Effect of abrasive flow machining on the roughness and microhardness of the small channels (holes) surface in samples of 12X18N10T steel workpieces

Автор: Levko V.A., Litovka O.V., Petetskaya A.E., Ivanov P.A., Snetkov P.A.

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Technological processes and material science

Статья в выпуске: 1 vol.26, 2025 года.

Бесплатный доступ

The article contains the results of research on the effect of abrasive flow machining on the roughness and microhardness of the surface of small channels (holes) in samples of workpieces made of 12X18H10T steel. Empirical dependencies of the change in roughness and microhardness of the surface of a small channel on the degree of filling of the working medium with a plasticizer and the shear pressure of the hydraulic system with the extreme of these functions in the studied area are obtained. Based on these dependencies, the composition of the working environment was selected: the degree of filling of the work-ing media base (with a constant content of white electro corundum – 30 %) with a plasticizer in the form of diamond paste (ACN 60/40 BOM Г) Ka 40 % and CKT rubber 30 %, respectively. As a result of abrasive flow machining, it was possible to reduce the roughness of the surface layer from Ra = 0.49…0.62 µm to Ra = 0.047…0.06 µm, and also to increase the microhardness of the surface from h = 188…192 HV to h = 213…220 HV. The thickness of the hardened layer is ≈ 7.24 µm. Analysis of surface profilograms shows that as a result of abrasive flow machining, both the height roughness parameters (average – Ra, Rz, Rp; maximum – Rmax) and the depth roughness parameters (Rk) were significantly reduced. Using electron microscopy (SEM MAG), a qualitative assessment of the structure of the surface layer of the small channel was carried out. The obtained results show good machinability by abrasive flow of austenitic steel blanks, in particular 12X18H10T steel.

Abrasive flow machining, 12X18N10T steel, roughness, microhardness, small channel

Короткий адрес: https://sciup.org/148330604

IDR: 148330604 | УДК: 621.923.01 | DOI: 10.31772/2712-8970-2025-26-1-140-152

Текст научной статьи Effect of abrasive flow machining on the roughness and microhardness of the small channels (holes) surface in samples of 12X18N10T steel workpieces

Currently in the production of parts from austenitic steels, one of the issues remains the final processing of the internal surfaces of channels (holes) with a small cross-sectional area. Therefore, when assessing the quality of execution of a small diameter hole, the main criteria are accuracy, shape, presence and size of taper along the depth of the channel, surface roughness, presence of microcracks, and burrs [1].

To form such surfaces, various methods are widely used: cutting (drilling) with small-diameter drills, laser and electron beams; electrical discharge machining; electrochemical and ultrasonic machining; jet-abrasive machining, and others, each of which has its own advantages and disadvantages [2]. One of the disadvantages is the low quality of the surface of such channels.

In mechanical engineering, to reduce roughness and increase the microhardness of the surface layer of parts made of austenitic steels, finishing and hardening technologies are used, such as ultrasonic impact hardening with strikers [3] and balls in a vacuum [4], complex liquid [5] and plasma nitriding [6], laser hardening [7], friction [8], shot blasting [9] and ion-plasma processing [10]. However, in the case of processing such hard-to-reach surfaces as holes and channels of small cross-sections, the above technologies have a number of limitations.

For the final machining of small holes and channels, abrasive flow machining (AFM) is increasingly used, in which a highly viscous material (working medium) is uniformly filled with abrasive particles; it is reciprocated by pistons of working cylinders through the workpiece. With this flow, the medium replicates the shape of the channel being processed, creating compressive pressure on the surface being processed and implementing abrasive contact [11].

Since the 1980s, the AFM method has been used to remove defective layers in cooling holes of blades and disks processed by laser or electrical discharge machining, remove burrs in fuel injector holes, and polish cast surfaces of blades, compressor wheels, and impellers [12].

Currently, this technology is increasingly used to reduce roughness and increase the microhardness of closed channels of parts made of austenitic-martensitic steels [13], including those obtained by selective laser melting [14].

