Effect of nanofibrillar cellulose on the cement paste setting kinetics

Автор: Pukharenko Yu.V., Khrenov G.M., Tkachenko V.I.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Construction materials science

Статья в выпуске: 1 Vol.16, 2024 года.

Бесплатный доступ

Introduction. The study addresses the effect of nanofibrillar cellulose (NFC) on the setting process of cement paste during the first hours of gauging. A brief justification of the research topic relevance is given. It has been noted that the modification of cement materials by nanoscale additives has sparked significant scientific and practical interest in recent years. NFC has emerged as one such additive, and the potential impacts of its incorporation into cement systems are currently under active investigation. The study aims at investigating the effect of NFC on the cement paste setting kinetics during the first hours of gauging. Materials and methods. We present the materials used in the research and their characteristics, in particular, two types of cement characterized by the presence or absence of false setting, as well as cement paste compositions with different NFC consumption (from 0 to 0.24% of dry matter by weight of cement). The technique of measuring conditional viscosity in time with a laboratory rheometer and a special measuring system is described. Results. The results of cement paste tests are presented in the form of setting process diagrams. Discussion. The results obtained and experimental data are given. The complex character of NFC influence on the cement paste setting kinetics has been noted, which depends on the cement quality and additive consumption. For cement without signs of false setting, a decrease in setting onset time was observed when increasing the NFC content. Conversely, increase in the amount of NFC leads to an increase in the setting onset time for cements with signs of false setting. Conclusion. NFC has a noticeable effect on cement paste setting kinetics in the first 3 hours: it accelerates the process when using cement without false setting and slows down the setting when using cement with false setting.

Cement paste, nanofibrillar cellulose, setting

Короткий адрес: https://sciup.org/142240521

IDR: 142240521 | DOI: 10.15828/2075-8545-2024-16-1-6-11

Текст научной статьи Effect of nanofibrillar cellulose on the cement paste setting kinetics

Original article

Pukharenko Yu.V., Khrenov G.M., Tkachenko V.I. Effect of nanofibrillar cellulose on the cement paste setting kinetics. Nanotechnology in construction. 2024; 16(1): 6–11. – EDN: QOESME.

M odern construction industry uses about 4 billion tons of cement annually to produce various construction materials based on it [1]. At the same time, the largest volume of application falls on the production of concretes and mortars, the properties of which are regulated, in particular, by means of directed changes in the structure of cement paste and stone.

Methods for controlling the structure of cement systems have been continuously developed for decades and in recent years have reached the nanoscale. The introduction of very small amounts of various nanoscale additives into the mixtures made it possible to significantly improve the technical and economic performance of cement com- posites. This is achieved either by improving the properties of nanomodified materials, such as strength, frost resistance, water resistance, delamination, storability, etc., or by reducing the cement consumption in the composition of mixtures, taking into account the provision of the required characteristics [2, 3, 4].

The published research results indicate serious prospects for nanostructuring of concretes and mortars. Carbon-based [5, 6, 7, 8] and silica nanoparticle-based modifiers [9, 10, 11] have been deeply studied and are already in practical use. Meanwhile, researchers continue to search for and study new nanoscale additives, such as nanofibrillar cellulose (NFC).

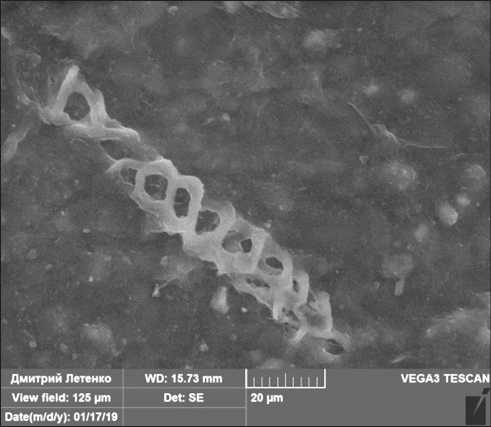

NFC is a product of dispersing plant cellulose-con-taining materials to the nanoscale. It represents tiny flex-

CONSTRUCTION MATERIALS SCIENCE ible fibers with high strength and deformation characteristics [12, 13]. Many scientists have noted the positive effect of NFC on the properties of cement composites, including increased strength [14, 15, 16, 17], reduced shrinkage deformations [18, 19], and improved processability of the mixture (reducing delamination) [20] and others. Since the results of studying NFC as a modifier of cement systems are relatively new, the search for possible effects of its application is still far from being finalized. Taking this into account, this study aims to investigate the effect of NFC on the cement paste setting kinetics during the first hours of gauging.

