Efficiency of carbon nanostructures in the composition of wood-polymer composites based on polyvinyl chloride

Автор: Abdrakhmanova L.A., Galeev R.R., Khantimirov A.G., Khozin V.G.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Development of new polymer materials

Статья в выпуске: 3 Vol.13, 2021 года.

Бесплатный доступ

Introduction. The most effective binding agents in wood-polymer composites based on polyvinyl chloride are carboncontaining nanostructures, which improve the electrical, physical-mechanical, rheological properties, as well as the structure and durability of the composites. Their main disadvantage is a high degree of particle aggregation, which makes it difficult to mix and process them in polymer compositions. In this regard, an urgent task is to search for such carbon nanomodifiers that would have a low degree of aggregation and low cost. Methods and materials. The paper studies the effectiveness of mechanically activated petroleum cokes as binding agents in building wood-polymer composites based on polyvinyl chloride. Mechanical activation leads to the functionalization of carbon particles of coke with the formation of oxygen-containing groups on the surface. The effect of various amounts of coke (up to 10% of the mass of wood flour) is considered and the relationship between the nature of coke and their concentration in the polymer compositions with the main technological (melt flow) and operational (tensile and bending strength, high elasticity modulus, hardness, water absorption and thermal stability) indicators and supramolecular structure of woodpolymer composites has been identified. Results and discussion. With the introduction of cokes, a high degree of orientation of the supramolecular structures of the composites in the direction of extrusion of the samples is observed, which leads to an increase in the breaking strength and bending strength, as well as the high elasticity modulus. The optimal concentration of additives was determined from 0.1 to 5%. In relation to wood flour, the amount of which in the wood-polymer composition is 50 mass parts per 100 mass parts PVC. Conclusion. The introduction of mechanically activated petroleum cokes as binding agents in wood-polymer composites based on polyvinyl chloride has been carried out. Mechanical activation made it possible to reduce the aggregation of coke particles into larger agglomerates, which makes it possible to efficiently introduce the nanomodifier in dry form and to exclude the introduction of nanomodifier in the form of aqueous dispersions, which is a rather energy-intensive production operation.

Polyvinyl chloride, wood-polymer composite, binding agent, carbon nanostructures

Короткий адрес: https://sciup.org/142226901

IDR: 142226901 | DOI: 10.15828/2075-8545-2021-13-3-150-157

Текст статьи Efficiency of carbon nanostructures in the composition of wood-polymer composites based on polyvinyl chloride

Wood-polymer composites (WPC) are modern composite materials obtained by combining thermoplastic polymers with organic fillers. Of greatest interest as a filler for WPC is wood flour, which makes it possible to obtain profile molded products of various functional purposes in construction. These products are characterized by high bioresistance, weather resistance, low water absorption, uniformity of structure and good combinability with other building materials [1].

As a polymer in WPC, polyethylene (PE), polypropylene (PP) and polyvinyl chloride (PVC) are usually used, however, from the point of view of performance characteristics for the construction industry, the use of PVC is most preferable [2–5].

The main way to reduce the cost of WPC products is to increase the degree of filling of composites (up to and

DEVELOPMENT OF NEW POLYMER MATERIALS more than 50 mass parts). However, this often negatively affects both technological and operational characteristics, which is associated with a deterioration in the adhesion between the filler and the polymer. The most effective way to increase the degree of interaction between wood flour and polymer matrix is the use of binding agents. Currently, for polymers, binding agents in the form of nanosized additives are widely used, mainly having a carbon base, among which the most effective are carbon nanotubes and nanosized technical carbon.

The effect of nanotubes on the properties of PVC composites has been studied rather extensively [6–12]. These researches show in detail the improvement of electrical, physical-mechanical, rheological properties, as well as the structure and durability of such composites.

Known studies of the effect of nanosized carbon black on various polymer composites [13–18]. However, the effect of carbon black on the properties of PVC composites has been little studied; to a greater extent, such studies were carried out on the basis of polyolefins. In [16], polymer composite materials based on high density polyethylene and carbon black with a particle size of 20–35 nm were obtained. Optimal improvement in properties (tensile strength, fracture strain, melt yield point, electrical conductivity) was observed in the range of 12–18%.