By treating the internal channels of maraging steel 300 samples obtained by selective laser melting with an abrasive flow, it was possible to increase the fatigue strength by 26%. However, when the diameter of the processed holes was reduced to 3 mm or less, problems with the flow of the medium in these holes arose [15].

These problems are associated with the high viscosity of the working medium of traditional composition. It is known that to process such holes in small-sized parts, the micro AFM method is widely used, in which low-molecular non-Newtonian media are used as the basis of the working medium [16]. However, the use of micro AFM technology for parts made of difficult-to-machine alloys leads to a decrease in processing productivity, since low-molecular media exhibit weak elastic properties [17].

Adding diamond paste to the high-molecular medium allows controlling the viscosity of the working medium relative to the geometric characteristics of the channel being processed and performing final processing of bidirectional AFM.

The purpose of the research is to study the effect of an abrasive flow treatment of a mediumviscosity working medium on the roughness and microhardness of the inner surface of small channels of samples made of austenitic steel 12X18N10T.

Research methodology

As a result of previous studies of the process of abrasive-extrusion processing of small holes, a composition of the working medium was experimentally determined that maintains the possibility of its shear flow in a hole with a small cross-section and the maximum stress-strain state, which makes it possible to achieve maximum productivity in processing small channels in samples made of aluminum alloy АМг6 (Al 93 % Mg – 6%). Composition of the medium (by weight): synthetic high-molecular rubber (СКТ) – 40 %, diamond paste – 60 %, dispersion of white corundum Ba = 40 – 63 µm. The paste used was АСН 60/40 ВОМ Г – Ка = 28 % (polishing slurry with diamond high in content). Shear pressure P inlet = 12 MPa. Processing time – 60 sec. The processing was carried out with the УЭШ-25 installation [17].

The above-described methodology was adopted as the methodological basis for these studies, taking into account that the previously obtained dependencies of the roughness of the machined hole Ra decrease monotonically over the entire studied interval, and the value of the removed metal layer Δ l increases monotonically during processing, that means the extremes are not defined [17].

To find the extremes of the empirical dependencies of the roughness Ra on the composition of the working environment and the shear pressure of the hydraulic system P shear, it is proposed to expand the range of variation of the parameters of the weight content of the components of the working environment.

The experiments were conducted according to the Kono plan (m = 2, number of repetitions at one level – 6). Variable factors: degree of filling of the working environment base (with constant content of white electrocorundum – 30%) with plasticizer in the form of diamond paste (АСН 60/40 ВОМ Г) Ka – 30, 40, 50% and rubber СКТ – 40, 30 and 20% respectively; hydraulic system shear pressure P shear – 8, 10, 12 MPa. Grains of normal electrocorundum were used as filler. The grain size Ba = 63 µm was determined according to the recommendations for selecting the type and size of filler grain during abrasive flow processing [18]. The processing time and shear pressure remained the same as in the previous study. For mathematical processing, variables were coded x 1 = Ка , x 2 = Ва , y 1 = Ra , y 2 = h .

The following properties of 12X18H10T steel should be noted: density – 7.9 g/cm3; elastic modulus (Young's modulus) – 193 GPa; tensile strength – in the annealed condition about 520–680 MPa, after heat treatment up to 900 MPa; yield strength in the annealed condition 205 MPa, after hardening up to 600 MPa; relative elongation after rupture – 40–60 %; impact toughness – 600–1000 kJ/m2; Brinell hardness – in the annealed condition 140–180 HV, after heat treatment up to 300 HV.

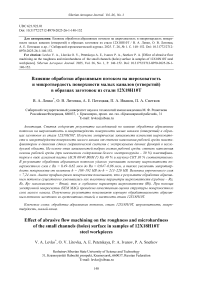

54 samples (Fig. 1, a ) are made of annealed sheet rolled austenitic steel 12Х18Н10Т (GOST 5632– 2014). Small channel 1 (Fig. 1, b ) was obtained by milling with an end mill in one pass; reference point 2 is intended to control the amount of metal removed based on the results of abrasive flow processing.

