Effect of locust bean pod epicarp ash (LBPEA) on the compressive strength of revibrated concrete

Автор: Auta Samuel Mahuta, Kabiru Adebayo

Журнал: Строительство уникальных зданий и сооружений @unistroy

Статья в выпуске: 5 (90), 2020 года.

Бесплатный доступ

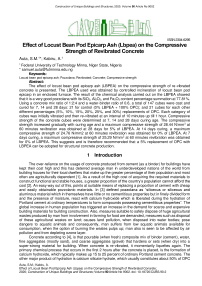

The effect of locust bean pod epicarp ash (LBPEA) on the compressive strength of re-vibrated concrete is presented. The LBPEA used was obtained by controlled incineration of locust bean pod epicarp in an enclosed furnace. The result of the chemical analysis carried out on the LBPEA showed that it is a very good pozzolana with its SiO2, Al2O3, and Fe2O3 content percentage summation at 77.81%. Using a concrete mix ratio of 1:2:4 and a water-binder ratio of 0.6, a total of 147 cubes were cast and cured for 7, 14 and 28 days: 21 for control (0% LBPEA + 100% OPC); and 21 cubes for each other different percentages (5%, 10%, 15%, 20%, 25%, and 30%) replacements of OPC. Each category of cubes was initially vibrated and then re-vibrated at an interval of 10 minutes up till 1 hour. Compressive strength of the concrete cubes were determined at 7, 14 and 28 days curing age. The compressive strength increased gradually with curing age and a maximum compressive strength of 28.44 N/mm2 at 60 minutes revibration was obtained at 28 days for 5% of LBPEA. At 14 days curing, a maximum compressive strength of 24.76 N/mm2 at 60 minutes revibration was obtained for 0% of LBPEA. At 7 days curing, a maximum compressive strength of 25.29 N/mm2 at 60 minutes revibration was obtained for 0% of LBPEA. This suggests and is therefore recommended that a 5% replacement of OPC with LBPEA can be adopted for structural concrete production.

Locust bean pod epicarp ash, pozzolana, revibrated, concrete, compressive strength

Короткий адрес: https://sciup.org/143172528

IDR: 143172528 | УДК: 69 | DOI: 10.18720/CUBS.90.2

Текст научной статьи Effect of locust bean pod epicarp ash (LBPEA) on the compressive strength of revibrated concrete

The over-reliance on the usage of concrete produced from cement (as a binder) for buildings have kept their cost high and this has deterred average man in underdeveloped nations of the world from building houses for their local dwellers that make up the greater percentage of their population and most often are agriculturally dependent [1]. As a result of the high cost of acquiring the required materials to construct functional and stable houses, a greater proportion of the country’s population cannot afford the cost [2]. An easy way out of this, points at suitable means of replacing a proportion of cement with cheap and easily obtainable pozzolanic materials. In [3] defined pozzolana as “siliceous or siliceous and aluminous material which in themselves have little or no cementitious properties but in finely divided form and the presence of moisture, react with calcium hydroxide which is liberated during the hydration of Portland cement at ordinary temperatures to form compounds possessing cementitious properties”. The global increase in human population has triggered an increase in the demand for scarce and expensive building materials for building construction. Also, measures suitable to safely dispose of huge agricultural wastes produced by man from involvement in farming for food are demanded, measures such as disposal of these agricultural wastes on land; causes land pollution, when disposed into water bodies; pose dangers to aquatic animals and consequently, man suffers from low aquatic animals available for consumption, when the option of burning the wastes pulps up; man also is seen to be affected by air pollution and from depleting ozone layer.

Concrete according to [4], is that pourable (when fresh) composite mix of binder (cement), water, fine aggregates (mostly sand), and coarse aggregates (gravel) that hardens or sets (when dry) into a super-strong material for building. When concrete is re-vibrated, it momentarily liquefies again. The primary chemical process that occurs in the first 2 hours after the concrete is placed, is the formation of calcium hydroxide, which typically makes up 15 to 25 percent of ordinary Portland cement concrete. The other major product of hydration is calcium silicate hydrate, which usually constitutes about 50% of OPC Auta, S.M.; Kabiru, A.

