Effect of the active powder of discretely devulcanized rubber on bitumen properties at low temperatures

Автор: Viktoria N. Gorbatova, Irina V. Gordeeva, Tatyana V. Dudareva, Irina A. Krasotkina, Vadim G. Nikol'skii, Victor M. Egorov

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: The results of the specialists’ and scientists’ researches

Статья в выпуске: 1 Vol.15, 2023 года.

Бесплатный доступ

Introduction. In the article the use of powder elastomeric modifier capable of rapid breakdown into micro- and nanofragments upon contact with hot bitumen to improve the low-temperature properties of bitumen is presented. The indicators of resistance to cracking are determined by various methods and their dependence on the thermal history of the samples. Methods and Materials. At temperatures up to –36оC the oscillatory rheological tests (4-mm DSR test) of RTFO-aged samples of bitumen BND 60/90 and modified binder (MB) which contain the active powder of discretely devulcanized rubber (APDDR) produced by high-temperature shear-induced grinding from the crumb rubber of worn tires have been conducted. MB was prepared by mixing bitumen (3 min; 160оC and 600 rpm) with 12.5 wt.% APDDR. Results and Discussion. The effect of the test parameters on the rheological parameters has been studied. Structural transitions in bitumen and MB by methods of differential scanning calorimetry (DSC) and the cracking temperature of the same samples in static conditions in the ABCD test were detected. It is revealed: a decrease in the temperature of actual cracking of the MB sample compared to bitumen. Conclusion. It is shown that APDDR as a modifier affects the structure of bitumen and reduces the temperature sensitivity of bitumen to external influences.

Bitumen, APDDR, low-temperature cracks, glass transition

Короткий адрес: https://sciup.org/142235808

IDR: 142235808 | DOI: 10.15828/2075-8545-2023-15-1-72-83

Текст научной статьи Effect of the active powder of discretely devulcanized rubber on bitumen properties at low temperatures

Original article

W hen selecting bitumen for road construction, it is necessary to be sure that its temperature plasticity interval, defined as the difference between the softening point and the cracking point, corresponds to the climatic conditions of the region. Otherwise, there is a high probability of formation of various kinds of defects, among which the formation of cracks in winter takes a significant place [1]. Low-temperature cracks because of shrinkage and tensile stresses can appear with a single drop in temperature and in the absence of traffic load. The resistance of bitumen to cyclic deformations caused by moving vehicles and static deformations arising over time under load are also important [2].

Fraas breaking point [3] most modem road bitumen does not reach -30°C [4], while on 65% of the Russian Federation the air temperature on the coldest days falls below -35°C [5]. Bitumen is modified with various additives (thermoplastic elastomers, elastomers, and etc.) to improve the performance [6]. As a rale, modification provides high resistance of pavement to plastic deformation in the hot period of the year. There is no consensus about the modifier effect on low-temperature and fatigue performance of bitumen, although there are positive results of pavement monitoring [7-9].

Despite many years of bitumen research, the prediction of low-temperature pavement behavior based on laboratory bitumen tests remains a relevant problem [ 10]. This is largely due to the complexity of bitumen chemical

THE RESULTS OF THE SPECIALISTS'AND SCIENTISTS' RESEARCHES composition [7] and the microstructures formed during the cooling of bitumen [11—12]. The presence in bitumen of two types of wax: paraffin and naphthenic (microcrystalline), capable of crystallization at positive and negative temperatures, respectively [13-15] determines the centers of stress concentration. Bitumen produced from different fields oil may differ in chemical composition and the content of paraffins, which leads to the possibility of glass transition, crystallization, recrystallization and melting of microstructures in a wide temperature range: from 80-90°C up to negative temperatures, even below —40°C [7, 15].

Fraas Breaking Point [ 16] and BBR test [ 17] are the most common methods of low-temperature bitumen testing. However, these methods are believed to underestimate the low-temperature characteristics of modified binders [18].

In recent years, new methods for low-temperature tests of bitumen binders have been proposed, which allow to determine the fracture temperature of the sample when cooling under static conditions (ABCD-test [19]) and rheological characteristics during dynamic tests on a dynamic shear rheometer with a diameter of 4 mm parallel plates (4-mm DSR test) [20].

The essence of the ABCD method is to cool a ringshaped bitumen binder sample with a fixed inner diameter and to register of the deformation and tensile stress.

In the 4-mm DSR test, oscillation tests are performed over a specified frequency range at 0.1% strain. Each specimen is tested at two temperatures differing by 10°C, starting with the lower temperature. Although DSR allows testing down to -40°C, rheological testing of bitumen binders at low temperatures is still not common practice [21]. In the development of the 4-mm DSR test it was even proposed to test at relatively high temperatures compared to the test temperature on a bending beam rheometer (BBR) and then to shift the results to the corresponding low temperature using simple shear coefficients [22].

According to the established practice, the stiffness values obtained in BBR tests are used in calculating the thermal stress of bitumen and asphalt concretes [23]. Therefore, for the 4-mm DSR test, a method was proposed to convert the complex shear modulus (G*) data into parameters determined in the BBR test: stiffness (S) and creep factor (m) [20]. It should be noted that the analysis of the relationship of these parameters for binders modified with styrene-butadiene-styrene block copolymer (SBS) showed a linear correlation in the case ofbitumen compatible with SBS, and deviation from the linear trend in binders with poor compatibility of SBS and bitumen, when there is separation on macrophase [9].

Another problem of low-temperature studies ofbitumen binder is that in most cases, laboratory test protocols ignore the effect of so-called thermoreversible aging or

hardening ofbitumen, which is a consequence of such physical processes occurring in bitumen, as crystallization, phase’s separation and glass transition. These processes are reversible when specimens are heated to high enough temperatures, in contrast to the oxidative aging [24-25]. For example, the schedule of sample preparation before testing in the 4-mm DSR test [26] does not include their annealing (only a brief heating to 70°C to improve adhesion to the rheometer plates), and does not set the sample storage time between the aging procedure and the testing, as opposed to the samples tested by the BBR test (heated to 163-175°C and “tested for 4 hours”) [27] and the ABCD test (heated to 163-175°C and “cooled to room temperature for at least 30 minutes”) [28]. As a result, testing is run on specimens that are often in a non-equilibrium state, which can lead to a discrepancy between predicted and actual pavement life [10, 24]. In view of tiffs, the thermal history of samples from the preparation and testing processes is of particular importance [29].