MATERIAL AND METHODS

In order to evaluate the setting kinetics, the Anton Paar MCR-102 oscillation-rotational rheometer equipped with a special measuring system developed at Saint Petersburg State University of Architecture and Civil Engineering was used (Fig. 2). This system is equipped with a metal needle that impinges on a material sample by moving circumferentially at a speed of 0.2 rpm/hour. The sample is in a disposable plastic container. The rheometer records

Fig. 1. Microphotography of NFC after dispersion in an ultrasonic bath the torque required to maintain a given speed, which is then converted to conditional viscosity. It is not possible to calculate the absolute value of the viscosity due to the complex deformation pattern of the material sample. Nevertheless, the conditional viscosity is considered to be sufficient for early setting of the cement paste, since it is the change in the resistance of the material to the specified effect, not its absolute value, that is important.

Fig. 2. Diagram and photos of the measuring system for controlling the kinetics of mineral binder setting

CONSTRUCTION MATERIALS SCIENCE

Table

Specification of cement paste of normal density

|

Indicator |

Value for composition 1–8 |

|||||||

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

|

|

Portland cement |

No signs of false setting |

With signs of false setting |

||||||

|

W/C |

0.26 |

0.261 |

0.262 |

0.275 |

0.266 |

0.267 |

0.271 |

0.295 |

|

NFC consumption, % |

0 |

0.0024 |

0.024 |

0.24 |

0 |

0.0024 |

0.024 |

0.24 |

In order to evaluate the effect of NFC on the cement paste setting kinetics, 8 cement paste compositions of normal density were made (see Table), in which the cellulose content is indicated by dry matter as a percentage of cement weight.

RESULTS

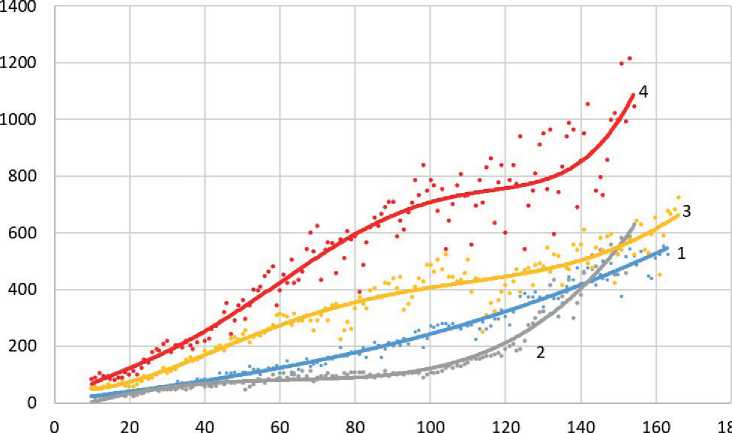

The results of testing the cement paste compositions No. 1–8 are shown graphically (Figs. 3 and 4).

DISCUSSION

Fig. 3 shows that the conditional viscosity of the cement paste without NFC (line 1) increases smoothly and starts to set after 160 minutes from gauging, reaching a value of 500 kPa*s. The NFC introduction has a noticeable effect on the viscosity change: at a rate of 0.0024% it slightly slows down the process of structure formation between 40 and 140 minutes, and then slightly accelerates it (line 2). The beginning of setting occurs after 145 minutes. Introduction of 0.024% of NFC leads to acceleration of the structure formation process in the whole time interval of the experiment, the beginning of setting occurs after 150 minutes (line 3). A significant acceleration of viscosity build-up is observed at 0.24% of NFC consumption, and the beginning of setting occurs after 70 minutes (line 4). Thus, the addition of NFC decreases the time of setting onset, but its significant effect is observed only at a high consumption of 0.24% by cement weight. In this case, NFC can be considered as a cement setting accelerant provided there is no evidence of false setting in the cement.

