Effective gypsum compositions with the addition of underburned ash and slag mixtures

Автор: Petropavlovskaya V.В., Novichenkova T.В., Buryanov A.F., Lykyanova N.A.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Construction materials science

Статья в выпуске: 5 Vol.16, 2024 года.

Бесплатный доступ

Introduction. Currently, research and development in the field of nanomaterials science is being conducted worldwide. The rationale for developing innovative energy-saving materials based on gypsum binders for buildings and structures with optimized carbon dioxide (CO2) emissions allows us to consider underburnt ash and slag mixtures as a promising technogenic product that allows us to comprehensively solve technological, economic and environmental problems in the construction industry. The study of the possibility of synthesizing promising mineral compositions based on underburnt products isolated from non-recyclable ash and slag mixtures (ASM) of coal-fired power plants ensures the development of a base of design and engineering solutions for buildings and facilities with rational energy consumption and optimized CO2 emissions using gypsum nanomaterials with unique properties. Materials and methods. In the study, technogenic carbon (underburning) was isolated from ash and slag mixtures by flotation enrichment using reagents (flotators). Results and discussions. The results of the study of energy-efficient gypsum composites based on a technogenic carbon modifier confirm its active participation in the processes of structure formation and crystallization of nanostructured building materials with high-tech characteristics. Conclusion. The research results obtained in the field of developing innovative, energy-efficient, cement-free building materials can contribute to an increase in the level of knowledge and the development of innovative approaches in construction materials science. These findings will be useful for subsequent implementation in the construction industry. The research topic is in line with the implementation of state programs, including the Strategy for Scientific and Technological Development of the Russian Federation.

Carbon footprint, cementless compositions, ash and slag waste, underburning, nanoreinforcement

Короткий адрес: https://sciup.org/142242273

IDR: 142242273 | DOI: 10.15828/2075-8545-2024-16-5-397-403

Текст научной статьи Effective gypsum compositions with the addition of underburned ash and slag mixtures

Original article

Petropavlovskaya V.В., Novichenkova T.В., Buryanov A.F., Lykyanova N.A. Effective gypsum compositions with the addition of underburned ash and slag mixtures. Nanotechnologies in Construction. 2024; 16 (5): 397–403. – EDN: MYNONY.

The construction industry and science, namely ma terials science, play an important role in the field of sustainable development related to ensuring the safety and cleanliness of the natural environment, energy efficiency of construction projects and technologies, reusable use of resources in the creation of infrastructure facilities and the formation of a favorable, comfortable and unique human habitat [1–4]. It is the materials science approaches to the processes of synthesis of materials [3–6] based on the management of the processes of structure for- mation through the organization of a multi-level system for managing their properties. Therefore, the structural characteristics of building composites currently have a decisive influence on the quality of materials and products obtained on their basis [4].

Materials science tasks in the field of composite synthesis today provide for the establishment, provision and maintenance of the required level of characteristics of materials as a system including a matrix (matrix material) and reinforcing components (reinforcing materials). Targeted management of the organization of multi-level reinforcement is based, first of all, determined by the choice of

CONSTRUCTION MATERIALS SCIENCE components, their ratios and the method of reinforcement at each scale level while maintaining their original characteristics [7]. Moreover, according to P.G. Komok-hov [8], it is the type of reinforcement that determines the mechanism for forming a high-strength composite structure. Dispersed strengthening of the binder matrix of artificial stone at the nano- and micro levels with particles up to 1 µm determines the strength and hardness of the composite at the level of the matrix material. The concentration of highly dispersed reinforcing material can reach 20–25%. While the content of fibers that determine the rigidity and strength of the composite at the micro-, meso- and macrolevels can reach 75% or even more.

Dispersed (micro-) reinforcement of the binder matrix in composites is known using polypropylene, glass, basalt or metal fibers [6, 9], acting as microfiber. Reinforcing components can also be filiform crystals of hydrosulfoaluminates [10] carbides, oxides and other compounds.