The purpose of the paper was to investigate the effect of a powder elastomeric modifier capable of rapid breakdown in hot bitumen into micro- and nano-fragments [30] on the low-temperature properties ofbitumen. The active powder of discretely devulcanized rubber (APDDR) produced by high-temperature shear-induced grinding [31] from crumb rubber of wom-out tires was used as a modifier. In the present study rheological tests ofbitumen BND 60/90 and modified binder were carried out at -20, -26, -30 and -36°C for samples with different thermal history. The data obtained were compared with the results of low-temperature cracking in static conditions (without load) the same samples in the ABCD test and with the data of differential scanning calorimetry (DSC).

METHODS AND MATERIALS

The following materials were selected in this research:

-

• Oil road bitumen grade BND 60/90 [37]; the main properties: penetration at 25°C - 60 dmm; softening temperature of the Ring and Ball - 48°C; Fraas Breaking Point — minus 18°C.

-

• Active powder of discretely devulcanized rubber (APDDR), obtained by high temperature shear-induced grinding (HTSG) of wom-out tire rubber. The particle size of APDDR is less than 0.63 mm; the specific surface determined by the BET method at T = 77 К was 0.45 m2/g.

-

• Modified binder (MB) prepared by mixing bitumen heated to 160°C and APDDR for 3 min using a paddle stirrer (IKA HB10 DIGITAL) at 600 rpm. The concentration of APDDR in the MB was 12.5 wt%.

For ABCD, DSC and 4-mm DSR tests, bitumen and MB samples were subjected to technological (oxidative, RTFO) aging [32] for 85 minutes at 163°C.

THE RESULTS OF THE SPECIALISTS'AND SCIENTISTS' RESEARCHES

Tests of resistance of samples to low-temperature cracking in accordance to [28] were performed on the device ABCD “Infotech” (RF) using 4 parallel samples.

The samples heat capacity (Cp) was investigated on a DSC-500 calorimeter in a nitrogen atmosphere at a heating rate of 1—5 K/min. The temperature scale was calibrated by the melting points of ice (273.1 K) and indium (429.7 K); the heat flow scale was calibrated by the heat capacity of leucosappliire. Measurements were performed from a temperature of 180 to 430 K. The weight of the test samples was 5 mg.

Tow-temperature rheological tests were performed on an “MCR 702e” dynamic shear rheometer “Anton Paar” (Austria) with four-mm diameter parallel plates (4-mm DSR test). Three sample preparation programs were used to evaluate the effect of specimen thermal history (see Table 1). Samples were placed in the rheometer

at 60°C, trimming of the samples was performed at the same temperature after 5 min of thermostating, the working gap between the plates of the rheometer was 1.87 mm at this time. A working gap of 1.75 mm was set at 30°C, followed by thermostating for 20 min. Oscillation tests were performed at shear strain (y) 0.1 % in the frequency range (m) 0.016 to 7.96 Hz at temperatures of-36, -30, -26 and -20°C, the samples were thermostated at the test temperature for 20 min.

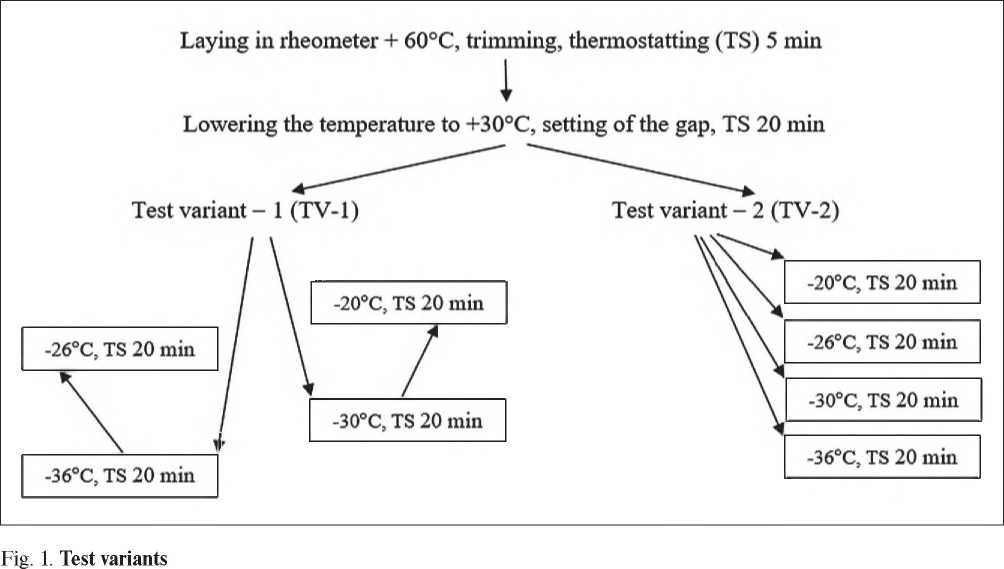

Test variants are shown in Figure 1: one sample was investigated at two temperatures with an interval of 10 °C, starting from the lower one in accordance with [26] in the test variant TV-1; a new sample was used for each temperature in the test variant TV-2.

Parameters of low-temperature crack resistance: creep stiffness S(60), m, T(S) and T(m) were computed in accordance with [26].