Compositions based on polyethylene filled with fuller-ene-containing technical carbon were studied in [18]. Fullerenes of the С50–С92 group were contained in the filler in an amount of 10% of the mass. It was found that the introduction of fullerene-containing carbon up to 1.5 mass parts significantly increases the tensile strength (by 1.5 times), but at the same time, the melt flow index decreases, which negatively affects the processability of the compositions.

There are two main hypotheses [19] to explain the effect of material enhancement upon the introduction of carbon black. According to one of them, this effect is explained by the presence of van der Waals forces of interaction between carbon atoms in the particles of the modifier and polymer chains; another hypothesis assumes interphase interaction due to the presence of free radicals on the surface of technical carbon particles capable of initiating the process of chemical crosslinking at the interface.

As is known, the main disadvantage of nanosized additives is their high tendency to aggregation, due to which it is difficult to achieve their uniform distribution in the volume of the polymer composite. To solve this problem, nanoadditives are distributed in various media-carriers, preventing their adhesion [20–22]. However, the additional distribution of nanostructures in media – carriers leads to an even greater rise in the cost of already expensive nanoadditives, to the introduction of additional equipment into the production technology.

Another way to prevent aggregation of nanostructures is the functionalization of their surface, which has already shown its effectiveness in comparison with native modifiers [23–26]. The introduction of functionalized nanostructures does not require the introduction of additional technological operations, however, this nanoproduct itself is quite expensive, which is a significant disadvantage for manufacturers of polymer products and affects the cost of production.

Thus, an urgent task is to search for such carbon nanomodifiers that would have a low degree of aggregation, low cost, and were also supplied in dry powder form to exclude additional energy-intensive stages in the production of WPC composites.

In this work, a mechanically activated product of petroleum coke processing, which is a finely dispersed black powder, was used as a nanomodifier. Mechanical activation is accompanied by the appearance of oxygencontaining groups on the surface of coke particles, which impart a negative charge, due to which the Coulomb repulsive forces between charged aggregates increase and, accordingly, their aggregation into larger agglomerates is prevented. We used coke with different degrees of mechanical activation: 1.34 (coke 1) and 0.57 (coke 2). If they are used in hydrophobic polymer compositions, it is possible to expect an increase in the interaction at the phase boundary.

The aim of this work was to study the effect of various amounts of coke (up to 10 mass parts per 100 mass parts PVC) on the performance properties of wood-polymer composites based on PVC and to evaluate its effectiveness as a binding agent in comparison with previously used nanoadditives of a carbon structure.

MATERIALS AND METHODS

The compositions included PVC S-7059-M (100 mass parts), stabilizer-lubricant calcium stearate (3 mass parts), heat stabilizer dibasic lead stearate (5 mass parts), impact strength modifier FM-50 (7 mass parts) and coke-modified wood flour grade 180 (50 mass parts). The introduction of cokes was carried out by adding and mixing them in the required amount into a small part of the wood flour (10% of the required amount), then the concentration of cokes in the wood flour was gradually reduced by adding and thoroughly mixing with the rest of the wood flour.

For the study of PVC composites, samples were obtained in the form of films and extrudates. Film samples were prepared by thermoplastication on laboratory rolls LB 200 100/100 at a roll temperature of 160-170оC for 4–5 minutes. Each series of samples was prepared simultaneously at the same temperature regime and at the same gap between the rolls ~0.010–0.020 cm.

The extrudates were produced by the extrusion method on a laboratory twin-screw extruder LabTechScientific LTE 16–40 with a flat die (2x20 mm) at a temperature in the forming zone of 210оC and a shaft rotation speed

DEVELOPMENT OF NEW POLYMER MATERIALS

Table 1

Test methods for PVC samples

The particle size distribution of cokes was obtained on a Horiba LA-950 laser analyzer using ultrasonic treatment.

