Effect of Various Filler Materials on Interlaminar Shear Strength (ILSS) of Glass/Epoxy Composite Materials

Автор: C.Venkateshwar Reddy, P.Ramesh Babu, R.Ramnarayanan

Журнал: International Journal of Engineering and Manufacturing(IJEM) @ijem

Статья в выпуске: 5 vol.6, 2016 года.

Бесплатный доступ

The main objective of the study was to investigate the effect of various filler materials on inter laminar shear properties of glass/epoxy composite materials. In this study three different filler materials were selected (SiO2, TiO2, Glass powder) for high strength and stiffness applications. The physical properties are also studied with the composites. The fiber volume fraction of material plays vital role in preparation of composite laminates. The fabrication method used was conventional hand lay-up process depending upon the resin system hot temperature cure and room temperature curing processes were selected. The short beam shear test was carried out to test inter laminar shear strength (ILSS). The short beam shear test results inter laminar shear strength and to find the significant influence of filler material on characterization of glass fiber reinforced plastic (GFRP) composite. The test results shown that high shear strength were observed with silicon dioxide(SiO2) filler material and with 10% of silicon dioxide filler material shows maximum ILSS value.

Glass fiber, hand layup process, filler material, ILSS

Короткий адрес: https://sciup.org/15014412

IDR: 15014412

Текст научной статьи Effect of Various Filler Materials on Interlaminar Shear Strength (ILSS) of Glass/Epoxy Composite Materials

Published Online September 2016 in MECS

Available online at

small amount of filler/foreign particles will significantly improve engineering properties of the polymers. Glass fiber reinforced plastics (GFRP) composite material was developed to fulfill all the requirements of industry for high strength and low weight. E-glass fibers are mostly used because they have special characteristics such as high strength to weight ratio, good dimensional stability, good resistance to heat and corrosion.

The properties of composite material depend greatly on the physical properties of polymer matrix and type of fillers used. The uniform dispersion of fillers in the polymer matrix is a pre requisite for achieving improved interfacial properties. The various filler materials are incorporated in the matrix to modify the physical properties. In this study three different filler material like SiO 2 , TiO 2 , Glass powder are used to investigate the inter laminar shear properties. Test results indicates that 10% of SiO 2 filler material exhibits better inter laminar shear strength compared to other filler materials.

Epoxy resin is one of the widely used polymer matrix in the composite industry due to its excellent addition to many reinforcement materials. Its high hardness, excellent resistance to humidity, good mechanical and thermal properties coupled with processability. The properties of fiber reinforced composite materials are different for different constituents. The end properties of the composites depend not only on the matrix but also on the material composition, size, and shape of the fiber. Surface modification can affect many properties such as strength, hardness, wear resistance, heat dissipation and dimensional stability.

Even though several research papers are available on epoxy filled with filler materials. A study on effect of fillers on inter laminar shear strength (ILSS) on special purpose composites has not been performed. Therefore the main objective of the study is the addition of various types of fillers to epoxy resin and specifically analyzing ILSS of composite materials.

-

2. Experimentation

-

2.1. Materials:

-

-

2.2. Preparation of Samples:

The test specimens was made from Bi-woven E-glass fiber with 0/90 fiber orientation as reinforcing material. The thickness of reinforcing fiber is measured as 13 mil(0.33 mm). In the present investigation organic filler materials were used with weight percentage to fabricate composite laminates. The details of materials used as shown in below

Table 1. Details of Materials Used

|

Constituents |

Specifications |

|

Reinforcement |

E-Glass fiber |

|

Epoxy |

LY-556 |

|

Hardener |

HY5200, HY 951 |

|

Filler materials |

SiO 2 , TiO 2 , Glass powder |

Test specimens prepared by hand layup process. In this process a metal mould of 300mm x 300 mm can be used. The mould inside surface is cleaned with acetone or any cleaning solution for easy removal of laminate from the mould can be used with wax or petroleum jelly agent is applied. The E-glass fibers are to be cut as per the size of mould and layered on flat surface of the mould. The matrix material epoxy resin LY556 and hardener HY5200 with varied fiber volume fraction of silicon dioxide and titanium dioxide filler is applied evenly on the surface of the fiber cloth. The excess resin is squeezed with the help of roller. The laminates are cured at high temperature (HT) curing.