Table 1

Sample preparation programs for RTFO-aged bitumen and MB samples for the 4-mm DSR test

|

Program code |

Description of the sample preparation procedure |

|

P-1 |

Samples weighing 2.5 ± 0.1 g were heated in a heating oven at 70°C for 15 min, then stirred, placed between 4 mm diameter rheometer plates with a heated spatula (according to [26]) and tested. |

|

P-2 |

Samples weighing 2.5 ± 0.1 g were brought to fluid state at 165°C (bitumen) / 175°C (MB) and poured into silicone molds of 4 mm diameter. The samples were then cooled at ambient temperature for 2 hours and tested. |

|

P-3 |

Samples prepared according to program P-2, seven days stored at ambient temperature, then tested. |

THE RESULTS OF THE SPECIALISTS'AND SCIENTISTS' RESEARCHES

RESULTS AND DISCUSSION

The tests of RTFO-aged samples of BND 60/90 bitumen and the modified binder (MB) on the ABCD device showed (see Table 2) that the actual cracking temperature of the MB was 7.6°C lower than the bitumen and at higher strain jump (1.7 times) and fracture stress (1.8 times), which indicates a positive effect of the modification.

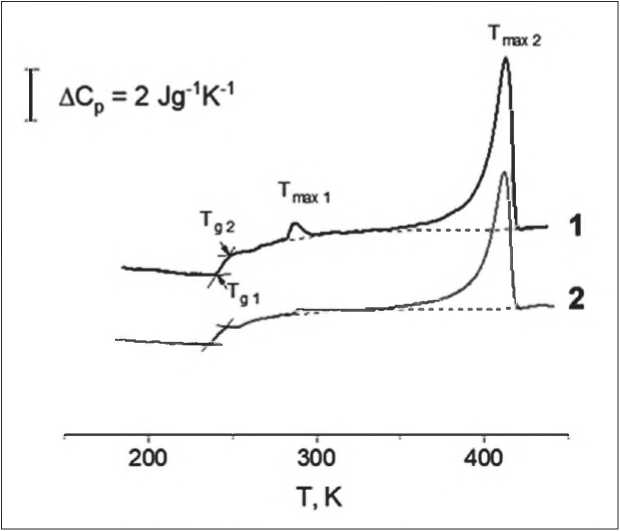

Experimental DSC curves for bitumen and modified binder are shown in Fig. 2. On both curves of heat flow in the temperature ranges Tg: 241—249 К (from —32°C to -24°C) for bitumen and 235-241 К (from -38°C to -32°C) for MB a “step” associated with the glass transition process is observed. According to the temperature position, tins “step” is into the temperature range of glass transition of the amorphous part of low molecular weight polyethylene (for bitumen - waxes). In the samples studied, the volume of this amorphous part is ~ 60%. The second interesting fact is that the peak observed for tins bitumen at T = 288 K, which is typical for the melting of paraffins with a chain length of about 16-19 units, is strongly reduced for the modified sample and slightly

shifted to 290 K. It should be noted that for the MB, the enthalpy of melting AHI decreases to 2 Jg-1 from 8 Jg-1 for bitumen and, accordingly, the content of the crystallized part of the wax is much lower than in the bitumen sample. Consequently, in this sample, most of the waxes do not form isolated local volumes in which microcrystalline nuclei can form (decrease in enthalpy of melting AH2) but serve as plasticizer for the matrix (tiffs is indicated by a decrease in the temperature range of melting). Most likely, this fact indicates that at these cooling rates, steric hindrances in the sample matrix significantly reduce the number and size of wax crystals due to the presence of micro- and sub-microparticles of rubber [33].

At the first stage of the rheological studies, the effect of sample preparation (thermal history) of samples (see Table 1) on the rheological parameters was evaluated.

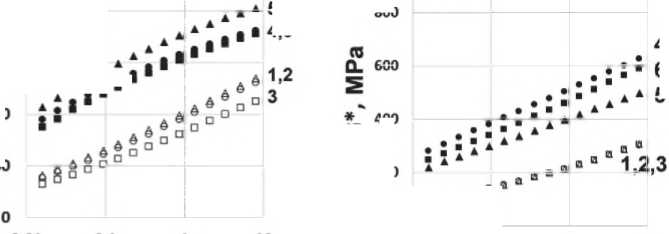

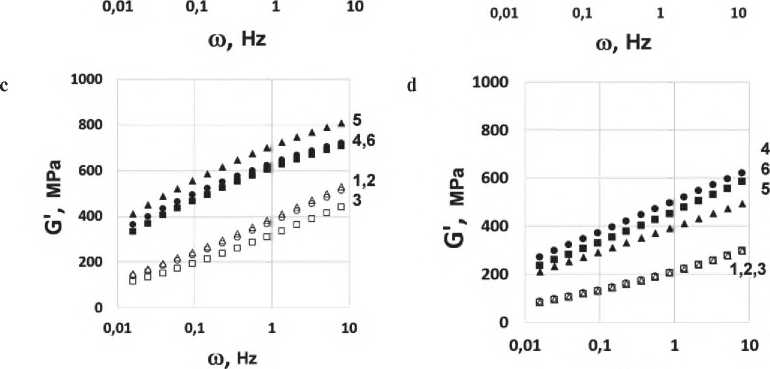

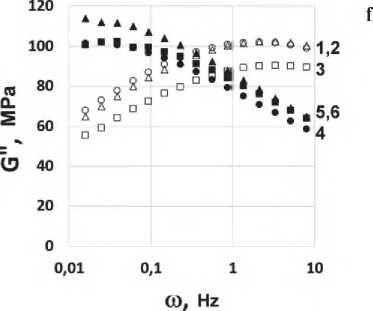

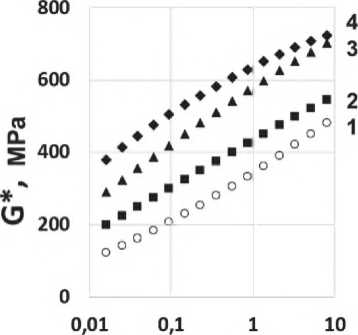

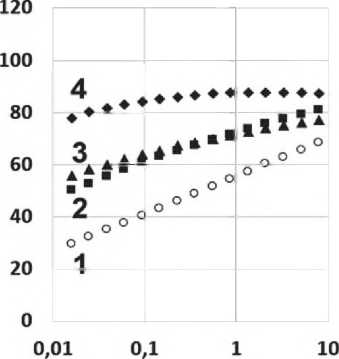

Fig. 3 shows plots of the complex modulus (G*) (a, b), storage modulus (G') (c, d), loss modulus (G" (e, 1) and phase angle (6) (g, h) for bitumen and MB at temperatures of -20 and -36°C for sample preparation program P-1 (curves 1, 4); P-2 (curves 2, 5); P-3 (curves 4, 6) as a function of test frequency (to) (test variant TV-1).

