Energy efficiency and decarbonization of cement and foamed glass production through the use of natural active mineral additives (opoka and diatomite)

Автор: Zhakipbayev B.Ye., Ismailova A.B., Tukhtamisheva A.Z., Seitkazinov O.D., Moldamuratov Zh.N.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: System solutions for technological problems

Статья в выпуске: 6 Vol.16, 2024 года.

Бесплатный доступ

Introduction. In the context of the need to improve energy efficiency and decarbonize cement production, the development of technologies using natural active mineral additives is becoming increasingly relevant. This article examines the use of opoka and diatomite as active additives for producing Portland cement, which allows the clinker content to be reduced by up to 50% while maintaining the operational properties of the cement. Methods and Materials. The research was conducted using electron microscopy, X-ray phase analysis, and energy-dispersive microanalysis. The study analyzed the composition of clinker from SAS-Tobe Technologies, gypsum from the Bagalin deposit, slags from the Novo-Dzhambul Phosphorus Plant, opoka from the Turkestan-Urangay deposit, and diatomite from the Utesai deposit. Physicochemical tests were carried out in the “SAPA” laboratories and at the LLP “SAS-Tobe Technologies” plant. Results and Discussion. The results of the study showed that the addition of opoka and diatomite in a quantity of 15% accelerates mineral formation processes due to the formation of a liquid clinker phase at lower temperatures. This reduces the firing temperature by 100–150 °C, leading to lower energy consumption and improved thermodynamic processes in clinker formation. Conclusion. The introduction of natural mineral additives in Portland cement production reduces clinker content by up to 50%, contributing to energy and resource savings without compromising cement quality. The research results confirm the potential of using opoka and diatomite for decarbonizing the cement industry and increasing its energy efficiency.

Active mineral additives, energy saving and decarbonisation, opoka, diatomite, cement production

Короткий адрес: https://sciup.org/142242751

IDR: 142242751 | DOI: 10.15828/2075-8545-2024-16-6-587-600

Текст научной статьи Energy efficiency and decarbonization of cement and foamed glass production through the use of natural active mineral additives (opoka and diatomite)

Original article

The implementation of energy efficiency and energysaving policies is currently one of the key tools for industrial modernization, ensuring the country’s energy and environmental security [1]. It also promotes the introduction of innovative technologies and solutions, which in turn fosters active interaction between science and technology transfer processes. The primary sources of carbon dioxide emissions in cement production are fuel consumption (mainly for kilns) and limestone calcination [1].

Furthermore, the main obstacle to decarbonizing cement production is the lack of economic incentives for implementing existing CO₂ reduction strategies [1, 2]. In the field of energy saving, the Government of the Republic of Kazakhstan, as part of the State Program for Accelerated Industrial and Innovative Development

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS

(2010–2014) and the State Program for Industrial and Innovative Development-2 (2015–2019), set goals to reduce the energy intensity of gross domestic product by 10% by 2015 and by 25% by 2020 [3, 4].

An analysis of energy consumption patterns in Kazakhstan shows that the primary energy consumers are the industrial sector, including the cement and foamed glass industries [3]. Most enterprises in this sector rely on outdated technologies and operate equipment with high wear levels [3, 4]. Among all building materials industries, the cement industry is the most energy-intensive, depending on both electrical energy (crushers, mills) and thermal energy (kilns) [4–7].

As of early 2023, 7.1 million tons of cement have been produced in Kazakhstan, which is 1.8% more than in the same period of 2022. The Turkestan region has demonstrated the highest growth rates, with production increasing by 23.8%, making the region the national leader in output volume [3, 4]. Between January and September 2023, 1.9 million tons of Portland cement were produced in the Turkestan region, accounting for 27.5% of Kazakhstan’s total production, compared to 22.6% in 2022. Cement plants in the region include Standard Cement LLP, Shymkent Cement JSC, and SAS-Tobe Technologies LLP, the latter planning to reduce product energy intensity by 15% through an energy-saving and efficiency agreement [1–4].

Currently, a modernization program has been developed for the SAS-Tobe Technologies cement plant, focusing on three main areas (cement plant SAS-Tobe, :

– increasing kiln efficiency and reducing fuel consumption through equipment upgrades and the installation of new systems;

– addressing environmental issues by reconstructing kiln electrostatic precipitators;

– transitioning to coal fuel to reduce product costs and improve competitiveness.

Modernization of cleaning systems has been completed, with 99.5% of solid pollutants generated during cement production now captured by new filters, preventing them from entering the atmosphere. The plant actively implements energy-saving technologies, such as replacing outdated clinker cooling systems with state-of-the-art coolers from the Danish company FL-Smidth. As part of the transition to solid fuel, the plant has begun installing a coal mill, which will further reduce production costs [9–12].

The cement industry can use amorphous silica-rich rocks as active mineral additives, where the primary quality criteria are the content of amorphous silica and their hydraulic activity [13–15]. Hydration products formed from such mineral additives do not require additional kiln processing, resulting in significant energy savings [14]. Effective binding of components and the creation of

Class I hybrid materials provide advantageous mechanical properties [12].

Amorphous silica-rich rocks widely found in Kazakhstan include diatomite, opoka, and tripoli. Their mineralogical and chemical characteristics are determined by the presence of siliceous residues derived from diatoms, radi-olarians, and sponge spicules. These components exhibit varying degrees of compaction and high silica content.

Diatomites are sedimentary rocks primarily composed of siliceous diatom residues, widely used in industry as filter materials and in the production of building materials. Opoka, formed through siliceous glass condensation, is used as a filler in cement mixtures. Tripoli, a lightweight rock, finds applications in insulation and as a component in ceramic production.

Due to their unique properties, these amorphous silica-rich rocks have a wide range of applications in construction, building materials production, filtration, and environmental technologies [1–4, 16].

This study focuses on the comprehensive examination of active mineral additives in the development of energysaving technologies for producing cement and foamed glass. The study considers positive results from analyzing cement pastes for plasticity and initial setting times, as reported in studies by Klapishevsky and co-authors [17–20]. The objects of research include technogenic materials (electrothermal phosphorus slags) and natural amorphous silica-rich rocks sourced from Kazakhstan deposits, which have significant reserves and potential as active mineral additives for cement production. The research scope includes the physicochemical processes of clinker formation, thermal treatment, and grindability of clinker combined with mineral additives in developing energy-efficient cement and foamed glass production technologies [21].

MATERIALS AND METHODS

Research was conducted using electron microscopy and energy-dispersive microanalysis of the raw materials and the resulting mixture. These studies were performed at the regional testing laboratory for engineering materials, “Structural and Biochemical Materials,” at South Kazakhstan University named after M. Auezov. A scanning electron microscope (SEM JSM-6490LV), capable of magnifications up to ×300,000, was used for these analyses [4].