However, the adhesion of the fiber, as, for example, in the case of using basalt fiber in a cement matrix, when the fiber and cement stone interact at the interface around the fiber, a shell is formed that prevents the adhesion of the matrix and microfiber. G.I. Yakovlev proposed to introduce dispersions of multilayer carbon nanotubes into the composition of the fiber-reinforced concrete mixture, which allow structuring the cement stone along the surface of the reinforcing basalt fibers and thereby develop the contact zone and ensure better adhesion of the stone to the surface of the basalt microfiber. The adhesive interaction of the reinforcing material and the matrix determines the properties of the composite structure with the involvement of structural elements of various sizes in the work, as a result of which the composite works as a single material.

High thermodynamic stability of nanocarbon reinforcing materials and anisotropy determine the efficiency of their use in the composition of dispersion-reinforced composites. However, their high cost and a number of technological aspects hinder their widespread implementation in the construction industry.

It is of interest to use unburned coal as a fuleroid-like reinforcing material, which has undergone high-temperature treatment in thermal power plant boilers and undergone physical and chemical changes. It is formed during the combustion of solid fuel – brown and hard coal, anthracite and is contained in the composition of ash and slag mixtures of hydro-removal, generated as waste at thermal coal power plants [9].

Since, according to various estimates, about 30 million tons of coal combustion products are formed per year during coal combustion in Russia alone, the feasibility of using unburned coal in construction technologies is quite high. So far, the utilization rate of fuel combustion products in our country as a whole does not exceed 10% [3, 9].

Coal ash is one of the largest-tonnage wastes generated as a result of the operation of thermal power plants [14]. So far, the utilization rate of fuel combustion products in our country as a whole does not exceed 10% [3, 7]. In this regard, work is currently being initiated to find all possible effective areas for the use of ash and slag waste from thermal power plants in industrial production [14, 15]. However, among them there are no developments yet aimed at the utilization of unburned waste as a component of binders and mixtures in the production of modern composite materials. Most often, its use is limited to the production of fuel briquettes or other similar materials for combustion as fuel.

Research into the possibility of synthesizing promising construction composites based on unburned coal products isolated from non-recyclable ash and slag mixtures (ASM) of coal plants can ensure a high level of energy efficiency for construction facilities and their production processes.

The objective of this study was to synthesize innovative energy-saving construction composites using enriched underburnt – an isolated component of ash and slag mixtures. A hypothesis was put forward about the interaction of the gypsum matrix, as the most comparable with the fulleroid-like reinforcing carbon technogenic material, the particles of which reach the nanoscale and can be considered as a component of energy-efficient composites for cost-effective production.

During the combustion of coal, various chemical reactions occur in the composition of their mineral part, resulting in the formation of a new technogenic raw material that differs from natural raw materials in chemical and phase composition and has other technological properties.

MATERIALS AND METHODS

In this study, technogenic carbon (underburnt) was isolated from ash and slag mixtures by flotation enrichment using reagents (flotators). The research used the flotation method used in the mining industry for finely dispersed coal sludge, in which flotation is carried out in two stages.

The conducted studies have shown that multi-stage enrichment and flotation of underburnt from the ZShS TPP from the combustion of brown coals is characterized by a higher consumption of reagents in comparison with the flotation of natural coals. This is an undoubted confirmation of the change in the surface properties of brown coal particles during their combustion.

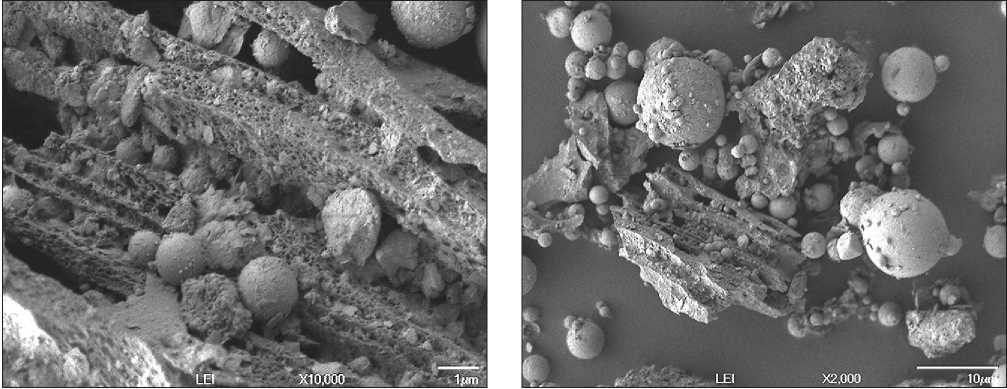

Electron microscopic studies of the microstructure of underburnt on a scanning electron microscope SEM JEOL JSM-6610LV (Fig. 1) showed that their surface is characterized mainly by increased porosity (Fig. 2), determined by the degree of its thermal transformation in the furnace.