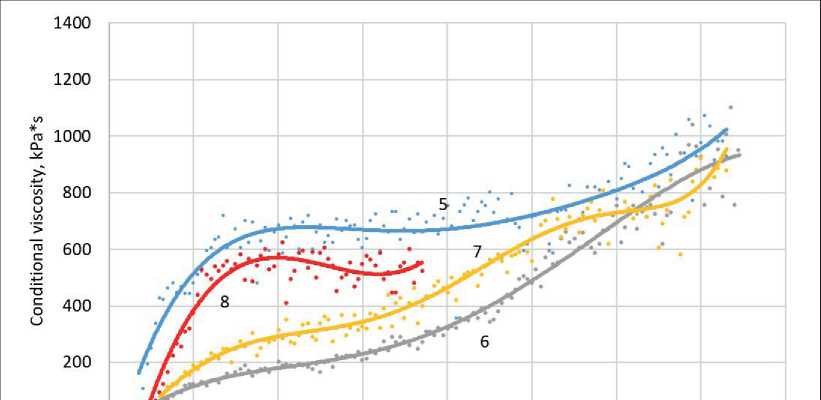

Fig. 4 shows the test results of cement paste compositions with signs of false setting, which is clearly visible by the sharp increase in the conditional viscosity on line 5

s%dy 、 A~SOUS>-euo-—puo。

о

Time after gauging, min.

Fig. 3. Kinetics of cement paste setting (compositions No. 1–4): 1 – without NFC; 2 – 0.0024% of NFC; 3 – 0.024% of NFC; 4 – 0.24% of NFC

CONSTRUCTION MATERIALS SCIENCE

40 60 80

120 140

Time after gauging, min.

Fig. 4. Kinetics of cement paste setting (compositions No. 5–8): 5 – without NFC; 6 – 0.0024% of NFC; 7 – 0.024% of NFC; 8 – 0.24% of NFC in the first 30 minutes after gauging. The time of setting beginning (false setting in this case) is 20 minutes. The addition of 0.0024% NFC results in a smoother increase in viscosity (line 6), and the setting onset time is 105 minutes. Further increase of NFC consumption up to 0.024% also restrains the setting onset time, but only up to 85 minutes (line 7). The addition of 0.24% NFC does not noticeably affect the viscosity value of the cement compared to the additive-free cement test: its intensive growth in the first 30–35 minutes is also observed, and the setting time has not practically increased and is 25 minutes (Composition 8).

The results obtained indicate the potential application of NFC as an additive to compensate false setting when its signs are detected in cement. At the same time, the most effective dosages do not exceed 0.024% of cement weight.

CONCLUSION

-

1. The introduction of nanofibrillar cellulose has a noticeable effect on the setting kinetics of cement paste at early periods of gauging, with the degree and nature of this effect depending on the quality of Portland cement.

-

2. In case of quality cements (without signs of false setting), NFC can be considered as an additive that accelerates the setting of cement paste during the initial (up to 3 hours) curing period. The optimum consumption of NFC in this case is about 0.24% of cement weight in the dry matter equivalent.

-

3. NFC can be considered as an additive for cements with signs of false setting, compensating for this effect in the cement paste and thus increasing its workability. An NFC consumption of about 0.0024% of the cement weight should be considered optimal for this purpose.

Список литературы Effect of nanofibrillar cellulose on the cement paste setting kinetics

- Ergashev M.M. Nanotechnology application in cement production . Economics and Socium. 2020;1(68): 952-955.

- Balmakov M.D., Pukharenko Y.V. Nanocomposite material science . Civil Engineers’ Bulletin. 2005; 3(4): 53-57.

- Pukharenko Yu.V., Aubakirova I.U., Nikitin V.A., Letenko D.G., Staroverov V.D. Cement composites modification by mixed nanocarbon material of fulleroid type. Concrete Technology. 2013; 12 (89): 13-15.