Ta b le 2

ABCD test results

|

Material |

Cracking temperature (actual), °C |

Strain jump, pr |

Fracture stress, o, MPa |

|

Bitumen |

-34.3 |

16.1 |

2.3 |

|

MB |

-41.7 |

26.8 |

4.2 |

Fig. 2. Heat capacity (Cp) curves of bitumen (1) and MB (2) samples. Heating rate 5 K/min

THE RESULTS OF THE SPECIALISTS'AND SCIENTISTS' RESEARCHES

a

*

ID

b

4,6

<0

CD a a a ° °

(0, Hz

g

e

CD

« CL E

0,01

aB§8

(0, Hz

§

h

Be

a IS

«S'

;

I

I

0,01

0,1

e

g

з

0,01

@ 8

CO, Hz

8sSsagB з

.....:;^2

4,5

0,1

to, Hz

Fig. 3. Frequency dependence curves of complex modulus (G*) — a, b, storage modulus (G') — c, d, loss modulus (G") — e, f, phase angle (5) — g, h at — 20°C (curves 1, 2, 3) and — 36°C (curves 4, 5, 6). Sample preparation programs: P-1 (curves 1, 4); P-2 (curves 2, 5); P-3 (curves 3, 6). Test variant TV-1. Bitumen on the left and MB on the right

THE RESULTS OF THE SPECIALISTS'AND SCIENTISTS' RESEARCHES

Analyzing the curves shown in Fig. 3, we can note a significant influence of thermal history on the behavior of bitumen samples at both test temperatures. For MB samples at -20°C the sample preparation program did not matter (all the curves are very close), whereas at -36°C the behavior of the MB is determined by the test program.

It should be noted that the bitumen sample with thermal history P-2 (annealing) at —36 oC showed maximum values of G*, G and G in the whole frequency range compared to samples with thermal history P-1 and P-3 (while sample MB - minimum); minimum values of phase angle (6) and stronger dependence of 6 on frequency compared to MB. A possible explanation for the different effect of “annealing” on the structure of the binder is that the bitumen sample was annealed at a lower temperature than the MB sample: - 165 and 175°C, respectively. Available data in the literature indicate that the complete disappearance of the microstructure of bitumen binder was observed at temperatures near 180°C [34]. In this case, it may be assumed that the P-2 sample preparation program for modified binders was accompanied by microstructure homogenization during annealing at 175°C with subsequent formation of a softer structure, as compared to the P-1 program, where low-temperature hardening is not completely removed by short-term heating to 70°C.

That said, let's note the closeness of the test results of samples with sample preparation programs P-1 and P-3 (keeping after annealing seven days) for both bitumen and MB, which indicates the reversibility of the binder microstructure after “annealing”. It is planned to reduce the keeping time of samples after annealing in the future in order to estimate the rate of microstructure reversibility, although it is obvious that it may be different for bitumen with various chemical compositions.

Also, in analyzing the results presented in Fig. 3, the difference in the behavior of the G" and G" curves of

bitumen and the MB is visible. If the values of storage modulus G' in both cases are increasing with increasing temperature and test frequency, the curves of loss modulus G" show a more complex behavior, being significantly different for bitumen and MB. The G" value grows like G' in the whole test frequency range at — 20°C for MB, while for bitumen the growth of G" is slowing and a very weakly pronounced maximum is observed, regardless of the sample preparation program. The values of the loss modulus G" of bitumen with sample preparation program P-2 (curve 5) decreases in whole range of test frequency, and there is a slight maximum at low frequencies with a further decrease for specimens prepared according to programs P-1 (curve 4) and P-3 (curve 6). For the MB at the same temperature, the curves corresponding to sample preparation programs P-2 and P-3 (curve 5 and 6, respectively) increase, while at P-1 program (curve 4) the growth of the loss modulus G" slows down and a very weakly pronounced maximum is observed.

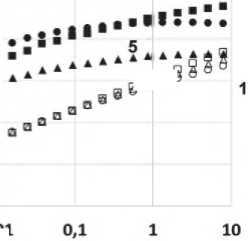

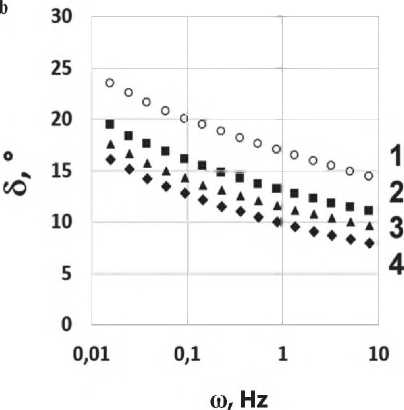

In Fig. 4 the graphical dependences of the loss modulus G" on the storage modulus G' (Cole-Cole diagram) are presented for bitumen and MB samples with different sample preparation programs at -30°C.

As can be seen, there is a maximum on the curves of RTFO-aged bitumen (Fig. 4 a) whose position in frequency is different in the test variants TV-1 and TV-2 (values are given in Table 3), while on the curves of the MB a maximum is not observed (Fig. 4 b).