Effect of Locust Bean Pod Epicarp Ash (Lbpea) on the Compressive Strength of Revibrated Concrete;

concrete which gives the concrete its hardness and durability. Initial vibration of concrete may not eliminate defects such as honeycomb and voids causing a reduction in strength and performance. But re-vibration can eliminate such defects (honeycomb and voids) and thereby increasing bond, improving concrete quality, better impermeability, reduction in shrinkage and creep, increasing the compressive strength of the concrete, reduction in surface and other voids as well as cracks in fresh concrete and so on [5]. Re-vibration can be done usually at any time as long as the running internal vibrator can sink by its own weight into the concrete before the final setting time of the concrete is reached ([5], [6]). Revibration time lag is one of the major factors that can affect the compressive strength of concrete [5]. Recommended a minimum re-vibration time lag interval of 30 minutes to 4 hours for different w/c ratio, while in another separate work [6] reported that the effect of re-vibration on the strength of concrete was dynamic. A research conducted suggests that re-vibration enhances the strength of concrete once done when the concrete is still plastic. Also, it was clear that flexural strength of Rice Husk Ash (RHA) concrete increases at the early stage of re-vibration, the flexural strength of RHA concrete decreases from 30 minutes to 60 minutes of re-vibration almost for all percentage replacement level of RHA. Further observations showed that re-vibration on early age retarded concrete in which the result shows that the maximum compressive strength was achieved when the concrete was re-vibrated and cured at an older age, thus re-vibration improves many of the quality of hardened concrete ([6], [7], [8]). Another investigation questioned the effect of re-vibration on compressive strength of concrete and concluded that re-vibration resulted in the improvement of compressive strength when carried out within the initial setting time confirming that good re-vibration within standards increases compressive strength ([5], [6], [9]). The effect of re-vibration on the compressive strength of 56 days aged RHA-cement concrete has been investigated and presented. Re-vibration was seen to increase the compressive strength of OPC and OPC-RHA concrete by completely eliminating void, provided it is carried out within the set time of concrete ([5], [7]). The compressive strength of the re-vibrated OPC-RHA at 56 days was generally observed to be higher than the re-vibrated and non-re-vibrated OPC concrete at 28 days curing. It is thus recommended to re-vibrate the concrete up to 20minutes and with reasonable replacement of up to 10% RHA for cement.

Pozzolana is classified into two groups [10]; natural and artificial. Though the natural and artificial classes have similar pozzolana activity, they differ slightly in chemical and mineralogical constituents, but greatly from one another in origin. A number of biomass residues are increasingly being identified as pozzolanas. Utilization of Rice Husk Ash is particularly well improved in the rice-producing regions of the United States and Thailand; rice husk is first used as fuel in the rice parboiling plants, with further utilization of the ash residue as pozzolana in making special quality cement concrete [11]. Other biomass residues that have been identified as having pozzolanic properties include Bamboo Leaf Ash [12], Palm Fruit Ash [13], Locust bean pod epicarp ash [14] and Corn Cob Ash [15]. Low-cost agro-wastes are also being investigated as partial OPC replacement materials because of their pozzolanic properties. These materials might also warrant further investigation in the development of regional hydraulic-lime pozzolana concretes (HLPCs): rice-husk ash [17], sugar cane bagasse [18], saw dust ash [19], corn cob ash [15], coconut husk ash [20], Locust bean pod ash [16], cassava waste ash [20], olive waste ash [21] and periwinkle, oyster and snail shell ash [22]. In [23] reported that the locust bean pods epicarp (Fig. 1) were spread over mud walls and as soon as rain begins to fall on the pods, the leachate percolates down the wall. These buildings and fence walls have been found by the natives to withstand over a long period of time under varying weather conditions such as rains, wind, and heat. The African locust bean (Parkia biglobosa) has a wide distribution ranging across the Sudan and western coast of Africa in Senegal. Concentrated locust bean pod extract is used to impart water resiliency to floors, walls, and ceramics pot. The tannins present in the epicarp act to bind the soil by their polymeric nature and render the surface impervious to water, sealant to the pot, and creates a dark, mottled surface.