The reinforcing materials are stacked one above the other to require thickness. The mould must be compressed. In the similar way different fiber volume fraction of titanium dioxide and glass filler material samples are to be prepared. The matrix material epoxy resin LY 556 and hardener HY 951 with varied fiber volume fraction of glass powder as filler material used to prepare the laminates at room temperature (RT) curing.

The prepared mould kept in the oven and set the temperature of the oven to 1500 C @ 10 C per minute. When the test specimen temperature reaches 1400C hold and maintain for four hours. After completing hold period start cooling the oven from 1400C to 600C @ 10C per minute. When the air temperature reaches to 600C the oven has to be switched off air temperature reaches to room temperature. Than the mould is taken out from the oven and the laminates are removed from the mould and cut into required size as per ASTM standards to test inter laminar shear strength (ILSS).

Fig.1. Specimen preparation by using Hand Layup Technique

Fig.2. Specimen preparation by using Hand Layup Technique

-

2.3. Specimen Testing:

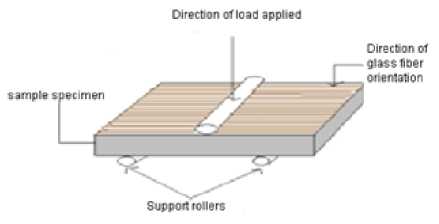

Four test specimens L 0 , L 1 , L 2 , L 3 with different fiber volume fractions 0%, 5%, 10% and 15% of filler materials of five samples of each were made and average value was considered to test inter laminar shear strength. The test was carried out by using universal testing machine INSTRON 4505 with cross head speed is 1 mm per minute and span length to specimen thickness ratio s/t = 4 was selected for this test. ILSS was calculated as per ASTM D 2344 standards. The force applied at the time failure was recorded.

The inter laminar shear strength (ILSS) = 0.75 P/bh

Where ILSS is Inter laminar shear strength (N.mm2) P is the braking load (N)

‘b’ and ‘h’ are width and depth of the specimen (mm)

Fig.3. Specimens Loading For Inter Laminar Shear Strength (ILSS)

Fig.4. Specimens Loading For Inter Laminar Shear Strength (ILSS)