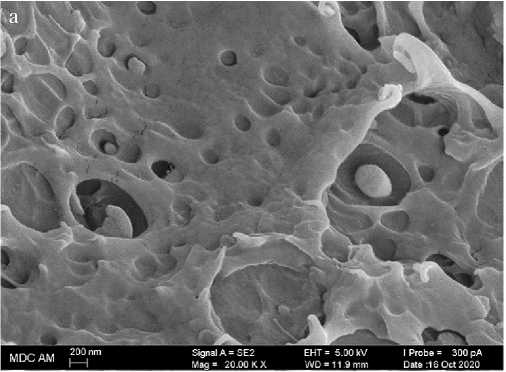

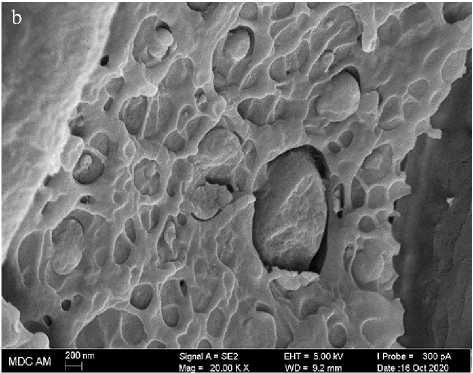

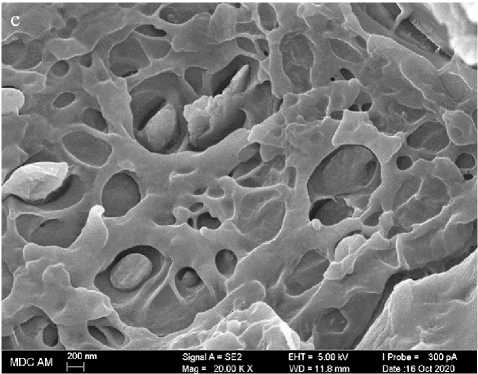

The study of the microstructure of brittle cleavages of the extrudates of WPC-compositions was carried out by high-resolution scanning electron microscopy on an AURIGA microscope, combined with an IncaEnergy 350 X-Max energy dispersion spectrometer (EDS).

Technological and operational properties of samples of composites based on PVC were carried out in accordance with the applicable standards given in Table 1.

RESEARCH RESULTS AND DISCUSSION

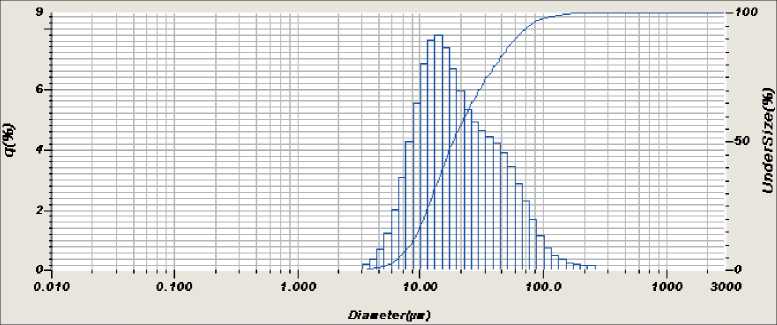

The study of the granulometric composition showed that the average size of agglomerates of coke 1 particles was 28 µm, coke 2–35 µm (Fig. 1). The large sizes of aggregates of coke 2 in comparison with aggregates of coke 1

Fig. 1. Size distribution of coke 1 (a) and coke 2 (b)

a)

b)

DEVELOPMENT OF NEW POLYMER MATERIALS are due to the fact that the latter has a higher degree of mechanoactivation, which means that there is a greater number of oxygen-containing groups on the surface of the particles, leading to different morphologies of aggregated coke particles and. It should be noted that the particle size distribution of coke 2 has a rather pronounced bimodal character.