Geometric characteristics of the processed channel: length L k = 10 mm, section dimensions (width x height) 20.625 mm, cross-sectional area SCSA = 1.25 mm2. The shape, size and angle of the inlet and outlet sections of the channel are identical.

а

b

Рис. 1. Образцы заготовок из стали 12Х18Н10Т с малыми каналами: а – набор из 54 образцов; b – единичный образец: 1 – малый канал; 2 – реперная точка

Fig. 1. Samples of 12X18H10T steel workpieces with small channels: a – set of 54 samples; b – single sample: 1 – small channel; 2 – reference point

The initial surface roughness of the samples varied in the range Ra = 1.2–1.4 μm, the initial surface roughness of the small channel after milling was Ra = 0.49–0.62 μm.

The initial microhardness of the sample surface varied in the range h = 175–179 HV. After milling, the microhardness of the surface of small channels in the samples increased and varied in the range h = 188–192 HV.

Research results and their discussion

The results of abrasive flow treatment of 54 samples with small channels depending on factors X1 and X2 are given in Tables 1 and 2.

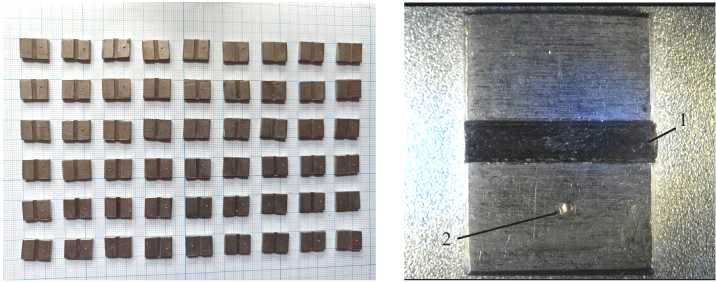

The the dependency graph of the change in the surface roughness of a small channel in a sample made of 12Х18Н10Т steel on the degree of filling of the working medium with plasticizer Ka (X1) and the shear pressure of the hydraulic system Pshear (Fig. 2, a) shows the presence of extremes of empirical dependencies in the region of 40% filling of the working medium with plasticizer (diamond paste) for the entire range of shear pressures under consideration.

Table 1

Surface roughness of small channels after abrasive flow treatment depending on the degree of filling of the working medium with plasticizer and the shear pressure of the hydraulic system

|

Factors |

Roughness Ra , µm |

Average value for 6 experiments Ra , µm |

||||||

|

X1 |

X2 |

1 |

2 |

3 |

4 |

5 |

6 |

|

|

1 |

1 |

0.102 |

0.099 |

0.105 |

0.106 |

0.098 |

0.106 |

0.103 |

|

–1 |

1 |

0.088 |

0.094 |

0.086 |

0.086 |

0.090 |

0.086 |

0.088 |

|

1 |

–1 |

0.120 |

0.130 |

0.123 |

0.135 |

0.127 |

0.125 |

0.127 |

|

–1 |

–1 |

0.099 |

0.095 |

0.095 |

0.101 |

0.105 |

0.105 |

0.100 |

|

1 |

0 |

0.120 |

0.123 |

0.118 |

0.120 |

0.121 |

0.117 |

0.120 |

|

–1 |

0 |

0.095 |

0.098 |

0.091 |

0.095 |

0.095 |

0.103 |

0.096 |

|

0 |

1 |

0.047 |

0.050 |

0.050 |

0.048 |

0.048 |

0.049 |

0.049 |

|

0 |

–1 |

0.065 |

0.067 |

0.069 |

0.070 |

0.065 |

0.065 |

0.067 |

|

0 |

0 |

0.060 |

0.055 |

0.065 |

0.060 |

0.059 |

0.061 |

0.06 |

Table 2

Microhardness of the surface of small channels after processing with an abrasive flow depending on the degree of filling of the working medium with a plasticizer and the shear pressure of the hydraulic system