Physicochemical analyses of raw materials, clinker, and cement were carried out at the specialized laboratory of physicochemical methods of analysis “SAPA”. Technical and operational tests were conducted at the laboratory of Astana IT University and the production laboratory of SAS-Tobe Technologies LLP [1–4, 7–9].

To produce energy-efficient cements, clinker from SAS-Tobe Technologies was used. Both technogenic and

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS natural materials were employed as additives. The additives included gypsum from the Bagalin deposit, electrothermal phosphorus slags provided by Novo-Dzhambul Phosphorus Plant LLP, opoka from the Turkestan-Urangay deposit, and diatomite from the Utesai deposit. Gypsum, used as an additive, regulates the setting time of cement mixtures and enhances their strength characteristics. Electrothermal phosphorus slags possess excellent adhesion properties, significantly increasing the strength of binding materials. Opoka, with its high silica content, improves water-repellent properties and resistance to external influences. Diatomite, with its lightweight porous structure, is used as an additive to enhance thermal insulation properties and reduce the weight of the final product. Thus, using these materials not only enhances the strength and durability of construction structures but also promotes more efficient utilization of natural resources, ensuring environmentally friendly production technologies [5–11].

The evaluation of the raw materials’ quality characteristics was conducted using both standard and innovative methods, including X-ray spectroscopic analysis, electron microscopy, and energy-dispersive microanalysis. X-ray phase analysis was widely used to study the composition of mineral raw materials. These studies were conducted at the “SAPA” testing center in the physicochemical methods laboratory using a general-purpose X-ray diffractometer (DRON-3), equipped with an X-ray tube (2.0 BGV 24-Cu) featuring a copper radiation source and a nickel filter. Sample analysis was carried out within a diffraction angle range of 4° to 64°, with detector angle displacement recorded via a goniometer and a self-recording potentiometer. The counter rotation speed was 4°/min, and X-ray diagrams were captured at 20 kV voltage and 20 A current. Samples were pre-ground to a size that could pass through a sieve with 10,000 openings per cm² [1–3, 15–18].

Transmission electron microscopy (TEM) investigations were performed using a JEOL JEM-100S (manufactured by JEOL, Japan), with field emission guns under ultra-high vacuum conditions (up to 10–8 Pa). This provided a stable probe current with a diameter of 0.2–0.3 nm and allowed for magnifications ranging from ×1,000 to ×60,000 at accelerating voltages of 40–100 kV. Sample preparation for analysis was carried out by ion etching in vacuum.

A series of electron microscopy and energy-dispersive microanalysis tests were conducted on samples of opoka, diatomite, clinker, gypsum, and slags. For this purpose, a scanning electron microscope SEM JSM-6490LV was used at the engineering profile testing laboratory “Structural and Biochemical Materials” at South Kazakhstan University named after M. Auezov. This microscope provides magnifications of up to ×300,000, enabling in-depth material analysis at the microscopic level. The studies were conducted at magnifications ranging from

×50 to ×1,000, allowing detailed examination of sample microstructures and chemical and X-ray phase analysis of their elemental composition. These analytical methods help determine not only the mineral composition of the studied materials but also their structural characteristics, which are critical for assessing their operational properties.

The results of these studies help establish the potential of these materials for use in construction and other industries while aiding in the development of new technological solutions to improve the quality of building materials [1–2, 7–15].

An integrated approach combining electron microscopy, X-ray phase analysis, energy-dispersive microanalysis, and physicochemical research provided comprehensive data on the structure and composition of the studied materials. This enabled a more accurate assessment of their quality and the determination of optimal component combinations to produce high-quality, energy-efficient cement.