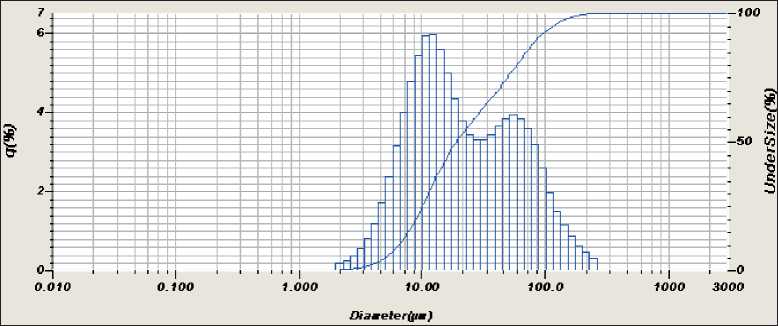

The most important property of carbon structures is the ability to form chain structures. If you look at the distribution of coke particles with an electron microscope, you can see a significant difference in the morphology of the particles of the two cokes (Figure 2).

Agglomerates of coke 2 are lined up in the form of chains, and coke 1 in the form of dispersed particles of various sizes from 6 microns to single aggregates up to 100 microns in size. Due to the formation of chain structures, a higher degree of hardening of the polymer composite can be expected when they are introduced into the formulation of the polymer composition.

The study of the effect of cokes on the properties of the obtained WPC was first carried out on film samples, for which such indicators as tensile strength, melt flow index (MFI), and thermal stability were determined (Table 2).

Fig. 2. Micrographs of coke 1 (a) and coke 2 (b)

Table 2

Dependences of strength (a), MFI (b) and thermal stability (c) for PVC film samples on the concentration of the modifier

|

Concentration, % by weight of DM |

Tensile strength, MPa |

Melt flow rate, g/10 min |

Thermal stability, min |

|

Coke 1 |

|||

|

0 |

32 |

0.49 |

225 |

|

0.1 |

40 |

0.31 |

238 |

|

0.35 |

38 |

0.76 |

210 |

|

1 |

36 |

0.47 |

226 |

|

5 |

31 |

0.47 |

240 |

|

10 |

32 |

0.42 |

197 |

|

Coke 2 |

|||

|

0.1 |

37 |

0.15 |

211 |

|

0.35 |

34 |

0.52 |

232 |

|

1 |

36 |

0.82 |

241 |

|

5 |

35 |

2.43 |

253 |

|

10 |

36 |

1.41 |

234 |

DEVELOPMENT OF NEW POLYMER MATERIALS

Table 3

Properties of extruded samples of PVC-WPC

|

Sample |

Density, kg/m3 |

Tensile strength, MPa |

Flexural strength, MPa |

Water absorption, % |

Vitrification interval, оC |

Flow point, о C |

High elasticity modulus, N/сm2 |

|

Basic |

1.156 |

32 |

85 |

1.68 |

89–125 |

238 |

17 |

|

0,1% coke 1 |

1.175 |

34 |

86 |

1.61 |

94–127 |

230 |

26 |

|

5% coke 2 |

1.320 |

40 |

94 |

1.41 |

87–120 |

236 |

28 |

It can be seen from the data that the extremum of the tensile strength at break falls on 0.1%. In general, up to 10% of modifiers, strength indicators remain stably high. Coke 2 in the amount of 5 and 10% influences the processability of the compositions to a greater extent, while a significant decrease in the viscosity of the melts is observed. Obviously, the chain structure and size of aggregates of coke particles, close to the size of wood flour fibers, facilitate the processing of the melt. The maximum thermal stability time also falls on the composition with 5% coke 2.

Based on the results of testing film samples, the following optimal concentrations were selected for further study: coke 1 – 0.1, and coke 2 – 5% of the mass of wood flour. Samples for these compositions were made in the form of extrudates.

The results of a number of operational and physical properties of the extrudates are shown in table 3.