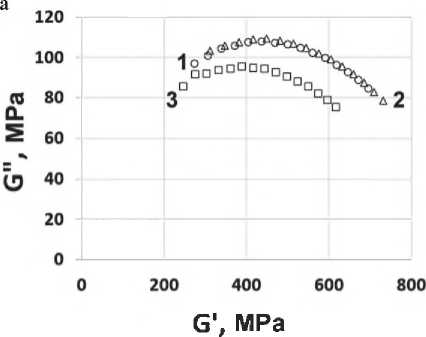

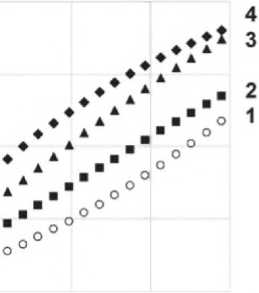

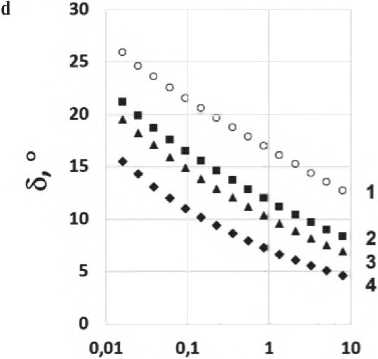

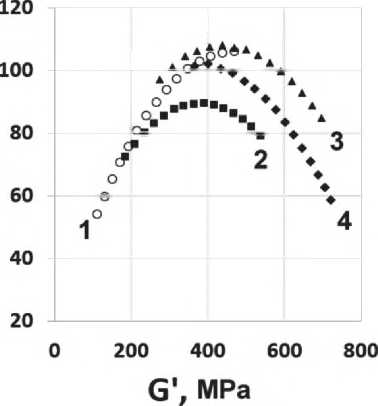

The sample preparation program P-1 was chosen for further tests as the most reproducible one. Fig. 5 shows curves the frequency dependence of complex modulus (G*) (a); storage modulus of (G') (b); loss modulus (G") (c); phase angle (6) (d) for RTFO-aged bitumen at temperatures: -20; -26; -30 and -36°C, for each temperature used a new sample (test variant - TV-2). As can be seen, with lowering temperature and increasing frequency

Fig. 4. Cole-Cole diagrams at temperature —30°C for bitumen (a) and MB (b). Sample preparation program P-1 (curves 1); P-2 (curves 2), P-3 (curves 3)

THE RESULTS OF THE SPECIALISTS'AND SCIENTISTS' RESEARCHES

CO, Hz

b 800

£ 400

S

CD 200

0,01 0,1 1 10

KO

CD 60 ® * 4

о

40 0,01 0,1 1 10

CO, Hz

CO, Hz

(O, Hz

Table 3

|

Bitumen binder |

Bitumen (P-1) |

MB (P-1) |

|||

|

Test variant |

TV-1 [26] |

TV-2 |

TV-1 [26] |

TV-2 |

|

|

Frequency corresponding to the maximum on the Cole-Cole diagram |

ш(...пих. Hz |

||||

|

Test temperature T, °C |

-36 |

0.0248 |

0.0248 |

2.1019 |

2.1019 |

|

-30 |

0.1465 |

0.1465 |

no |

no |

|

|

-26 |

0.1465 |

0.5556 |

no |

no |

|

|

-20 |

2.1019 |

no |

no |

no |

|

Fig. 5. Plots of test frequency dependence (co) in DSR-4mm test: a — complex modulus (G*), b —storage modulus (G'), c - loss modulus (G"), d - phase angle (6) for RTFO-aged bitumen sample at temperatures: -20°C (1); -26°C (2); -30°C (3) and -36°C (4). Sample preparation program P-1, the test variant - TV-2

THE RESULTS OF THE SPECIALISTS'AND SCIENTISTS' RESEARCHES of testing, the complex modulus G* and storage modulus G' grow. The loss modulus G"behaves otherwise: it shows an increase at — 20°C, and has a broad maximum at —26 and -30°C. At -36°C, there is a decrease in the G" values, almost in the whole frequency range. The low phase angle values are worth noting, especially at -36°C, where they are 16 to 4 degrees in this frequency range.

It should be noted that the temperature of -36°C is close to the cracking temperature of bitumen in static conditions in the AB CD test, which was determined to be —34.3°C. There is an opinion that among all methods of low-temperature tests, the results of AB CD method with relative deformation about 0.012 % are the closest to the dilatometric method for determining the glass transition temperature [35].

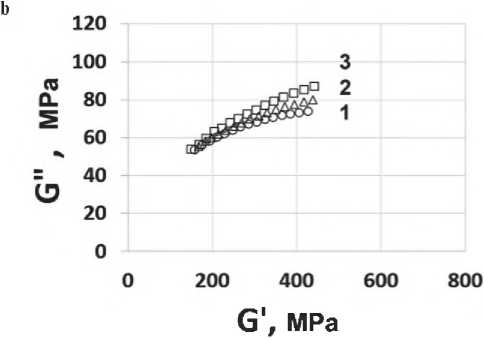

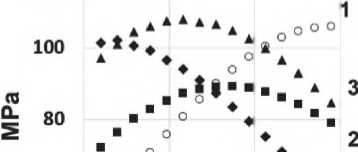

Fig. 6 shows plots (G") (a) and phase angle (6) (b) as a function of frequency at temperatures of -36 and -30°C for the RTFO-aged modified binder. Samples were prepared according to the P-1 program, a new sample was used for each temperature (test variant - TV-2). For the MB, as well as for bitumen, there is an increase of G* and G' (not given) and a decrease of phase angle (6) in the studied temperature range. At the same time, the slope angle of the 6 plot at -36°C is less than that of bitumen and there are higher 6 values: from 16 to 8 degrees. The growth of the MB loss modulus (G") is slowing down with decreasing temperature; so that the G" curves corresponding to the test temperatures -26 and -30°C are crossing each other; and a plateau-like curve is observed at -36°C.