CONSTRUCTION MATERIALS SCIENCE

Fig. 1. External view of the scanning electron microscope JEOL JSM-6610LV

Fig. 2. SEM image of man-made carbon

A typical example of underburnt particles with varying degrees of porosity is shown in microscopic images and dark-field images.

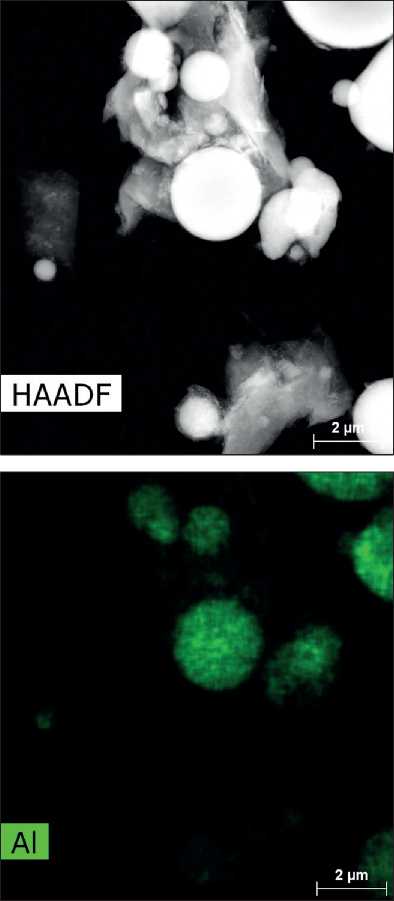

It has been established that unburned carbon is a mesh framework (Fig. 3), which is probably formed during volumetric diffusion of gas during the combustion of brown coal fuel.

It also follows from the data obtained that, since particles of unburned fuel are in the combustion zone or in the temperature zone below 1500–1600°C for a short period of time, then in addition to the carbon skeleton in the composition of the unburned fuel separated from the ash and slag mixture during flotation, there are also individual spheroidal micro- and nanoparticles of aluminosilicates with the presence of a crystalline and amorphous phase (Fig. 2).

The main crystalline phase is the mullite phase, which is typical for aluminosilicate particles formed during thermochemical transformation during coal combustion in a furnace.

Aluminosilicate inclusions are captured by the mesh structure of carbon. They have a wide size distribution, which is confirmed by the analysis of the granulometric composition and dark-field images of underburnt (Fig. 4). The size distribution of underburnt particles in the composition of the separated mixture, determined using a Winner2005A Intelligent Laser Particle Size Analyzer (Fig. 3), was D10 – 2.02 µm, D50 – 7.34 µm,

CONSTRUCTION MATERIALS SCIENCE

Fig. 3. Winner2005A Intelligent Laser Particle Size Analyzer Appearance

Fig. 4. Dark-field images of a sample of man-made carbon (underburnt) and maps of the distribution of chemical elements in its composition

CONSTRUCTION MATERIALS SCIENCE

D0 – 33.56 µm, which differs significantly from the data of other researchers on the sizes of separated fractions (concentrates) from the ash-slag mixture [2].

The study of underburnt particles using a JSM 7401F SEM; TEM/STEM/Osiris (200 kV) electron microscope showed that the spheroid particles are represented by compounds of aluminum and silicon oxides in chemical composition. They are characterized by a compacted vitrified surface of the shell, depending on the degree of its heat treatment in the furnace [16].