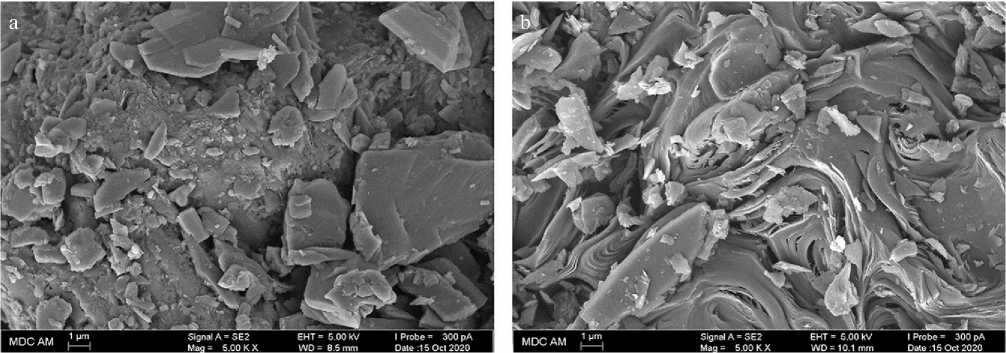

Indicators (vitrification interval, vitrification and flow temperatures, high elasticity modulus) were obtained from the analysis of thermomechanical curves shown in Fig. 3.

Tensile strength increases by 23% with 5% coke 2. At these concentrations, coke particles apparently penetrate into the interglobular space of PVC macromolecules and wood flour particles, fill the voids and serve as a compatibilizer for the polymer-filler interface.

Fig. 3. Thermomechanical curves of PVC-WPC samples (rate of temperature rise 3оC/min, specific compressive load 1N)

DEVELOPMENT OF NEW POLYMER MATERIALS

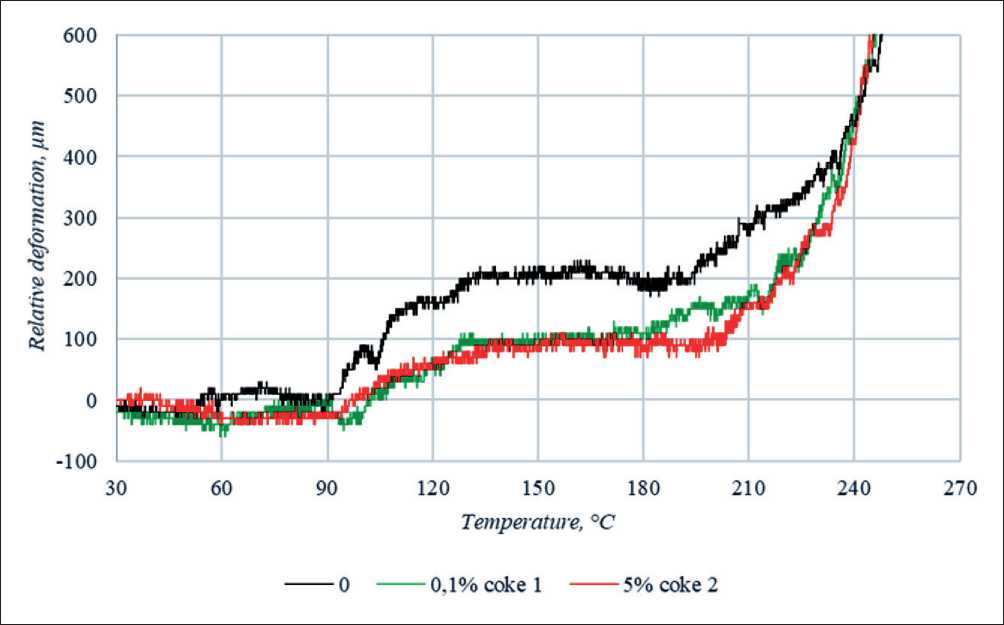

Fig. 4. Micrographs of the surface of a brittle cleavage of PVC-specimen extrudates:

a – without modifier;

b – with 0.1% coke 1;

c – with 5% coke 2 (scale 200 nm)

In WPC, in the presence of modifiers, the pour point decreases in all cases. A decrease in the magnitude of the highly elastic deformation is observed, and, accordingly, an increase in the modulus of elasticity.