RESULTS AND DISCUSSION

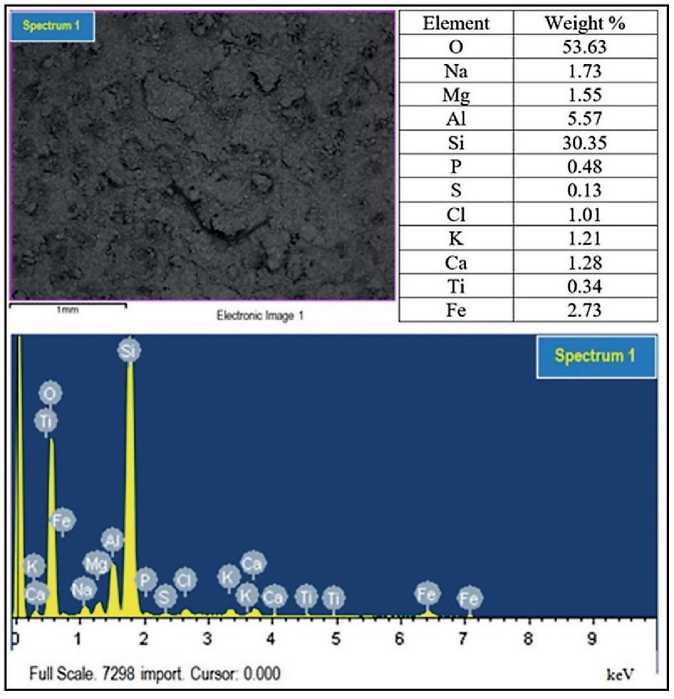

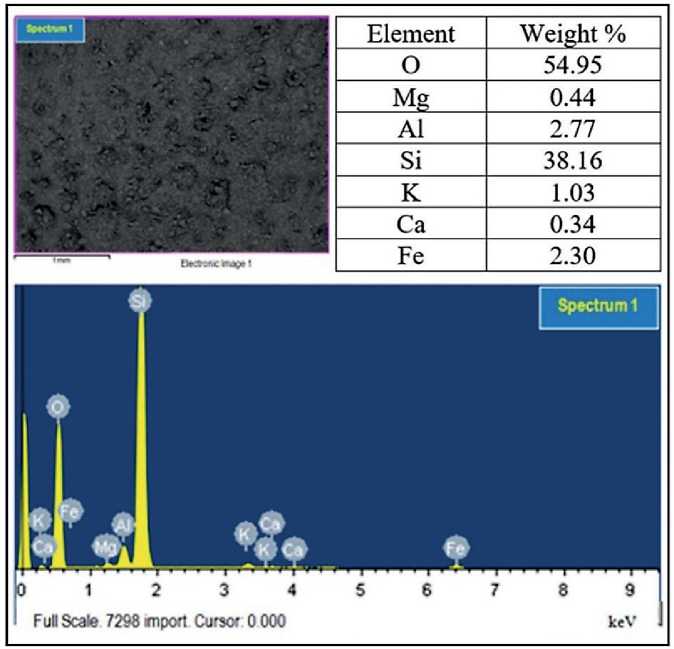

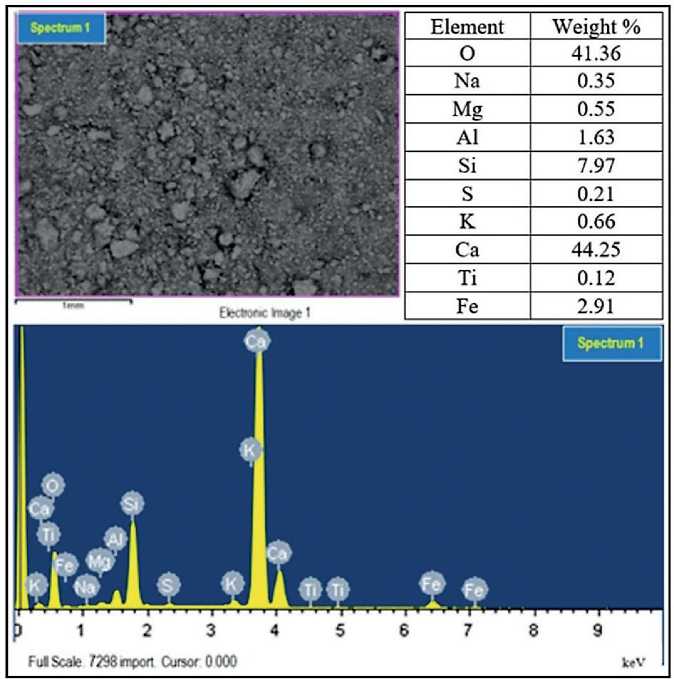

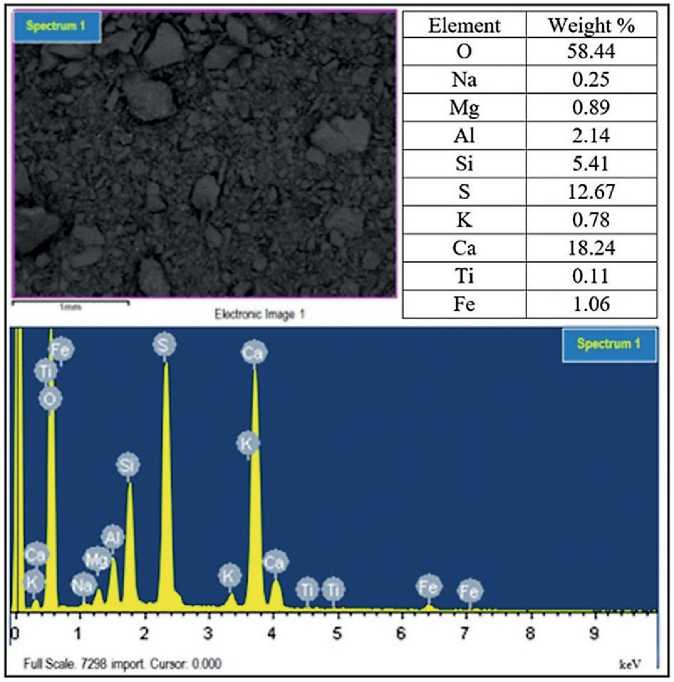

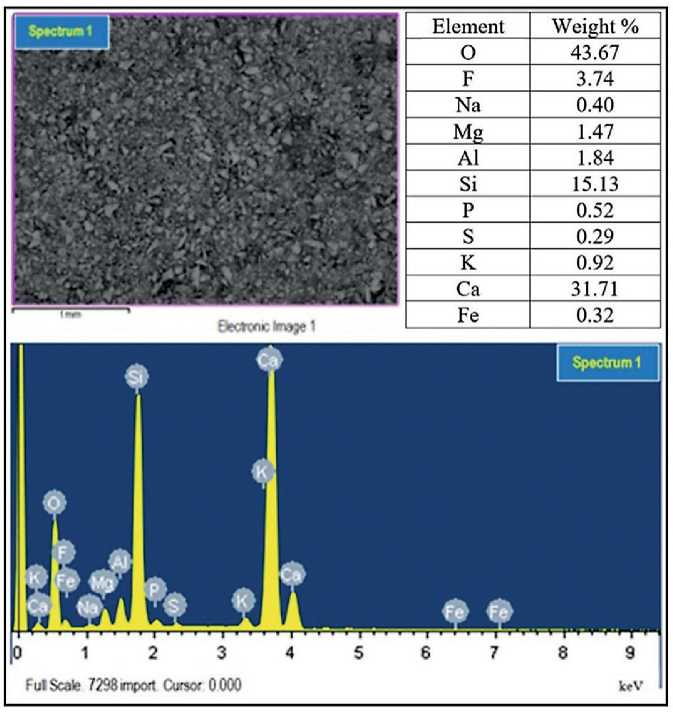

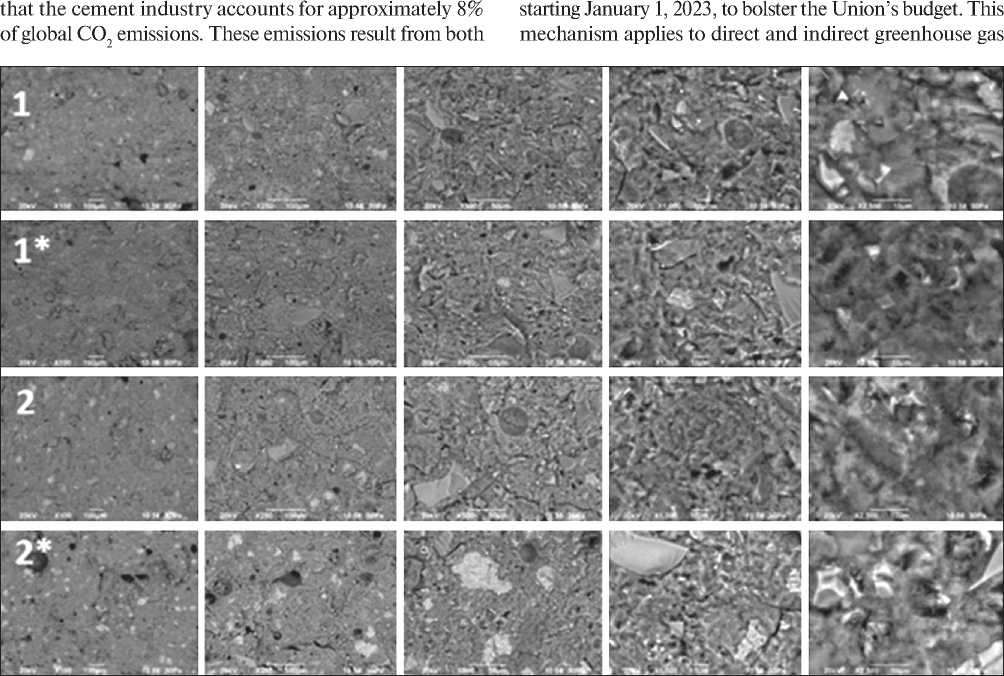

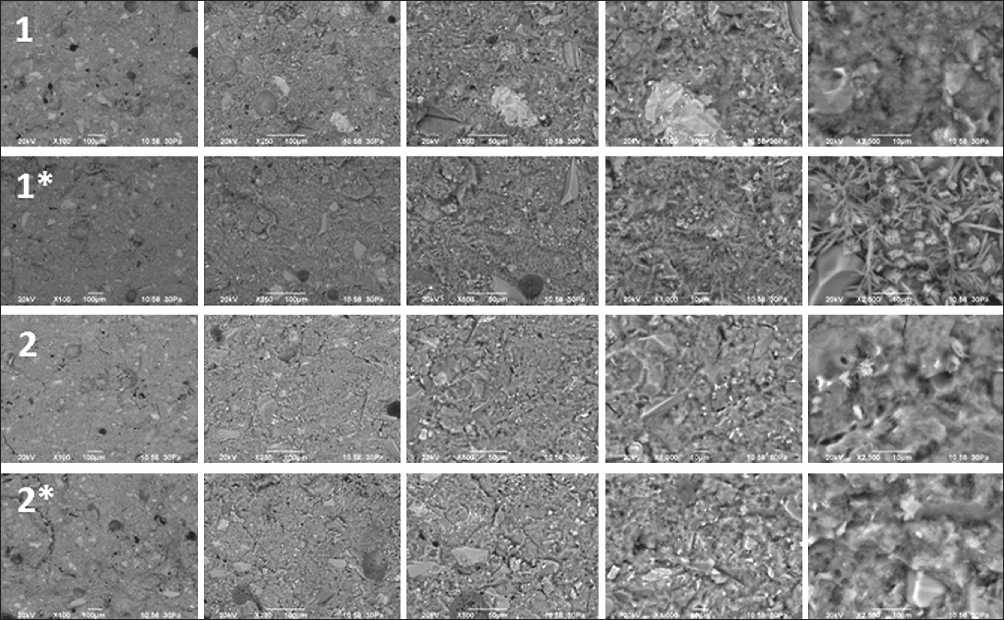

Figures 1–5 present the results of electron microscopy and energy-dispersive X-ray microanalysis of various materials: opoka (Fig. 1), diatomite (Fig. 2), clinker (Fig. 3), gypsum (Fig. 4), and slag (Fig. 5).

Energy-dispersive X-ray microanalysis of opoka, performed using a scanning electron microscope, revealed that most of the material consists of globules formed from small spheroidal mineral aggregates composed of rounded amorphous silica phases at the microscopic level.

Figure 2 shows an electron micrograph of specific areas and the elemental composition of diatomite from the Utesai deposit.

Figure 3 presents the microstructure and elemental composition of clinker from SAS-Tobe Technologies LLP.

The chemical and mineralogical composition of Portland cement clinkers produced by cement plants is presented in Tables 1 and 2. These tables list the main components, such as oxides of calcium, silicon, aluminum, and iron.

Cements produced directly from clinkers often exhibit a tendency for rapid setting in water, which necessitates controlling their hydration rate in practical applications. The most effective way to regulate this process is by adding gypsum [20].

Gypsum is a natural, water-soluble salt of calcium sulfate with the chemical formula CaSO4•2H2O, formed through sedimentary and chemical processes (Fig. 4).

This mineral has a characteristic crystalline structure and is widely used in construction, particularly in the production of drywall, plaster, and other building materials. Due to its unique physicochemical properties, such as ease of processing and high adhesion, gypsum also finds

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS

Fig. 1. Electron micrographs of individual sections and the elemental composition of the investigated opoks of the Turkestan-Urangai deposit. Dominant Element: Si

Fig. 2. Electron micrography of individual sections and elemental composition of diatomite from the Utesay deposit

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS

Fig. 3. Microstructure and elemental composition of clinker «SAS-Tobe Technologies» LLP

Fig. 4. Electron micrography of individual sections and elemental composition of gypsum from the Baganaly deposit

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS

Fig. 5. Microstructure and elemental composition of electro Novo-Dzhambul Phosphorous Plant thermophosphorus slag

Table 1

Chemical composition of clinkers

|

Clinker |

СаО |

SiO2 |

Fe 2 O 3 |

Al 2 O 3 |

MgO |

СаО free |

Calcination losses |

|

STT |

64.47 |

23.07 |

5.54 |

4.33 |

1.81 |

0.80 |

0.36 |

|

SC |

64.78 |

21.70 |

5.23 |

4.12 |

1.97 |