Fig. 1: Locust Bean Pod Epicarp

When rice husk is burnt under controlled conditions, the RHA is highly pozzolanic, but when in an uncontrolled manner, it was concluded that the ash which is essentially silica is converted to crystalline forms and become less reactive [24]. However, when blended with cement to produce concrete, it is observed to be highly pozzolanic. In [25] obtained LBPEA by incinerating locust bean pod peel up to 600oC using a kiln fueled by kerosene. The ash was allowed to cool, then grinded and sieved through sieve 0.250 ASTM micro sieve. Cement was replaced with 5 to 25% LBPEA and the result showed that the higher the ash content, the less the compressive strength value. In [25] concluded that the decrease in strength was due to the percentage of (SiO 2 + Al 2 O 3 + Fe 2 O 3 ) content of the ash (63.57%) which was less than 70% as required for any material to behave as a pozzolana although they later maintained that the compressive strength of the cement-LBPEA concrete is adequate enough for use as a load bearing building material. According to [7] the use of RHA as a partial replacement for cement in concrete is not recommended when re-vibration is not envisaged as it results in concrete having very low compressive strength at all ages of curing. An average duration of 90 minutes is recommended for re-vibration of concrete with 20 % RHA as cement replacement for optimal or higher compressive strength. An investigation was conducted on the usage of wood waste ash as a partial cement replacement material in the production of structural grade concrete and mortar, assessment of the fresh concrete properties of self-compacting concrete containing SDA, and it was evident that ash from timber waste was a material capable of replacing cement [26].

Much work has not been reported on the behavior of re-vibrated concrete produced from Locust bean pod epicarp ash (LBPEA) as a partial replacement for cement. As such, this study aims to examine the effect of LBPEA on compressive strength of re-vibrated concrete cubes made from 5%, 10%, 15%, 20%, 25%, and 30% replacements of OPC.

2 Materials and Methods

Materials that were used in the laboratory experiments were subjected to tests of their physical, chemical, and engineering properties with the ultimate aim of determining the compressive strength of re-vibrated concrete using 5% to 30% of LBPEA as a replacement for OPC.

-

2.1 Materials

The materials for this research work include:

OPC: The binder used for this work was Ordinary Portland Cement grade 43 (Dangote Cement), obtained from a cement depot at Mobile area of Minna, Niger State, conforming to BS 12:1996 was used;

Fine aggregates: Clean sharp sand of maximum size 5 mm collected from a nearby building material dealer in Minna, Niger State conforming with the provisions of BS EN 12620: 2013 was used.

Coarse aggregates: Coarse aggregates of maximum size 20 mm collected from a nearby building material dealer in Minna, Niger State conforming with the provisions of BS EN 12620: 2013 was used.

Locust bean pod epicarp ash (LBPEA): Clean dry Locust bean pod epicarp (Fig. 1) collected from trees at Kangi village in Bida local government area and around Gidan kwano campus of the Federal University of Technology-Minna, both in Niger state. The pods were incinerated using a furnace at the Civil Engineering laboratory of the Federal University of Technology, Minna. The ashes (Fig. 2) obtained, Auta, S.M.; Kabiru, A.

Effect of Locust Bean Pod Epicarp Ash (Lbpea) on the Compressive Strength of Revibrated Concrete;

were passed through sieve 75μm. The chemical analysis of the LBPEA (Fig. 2) was conducted at the chemistry laboratory and the result presented in Table 1.

Water: Potable tap water from the borehole provided near the Civil Engineering laboratory of the Federal University of Technology, Minna (Gidan Kwano campus), Niger state was used.

Fig. 2: Locust bean pod epicarp ash (LBPEA)

-

2.2 laboratory tests methods

-

2.3 Concrete production

-

2.4 Vibration and re-vibration of concrete samples

-

2.5 Curing of concrete cubes

-

2.6 Compressive strength test

For the purpose of classification and checking compliance, the following laboratory tests were carried out on the aggregates: Specific gravity test; Bulk density, porosity and void ratio test; Moisture content test; Particle size distribution (sieve analysis) test.

Component materials for concrete were mixed using the Absolute Volume Method and the concrete was cast into moulds of dimension 150 × 150 × 150 mm. The fresh concrete in the moulds were vibrated immediately and re-vibrated at 10 minutes’ intervals for 1 hour. A slump test was conducted on the fresh concrete to check workability. Water curing method was used to cure the concrete produced. Compressive strength of the concrete was obtained using a compressive testing machine at the ages of 7, 21, and 28 days of curing.