The water absorption of the samples decreases in the presence of modifiers, which correlates with the data on strength and density (Fig. 3c). The water absorption of the composition with coke 1 is reduced by 17% and for coke 2 by 20%.

To explain the peculiarities of changes in the properties of extruded composites upon the introduction of cokes, the microstructure of the samples was studied. As shown in Fig. 4 micrographs in the nanometer range can be seen that for samples with 0.1% coke 1 and 5% coke 2, a greater degree of orientation of supramolecular structures in the direction of extrusion is observed as compared to an unmodified sample (especially in the presence of coke 2), which also causes a higher tensile strength.

CONCLUSION

The introduction of mechanically activated petroleum cokes as binding agents in wood-polymer composites based on polyvinyl chloride has been carried out. Mechanical activation made it possible to reduce the aggregation of coke particles into larger agglomerates, which makes it possible to effectively introduce the nanomodifier in dry form, and not in the form of aqueous dispersions, which is a rather energy-intensive production operation.

The introduction of coke 1 in an amount of 0.1% increases strength by 18%, density by 9% and reduces water absorption by 17%. In compositions with a coke content of 2 in an amount of 5%, strength increases by 23%, density by 12%, water absorption decreases by 20%; in addition, the melt yield point increases by a factor of 5 in comparison with the base unmodified composition, which is especially important for obtaining high-quality samples when extruding profiles.

DEVELOPMENT OF NEW POLYMER MATERIALS

Список литературы Efficiency of carbon nanostructures in the composition of wood-polymer composites based on polyvinyl chloride

- Klesov A.A. Wood-polymer composites. Saint-Petersburg: Scientific bases and technologies; 2010.

- Matseevich T.A., Askadsky A.A. Mechanical properties of decking based on polyethylene, polypropylene and polyvinyl chloride. Construction: Science and Education. 2017; 7: 3(24): 48–59. Available from: doi: 10.22227/2305-5502.2017.3.4.

- Musin I.N., Faizullin I.Z., Novokshonov V.V., Wolfson S.I. Influence of polymer binder on the properties of wood-polymer composites. Bulletin of Kazan Technological University. 2014; 17(14): 306–309.

- Engel R.G., Ablyasova A.G., Galimova N.Y., Kuryntsev S.V., Nizamov R.K. Composite Materials based on poly(vinyl chloride). Journal of International Scientific Publications: Materials, Methods & Technologies. 2011; 5(3): 27.

- Nizamov R.K. Polyfunctional fillers for polyvinyl chloride compositions for construction purposes. Building materials. 2006; 7: 68–70.

- Silvano L.T., Vittorazzo Jr. A.L., Araujo R.G. Effect of preparation method on the electrical and mechanical properties of PVC Carbon nanotubes nanocomposites. Materials Research. 2018; 21(5): 1–6. Available from: doi: 10.1590/1980-5373-MR-2017-1148.

- Shieh Y.-T., Hsieh K.-C., Cheng C.-C. Carbon nanotubes stabilize polyvinyl chloride against thermal degradation. Polymer Degradation and Stability. 2017; 144: 221–230. Available from: doi: 10.1016/j.polymdegradstab.2017.08.017.

- Aigubova A.Ch., Kozlov G.V., Magomedov G.M., Zaikov G.E. Structural analysis of water absorption for nanocomposites polyvinyl chloride/carbon nanotubes. Vestn. Volgogr. State University. 2015; 4(19): 40–46. Available from: doi: 10.15688/jvolsu10.2015.4.6.

- Pachina A.N., Kassin A.S., Tikhonov N.N., Komissarov D.M. Methods for increasing the atmospheric resistance of polyvinyl chloride. Advances in chemistry and chemical technology. 2017; 31(11): 93–95.

- Zaporotskova IV, Krutoyarov AA, Polikarpova NP Theoretical studies of polymer nanocomposites based on polyethylene, polypropylene and polyvinyl chloride, reinforced with carbon nanotubes. Perspective materials. 2015; 3: 5–11.