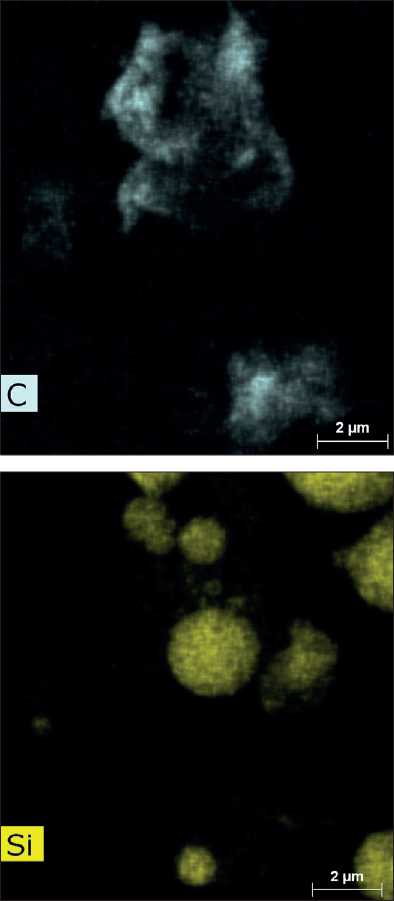

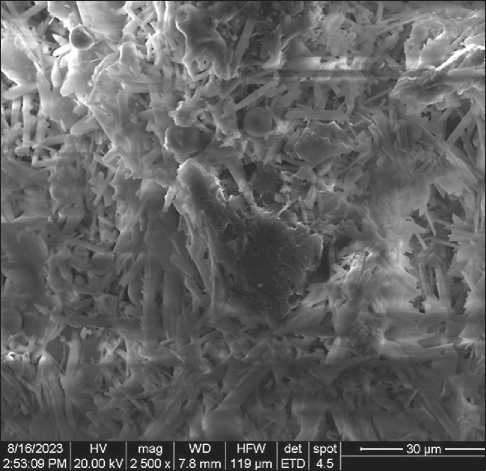

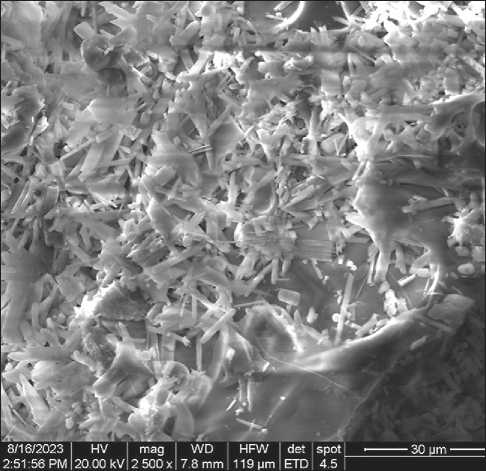

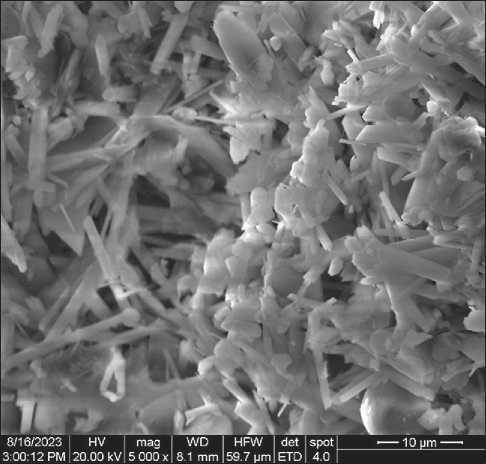

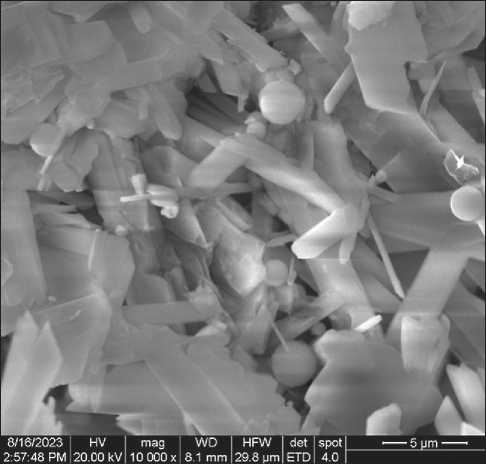

High open porosity and developed surface of unburned metamorphosed carbon fuel particles with captured nano- and microparticles contribute to the active crystallization of the gypsum matrix with a modified morphology of crystals (Fig. 5).