|

Factors |

Microhardness h , HV |

Average value for 6 experiments h , HV |

||||||

|

X1 |

X2 |

1 |

2 |

3 |

4 |

5 |

6 |

|

|

1 |

1 |

215 |

213 |

216 |

216 |

214 |

216 |

215 |

|

–1 |

1 |

212 |

211 |

210 |

213 |

213,00 |

213 |

212 |

|

1 |

–1 |

209 |

210 |

208 |

209 |

208 |

210 |

209 |

|

–1 |

–1 |

206 |

206 |

205 |

205 |

207 |

207 |

206 |

|

1 |

0 |

212 |

212 |

211 |

213 |

213 |

211 |

212 |

|

–1 |

0 |

209 |

207 |

210 |

210 |

209 |

209 |

209 |

|

0 |

1 |

220 |

221 |

218 |

221 |

220 |

220 |

220 |

|

0 |

–1 |

213 |

211 |

214 |

214 |

213 |

213 |

213 |

|

0 |

0 |

217 |

218 |

218 |

216 |

216 |

217 |

217 |

Roughness Ra, µm

0,14

0,04

0,02

Factor X1

a

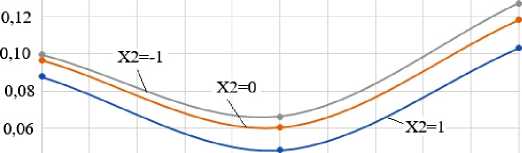

Рис. 2. График зависимости показателей поверхности малого канала в образце из стали 12Х18Н10Т от степени наполнения рабочей среды пластификатором Ка (X1) и давлением сдвига гидравлической системы P сд (X2): а – шероховатости; b – микротвердости

-

Fig. 2. Dependency graph of the small channel surface parameters in a 12X18H10T steel sample on the degree of filling of the working medium with plasticizer Ka (X1) and the shear pressure of the hydraulic system Pshear (X2): a – roughness; b – microhardness

With such ratios of the controlled factors X1 and X2, the working medium in the processed sample carries out shear flow with the best combinations of viscous and elastic properties. For the microhardness index (Fig. 2, b ), the extremum of the empirical dependency is also observed for the region of 40 % filling of the working medium with plasticizer and the maximum value of shear pressure.

In the coded expression, the empirical dependence of roughness is defined as roughness:

Y1 = 60,63 + 10,8X1 – 8,9X2 + 47,1X12 – 3,1X22 – 3,1X1X2. (1)

Statistical characteristics: maximum dispersion S2max = 0.236; dispersion of mean value reproducibility S2(y) = 0.261; dispersion of first-order responses S 1 2 = 293.99 (non-zero, since S 1 2/S2(y) = 1126.4 > F0.05(2;18) = 3.55); dispersion of second-order responses S 2 2 = 148567 (significantly nonzero, since S 2 2/S2(y) = 569222 > F0.05 (3;18) = 5.09); residual dispersion S2 residual = 1.389; the value of Fisher's criterion at a significance level of α = 0.05 is equal to Fad = 1.389/1.564 = 0.89, which is less than 5.09. The resulting equation adequately describes the experimental data.

Microhardness: Y1 = 216,8 + 1,5X1 + 3,2X2 – 6,2X12 – 0,2X22. (2)

Statistical characteristics: maximum dispersion S2max = 1.333; dispersion of mean value reproducibility S2(y) = 0.16; dispersion of first-kind responses S 1 2 = 198.9 (non-zero, since S 1 2/S2(y) = 1243.1 > F0.05(2;18) = 3.55); dispersion of second-kind responses S 2 2 = 126601 (significantly nonzero, since S22/S2(y) = 791256 > F0.05 (3;18) = 5.09); residual dispersion S2residual = 0.148; the value of Fisher's criterion at significance level = 0.05 is equal to Fad = 0.148/1.564 = 0.09, which is less than 5.09. The resulting equation adequately describes the experimental data.