-

3. Results and Discussions

-

3.1 Physical properties:

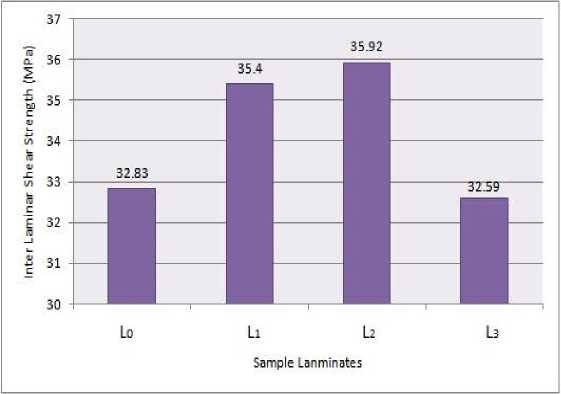

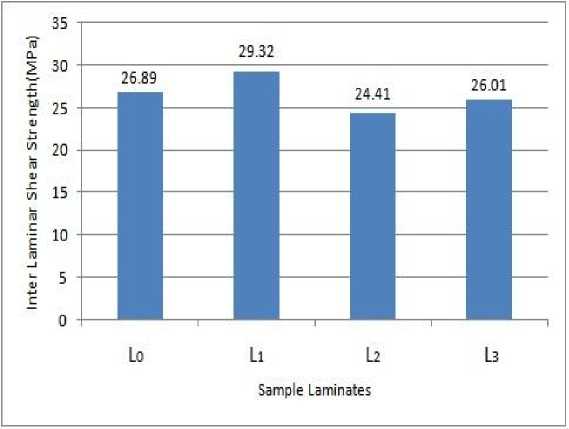

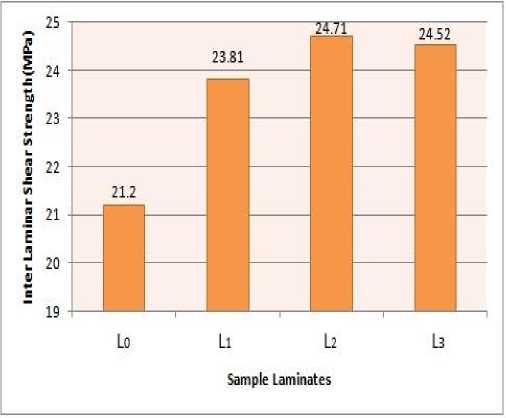

In this study ILSS of glass epoxy composites filled with varied volume fraction of SiO2, TiO2, Glass powder filler materials were evaluated.

The physical properties of any composite material depend on fiber volume fraction and density. The matrix and reinforcement of material plays vital role for determining the strength and stiffness.

Table 2. Details of Physical Properties of Silicon Dioxide Filler Material

|

Fiber volume fraction (%) |

|||

|

Specimen Code |

Resin |

Fiber |

Density (gm/cc) |

|

L 0 |

31.26 |

68.74 |

1.80 |

|

L 1 |

42.12 |

57.88 |

1.67 |

|

L 2 |

32.74 |

67.26 |

1.81 |

|

L 3 |

35.16 |

64.84 |

1.78 |

The physical properties of test results indicates that optimum fiber volume fraction (32.74% of resin and 67.26% of fiber) and maximum density is 1.81 is obtained in the composite filled with 10% volume of silicon dioxide.

Table 3. Details of Physical Properties of Titanium Dioxide Filler Material

|

Fiber volume fraction (%) |

|||

|

Specimen Code |

Resin |

Fiber |

Density (gm/cc) |

|

L 0 |

40.65 |

59.35 |

1.6288 |

|

L 1 |

39.74 |

60.26 |

1.6954 |

|

L 2 |

37.60 |

62.40 |

1.6973 |

|

L 3 |

36.60 |

63.40 |

1.7623 |

The physical properties of test results indicates that optimum fiber volume fraction (36.60% of resin and 63.40% of fiber) and maximum density is 1.7623 is obtained in the composite filled with 10% volume of Titanium dioxide.

Table 4. Details of Physical Properties of Glass Powder Filler Material

Fiber volume fraction (%)

|

Specimen Code |

Resin |

Fiber |

Density (gm/cc) |

|

L 0 |

28.64 |

71.36 |

1.6032 |

|

L 1 |

34.00 |

66.00 |

1.6786 |

|

L 2 |

38.83 |

61.17 |

1.7247 |

|

L 3 |

29.50 |

70.50 |

1.7083 |

The physical properties of test results indicates that optimum fiber volume fraction (38.83% of resin and 61.17% of fiber) and maximum density is 1.7247 is obtained in the composite filled with 10% volume of glass powder.

-

3.2 . Inter laminar shear strength analysis:

Inter laminar shear strength (ILSS) depends on matrix properties and fiber matrix interfacial strength.

Details of inter laminar shear properties of different filler materials.

Table 5. Average ILSS Values of SiO2, TiO2 and Glass Powder Filled Glass/Epoxy Composite Specimens.

|

Specimens |

ILSS(MPa) of S i O 2 |

ILSS (MPa) of T i O 2 |

ILSS (MPa) of Glass Powder |

|

L 0 |

32.83 |

26.89 |

21.20 |

|

L 1 |

35.40 |

29.32 |

23.81 |

|

L 2 |

35.92 |

24.41 |

24.71 |

|

L 3 |

32.59 |

26.01 |

24.52 |

Fig.5. Shows ILSS Value of S i O 2 Filled Glass/Epoxy Composite Specimen

Fig.6. Shows ILSS Value of T i O 2 Filled Glass/Epoxy Composite Specimen

Fig.7. Shows ILSS Value of Glass Powder Filled Glass/Epoxy Composite Specimen

-

4. Conclusion

The addition of fillers (S i O 2, T i O 2 , Glass Powder) materials in Glass/Epoxy composite material influence the inter laminar shear strength. From the test results it indicates that Physical properties of silicon dioxide filler material shows improved density compare to other two filler materials. Laminates filled with 10% of S i O 2 , Glass Powder filler material shows maximum inter laminar shear strength. To conclude fillers can be used as reinforcing filler in epoxy for thermo set polymers. However careful analysis has to be made to decide which type of filler to be used depending upon their application and use.