A thin layer of mineral oil was applied to the inside surfaces of the moulds in order to prevent the bond between the concrete and the mould. Concrete was then poured in the mould in 3 layers, each layer being compacted by 25 strokes of 16 mm diameter steel rod with a bullet end. Thereafter, the top surface was finished using a trowel, the compacted cubes were vibrated and re-vibrated on the vibrating machine. The cubes were then properly stored and allowed to harden. The hardened cubes were demoulded after 24 hours.

The time lag used for the study was 60 minutes. The duration of each initial vibration was 40 seconds and subsequent re-vibration lasted for 20 seconds each with intervals of 10 minutes between successive re-vibrations. 42 numbers of 150 x 150 x 150 mm cubes were cast using Ordinary Portland Cement alone as the binder (control), representing 2 cubes per test for 7-time lag intervals namely: 0 min, 10 min, 20 min, 30 min, 40 min, 50 min, and 60 min, for three ages (7, 14, 21 days) for crushing. Additional 21 cubes were cast using a binary blend of Ordinary Portland Cement and LBPEA.

A Humboldt 800 mm x 400 mm 55-C0160/H vibrating table fitted with a clamping device and waterproof pedal switch was used for both initial vibration and subsequent re-vibrations. It is capable of vibrating two 150 mm cube moulds simultaneously.

Considering that the cement requires time to fully hydrate before it acquires strength and hardness, concrete must be cured once it has formed and achieved the initial setting. Curing is the process of keeping or storing concrete under a suitable specific environmental condition until hydration is relatively complete. The environment promotes hydration after the moulds are removed in a process. Although before striking, it is assumed that the concrete should have formed, hardened, and set after 24 hours of casting. The concrete specimens were cured for 7, 14, and 28 days after which they are removed for crushing.

The weights of the samples were taken before the compressive strength test was conducted. The cubes (both with and without LBPEA vibrated and re-vibrated from zero to one hour) were removed from the curing tank after 7, 14, and 28 days of curing consecutively. On the designated days for crushing, fifty-six (56) sample cubes (i.e. 14 without LBPEA and another 42 with LBPEA) were crushed. The maximum load carried by each specimen before failure was recorded. The maximum load divided by the net surface area of the specimen gave the compressive strength of the concrete.

The test result for the compressive strength of hardened re-vibrated concrete for the different percentages of replacement of OPC with LBPEA at ages 7, 14 and 28 days of curing are shown in Tables 2, 3 and 4

3 Results and Discussion

The result of the chemical analysis conducted on the LBPEA is presented in Table 1.

Table 1: Laboratory chemical analysis of LBPEA

|

Chemical |

Content (%) |

|

Na 2 O |

0.926 |

|

K 2 O |

2.626 |

|

MgO |

3.659 |

|

Pb 2 O 5 |

3.449 |

|

Fe 2 O 3 |

3.365 |

|

Al 2 O 3 |

9.785 |

|

CaO |

7.416 |

|

SiO 2 |

64.659 |

|

SO 3 |

1.990 |

|

Cl |

0.791 |

|

TiO 2 |

1.068 |

|

Cr 2 O 3 |

0.002 |

|

Mn 2 O 3 |

0.183 |

|

ZnO |

0.021 |

|

SrO |

0.060 |

The result of the chemical analysis carried out on the LBPEA showed that it is a very good pozzolana with its SiO 2 , Al 2 O 3 , and Fe 2 O 3 content summing to 77.81% as required by ASTM C618 [3]. As such, the usage of the LBPEA in this work is justified.

The ash content of the LBPE was obtained as 2.83% showing that only that much percentage of the burnt LBPE is useful for this work as it is the portion that passed sieve 75µm as required for cement fineness.

Results of the specific gravity test; Bulk density, porosity and void ratio test; Moisture content test; Particle size distribution (sieve analysis) test actually demonstrated that the aggregates were standard within specifications. However, the moisture content of the LBPEA was 21.07% indicating that it requires to be dried out before incinerating.