Fig. 7 shows the Cole-Cole diagrams of RTFO-aged bitumen and MB (sample preparation program P-1, test variant - TV-2) at temperatures: -20; -26; -30 and

—36°C. As can be seen from Fig. 7a, Cole-Cole diagrams of bitumen at temperatures -26; -30 and -36°C are characterized by the presence of a well-defined maximum, which can be interpreted as a dynamic (mechanical) glass transition, arising under the action of the applied load at a frequency (tOy..^). It can also be assumed that the temperature at which the loss modulus of bitumen already goes down at a small (0.016 Hz) frequency is close to the temperature of glass transition. On the Cole-Cole diagram of the modified binder (Fig. 7b), as can be seen, a similar maximum appears only at -36°C.

The absence of a maximum in the Cole-Cole diagram of the MB (Fig. 7 b), combined with higher phase angle values compared to bitumen and lower modulus values (Fig. 6), suggests a favorable effect of the modifier on the bitumen structure and a lower dynamic glass transition temperature. This conclusion is confirmed by the lowering of the cracking temperature in the AB CD test for the MB compared to bitumen (Table 1), as well as the shift towards lower temperatures of the glass transition “step” on the DSC curve (Fig. 2).

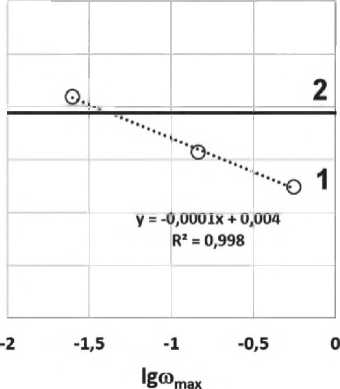

In Fig. 8 for RTFO-aged bitumen a plot of the dependence of the frequency (o)G..max) on the inverse test tempera -true is shown, which has a linear character with a reliability of approximation (R2) of 0.9988. The line (2), parallel to the abscissa axis, corresponds to the value of the inverse cracking temperature of bitumen in ABCD test.

It can be expected that at temperatures below -20°C, loads applied to the samples, even in the FVE-range, will lead to the accumulation of damage affecting the reuse of the specimen. This assumption was confirmed when tests were compared for TV-1 and TV-2 variants. When analyz-

Fig. 6. Plots of the test frequency (co) dependence: a — loss modulus (G"); b — phase angle (6) at the temperatures: -20°C (1); -26°C (2); -30°C (3) and -36°C (4) for the RTFO-aged MB sample. Sample preparation program P-1, the test variant - TV-2

THE RESULTS OF THE SPECIALISTS'AND SCIENTISTS' RESEARCHES

Fig. 7. Cole-Cole diagram for RTFO-aged bitumen samples (a) and MB (b) at the temperatures: — 20°C (1); — 26°C (2); -30°C (3) and -36°C (4). Sample preparation program - P-1, the test variant - TV-2

0,0044

0,0043

0,0042

^ 0,0041

0,004

0,0039

0,0038

ing the table 3, it should be remembered that in both test variants new samples were tested at temperatures of -30 and -36°C. At the temperatures of -20 and -26°C in the TV-2 variant new samples were used, and in the TV-1 variant the samples which had been tested before at -30 and -36°C, respectively. Recall that the test variant TV-1 corresponds to the requirements [26], based on the results of which the bitumen binders are marked by the allowable operating temperature at low temperatures. It can be seen

that preliminary cooling of samples to lower temperature (TV-1 variant), led to the appearance of maximum G" in Cole-Cole diagram ofbitumen at -20°C, which is absent in the TV-2 variant, and to the shift of (0G..max at -26°C towards lower frequencies. Such effects were not observed for MB when tested by variant TV-1.

The 4-mm DSR testing was used to determine the stiffness (S), which characterizes the low-temperature creep of the bitumen binder; the parameter m (m-value), which characterizes the ability to relax and is defined as the slope of the stiffness-time curve. The critical temperatures T(S) (temperature at which S = 300 MPa) and T(m) (temperature at which m = 0. 3, which corresponds to a phase angle of the order of 28 degrees), the parameter AT = T(S)-T(m) (according to [26]) were then calculated. Calculation results are shown in Table 4.

As it can be seen, T(S) of modified binder at any sample preparation program and test variant is lower than that ofbitumen, which can be interpreted as a positive effect of modification. At the same time, there is a wide variation in the results, especially for T(m) modified binder, which in all cases above T(S) and above T(m) bitumen. This should indicate the failure of the modification, but is absolutely against the nature of the experimental curves: the absence of dynamic glass transition in the MB samples. High values of T(m) are also characteristic for binders modified with SBS [36], which are known to resist crack propagation better than unmodified bitumen [37].

Most likely, the accepted limit value of creep coefficient m = 0.3 does not sufficiently satisfy the conditions of brittle fracture, especially for modified samples. It should be taken into account that APDDR rapidly breaks down in hot bitumen, is built into the bitumen structure and

THE RESULTS OF THE SPECIALISTS'AND SCIENTISTS' RESEARCHES forms a physical and/or chemical network, which leads to a decrease in the phase angle. It can be assumed that the bitumen binder is approaching the solid body state (storage modulus gets closer the complex modulus) when the phase angle reaches at least 10 degrees. Therefore, it is reasonable to assume that the value “m = 0.3” for the calculation of the fracture temperature T(m), should be revised by lowering the value of m to 0.1-0.15 [35].

The successful modification effect when using a powder elastomeric modifier capable of structuring bitumen due to rapid breakdown of particles into micro- and nanofragments at their concentration near the threshold of percolation [30,33] may be related to a number of factors, among which should be noted the possibility of including additional stress relaxation mechanisms, since the APDDR particles are above their glass transition temperature in the considered temperature interval. It should also be noted that theoretical studies of the fracture process under applied strains show that elastic particles in the size range from a few microns to a hundred nanometers are the most suitable to protect the binder from cracking. The modification effect is stronger with increasing stress [38].

