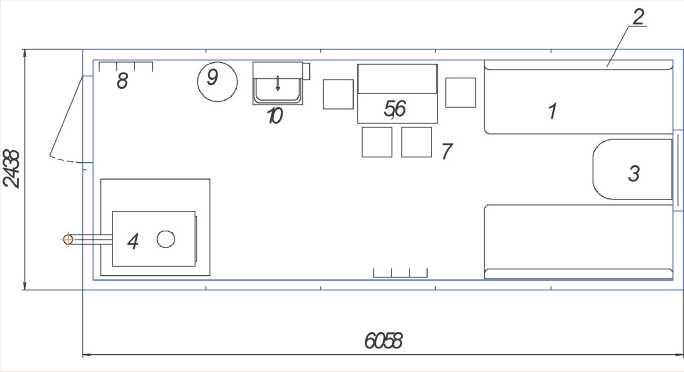

The engineering solutions that are designed in the building structures make it possible to construct the projects with different architecture-planning solutions. The examples of planning decisions in the structures made of detached and semidetached block-containers are given in figures 1 and 2 .

Figure 1. Block-section composed of two containers for 4 persons

Symbols: 1 – bed, 2 – bedside table, 3 – two-door wardrobe, 4 – stool, 5 – dinner table, 6 – household refrigerator, 7 – kitchen table with fitting kitchen sink and electric cooker, 8 – shower tray, 9 – ceramic wash basin, 10 – toilet bowl, 11 – built-in closet.

Figure 2. The workers’ building structure “Lesnik

Symbols: 1 – bed-chest, 2 – folding bed, 3 – table, 4 – solid fuel stove, 5 – dinner table, 6 – hinged shelf, 7 – stool, 8 – wall hung clothes rack, 9 – water tank, 10 – wash basin and waterheater.

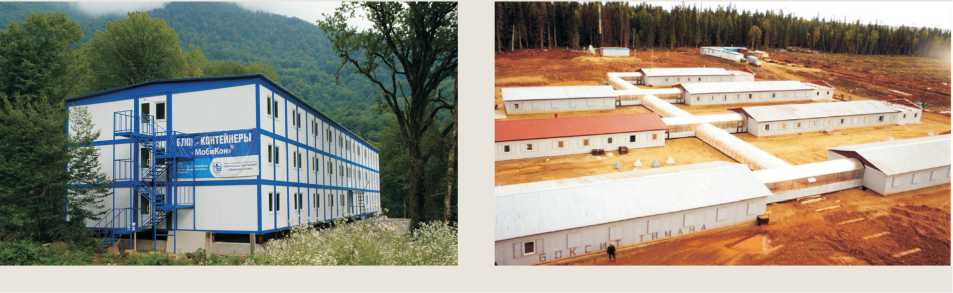

Two- and three-storey building structures are assembled on the basis of prefabricated demountable structures of block-containers BCS-600 (fig. 3). The use of interstorey panels protected by the RF patent №81507 makes it possible to reduce the heat loss at the expense of absence of interstorey clearance and to cut the costs by 15 – 20% for making and constructing the building structures.

The plant worked out the structures and made habitable complexes, personal services complexes, administrative and production

Figure 4. Camp for shift work with pedestrian tunnels (square is 1880 sq m) in the Komi Republic, Sredne-Timanski mine

Figure 3. The prefabricated demountable three-storey building structure composed of blockcontainers (the city of Sochi)

complexes: hostels from 8 to 300 and more people, canteens for 20 – 200 seats, offices, medical stations, shops, bathhouses, shower cubicles, laundry and other buildings of different levels of decoration work and kitting-up.

The high grade of block-containers manufacture makes it possible to erect buildings in the natural disaster areas within the shortest possible time and to organize the camps for shift work especially in the places of undeveloped infrastructure (fig. 4) .

The execution of the innovation program in the value of 454.3 million roubles enabled the plant to increase in the following: sales of products from 1731.2 to 2183.9 million roubles; production of block-containers from 2,993 to 6,361 units; profit from 260 to 399.4 million roubles in 2009 as against 2007 (tab. 2) .

The use of patented workings made it possible to bring down the prime cost of modular building structures by 15 – 20% and to get the economic effect overall 76.2 million roubles in 2009. The plant facilities ensure the production of over 400 block-containers every month and 8,000 sq m building structures of panel and rack-mount construction. The structures produced by the plant have the cost by 20 – 30% less than the cost of the traditional house building (brick, block, cast-in-situ and others).

Being new products of 2009 the block-containers of prefabricated demountable structure and removable model are listed for “The 100 best Russia’s goods” and PlC “Vologda building structures and road machines plant” became a laureate of “The 100 best Russia’s goods” program.

Table 2. The financial and economic indicators of plc “Vologda building structures and road machines plant” activity

|

Technical and economic indicators of the enterprise |

Unit of measurement |

Reporting periods by years |

||

|

2007 |

2008 |

2009 |

||

|

Sales of products |

Million roubles |

1731.20 |

1762.80 |

2183.90 |

|

Production of block-containers |

Unit |

2,993 |

3,141 |

6,361 |

|

Average list number of workers |

Person |

1,141 |

1,173 |

1,211 |

|

Output per a worker |

Roubles/month |

126438.80 |

125234.44 |

150282.14 |

|

Amount of paid taxes |

Million roubles |

277.00 |

326.00 |

340.90 |

|

Including: in the federal budget |

Million roubles |

125.00 |

142.00 |

152.00 |

|

in the regional budget |

Million roubles |

92.0 |

118.00 |

120.00 |

|

in the state off-budget funds |

Million roubles |

60.00 |

66.00 |

68.70 |

|

Capital investments |

Million roubles |

111.00 |

201.00 |

142.30 |

|

Profit before taxes |

Million roubles |

260.00 |

310.80 |

399.40 |

In 2008 – 2009 the plant got the medals and awards for high quality of its products: at the exhibition “The future building industry – 2008” in Sochi; at the IX All-Russian exhibition “The Russian producers and supplies of armed forces”; at the international show “Complex safety – 2008”.