- Ashrapov A.Kh., Abdrakhmanova L.A., Nizamov R.K., Khozin V.G. Investigation of polyvinyl chloride compositions with carbon nanotubes. Nanotechnologies in Construction: A Scientific Internet-Journal. 2011; 3(3): 13–24. Available from: http://nanobuild.ru/ magazine / nb / Nanobuild_3_2011.pdf [Accessed 14th April 2021].

- Khozin V.G., Nizamov R.K. Polymer nanocomposites for construction purposes. Building materials. 2009; 8: 32–34.

- Baccaro S., Cataldo F., Cecilia A., Cemmi A., Padella F., Santini A. Interaction between reinforce carbon black and polymeric matrix for industrial applications. Nuclear Instruments and Methods in Physics Research. 2003; 208: 191–194. Available from: doi: 10.1016/S0168-583X(03)00638-4.

- Hatthapanit K., Sae-Oui P., Sombatsompop N., Sirisinha C. Enhancement of Rubber–Carbon Black Interaction by Amine-Based Modifiers and their Effect on Viscoelastic and Mechanical Properties. Journal of Applied Polymer Science. 2012; 1–7. Available from: doi: 10.1002/app.36969.

- Mazlina M.K. Influence of Fillers Surface Characteristics on Bound Rubber Properties of Filled Natural Rubber Compounds. Advanced Materials Research. 2014; 412–416. Available from: doi: 10.4028/www.scientific.net/AMR.845.412.

- Borukaev T.A., Gaev D.S. Physical and mechanical properties of composites based on high density polyethylene and carbon black. Applied Physics. 2017; 5: 76–81.

- Saatchi M.M, Shojaei A. Effect of carbon-based nanoparticles on the cure characteristics and network structure of styrene-butadiene rubber vulcanizate. Polym. Int. 2012; 4: 83–93.

- Igumenova T.I., Kleimenova N.L., Akatov E.S., Popov G.V. Application of fullerene-containing carbon black for modification of polyethylene properties. Vestnik TSTU. 2011; 17(4): 1071–1076.

- Svistkov A.L., Solodko V.N., Kondyurin A.V., Eliseeva A.Yu. Hypothesis on the role of free radicals on the surface of carbon black nanoparticles in the formation of mechanical properties of filled rubber. Physical Mesomechanics. 2016; 19(5): 84–93.

- Amirov R.R., Neklyudov S.A., Amirova L.M. A method of obtaining compositions based on carbon nanotubes and polyolefins. Russian Federation Patent 2490204. 12-19-2011.

- Bogdanova S.A., Gataullin A.R., Galyametdinov Yu.G. Dispersions of carbon nanotubes as modifying additives for polymer composite materials. Actual problems of science on polymers. 2018: 82.

- Gusev K.V., Soloviev V.G. Influence of carbon nanotubes on the mechanical properties of polymer composites. Bulletin of the Pskov State University. Series: Natural and physical and mathematical sciences. 2017; 11: 150–153.

- Ferreire T., Paiva M.C., Pontes A.J. despersion of carbon nanotubes in polyamide 6 for microinjection moulding. Journal of Polymer Research. 2013; 20: 301-310. Available from: doi: 10.1007/s10965-013-0301-7.

- Paiva M., Simon F., Novais R. et al. Controlled functionalization of a solvent-free multicomponent approach. ACSNano. 2010; 4(12): 7379–7386. Available from: doi: 10.1021/nn1022523.

- Nasir M., Mohammad I., Asad H. et al. Polyamide-6-based composites rein-forced with pristine or functionalized multi-walled carbon nanotubes produced using melt extrusion technique. Journal of Composite Materials. 2014; 48(10): 1197–1207. Available from: doi: 10.1177/0021998313484779.

- Dyachkova T.P., Tarov D.V., Kobzev D.E. Investigation of the properties of polyethylene composites based on functionalized carbon nanotubes. Nauchno-tekhnicheskie vedomosti SPbPU. Natural and engineering sciences. 2019; 25(1): 163–173. Available from: doi: 10.18721/JEST.25116.