Microscopic studies of the structure at high magnification (Fig. 6) confirm morphological changes in the crystals with their transition to tabular fine-crystalline forms.

The experimental studies of the inclusion of under-burnt as a substance capable of changing the course of

Fig. 5. Amorphized microstructure of gypsum composite

Fig. 6. Electron micrographs of the structure of a gypsum composite with inclusions of nanosized aluminosilicate particles

CONSTRUCTION MATERIALS SCIENCE hydration and structure formation processes in the gypsum matrix and modifying the gypsum stone formed in this case confirmed the accepted hypothesis. An artificial stone with unique properties and structure that meet high energy efficiency requirements in the field of building materials was obtained.

In addition to increasing the overall porosity of the gypsum composite based on underburnt (more than twice), the nature of the porosity also changes. Research using mercury porosimetry methods has established that the introduction of a porous filler in the form of under-burnt containing aluminosilicate particles in the structure significantly changes the distribution of pores. In the structure of the obtained artificial stone based on a manmade carbon modifier, pores no larger than 10 microns are observed, which has a beneficial effect on the thermal and structural characteristics of the gypsum composite.

The results of the study of energy-efficient gypsum composites based on a technogenic carbon modifier confirm its active participation in the processes of structure formation and crystallization of nanostructured building materials with high-tech characteristics. Based on a matrix binder and a fulleroid-like technogenic additive, dispersion-hardened gypsum composites were obtained, characterized by a fine-crystalline structure with high closed microporosity. The studies have established that underburnt waste has a unique structure and properties, which can be effectively used for the synthesis of building composites.

CONCLUSION

Thus, this paper presents research data describing innovative energy-saving building composites for their use in the form of lightweight gypsum structural elements of buildings created by synergistically adding enriched waste from thermal power plants in the form of under-burnt (5–30 wt.%) and aluminosilicate ash microspheres present in its composition. Compared with traditional methods, which include the use of technogenic or artificial nanostructuring additives, the underburnt used in this study has undeniable advantages both in terms of cost and in terms of safety and environmental sustainability [12].

The obtained gypsum composites with additives of a fulleroid-like reinforcing material of underburnt demonstrate comparable physical and mechanical characteristics with other gypsum lightweight materials [17, 18] after standard tests.

However, in these composites, with an increase in total porosity, a significant reduction in the average pore size is observed with their transition to the micro- and nanolevel. In this way, these composites compare favorably with the proposed traditional lightweight materials. At the same time, closed porosity increases by more than a third. This will further determine the high performance properties and corrosion resistance of the resulting artificial lightweight gypsum stone.

Список литературы Effective gypsum compositions with the addition of underburned ash and slag mixtures

- Petropavlovskii K., Ratkevich E., Novichenkova T., Petropavlovskaya V. The use of technogenic carbon in gypsum compositions for green building. E3S Web of Conferences. 2023; 403: 03013. https://doi.org/10.1051/e3sconf/202340303013

- Fomenko E.V., Anshits N.N., Vasilieva N.G., Mikhaylova O.A., Rogovenko E.S., Zhizhaev A.M., Anshits A.G. Characterization of fly ash cenospheres produced from the combustion of Ekibastuz coal. Energy Fuels. 2015; 29(8): 5390–5403. https://doi.org/10.1021/acs.energyfuels.5b01022

- Akulova I.I., Artamonova O.V., Goncharova M.A., Korotkikh D.N., Makeev A.I., Slavcheva G.S. Scientific school of the academician of the Russian Academy of Architecture and Construction Sciences E.M. Chernyshov (in memory of the teacher). Part 2. Scientific and practical developments. Nauchnyj zhurnal stroitel’stva i arhitektury. 2023; 1 (69): 47–67. https://doi.org/10.36622/VSTU.2023.69.1.004. (In Russian)