The sieve analysis result of the fine aggregates showed that it is chiefly composed of sand passing sieve 5.0 mm and retained on sieve 0.15 mm. For the coarse aggregates, bulk of the materials were seen to pass sieve 20.0 mm and retained on sieve 10.0 mm.

Table 2: Effect of LBPEA on the compressive strength of re-vibrated concrete at day 7

|

Revibration time interval (mins) |

Compressive strength, N/mm2 |

||||||

|

0% LBPEA+ 100% OPC (Control) |

5% LBPEA + 95% OPC (5L95C) |

10% LBPEA + 90% OPC (10L90C) |

15% LBPEA+ 85% OPC (15L85C) |

20% LBPEA + 80% OPC (20L80C) |

25% LBPEA + 75% OPC (25L75C) |

30% LBPEA + 70% OPC (30L70C) |

|

|

0 |

18.87 |

17.33 |

17.07 |

11.51 |

5.78 |

5.33 |

4.93 |

|

10 |

18.60 |

18.89 |

13.87 |

10.84 |

6.49 |

5.87 |

5.24 |

|

20 |

20.40 |

17.51 |

12.89 |

11.47 |

7.38 |

6.40 |

5.33 |

|

30 |

19.93 |

18.76 |

13.33 |

11.69 |

7.33 |

6.67 |

5.56 |

|

40 |

18.11 |

17.07 |

12.84 |

11.78 |

7.42 |

6.98 |

5.78 |

|

50 |

23.98 |

18.84 |

14.09 |

12.67 |

8.00 |

6.89 |

5.47 |

|

60 |

25.29 |

21.11 |

15.64 |

12.62 |

7.82 |

7.56 |

6.13 |

The trends of the effect of LBPEA on the day 7 compressive strength of re-vibrated concrete at various re-vibration times are shown in Fig. 3. There was a sinusoidal behavior in the strength of the concrete at different re-vibration times. The maximum strength at day 7 was obtained at the control stage to be 25.29 N/mm2 at 60 minutes re-vibration time. Closest to this value is that obtained at 5% ash replacement at 60 minutes re-vibration gotten as 21.11 N/mm2. Other replacement percentages were seen to have relatively low strength compared to the control and 5% replacement at almost all the re-vibration time.

Fig. 3: Effect of LBPEA on the Compressive Strength of Re-Vibrated Concrete at Day 7

Table 3: Effect of LBPEA on the compressive strength of re-vibrated concrete at day 14