0.90 |

0.29 |

|

ShC |

64.78 |

22.73 |

5.86 |

3.77 |

2.30 |

0.74 |

0.11 |

Table 2

Mineralogical composition of clinkers

Gypsum reserves in the South Kazakhstan region amount to approximately 43 million tons [1–3, 22]. This mineral occurs in various forms, including massive tabu-

lar, prismatic, and columnar crystals, as well as twinned crystals resembling a “swallowtail.” Gypsum can also have coarse-grained, foliated, and fibrous structures. Major gypsum deposits, as well as global production (estimated at about 70 million tons per year), are formed through sedimentary processes in isolated saline lagoons and water bodies saturated with calcium sulfate. In these conditions,

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS gypsum precipitates during the initial stages of evaporation, creating significant salt deposits.

When gypsum is added to water, rapid formation of calcium sulfoaluminate hydrate occurs due to the interaction of sulfate ions with tricalcium aluminate (C₃A). This calcium sulfoaluminate hydrate has low solubility, leading to its precipitation and the binding of a significant portion of C₃A, thereby accelerating the setting process. Once this reaction is complete, and after the hydration of calcium silicates and aluminates, hardening continues slowly, contributing to the high mechanical strength of the final products [23–25].

During solid-phase reactions and the sintering process that promotes the formation of poly-eutectic intermediate melts in raw mixes, mechanical activation of components plays a key role. The inclusion of pre-calcined or molten (glassy) silicates in the raw material composition significantly accelerates production processes. Electrothermal phosphorus slags obtained from the Novo-Dzhambul Phosphorus Plant were used as additives in the raw mixes (Fig. 5) [1–5, 28, 29].

In addition, the use of such additives positively affects the properties of the final products, enhancing their resistance to various aggressive environments and increasing their service life. This opens new prospects for using cement and construction materials in harsh operating conditions, making them more competitive in the market.

The most suitable materials in terms of chemical and mineralogical composition are granulated electrothermal phosphorus slags produced at the Novo-Dzhambul Phosphorus Plant. These slags contain a glassy phase in amounts ranging from 90 to 95%. Their chemical composition includes (%): CaO – 43.91, SiO2 – 32.78, Al2O3 – 3.27, MgO – 2.49, Fe2O3 – 0.57, F2O3 – 1.5, and

P2O5 – 1.4–2.0. Clinkers derived from these slags are characterized by the presence of a molten phase, which upon cooling forms a glassy cementitious matrix with embedded crystals. A correlation is also observed between the thermal treatment of clinker and its grindability: as the volume increases, alite crystals develop numerous cracks, which facilitate a faster grinding process [3–6, 22–24].