Based on the results of the study and the obtained dependencies (1) and (2), it is recommended to carry out the abrasive flow treatment of small channels in samples made of 12X18H10T steel with a working medium of the following composition: the degree of filling of the working medium base (with an unchanged content of white electrocorundum - 30%) with a plasticizer in the form of diamond paste (AСH 60/40 BOM Г) Ka 40% and СKT rubber 30%, respectively. The maximum shear pressure of the hydraulic system P shear 12 MPa is limited by the technical capabilities of the installation.

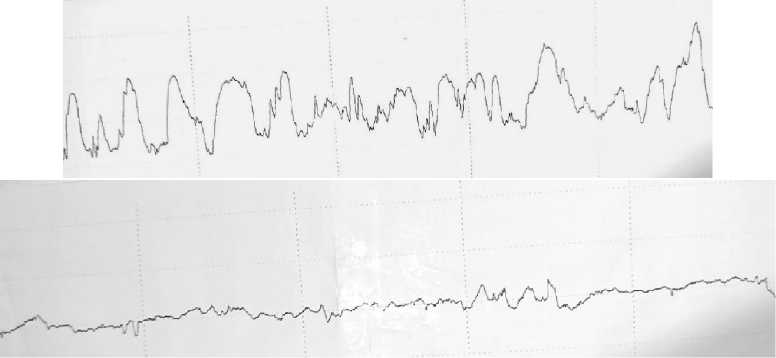

Further studies on the qualitative and quantitative assessment of changes in the structure of the surface layer were carried out on samples processed under the conditions Ka (X1) = 40% and Pshear (X2) = 12 MPa. A quantitative assessment of the change in surface layer roughness was carried out based on profilogram protocols (Fig. 3) obtained on a MarSurf M300 profilometer. Table 3 presents comparative characteristics of the roughness of the surface layer of a small channel.

A comparison of the two obtained profilograms demonstrates that as a result of abrasive flow processing, both the height roughness parameters (average – Ra, Rz, Rp ; maximum – R max) and the depth roughness parameters ( Rk ) were significantly reduced.

The increase in the material components Mr 1 and Mr 2 from 7 to 10% and from 72 to 87%, respectively, shows that such types of contact as microcutting and plastic deformation occurred during the processing. This fact is confirmed by an increase in the microhardness of the channel surface after treatment with an abrasive flow by 12–15% (for the samples under consideration from 189–191 to 213–220 HV).