|

Revibration time interval |

Compressive strength, N/mm2 |

||||||

|

0% LBPEA + 100% |

5% LBPEA + 95% |

10% LBPEA + 90% OPC |

15% LBPEA + 85% OPC |

20% LBPEA + 80% OPC |

25% LBPEA + 75% OPC |

30% LBPEA + 70% OPC |

|

|

0 |

19.27 |

18.58 |

12.36 |

12.09 |

6.31 |

6.04 |

5.11 |

|

10 |

18.80 |

20.89 |

14.00 |

12.44 |

7.47 |

7.11 |

5.24 |

|

20 |

21.84 |

18.76 |

13.73 |

12.80 |

7.42 |

7.24 |

5.38 |

|

30 |

20.40 |

20.27 |

12.44 |

12.36 |

7.20 |

7.07 |

5.24 |

|

40 |

19.33 |

20.49 |

13.24 |

13.51 |

7.33 |

7.16 |

6.00 |

|

50 |

24.71 |

21.42 |

13.02 |

13.11 |

7.56 |

7.6 |

5.69 |

|

60 |

24.76 |

21.60 |

12.67 |

13.16 |

7.73 |

8.04 |

6.40 |

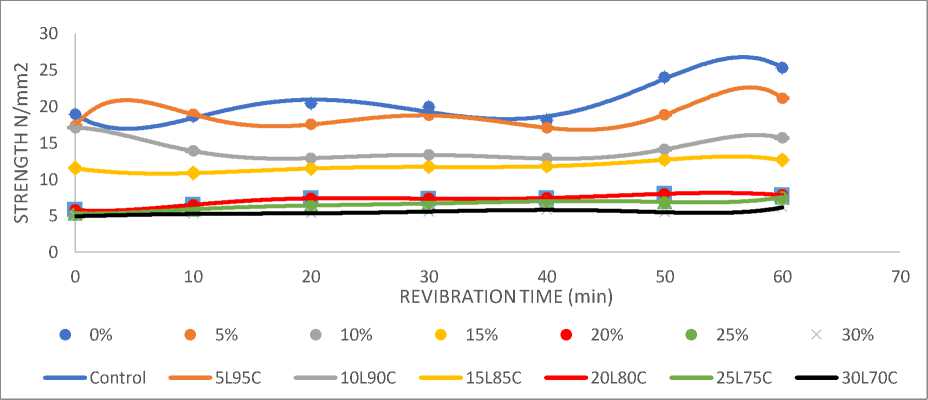

The trends of the effect of LBPEA on the day 14 compressive strength of re-vibrated concrete at various re-vibration times are shown in Fig. 4. There was a sinusoidal behavior in the strength of the concrete at different re-vibration times. The maximum strength at day 14 was obtained at the control stage to be 24.76 N/mm2 at 60 minutes re-vibration time. Closest to this value is that obtained at 5% ash replacement at 60 minutes re-vibration gotten as 21.60 N/mm2. Other replacement percentages were seen to have relatively low strength compared to the control and 5% replacement at almost all the revibration time.

|

0 |

10 20 30 40 50 60 70 REVIBRATION TIME (min) |

|

• 0% |

• 5% • 10% • 15% • 20% • 25% • 30% |

Control ^^^^^^е 5L95C ^^^^^^е 10L90C < ■ 15L85C ^^^^^^е 20L80C ^^^^^^е 25L75C ^^^^^^е 30L70C

Fig. 4: Effect of LBPEA on the Compressive Strength of Re-Vibrated Concrete at Day 14

Table 4: Effect of LBPEA on the compressive strength of re-vibrated concrete at day 28

|

Revibration time interval (mins) |

Compressive strength, N/mm2 |

||||||

|

0% LBPEA + 100% OPC |

5% LBPEA + 95% OPC (5L95C) |

10% LBPEA + 90% OPC (10L90C) |

15% LBPEA + 85% OPC (15L85C) |

20% LBPEA + 80% OPC (20L80C) |

25% LBPEA + 75% OPC (25L75C) |

30% LBPEA + 70% OPC (30L70C) |

|

|

0 |

22.27 |

20.36 |

13.78 |

12.27 |

6.71 |

6.31 |

5.69 |

|

10 |

22.58 |

20.67 |

15.78 |

13.42 |

7.16 |

7.02 |

5.87 |

|

20 |

22.78 |

19.33 |

14.31 |

13.16 |

7.56 |

7.38 |

6.22 |

|

30 |

21.34 |

22.22 |

15.29 |

14.22 |

7.33 |

7.24 |

6.44 |

|

40 |

20.65 |

21.78 |

15.38 |

15.20 |

7.64 |

7.56 |

6.22 |

|

50 |

24.09 |

24.44 |

13.87 |

13.33 |

8.44 |

7.82 |

6.13 |

|

60 |

22.27 |

28.44 |

16.09 |

15.56 |

8.00 |

8.18 |

6.93 |

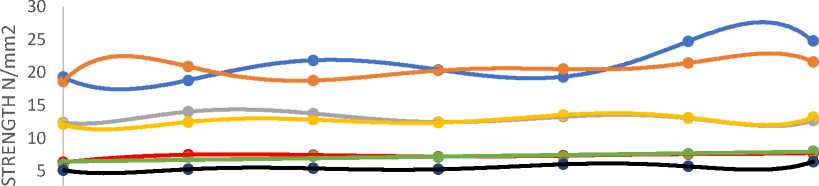

The trends of the effect of LBPEA on the day 28 compressive strength of re-vibrated concrete at various re-vibration times are shown in Fig 5. There was also a sinusoidal behavior in the strength of the concrete at different re-vibration times. The maximum strength at day 28 was at 5% ash replacement at 60 minutes re-vibration and gotten as 28.44 N/mm2. Nearest to this percentage is that obtained at the control stage to be 24.09 N/mm2 at 50 minutes re-vibration time. This day 28 strength for the 5% replacement cubes indicates about 18.1% in the peak value for the control. Other replacement percentages were seen to have relatively low strength compared to the control and 5% replacement at almost all the re-vibration time.