To evaluate the grindability of the raw mixture, it was processed in a laboratory vibromill (SVM-3) using a set of steel balls with a diameter of 20 mm, totaling 10 kg, for 30 minutes. The fineness of the grind was assessed based on specific surface area, average particle size, and the air permeability of the dispersed raw material using a modern autonomous PSKh-K device. This device operates on the principle of the relationship between the air permeability of a powder layer and its specific surface area. Cements were produced by mixing prepared components in various proportions (Tables 3 and 4) with the addition of gypsum, electrothermal phosphorus slags, and active mineral additives such as opoka and diatomite [5, 8, 24, 29].

It should be noted that the use of electrothermal phosphorus slags in cement production can significantly improve its strength characteristics and durability. These additives not only enhance the mechanical properties of the final products but also make the production process more environmentally friendly by reducing carbon dioxide emissions. Research indicates that incorporating such slags into cement mixtures can also improve their resistance to aggressive chemical environments, which is particularly relevant for structures exposed to high levels of corrosion.

For the experiment, samples in the form of cubes with an edge length of 2 cm were prepared. These cubes were made from normal consistency paste based on the prepared binders and placed in a steam curing chamber under standard conditions. The binder consisted of a mixture of

Table 3

Composition of cements based on active mineral additives – opok

|

No. |

Composition of cements, % |

Specific surface, S, cm2/g |

Average particle size, microns |

|||

|

Clinker |

Gypsum |

Slag |

Opok |

|||

|

1 STT |

65 |

5 |

15 |

15 |

6715 |

3 |

|

2 SC |

65 |

5 |

15 |

15 |

5860 |

3.4 |

|

3 ShC |

65 |

5 |

15 |

15 |

5789 |

3.5 |

Table 4

Composition of cements based on active mineral additives – diatomite

|

No. |

Composition of cements, % |

Specific surface, S, cm2/g |

Average particle size, µm |

|||

|

Clinker |

Gypsum |

Slag |

Diatomite |

|||

|

1 STT |

65 |

5 |

15 |

15 |

6700 |

2.9 |

|

2 SC |

65 |

5 |

15 |

15 |

5850 |

3.2 |

|

3 ShC |

65 |

5 |

15 |

15 |

5775 |

3.3 |

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS

Portland cement clinker, gypsum, electrothermal phosphorus slags, and active mineral additives such as opoka and diatomite in a 1:1 ratio.

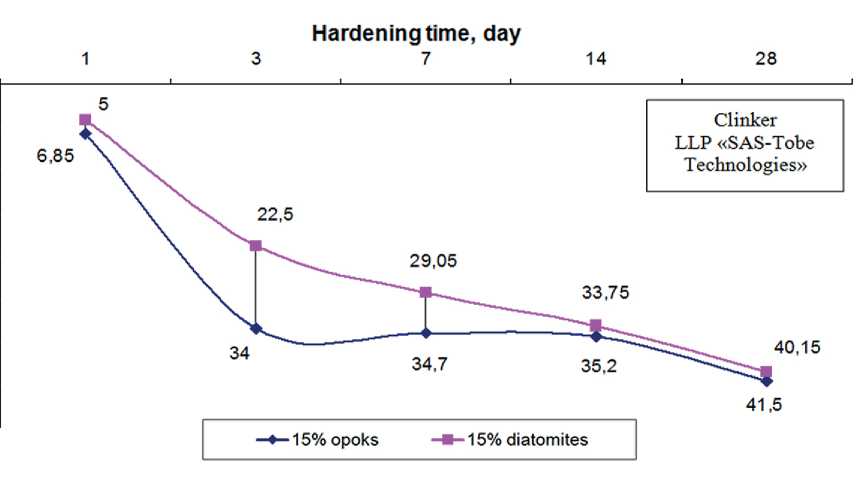

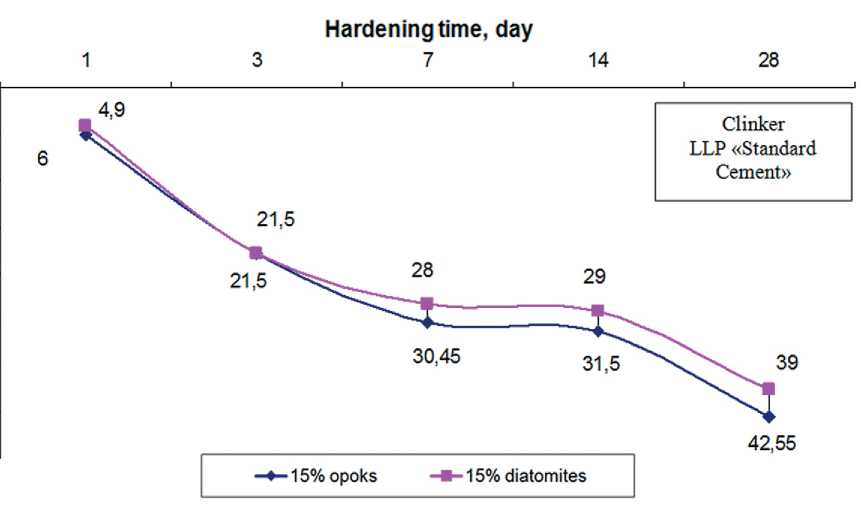

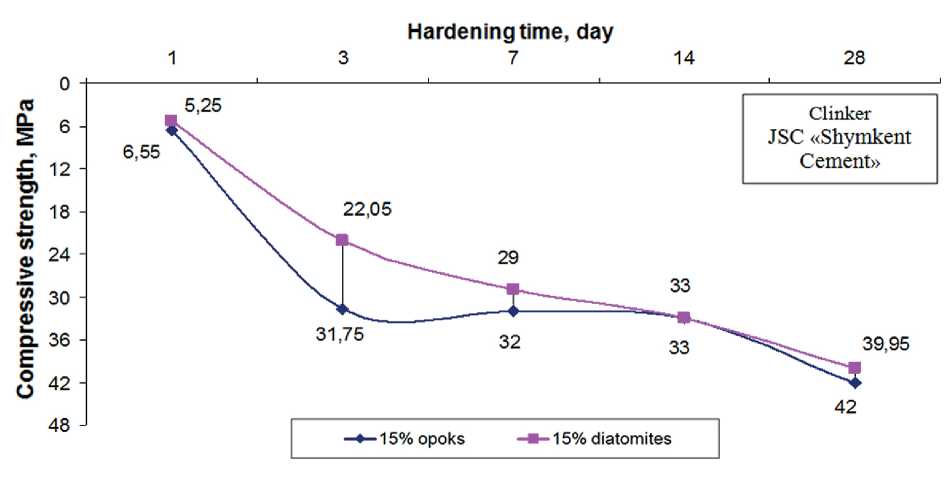

The hydration process of this binder, conducted under normal conditions, demonstrated compressive strength ranging from 5 to 42 MPa on days 1, 3, 7, 14, and 28 (detailed data are presented in Tables 5 and 6 and illustrated in Figures 6, 8 and 10).