- Chernyshev E.M., Artamonova O.V., Slavcheva G.S. Nanomodification of cement composites at the technological stage of life cycle. Nanotechnologies in Construction: A Scientific Internet-Journal. 2020; 12(3): 130-139. https://doi.org/10.15828/2075-8545-2020-12-3-130-139. EDN NDNJES

- Pukharenko Yu.V., Ryzhov D.I., Staroverov V.D. Features of cement composites structure formation in the presence of carbon nanoparticles of fulleroid type . Bulletin of MSCU. 2017; 12: 7(106): 718-723. https://doi.org/10.22227/1997-0935.2017.7.718-723. EDN ZATDHP

- Pukharenko Yu.V., Staroverov V.D., Ryzhov D.I. Fulleroid carbon-based nanoparticles for concrete modification. Concrete Technology. 2015; 3-4(104-105): 40-43. EDN TTMPBN

- Kovaleva, A.Yu.; Belyaeva, Zh.V.; Aubakirova, I.U.; Staroverov, V.D. The experience of industrial application of nanomodified concrete mixtures. Civil Engineers’ Bulletin. 2008; 3(16): 74-76.

- Ryzhov D.I., About the durability of concrete from nanomodified mixtures . Civil Engineers’ Bulletin. 2013; 2(37):146-151. EDN QZJSGZ

- Prudkov E.N., Zakurazhnov M.S. Modification of fine-grained concrete with nanosilica . Scientific Bulletin of Voronezh State University of Architecture and Civil Engineering. A series: Physico-chemical problems and high technologies of building materials science. 2014; 1(8): 44-48. EDN SUFKBP

- Potapov V., Efimenko Y., Mikhailova N., Kashutin A., Gorev D. Application of nanosilica to increase the strength of concrete. Nanoindustry. 2014; 7(53): 64-69. EDN SZIQED

- Urkhanova L.A., Lkhasaranov S.A., Bardakhanov S.P. Modified concrete with nanodisperse additives. Construction Materials. 2014; 8:52-55. EDN SJVXOJ

- Toptunov E.A., Sevastyanova Yu.V. Powder cellulosic materials: review, classification, characteristics and applications. Chemistry of plant raw materials. 2021; 4: 31-45. https://doi.org/10.14258/jcprm.2021049186. EDN PIMJOE

- Revol J. F., Bradford H., Giasson J., Marchessault R. H., Gray D. G. Helicoidal self-ordering of cellulose microfibrils in aqueous suspension. International Journal of Biological Macromolecules. 1992; 14(3):170-172.

- Hisseine O.A., Wilson W., Sorelli L., Tolnai B., Tagnit-Hamou A. Nanocellulose for improved concrete performance: A macro-to-micro investigation for disclosing the effects of cellulose filaments on strength of cement systems. Construction and Building Materials. 206: 84–96.

- Jiao L.Su.M., Chen L., Wang Y., Zhu H., Dai H. Natural Cellulose Nanofibers as Sustainable Enhancers in Construction Cement. PLOS ONE. 11(12). e0168422.

- Khirkhasova, V. I. Effect of nanocellulose on the process of Portland cement hydration and concrete properties. Civil Engineers’ Bulletin. 2020; 5(82): 155-160. https://doi.org/10.23968/1999-5571-2020-17-5-155-160. EDN LKNNNJO

- Cao Y., Zavaterri P., Youngblood J., Moon R., Weiss J. The influence of cellulose nanocrystal additions on the performance of cement paste. Cement and Concrete Composites. 2015. Vol. 56: 73-83.

- Pukharenko Yu.V., Aubakirova I.U., Khirkhasova V.I. Cellulose in concrete: a new direction in construction nanotechnology development. Construction Materials. 2020; 7: 39-44. https://doi.org/10.31659/0585-430X-2020-782-7-39-44. EDN WORYOY

- Lee H.-J., Kim S.-K., Lee H.-S., Kim W. A Study on the Drying Shrinkage and Mechanical Properties of Fiber Reinforced Cement Composites Using Cellulose Nanocrystals. International Journal of Concrete Structures and Materials. 2019; 13(39).

- Pukharenko Yu.V., Khrenov G.M., Rerikh A.V. Effect of nanocellulose on the manufacturability of masonry mortar mixtures. ALITinform: Cement. Concrete. Dry mixes. 2022; 3(68): 62-68. EDN WPYMED