Список литературы Effect of Various Filler Materials on Interlaminar Shear Strength (ILSS) of Glass/Epoxy Composite Materials

- M.N Channa pagoudra, Ajith G joshi, Sunil thaned, Mahantesh Patil, "Effect of Hematite filler material on mechanical properties of Glass/epoxy composites" International Journal of Innovative Research in Science and Technology Vol.2, Issue II, November 2013, ISNN: 2319-1163.

- Anshuman Srivastava, Madhusoodan Mourya "Preparation and Mechanical Characterization of epoxy based composites developed by Bio-waste material" International Journal of Research in Engineering and Technology Vol.4, Issue 04 April 2015, ISNN: 2395-0056.

- Manjunath Shettan, Vithal Rao Chauhan, "Investigation of Mechanical Properties of E-glass epoxy resin with Asbestas filled/Hybrid Composites" Global Journal of Engineering Science and Research Management. Shetter, 2(2) February 2015] ISNN: 2349-4506.

- Venkat Reddy. G., Shobha Rani. T., Chowdji Rao, K. and Venkata naidu,S. (2009) Composites Flexural, Compressive and Inter laminar Shear Strength Properties of Kapok/glass, Journal of Reinforced Plastics and Composites, 28: 1665-1677.

- Ibtihal A. Mahmood, Wafa A. Soud, Orhan S. Abdullah, "Effect of Different types of fillers on wear Characteristics of Carbon-Epoxy Composites" Al-Khwarizmi Engineering Journal, 2013, Vol. 9, No.2, PP-85-93.

- Ashok Kumar. M., Hemachandra reddy. K., Mohan reddy.Y.V., Ramachandra Reddy. G., Venkat Naidu.S., 2010 "Improvement of Tensile and Flexural Properties in epoxy/Clay Nano composites reinforced with Weave glass fiber reel". International Journal of Polymeric Material, 59:854-862.

- S.Chandra basava raju, Dr. H.K. Shivanand, Santhosh Kumar S, "Evaluation of Tensile and Flexural Properties of Polymer matrix Composites", International Journal of Modern Engineering research, Vol. 3, Issue 5 Sep-Oct 2013, PP-3312-3180, ISNN: 2249-6845.

- D.Chandra Mohan, Dr.K. Marimuthu, Tensile and Hardness Tests Natural fiber reinforced Polymer Composite Material., IJAEST Vol.6, Issue 1, 97-104, 2011.

- Sankara Rao B, Buragohain M and Ramaswamy K 'Composite Rocket Motor Casing Design, Materials & Technologies', National symposium on strategic materials &technologies for composites, 10-15, 2003.

- Madhavi M, Rao KVJ and Narayana Rao K 'Design and analysis of Filament wound Composite Pressure Vessel with integrated end domes', Defence Science Journal, 59(1), 73-81, 2009.

- Donnet JB, Bansal RC. Carbon fiber, 3rded. New York; Marcel Dekker, 1998.

- H. Zhuang & J. P. Wightman, 'The Influence of surface properties on Carbon Fiber/Epoxy Matrix Interfacial Adhesion', 62(1-4), 1997.

- Jang BZ. Advanced polymer composites: principles and applications. ASM Int 1994.

- D. M. Miller. "Glass Fibers, Engineered Materials Handbook," Vol.3 – Composites, ASM International. 2000, pp. 45-48.

- L. L. Zhai, L. GP and W. YW. "Effect of nano-Al2O3 on adhesion strength of epoxy adhesive and steel" International Journal of Adhesion &Adhesives, Vol. 28 (2008) 23-28.