It should be noted that such strength characteristics confirm the efficiency of the materials and their combinations, highlighting the potential for further use of this binder in construction. Moreover, these results empha-

size the importance of optimizing binder compositions to achieve high mechanical properties under various operating conditions. Compressive strength analysis allows for predicting the durability and reliability of structures made with the proposed binder, which is a critical aspect of modern construction.

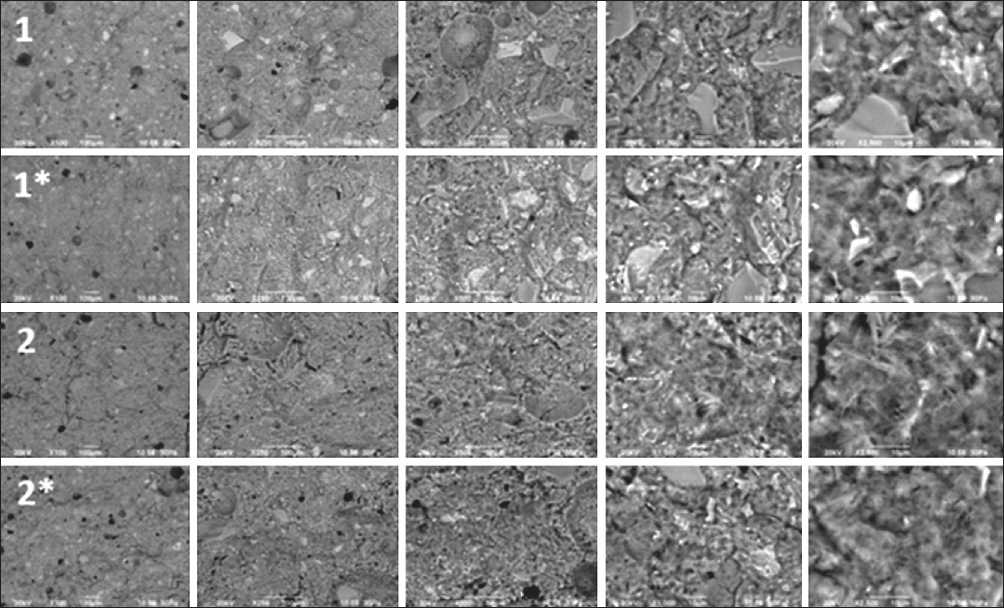

Figures 6, 8 and 10 present a comparative graph showing the strength development of stone produced from binder based on cement plant clinkers with the addition of opoka and diatomite in an optimal amount of 15%.

Comparative electron micrographs of cube-shaped samples with an edge length of 2 cm, cured in a steam

062840628 1 1 2 3 3 4 4 EdW С£6и8」«O>-WWOW^EOO

Table 5

Indicators of compressive strength (with opok)

|

Test No. |

W/C, % |

Compressive strength, MPa |

||||

|

1 day |

3 day |

7 day |

14 day |

28 day |

||

|

1 STT |

27 |

6.85 |

34.0 |

34.7 |

35.2 |

41.5 |

|

2 SC |

27 |

6.0 |

21.5 |

30.45 |

31.5 |

42.55 |

|

3 ShC |

27 |

6.55 |

31.75 |

32.0 |

33.0 |

42.0 |

Table 6

Indicators of compressive strength (with diatomite)

|

Test No. |

W/C, % |

Compressive strength, MPa |

||||

|

1 day |

3 day |

7 day |

14 day |

28 day |

||

|

1 STT |

27 |

5.0 |

22.5 |

29.05 |

33.75 |

40.15 |

|

2 SC |

27 |

4.9 |

21.5 |

28.0 |

29.0 |

39.0 |

|

3 ShC |

27 |

5.25 |

22.05 |

29.0 |

33.0 |

39.95 |

Fig. 6. Set the strength of the stone obtained binder (clinker LLP “SAS-Tobe Technologies” with opok and diatomite)

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS

Fig. 7. Comparative microstructures of samples-cubes with an edge of 2 cm, hardened in a normal hardening steam chamber (clinker from SAS-Tobe Technologies LLP with opok and diatomite): 1 – 7 days of hardening with opok; 1* – 7 days of hardening with diatomite; 2 – 14 days of hardening with opok; 2* – 14 days of hardening with diatomite; Magnification: ×100, ×250, ×500, ×1000, ×2500

Fig. 8. Set the strength of the stone obtained binder (clinker LLP “Standard Cement” with opok and diatomite)

BdzCSEUaus EssaldEO。

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS chamber under normal conditions, are shown in Figures 7, 9 and 11.

The current cement plants in Kazakhstan are relatively new; most of them (12 units) using the dry production method were commissioned within the last 10 years. Three plants using the wet production method could potentially transition to the dry method, but this would require significant capital investments to reconfigure the production process. Import dumping has led to underutilized capacities at Kazakh cement plants. Some of them are at risk of bankruptcy and have been mothballed. The closure of these plants would result in job losses, worsening family welfare, increased government expenditure on subsidies, and other social consequences.

One of the development paths for the industry is the creation of “green” cement and conducting related research. Most greenhouse gas emissions caused by industrial activities are associated with the production of key materials such as cement, steel, pig iron, and aluminum. In the cement production process, limestone (CaCO3) is calcined, removing carbon and forming lime (CaO), accompanied by the release of carbon dioxide (CO2). This significantly impacts the environment, as experts estimate chemical reactions and the combustion of fossil fuels used to heat kilns.

Modern technologies aim to reduce the carbon footprint. These include the implementation of carbon capture and storage methods, the use of alternative binders, and the transition to cleaner energy sources. Achieving sustainable cement production will not only reduce greenhouse gas emissions but also minimize its impact on climate change, which is critical for the future of our planet.

According to the 2019 greenhouse gas emissions inventory, the metallurgical industry accounted for 60.8% of all emissions in the “Industrial Processes and Product Use” sector (excluding ozone-depleting substance consumption). The second most significant source of emissions was the “Mineral Material Production” category, responsible for 30.9% of the sector’s emissions. In cement production, most technological emissions are caused by the calcination of limestone to transform it into lime and clinker, which is a significant source of global CO2 emissions. Reducing the clinker content in cement could decrease these related emissions by up to 30%.