CONCLUSION

Methods ABCD, DSC and 4-mm DSR were used to test RTFO-aged samples for oil road bitumen BND 60/90 with a Fraas Breaking Point —18°C and modified binder (MB), obtained by short-term mixing (3 min; 160°C and 600 rpm) bitumen with active powder of discretely devulcanized rubber (APDDR), produced by high temperature shear-induced grinding of crumb rubber.

It is shown that:

-

- modification lowers the actual cracking temperature of bitumen under static ABCD test conditions and increases the strain jump and fracture stress;

-

— modification shifts the position of the glass transition “step” for bitumen (from -32°C to -24°C) on the experimental DSC curves towards lower temperatures (from -38°C to -32°C). By its temperature position, tins “step” is into the glass temperature range of amorphous waxes;

-

- the results of the 4-mm DSR test showed that there is no phenomenon of dynamic glass transition for MB samples in test temperature and frequency range, which is observed for bitumen;

-

— thermal history of sample preparation has a significant effect on the rheological parameters, on T(S) and T(m) of bitumen and MB, with the most differences observed for the “annealing” of samples;

-

- the smaller scatter of parameter T(S) values for MB than for bitumen may indicate a greater homogeneity of MB samples microstructure;

-

— the high values of T(m) of MB, which are higher than T(S) of MB and higher than T(m) ofbitumen for all thermal histories of the test samples, can be explained by the fact that the modifier is built into the bitumen structure and forms a physical and/or chemical network. It seems reasonable to propose that the norm “m = 0.3” for conversion to the fracture temperature T(m), should be revised by changing the value of m to 0.1-0.15 [36].

The obtained results (lower actual cracking temperature of MB sample by 7oC than bitumen in ABCD test, shift of MB glass transition “step” towards lower temperatures by 6°C on experimental DSR curves, lower dynamic glass transition temperature of MB by at least 10-16°C; reduction of the storage modulus in the 4-mm DSR test) allow to conclude about the increased resistance of the APDDR modified binder to low-temperature cracking in static and dynamic operating conditions of pavement.

Table 4

Values of T(S), T(m) and ДТ parameters determined by 4-mm DSR test

|

Bitumen binder |

Sample preparation program and test variant |

T (S), °C |

T(m), °C |

дт,°с |

|

Bitumen |

P-1 TV-1 [26] |

-20.24 |

-26.9 |

6.72 |

|

P-1 TV-2 |

-18.01 |

-24.07 |

6.06 |

|

|

P-2 TV-1 |

-14.19 |

-38.80 |

14.61 |

|

|

P-3 TV-1 |

-21.19 |

-23.75 |

2.56 |

|

|

MB |

P-1 TV-1 [26] |

-28.07 |

-11.8 |

-9.82 |

|

P-1 TV-2 |

-23.9 |

-2.3 |

-21.6 |

|

|

P-2 TV-1 |

-24.78 |

-7.95 |

-16.83 |

|

|

P-3 TV-1 |

-27.97 |

-14.89 |

-13.08 |

THE RESULTS OF THE SPECIALISTS'AND SCIENTISTS' RESEARCHES

Список литературы Effect of the active powder of discretely devulcanized rubber on bitumen properties at low temperatures

- Partl M.N., Bahia H.U., Canestrari F., etc. Advances in Interlaboratory Testing and Evaluation of Bituminous Materials. The International Union of Laboratories and Experts in Construction Materials, Systems and Structures (RILEM). Switzerland: Springer; 2013.

- Vinogradov G.V., Isayev A.I., Zolotarev V.A., Verebskaya E.A. Rheological properties of road bitumens. Rheol. Acta. 1977; 16: 266-281.

- Goon R.B. Petroleum bitumens. Moscow: Chemistry; 1973.

- GOST 33133. Public roads. Viscous petroleum bitumen for roads. Technical requirements.

- Dubina S.I., Kondrashin V.G. Quality of Russian highways. Transport of Russian Federation. 2006; 2: 49-50.

- Porto M., Caputo P., Loise V., etc. Bitumen and Bitumen Modification: A Review on Latest Advances. Appl. Sci. 2019; 9(4): 742. https://doi.org/10.3390/app9040742

- Lesueur D. The colloidal structure of bitumen: Consequences on the rheology and on the mechanisms of bitumen modification. Advances in Colloid and Interface Science. 2009; 145: 42–82. https://doi.org/10.1016/j.cis.2008.08.011

- Von Quintus H.L., Mallela J., Buncher M. Quantification of Effect of Polymer-Modified Asphalt on Flexible Pavement Performance. Journal of Transportation Research Board. 2007; 2001(1): 141–154. https://doi.org/10.3141/2001-16

- Laukkanen O-V., Soenen H., Winter H.H., Seppälä J. Low-temperature rheological and morphological characterization of SBS modified bitumen. Construction and Building Materials. 2018; 179: 348–359. https://doi.org/10.1016/j.conbuildmat.2018.05.160

- Elwardany M.D., Planche J.P., King G. Universal and practical approach to evaluate asphalt binder resistance to thermally-induced surface damage. Construction and Building Materials. 2020; 255: 119331. https://doi.org/10.1016/j.conbuildmat.2020.119331

- Masson J-F., Leblond V., Margeson J., Bundalo-Perc S. Low-temperature bitumen stiffness and viscous paraffinic nano-and micro-domains by cryogenic AFM and PDM NRCC-49710. Journal of Microscopy. 2007; 227(3): 191–202. https://doi.org/10.1111/j.1365-2818.2007.01796.x

- Frolov I.N., Yusupova T.N., Ziganshin M.A., Okhotnikova E.S., Firsin A.A. Features of formation of colloidal disperse structure in oil bitumen. Colloidal Journal. 2016; 78(5): 650–654. https://doi.org/10.7868/S0023291216050062.