0 10

20 REVIB3R0ATION TIME4(0min) 50 60 7

• 10% • 15% • 20% • 25% • 30%

^^^^^^е 10L90C ^^^^^^е 15L85C ^^^^^^е 20L80C ^^^^^^е 25L75C ^^^^^^™ 30L70C

-

• 0% • 5%

Control ^^^^^^е 5L95C

Fig. 5: Effect of LBPEA on the Compressive Strength of Re-Vibrated Concrete at Day 28

4 Conclusions

Effect of locust bean pod epicarp ash (LBPEA) on the compressive strength of re-vibrated concrete has been investigated and the results have been presented, analyzed, and discussed. From the study, the following conclusions were drawn:

LBPEA used is a good pozzolana with its SiO 2 , Al 2 O 3 , and Fe 2 O 3 content summing to 77.81% (ASTM C618); The compressive strength at 28 days curing of re-vibrated concrete for 0% and 5% LBPEA replacement were all greater than 20 N/mm2 which showed an advantage in compressive strength due to LBPEA incorporation as the binder in concrete mix. Thus, a 5% replacement of OPC with LBPEA can be adopted for structural concrete production. However, the addition of LBPEA beyond 5% only weakens the concrete.

Список литературы Effect of locust bean pod epicarp ash (LBPEA) on the compressive strength of revibrated concrete

- Aguwa, J.I., Alhaji, B., Jiya, A., Kareem, D.H. Effectiveness of Locust Bean Pod Ash (LBPA) in the Production of Sandcrete Blocks for Buildings (2016) Nigerian Journal of Technological Development, 13(1), pp.13-16. DOI: 10.4314/njtd.v13i1.3

- Aguwa, J.I. Study of Compressive Strengths of Laterite-Cement Mixes as Building Material (2009) Assumption University Journal of Technology (A.U.J.T.), 13(2), pp.114-120.

- ASTM C618, Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International, West Conshohocken, 2012.

- Anzar, H.M. Improved Concrete PropertiesUsing Quarry Dust as Replacement for Natural Sand (2015) International Journal of Engineering Research and Development. 11(3), pp.46-52. https://pdfs.semanticscholar.org/6618/1d1fb2e55a797c7cf27556f77e7e4f529fa4.pdf

- Krishna Rao, M.V., Rathish Kumar. P., Bala Bhaskar, N.V.R.C. Effect of Re-vibration on Compressive Strength of Concrete (2008) Asian Journal of Civil Engineering (Building and Housing). 9(3), pp. 291-301. https://pdfs.semanticscholar.org/2371/cf40c6a9858bbb268bdd1a476858ae6b4d7c.pdf

- Auta, S.M. Dynamic Effect of Revibration on Compressive strength of concrete (2011) Nigeria Journal of Technological Research, 6(2), pp.13-17.

- Auta, S.M., Abanda M.A. Tsado, T.Y. Experimental Study on the flexure strength of a reinforced and re-vibrated RHA concrete beam (2015) Proceedings of 1st International Conference on green engineering for sustainable development (ICGESD), B. U. K. Kano, Nigeria in collaboration with Tanta University, Egypt, 8th-10th December, 2015, pp.54-58.

- Kassim, M.M. Effect of Revibration on early age retarded (2012) Concrete Journal, 124(1), pp. 85 - 93. D0I:

- DOI: 10.2495/HPSM120081

- Dunham, M.R., Rush, A.S., Hanson, J.H. Effects of Induced Vibrations on Early Age (2007) Concrete Journal of Performance of Constructed Facilities, 21(3), 179184.

- Neville, A.M., Brooks, J.J. Concrete Technology. 2nd Edition (2002) New Delhi India, Pearson education publisher limited, 623(8),. 464 p.

- Chungsangunsit, T., Gheewla, H., Patumsawad, S. Emission Assessment of Rice Husk Combustion for Power Production (2009) World Academy of Science, Engineering and Technology Journal, (53), pp.1070 - 1075.