The production activity of PlC “Vologda building structures and road machines plant” has a great influence over the improvement of social and economic condition of the Vologda region. During three recent years (2007 – 2009) in the region the administrative and personal service complex in the industrial park “Sheksna”, the camp for those who build the compressor station “Yubileynaya” (the Totem district) and the personal service building for the closed corporation “North gas mains” (the town of Gryazovetz) have been constructed with over 300 block-containers being used.

In 2005 – 2009 in the Vologda region the plant built 23 building structures of panel and rack-mount construction at the total square 21,600 sq m including 9 habitable houses at the square of 12,550 sq m besides the buildings of container structure. The plant is the participant of the national project “Affordable and comfortable dwelling – for the citizens of Russia” and built comfortable and low-cost houses in the towns of Babaevo, Vologda, Velikii Ustyug, Harovsk and in the settlements of Vozhega and Sheksna. The projects built by the plant are also the treatment and health-improving building for 100 seats in the town of Velikii Ustyug, the school in the settlement of Turovetz and the bus station in the settlement of Nyuksenitza.

In 2007 – 2009 the plant paid the taxes overall 330 million roubles in the regional budget including 120 million roubles in 2009. The number of workers at the plant increased by 70 people in 2009 as against 2007 and made up 1,211 people by increasing the output per one worker up to 150,3 thousand roubles per month (tab. 2). To provide the production with raw materials, stock and component parts PlC “Vologda building structures and road machines plant” make use of services of more than 50 enterprises and organizations of the Vologda region including the Closed Corporation “Severstal-invest”, Society with Limited Liability “Tekhnoindustriya”, Society with Limited Liability “Teplosfera”, the concern “Vologda lumbermen” and the Sheksna fiberboard center. These enterprises and some others render services to PlC “Vologda building structures and road machines plant” every year to the amount of over 500 million roubles and that in turn ensures the additional employment of more than 500 people at these enterprises.

Thus the active innovation and investment development strategy prevented PlC “Vologda building structures and road machines plant” from being involved in economic crisis and from declining in production economy at some co-operating enterprises in the region. All this favoured the improvement of social and economic condition in the Vologda region.

The product produced by the plant is widely used in gas and oil processing sectors, mining sectors, geological survey sectors and building sectors when erecting some temporary camps for builders, camps for shift workers which are composed of the projects of various functionalities: hostels, canteens, administrative and personal service complexes, office blocks, hotels, diesel-engine power plants and others.

The regular consumers of removable blockcontainers are such famous companies as PlC “Rosneft”, “Lengasspetzstroy”, “Most”, Closed Company “Transstroy” as well as a number of foreign companies operating in the territory of Russia: the French companies “Total” and “Schlumberger”, the Russian and American company “Polyarnoe siyanie”. The plant developed, made and assembled 18 building structures of block-container construction for the corporation “Transstroy” in the Sakhalin Island.

The vigorous innovation and investment activity enabled the plant to become one of the

Russia’s leading removable structure producers and to take part in two large federal programs as well: the project construction for the Sochi Olympic Games in 2014 and the Asian-Pacific economic community summit in 2012. It is planned to build 14 camps with more than 110,000 sq. m of the total square of removable building structures in these projects.

Список литературы Economic efficiency of innovation production of removable building structures

- Stepanov, I.V. Removable buildings and structures: reference book/I.V. Stepanov. -M.: Stroizdat, 1998 -319 p.

- Karasev, N.N. Removable buildings and complexes on the basis of open structural systems/N.N. Karasev -M.: Stroizdat, 1987 -136 p.

- Persich, A.I. On the issue of removable building made of lightweight constructions/A.I. Persich//Industrial and civil construction. -2006. -№1. -Pp. 45-46.

- Patent 66756 Russian Federation, MPK7 E04 B1/38. Butt joint elements of the block-container (options)/Yu.A. Shalagin; applicant and patentee PlC “Vologda building structures and road machines plant”. -№2007111144; Applied March, 26, 2007; Published September, 27, 2007. Bulletin №27.

- Patent 81507 Russian Federation, MPK7 E04 B1/343. Connection between the frame interstorey panel with corner posts (options)/Yu.A. Shalagin; applicant and patentee PlC “Vologda building structures and road machines plant”. -№2008130690; Applied July, 24, 2008; Published March, 20, 2009. Bulletin №8.

- Patent 20 2008 017 414.7 Germany, IPC B65D 90/08, Sto verbindung der Elemente eines Block-Containers, Otkrytoe Akcionernoe Obshestvo Vologodskiy Zavod Stroiteinyh Konstrukciy I Dorojnyh Mashin, Vologda, RU. -10 2008 015 468.7; Applied March, 22, 2008; Published September, 24, 2009.

- Patent 86623 Russian Federation, MPK7 E04 С2/38. Frame panel/Yu.A. Shalagin; applicant and patentee PlC “Vologda building structures and road machines plant”. -№2009118753; Applied May, 18, 09; Published September, 10, 2009. Bulletin №25.