On July 21, 2020, the European Council decided to implement a carbon border adjustment mechanism (CBAM)

Fig. 9. Comparative microstructures of samples-cubes with an edge of 2 cm, hardened in a normal hardening steam chamber (clinker of Standard Cement LLP with opok and diatomite): 1 – 7 days of hardening with opok;

1* – 7 days of hardening with diatomite; 2 – 14 days of hardening with opok; 2* – 14 days of hardening with diatomite; Magnification: ×100, ×250, ×500, ×1000, ×2500

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS

Fig. 10. Set the strength of the stone obtained binder (clinker JSC “Shymkent Cement” with opok and diatomite)

Fig. 11. Comparative microstructures of sample cubes with an edge of 2 cm, hardened in a normal hardening steaming chamber (clinker of Shymkent Cement JSC with opok and diatomite): 1 – 7 days of hardening with opok;

1* – 7 days of hardening with diatomite; 2 – 14 days of hardening with opok; 2* – 14 days of hardening with diatomite; Magnification: ×100, ×250, ×500, ×1000, ×2500

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS emissions at all stages of the production chain, from raw material extraction to finished product manufacturing. Importers are required to pay a carbon fee equivalent to the cost of EU emissions quotas, with deductions for carbon fees already paid in the product’s country of origin.

Kazakh exporters may face carbon fees imposed by importing countries, including the EU, which could significantly reduce their profits. Consequently, state budget revenues could also decline. To ensure equitable redistribution of income, it is advisable to retain the carbon price within Kazakhstan’s economy rather than pay it to other countries. This effectively means that the greenhouse gas emissions related to the production of export goods should be paid for by consumers in other countries driving this demand. Introducing a carbon export duty equivalent to the market price of quotas in Kazakhstan, adjusted for the carbon component of the cost of exported goods, could become a sectoral contribution to decarbonization.

One promising direction is the development of carbon-cured concrete. This technology is based on cement’s ability to absorb carbon dioxide, embedding CO2 into its structure during production. This approach not only facilitates carbon capture but also enhances the physical characteristics of concrete, making it more durable and long-lasting.

This innovation could significantly reduce the carbon footprint of the cement industry and create additional demand for captured carbon from other sectors, such as energy production. Combined with existing carbon capture and storage methods, this approach has the potential to reduce CO2 emissions in the cement industry by up to 48%.

Implementing this technology requires further research and the development of efficient production processes. However, its adoption could be a significant step toward sustainable development and mitigating the construction industry’s impact on climate. This not only aligns with modern environmental requirements but also opens new opportunities for economic growth as the world transitions to a carbon-neutral economy.

CONCLUSION

Natural mineral additives, such as opoka and diatomite, when added in an amount of 15%, contribute to the acceleration of mineral formation processes by enabling the appearance of a liquid clinker phase at lower temperatures.

The study of solid-phase reactions in the CaO-SiO2 system is of significant theoretical and practical interest in cement production technology. Determining the sequence of these reactions and the thermodynamic conditions for the formation of various compounds helps to better understand the processes and identify new ways to optimize them. Understanding the thermal effects at high temperatures aids in developing thermal balances for production processes, improving thermal equipment, and contributing to the decarbonization of the cement industry. Thanks to such additives, the firing process is accelerated, and clinker formation is completed at temperatures 100–150 °C lower than those required for traditional raw mixes calcined at 1450 °C.

Based on the conducted research, the following conclusions can be drawn:

-

1. X-ray phase and electron microscopy analyses of raw components were performed.

-

2. Compositions of raw material mixes were developed and prepared.

-

3. The phase composition, structure, and microstructure of the resulting cements were investigated.

-

4. The physical and technical properties of the resulting cements were determined.

-

5. The phase composition, structure, and microstructure of cubic samples with 2 cm edges, cured in a steam chamber under standard conditions, were analyzed.

-

6. The strength characteristics of cubic samples with 2 cm edges, cured in a steam chamber under normal conditions, were studied.

By adding various domestic natural active mineral components (opoka and diatomite) to reduce the clinker content while increasing alite content, methods and opportunities were identified for the efficient use of expensive Portland cement clinker in the framework of energy-and resource-saving technology.

The use of amorphous silica-rich materials as natural active mineral additives to produce low-clinker Portland cements allows for a reduction in the clinker content in cement (by 20–65%) without compromising its performance characteristics.

In conclusion, the results of the research indicate that Portland cement clinkers produced at various cement plants, when combined with the studied additives, can be effectively utilized in technologies aimed at energy conservation and resource efficiency in Portland cement production.

Список литературы Energy efficiency and decarbonization of cement and foamed glass production through the use of natural active mineral additives (opoka and diatomite)

- Smirnov P.V., Zhakipbayev B.Y., Staroselets D.A., Deryagina O.I., Batalin G.A., Gareev B.I., Vergunov A.V. Diatomites and opoka from western Kazakhstan deposits: lithogeochemistry, structural and textural parameters, potential of use. Bulletin of the Tomsk Polytechnic University, Geo Assets Engineering. 2023; 334(7): 187–201. https://doi.org/10.18799/24131830/2023/7/4046

- Zhakipbayev B.Ye., Zhanikulov N.N. Use of tephritobasalt and lead slag as an alternative raw material in burning portland cement clinker. Bulletin of Kazakh Leading Academy of Architecture and Construction. 2023; 88(2): 162–177. https://doi.org/10.51488/1680-080x/2023.2-18

- Kolesnikov A.S., Kuraev R.M. Thermodynamic modeling of the synthesis of the main minerals of cement clinker from technogenic raw materials. Kompleksnoe Ispolʹzovanie Mineralʹnogo Syrʹâ/Complex Use of Mineral Resources/ Mineraldik Shikisattardy Keshendi Paidalanu. 2021; 318(3): 24–34. https://doi.org/10.31643/2021/6445.25

- Zhakipbayev B.Y., Alferyeva Y.O., Ksenofontov D.A., Kotel’nikov A.R. An Experimental Study of the Possible Use of Opoka as a Si Source in Glass Production of the Turkestan Region, Kazakhstan. Moscow University Geology Bulletin. 2021; 76(4): 398–406. https://doi.org/10.3103/S0145875221040128

- Balykov A.S., Nizina T.A., Kyashkin V.M., Volodin S.V. Prescription and technological efficiency of sedimentary rocks of various composition and genesis in cement systems. Nanotechnologies in Construction. 2022; 14(1): 53–61. https://doi.org/10.15828/2075-8545-2022-14-1-53-61

- Zhernovoi F.E., Zhernovaya N.F., Snukaeva M.V. Effectiveness of opoka-containing causticized batches for glass containers. Glass and Ceramics (English Translation of Steklo i Keramika). 2015; 72(3): 83–85. https://doi.org/10.1007/s10717-015-9729-z