- Dwivedi, V.N., Singh, N.P., Das, S.S. Singh, N.B. A new pozzolanic material for the cement industry: Bamboo leaf ash (2006) International Journal of Physical Sciences, 1 (3), pp.106 - 111. https://academicjournals.org/article/article1380106481_Dwivedi%20et%20al.pdf

- Colonnade, K.A. Prospect of Agro-By-Products as Pozzolanas in Concrete for Low Cost Housing Delivery in Nigeria (2010) Proceedings of the International Conference of the Obafemi Awolowo University, Faculty of Technology. 1, pp.217 - 221.

- Adama, Y.A., Jimoh, Y.A. Production And Classification Of Locust Bean Pod Ash (LBPA) As A Pozzolan (2011) URL: https://www.engineeringcivil.com/production-and-classification-of-locust-bean- pod-ash-lbpa-as-a-pozzolan.html (date of application: 10.07.2020).

- Adesanya, D.A., Raheem, A.A. Development of corn cob ash blended cement (2009) Construction and Building Materials, 23 (1), pp. 347-352.

- DOI: 10.1016/j.conbuildmat.2007.11.013

- Adama, A.Y., Jimoh, Y.A. Effect of Locust bean pod epicarp ash on Strength Properties of Weak Soils (2012) AU Journal of Technology, 16(1), pp.27-34.

- Chao-Lung, H., Anh-Tuan, B.L., Chun-Tsun, C. Effect of rice husk ash on the strength and durability characteristics of concrete (2011) Construction and Building Materials, 25 (9), pp. 3768-3772.

- DOI: 10.1016/j.conbuildmat.2011.04.009

- Cordeiro, G.C., Toledo Filho, R.D., Tavares, L.M., Fairbairn, E.M.R. Pozzolanic activity and filler effect of sugar cane bagasse ash in Portland cement and lime mortars (2008) Cement and Concrete Composites, 30 (5), pp. 410-418.

- DOI: 10.1016/j.cemconcomp.2008.01.001

- Ottosen, L.M., Hansen, E.Ø., Jensen, P.E., Kirkelund, G.M., Golterman, P. Wood ash used as partly sand and/or cement replacement in mortar (2016) International Journal of Sustainable Development and Planning, 11 (5), pp. 781-791.

- DOI: 10.2495/SDP-V11-N5-781-791

- Cruz-Yusta, M., Mármol, I., Morales, J., Sánchez, L. Use of olive biomass fly ash in the preparation of environmentally friendly mortars (2011) Environmental Science and Technology, 45 (16), pp. 6991-6996.

- DOI: 10.1021/es200968a

- Ettu, L.O., Ezeh, J.C., Ibearugbulem, O.M., Anya, U.C., Njoku, K.O. Strength of binary blended cement composites containing coconut husk ash (2013) International Journal of Science and Research, 2(4), Pp. 282-286.

- Etuk, B.R, Etuk, I.F., Asuquo, L.O. Feasibility of using sea shells ash as admixtures for concrete (2012) Journal of Environmental Science and Engineering, 1(1), pp.123-129.

- Aguwa, J. I., Okafor, J. O. Preliminary investigation in the use of locust bean pod extract as binder for production of laterite blocks for buildings (2012) International Journal of Environmental Science, Management and Engineering Research, 1(2), pp. 57-67.

- Ogunbode, E.B., Hassan, I.O., Isa, R.B. An Evaluation of Compressive Strength of Concrete made with Rice Husk Ash obtained by Open Air Burning (2011) Environmental Technology and Science Journal, 4(1), pp. 137-147.

- Ndububa, E.E., Uloko, J.O. Locust bean pod Epicarp ash (LPBA) as a pozzolanic material in concrete (2015) Proceedings of The International Academic Conference for Sub-Sahara African Transformation and Development. 3(4). https://www.cambridgenigeriapub.com/wp- content/uploads/2016/03/LOCUST-BEAN-POD-ASH.pdf

- Elinwa, A.U., Ejeh, S.P., Mamuda, A.M. Assessing of the fresh concrete properties of self- compacting concrete containing sawdust ash (2008) Construction and Building Materials, 22 (6), pp. 1178-1182.

- DOI: 10.1016/j.conbuildmat.2007.02.004