- Kane M., Djabourov M., Volle J.L., Lechaire J.P., and Frebourg G. Morphology of paraffin crystals in waxy crude oils cooled in quiescent conditions and under flow. Fuel. 2003; 82: 127–135. https://doi.org/10.1016/S0016-2361(02)00222-3

- Musser B.J., Kilpatrik P.K. Molecular characterization of wax isolated from a variety of crude oils. Energy Fuels. 1998; 12(4): 715–725. https://doi.org/10.1021/EF970206U

- Lu X., Langton M., Olofsson P., Redelius P. Wax morphology in bitumen. Journal of Materials Science. 2005; 40: 1893–1900. https://doi.org/10.1007/s10853-005-1208-4

- EN 12593:2015 Bitumen and bituminous binders – Determination of the Fraass breaking point.

- AASHTO T 313. Determining the Flexural Creep Stiffness of Asphalt Binder Using the Bending Beam Rheometer (BBR).

- Jellema E., Scholten E., De Vries S., Soo Kim S., Kluttz B. Comparing cold performance results using fracture toughness test, asphalt binder cracking device, Fraass breaking point and bending beam rheometer. 5th Eurasphalt & Eurobitume Congress. Istanbul. 2012.

- Kim S. Asphalt Binder Cracking Device to Reduce Low-Temperature Asphalt Pavement Cracking. Final Report. Highways for LIFE, Federal Highway Administration, 2010. [Electronic resource]. URL. www.fhwa.dot.gov/hfl/partnerships/asphalt/ez/ez.pdf January 2023.

- Farrar M. Technical White Paper. Determining the Low-Temperature Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). Fundamental Properties of Asphalts and Modified Asphalts III Product: FP. 2015.

- Büchner J., Wistuba M.P., Remmler T., Wang D. On low temperature binder testing using DSR 4 mm geometry. Materials and Structures. 2019; 52: 113. https://doi.org/10.1617/s11527-019-1412-3

- Kommidi S.R. and Kim Y.-R. Investigation of DSR Test Methods to Determine Binder Low Temperature Properties. A Report on Research Sponsored by Nebraska Department of Transportation. 2019. [Electronic resource] URL: https://trid.trb.org/view/1652812 January 2023.

- Radovsky B.S., Teltaev B.B. Viscoelastic characteristics of bitumen and their assessment by standard indicators. – Almaty: Bilim; 2013.

- Hesp S.A.M., Iliuta S., Shirokoff J.W. Reversive Aging in Asphalt Binders. Energy and Fuels. 2007; 21: 1112–1121. https://doi.org/10.1021/ef060463b

- Berkowitz M., Filipovich M., Sevilla A.B., Hesp S.A.M. Oxidative and Thermoreversible Aging Effects on Performance-Based Rheological Properties of Six Latin American Asphalt Binders. Energy and Fuels. 2019; 33(4): 2604–2613. https://doi.org/10.1021/acs.energyfuels.8b03265

- GOST R 58400.9-2019 Petroleum bituminous binder materials. Method for determining the low-temperature properties using a dynamic shear rheometer (DSR).

- GOST R 58400.8-2019 Petroleum bituminous binder materials. Method for determining the stiffness and creep of bitumen at negative temperatures using a beam bending rheometer (BBR).

- GOST R 58400.11-2019 Petroleum bituminous binder materials. Method for determining the temperature of cracking with the device ABCD.

- Büchner J., Wistuba M.P., Dasek O., Staschkiewicz M., Soenen H., Zofka A., Remmler T. Interlaboratory study on low temperature asphalt binder testing using Dynamic Shear Rheometer with 4 mm diameter parallel plate geometry. Road Materials and Pavement Design. 2022; 23(4): 890–906. https://doi.org/10.1080/14680629.2020.1851291

- Nikol’skii V., Dudareva T., Krasotkina I., Gordeeva I., Vetcher A.A., Botin A. Ultra-Dispersed Powders Produced by High-Temperature Shear-Induced Grinding of Worn-Out Tire and Products of Their Interaction with Hot Bitumen. Polymers. 2022; 14(17): 3627. https://doi.org/10.3390/polym14173627

- Nikolsky V.G., Sorokin A.V., Lobachev V.A., Krasotkina I.A. Dudareva T.V. Method of obtaining highly dispersed polymeric material and device for its implementation: RF Patent 2 612 637. 09.03.2017. Application № 2015131481 from 29.07.2015.

- GOST 33140-2014. Petroleum viscous road bitumens. Method for determination of aging under the influence of high temperature and air (RTFOT method).

- Nikol’skii V., Dudareva T., Krasotkina I., etc. Mechanism of multi-stage degradation in hot bitumen of micronized Elastomeric Powder Modifiers from worn-out tire’s rubber. Polymers. 2022; 14(19): 4112. https://doi.org/10.3390/polym14194112.

- Nahar S.N., Schmets A.J.M., Scarpas A., Schitter G. Temperature and thermal history dependence of the microstructure in bituminous materials. European Polymer Journal. 2013; 49(8): 1964–1974. https://doi.org/10.1016/j.eurpolymj.2013.03.027

- Zolotarev V. Methods for determining stresses at key temperatures. Construction and Building Materials. 2022; 345: 128365. https://doi.org/10.1016/j.conbuildmat.2022.128365

- FHWA-HIF-21-042 Delta Tc Binder Specification Parameter. Technical Brief. Federal Highway Administration (FHWA). 2021. [Electronic resource] URL. https://www.fhwa.dot.gov/pavement/asphalt/HIF_Delta_Binder_Spec_Tch-Brf.pdf January 2023.

- Lesueur D., Elwardany M.D., Planche J.-P., Christensen D., King G.N. Methods for determining stresses at key temperatures. Construction and Building Materials. 2021; 293(1–2): 123464. https://doi.org/10.1016/j.conbuildmat.2021.123464

- Kaplan A.M., Chekunaev N.I. Theoretical Foundations of Grinding Heterogeneous Materials. Theoretical foundations of chemical technology. 2010; 44(3): 354–362.