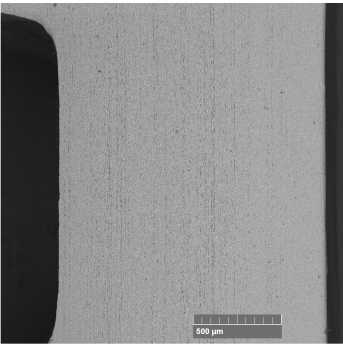

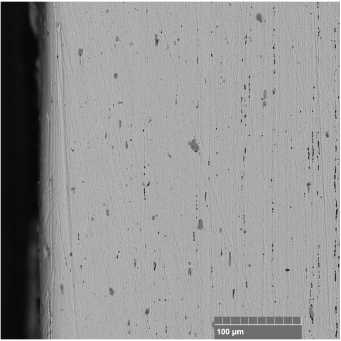

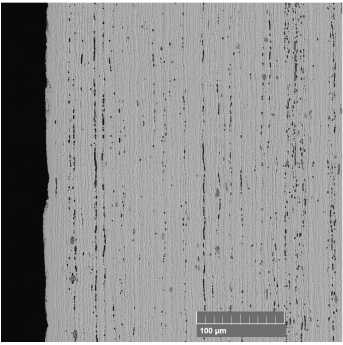

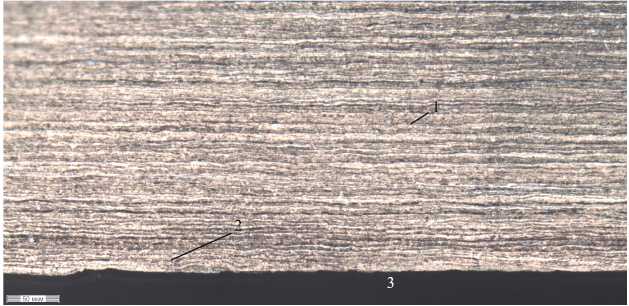

A qualitative assessment of the change in the state of the surface layer of small channels of samples made of 12X18H10T alloy was performed on the basis of images obtained with an optical microscope (Fig. 4). Using electron microscopy (SEM MAG), an image of the channel cross-section profile after AFM (Fig. 5), the structure of the channel surface layer after milling (Fig. 6) and abrasive flow treatment (Fig. 7) were obtained. To study the change in the structure of the sample material after processing with an abrasive flow, a microsection of the channel (Fig. 8) cut along the axial line was examined.

а b

Рис. 3. Профилограмма поверхности канала: а – после фрезерования; b – после обработки абразивным потоком

-

Fig. 3. Profile of the channel surface: a – after milling; b – after AFM

Table 3

Comparative characteristics of the surface layer roughness of a small channel after milling and abrasive flow processing according to profilogram protocols

|

Roughness parameters designation |

Numerical value of parameters |

|

|

after milling |

after AFM |

|

|

Average arithmetic roughness, Ra , µm |

0.464 |

0.047 |

|

Average roughness height, Rz , µm |

1.954 |

0.345 |

|

Maximum roughness height, R max, µm |

2.484 |

0.757 |

|

Average height of profile protrusions, Rp , µm |

0.883 |

0.133 |

|

Core roughness depth, Rk , µm |

1,187 |

0,154 |

|

The material component is defined for the cut line that separates the protruding peaks from the main roughness profile; Mr 1, % |

7 |

10 |

|

The material component is determined for the cut line that separates deep depressions from the main roughness profile; Mr 2, % |

72 |

87 |

The surface structure of the samples in the initial state (Fig. 4, a ) is characterized by rolling traces in the longitudinal direction, forming a regular roughness. Scratches from mechanical impact during movement of samples and their shaping are also visible on the surface. After milling, the surface structure of the small channel (Fig. 4, b ) underwent a number of changes. It is represented by a complex of parallel scratches and depressions of the cutter trace, which are confirmed by the surface profilogram protocol (see Fig. 3, a ).

In general, the surface of the small channel corresponds to the typical surface structure of parts made of 12X18H10T steel after milling.

After treatment with an abrasive flow, the direction of the surface roughness did not change (Fig. 4, c ), but the depth of the scratches was significantly reduced. Micro-roughness of the milling cutter trace is completely removed. This is confirmed by the profilogram protocol (see Fig. 3, b), as well as by a decrease in the R max values from 2.484 to 0.757 µm, Rp from 0.883 to 0.133 µm and Rk from 1.187 to 0.154 µm.

An increase from 72 to 87 % of the material component for the cut line separating the deep depressions from the main roughness profile allows us to conclude that the defective layers from previous rolling and milling operations have been completely removed. An increase in the material component for the cut line separating the protruding peaks from the main roughness profile from 7 to 10 % also indicates a leveling of the structure of the microroughness of the surface layer.

After abrasive flow treatment, a uniform surface layer structure was obtained. In this case, the roughness value was reduced from Ra = 0.49–0.62 µm to Ra = 0.047–0.06 µm. As a result of AFM, the surface microhardness increased from h = 188–192 HV to h = 213–220 HV.

In general, the surface structure shows layering of the material and the presence of microinclusions characteristic of the main layer of the sample material in microsections (Fig. 8).

The cross-sectional shape of the small channel corresponds to the profile of the end mill. Analysis of the geometric contour of the profile of the output edge of the channel cross-section after AFM (Fig. 5) shows the uniformity of processing of the entire profile within the specified processing tolerances.