- Chernyshov E.M., Korotkikh D.N. Effects of self-microreinforcement of cement stone in the presence of gypsum. Improving the efficiency of production and application of gypsum materials and products: collection of materials of the X International scientific and practical conference. 2021. P. 178–183. (In Russian)

- Zhang W., Che J., Wen P., Xia L., Ma B., Chen J., Wang C. Co-treatment of copper smelting flue dust and arsenic sulfide residue by a pyrometallurgical approach for simultaneous removal and recovery of arsenic. Journal of Hazardous Materials. 2021; 416: 126149. https://doi.org/10.1016/j.jhazmat.2021.126149

- Karpova E.A., Yakovlev G.I., Averkiev I.K., Volkov M.A., Kuzmina N.V., Knyazeva S.A. Effect of carbon black and microsilica on the properties of self-compacting concrete. Stroitel’nye materialy. 2022; 12: 45-51. https://doi.org/10.31659/0585-430X-2022-809-12-45-51. (In Russian)

- Makul N., Fediuk R., Amran M., Al-Akwaa M.S., Pralat K., Nemova D., Petropavlovskii K., Novichenkova T., Petropavlovskaya V., Sulman M. Utilization of biomass to ash: an overview of the potential resources for alternative energy. Materials. 2021; 14(21): 6482. https://doi.org/10.3390/ma14216482

- Komokhov P.G., Sycheva A.M., Stepanova I.V., Filatov I.P. Classification of nanostructure dimensions and properties of composite materials. Academia. Arhitektura i stroitel'stvo. 2008; 4: 90-92. (In Russian)

- Saraikina K.A., Golubev V.A., Yakovlev G.I., Senkov S.A., Politaeva A.I. Nanostructuring of cement stone with dispersed reinforcement with basalt fiber. Stroitel’nye materialy. 2015; 2: 34-38. (In Russian)

- Petropavlovskaya V., Novichenkova T., Petropavlovskii K., Buryanov A. Gypsum composites reinforcement. IOP Conference Series: Materials Science and Engineering. 2018; 032060. https://doi.org/10.1088/1757-899X/365/3/032060

- Yu Q.L., Brouwers H.J.H. Development of a self-compacting gypsum-based lightweight composite. Cement and Concrete Composites. 2012; 34(9): 1033-1043. https://doi.org/10.1016/j.cemconcomp.2012.05.004

- Wang S., Pancheti J., Xi Y., Mahendran M. Lightweight composite gypsum boards with clay mineral and glass fibre for enhanced fire-resistance. Composites Part B: Engineering. 2023; 266: 111044. https://doi.org/10.1016/j.compositesb.2023.111044

- Li D., Wu D., Xu F., Lai J., Shao L. Literature overview of Chinese research in the field of better coal utilization. Journal of Cleaner Production. 2018; 185: 959-980. https://doi.org/10.1016/j.jclepro.2018.02.216

- Petropavlovskaya V., Novichenkova T., Sulman M., Petropavlovskii K., R. Fediuk, Amran M. Coal ash enrichment with its full use in various areas. Materials. 2022; 15(19): 6610. https://doi.org/10.3390/ma15196610

- Hajiyev Sh., Delitsyn L., Kulumbegov R., Popel O., Sulman M., Petropavlovsk K., Firsov S. Pilot tests of coal-fired thermal power plant ash processing. Ekologiya i promyshlennost’ Rossii. 2022; 26(12): 4-9. https://doi.org/10.18412/1816-0395-2022-12-4-9. (In Russian)

- Aladesuyi O., Pal M., Das S.K., Ajanaku K.O. Phase and Microstructural evolution during sintering of mixture of 75:25 Nigeria kaolin and calcined alumina powder compacts. Journal of Materials and Environmental Sciences. 2016; 8(8): 2682-2838.

- Peng Y., Unluer C. Development of alternative cementitious binders for 3D printing applications: A critical review of progress, advantages and challenges. Composites Part B: Engineering. 2023; 252:110492. https://doi.org/10.1016/j.compositesb.2022.110492

- Q. Yu, H. Brouwers Development of a self-compacting gypsum-based lightweight composite. Cement and Concrete Composites. 2012; 34 (9): 1033-1043. https://doi.org/10.1016/j.cemconcomp.2012.05.004