- Zhernovoi F.E., Zhernovaya N.F., Snukaeva M.V. Effectiveness of opoka-containing causticized batches for glass containers. Glass and Ceramics (English Translation of Steklo i Keramika). 2015; 72(3): 83–85. https://doi.org/10.1007/s10717-015-9729-z

- Kaz’Mina O.V., Vereshchagin V.I., Semukhin B.S., Abiyaka A.N. Low-temperature synthesis of granular glass from mixes based on silica-alumina-containing components for obtaining foamed materials. Glass and Ceramics (English Translation of Steklo i Keramika). 2009; 66(9–10): 341–344. https://doi.org/10.1007/s10717-010-9193-8

- Yatsenko E.A., Smolii V.A., Yatsenko L.A., Gol’tsman N.S. Physicochemical Studies of Raw Materials from the Far East Russia for Synthesizing Foamed Glass and Protective Enamel Coatings. Glass and Ceramics (English Translation of Steklo i Keramika). 2019; 76(5–6): 235–238. https://doi.org/10.1007/s10717-019-00172-9

- Suleimenov Z.T., Sagyndykov A.A., Moldamuratov Z.N., Bayaliyeva G. M., Alimbayeva Z.B. High-strength wall ceramics based on phosphorus slag and bentonite clay. Nanotechnologies in Construction. 2022; 14(1): 11–17. https://doi.org/10.15828/2075-8545-2022-14-1-11-17

- Yatsenko E.A., Smolii V.A., Klimova L.V., Gol’tsman B.M., Ryabova A.V., Golovko D.A., Chang C.C. Foamed Glass Synthesis by the Hydrate Method Based on Different Natural Materials. Glass and Ceramics (English Translation of Steklo i Keramika). 2020; 77(3–4): 135–138. https://doi.org/10.1007/s10717-020-00256-x

- Kononenko O.A., Gelis V.M., Milyutin V.V. Incorporation of bottoms from nuclear power plants into a matrix based on Portland cement and silicic additives. Atomic Energy. 2011; 109(4): 278–284. https://doi.org/10.1007/s10512-011-9357-9

- Makarov D.V., Manakova N.K., Suvorova O.V. Production of Rock-Based Foamed-Glass Materials (Review). Glass and Ceramics (English Translation of Steklo i Keramika). 2023; 79(9–10): 411–417. https://doi.org/10.1007/s10717-023-00522-8

- Durastanti C., Moretti L. Environmental impacts of cement production: A statistical analysis. Applied Sciences (Switzerland). 2020; 10(22): 1–23. https://doi.org/10.3390/app10228212

- Uwasu M., Hara K., Yabar H. World cement production and environmental implications. Environmental Development. 2014; 10(1): 36–47. https://doi.org/10.1016/j.envdev.2014.02.005

- Tautorat P., Lalin B., Schmidt T.S., Steffen B. Directions of innovation for the decarbonization of cement and steel production – A topic modeling-based analysis. Journal of Cleaner Production. 2023; 407. https://doi.org/10.1016/j.jclepro.2023.137055

- Obrist M.D., Kannan R., Schmidt T.J., Kober T. Decarbonization pathways of the Swiss cement industry towards net zero emissions. Journal of Cleaner Production. 2021; 288. https://doi.org/10.1016/j.jclepro.2020.125413

- Rumayor M., Fernández-González J., Domínguez-Ramos A., Irabien A. Deep Decarbonization of the Cement Sector: A Prospective Environmental Assessment of CO2 Recycling to Methanol. ACS Sustainable Chemistry and Engineering. 2022; 10(1): 267–278. https://doi.org/10.1021/acssuschemeng.1c06118

- Busch P., Kendall A., Murphy C.W., Miller S.A. Literature review on policies to mitigate GHG emissions for cement and concrete. Resources, Conservation and Recycling. 2022; Elsevier B.V. https://doi.org/10.1016/j.resconrec.2022.106278

- Wang Y., Yi H., Tang X., Wang Y., An H., Liu J. Historical trend and decarbonization pathway of China’s cement industry: A literature review. Science of the Total Environment. 2023; Elsevier B.V. https://doi.org/10.1016/j.scitotenv.2023.164580

- Moldamuratov Z.N., Ussenkulov Z.A., Yeskermessov Z.E., Shanshabayev N.A., Bapanova Z.Z., Nogaibekova M.T., Joldassov S.K. Experimental study of the effect of surfactants and water-cement ratio on abrasion resistance of hydraulic concretes. Rasayan Journal of Chemistry. 2023; 16(3): 1116–1126. https://doi.org/10.31788/RJC.2023.1638391

- Turakulov Z., Kamolov A., Turakulov A., Norkobilov A., Fallanza M. Assessment of the Decarbonization Pathways of the Cement Industry in Uzbekistan. Engineering Proceedings. 2023; 37(1). https://doi.org/10.3390/ECP2023-14639

- Carbone C., Ferrario D., Lanzini A., Stendardo S., Agostini A. Evaluating the Carbon Footprint of Cement Plants Integrated With the Calcium Looping CO2 Capture Process. Frontiers in Sustainability. 2022; 3. https://doi.org/10.3389/frsus.2022.809231

- Cormos A.M., Dragan S., Petrescu L., Sandu V., Cormos C.C. Techno-economic and environmental evaluations of decarbonized fossil-intensive industrial processes by reactive absorption and adsorption CO2 capture systems. Energies. 2020; 13(5). https://doi.org/10.3390/en13051268

- Kabdushev A.A., Agzamov F.A., Manapbayev B.Z., Moldamuratov Z.N. Microstructural analysis of strainresistant cement designed for well construction. Nanotechnologies in Construction. 2023; 15(6): 564–573. https://doi.org/10.15828/2075-8545-2023-15-6-564-573

- Karlsson I., Rootzén J., Toktarova A., Odenberger M., Johnsson F., Göransson L. Roadmap for decarbonization of the building and construction industry-A supply chain analysis including primary production of steel and cement. Energies. 2020; 13(6). https://doi.org/10.3390/en13164136

- Manapbayev B., Alimbayev B., Amanbayev E., Kabdushev A., Moldamuratov Z. Study of internal corrosion on the turning angles in steel pipes. In E3S Web of Conferences. 2021; 225. https://doi.org/10.1051/e3sconf/202122501004

- Cormos C.C., Cormos A.M., Petrescu L., Dinca C. Decarbonization of fossil energy-intensive industrial processes using innovative calcium looping technology. Chemical Engineering Transactions. 2021; 86: 937–942. https://doi.org/10.3303/CET2186157

- Zhakipbayev B.Ye., Kan X.S., Kulmakhanova A.Sh., Kuntubayeva M.N. Low-temperature synthesis of glass phase through the use of opok matrices South Kazakhstan amorphous siliceous rocks in the production of container glass. VESTNIK KazNRTU. 2016; 6 (118): 486-491.