The image of the surface layer of the channel after milling (Fig. 6) also shows the presence of a number of micro-irregularities of different heights and lengths.

b

c

Рис. 4. Структура поверхности канала:

а – поверхность образца до формообразования канала; b – после фрезерования;

c – после 60 с обработки абразивным потоком

-

Fig. 4. Structure of the channel surface:

-

a – sample surface before channel formation; b – after milling;

c – after 60 seconds of AFM

Рис. 5. Геометрический контур профиля поперечного сечения канала после AFM (142 x)

Fig. 5. Geometrical contour of the channel cross-section profile after AFM (142 x)

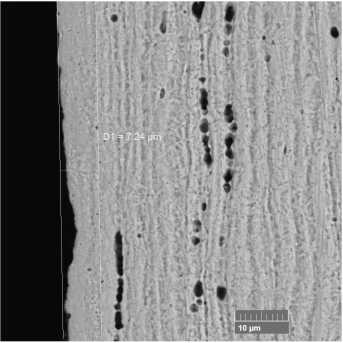

The structure of the surface layer of the channel after abrasive flow treatment, obtained using electron microscopy (SEM MAG) (Fig. 7), reveals the presence of a hardened layer. The image with a magnification of 710 x (Fig. 7, a ) shows the relative uniformity of this layer relative to the entire surface of the channel, and the image with a magnification of 4.33 kx (Fig. 7, b ) made it possible to establish the thickness of the hardened layer as ≈ 7.24 µm. The topography of the treated surface (Fig. 7) also shows an increase in the material components Mr 1 and Mr 2.

Рис. 6. Структура поверхностного слоя канала после фрезерования (708x)

Fig. 6. Structure of the surface layer of the channel after milling (708x)

а

Рис. 7. Структура поверхностного слоя канала после обработки абразивным потоком: а – увеличение 710 x; b – увеличение 4,33 kx

b

Fig. 7. Structure of the surface layer of the channel after AFM: a – magnification 710 x; b – magnification 4.33 kx

A microsection of the sample (Fig. 8), demonstrating the structure of its material, also confirms an increase in the microhardness of the surface layer. Thus, the base material has a layered structure of zone 1 , characteristic of 12X18H10T steel. In the surface layer of zone 2 , the thickness of the layers decreases, which indicates their deformation. Zone 3 corresponds to the radius of rounding of the side wall of the channel.

b

Рис. 8. Структура материала образца, разрезанного вдоль осевой линии канала (микрошлиф): а – увеличение 1,52 kx; b – увеличение 3,81 kx

Fig. 8. Structure of the sample material cut along the channel centerline after AFM (microsection) of the channel surface cut: a – magnification 1.52 kx; b – magnification 3.81 kx

Therefore, as a result of processing with an abrasive flow of the working medium of the established composition in one stage, it was possible to ensure a significant reduction in the roughness of the surface layer of the small channel and increase its microhardness. This demonstrates the good machinability of 12X18H10T steel, in contrast to austenitic-martensitic steels and powder molybdenum alloys, the processing of which was carried out in two stages [13; 19].

Conclusion

As a result of the study of the dependency of the change in roughness and microhardness of the surface of a small channel in a sample made of 12X18H10T steel on the degree of filling of the working medium with a plasticizer and the shear pressure of the hydraulic system, empirical dependencies with the extreme of these functions in the researched area were obtained.

This has made it possible to recommend processing the working medium with an abrasive flow of the following composition: the degree of filling of the working medium base (with a constant content of white electrocorundum - 30%) with a plasticizer in the form of diamond paste (ACH 60/40 BOM Г) Ka 40% and СKT rubber 30%, respectively.

Due to the result of abrasive flow processing, it was possible to reduce the roughness of the surface layer from Ra = 0.49–0.62 µm to Ra = 0.047–0.06 µm, and also to increase the microhardness of the surface from h = 188–192 HV to h = 213–220 HV. The thickness of the hardened layer is ≈ 7.24 µm.

Analysis of surface profilograms shows that as a result of abrasive flow processing, both the height roughness parameters (average – Ra, Rz, Rp ; maximum – Rmax ) and the depth roughness parameters ( Rk ) were significantly reduced.

The results obtained show good machinability of 12X18H10T steel blanks by abrasive flow.