Engineering and siting of new industries in the Komi Republic (experimental approach)

Автор: Lazhentsev V.N.

Журнал: Economic and Social Changes: Facts, Trends, Forecast @volnc-esc-en

Рубрика: Branch-wise economy

Статья в выпуске: 3 т.18, 2025 года.

Бесплатный доступ

The socio-economic development of the Komi Republic largely depends on timely structural transformation of production based on innovative technologies and the territorial organization of the economy relative to the northern environmental conditions. In this context, the background and prospects of an experimental scientific approach to the development and processing of mineral and biological resources are considered. The enterprises that have played a driving role in solving technical problems relevant to the country and in developing new research areas in the past are highlighted. Syktyvkar pilot shipbuilding yard has developed a technique for timber bundling and lifting sunken timber from the river-bed. Ukhta radiochemical plant in Vodny village was the only enterprise in the world where radium was isolated from mineralized groundwater; in fact, radiogeochemistry of groundwater originated here. At the Yarega oil and titanium deposit, thermoshaft extraction of the heavy high-viscosity oil was used for the first time and an attempt is being made to extract titanium from complex ores. The future of the republic’s economy is connected with the development and implementation of technologies for hydrocarbon chemistry, physico-chemical geotechnology, and organic chemistry. It is proposed to create experimental scientific enterprises and site them according to the issues of the Pechersk coal basin, the Arctic Ural and the Sysolo-Vychegodsky forest economic region. To successfully resolve these issues, a national-economy approach is required, in which the key driver of new industries development is a government order for programs and projects of a full investment cycle, including enterprise institutions. The novelty of the presented research lies in the development of methods for introducing scientific results into the practical economic activity by combining experimental scientific and common economic activities, taking into account the environmental conditions of the northern and arctic territories

North of Russia, Komi Republic, research and production experiment, hydrocarbon chemistry, physico-chemical geotechnologies, organic chemistry, siting of plants and technology parks

Короткий адрес: https://sciup.org/147251530

IDR: 147251530 | УДК: 332.1 | DOI: 10.15838/esc.2025.3.99.5

Текст научной статьи Engineering and siting of new industries in the Komi Republic (experimental approach)

The current state of the Komi Republic’s economy is characterized as transitional – from the quantitative growth of the industrialization to the qualitative transformations of goods and their production technologies of the post-industrial development (Lazhentsev, 2024a). The nature of work is changing, and interest in creativity and high technology is increasing. There are still limited opportunities in the Komi Republic to achieve such an interest, which is one of the reasons for the negative net migration. The population of the Republic decreased from 1,261 thousand in 1989 to 720 thousand in 2025. At the peak of economic growth in the 1980s, up to 90 million tons of fuel and raw materials (including coal, oil, gas, non-metallic materials, mason sand, and wood) were mined and harvested in the region; currently, the number is approximately 30 million tons. Such a significant reduction is due not only to the deep economic crisis of the 1990s, but also to the economy transformation during the recovery from the depression toward increasing shares of manufacturing, industrial and consumer services. As a result, gross domestic product in comparable prices over the past 15 years has had an average annual change in the range –1+1%, which again underlines the problematic development of the Komi Republic’s economy.

Various kinds of emergency circumstances are “superimposed” on the objective process of economic transformation. For example, the urgent need to increase the level of technological self-sufficiency of Russia and, in this regard, to reequip the mining-and-metallurgical industry, transform coal mining and processing, oil, gas and biological resources. Accordingly, the issues of integrated territorial development and assessment of the impact of northern and arctic environmental conditions on the development of economic and life support systems are being updated. The change in the technical and economic structure is associated with an active search for new forms of industrial management and siting.

The aim of the work is to show the possibilities and ways of scientific-and-production experiment as an element of the general process of economic development of the Komi Republic based on the results of specific research projects. This aim correlates in a certain way with the key concepts of Russian modern technology policy: institutes of innovative development, high-tech products, technological cooperation, end-to-end technology, own technology development line, etc.1

The author characterizes the research methodology as interdisciplinary, when social forms of production organization (the subject of political economy and economics of national economy sectors) and forms of productive forces location (the subject of socio-economic geography and regional economics) are studied in conjunction. Information on geology, mining, technology, and innovation processes is included in the task-oriented research on a specific region (the Komi Republic), the development prospects of which are related to the search for alternative forms of economic organization.

Features of the scientific-and-production experiment in the northern conditions

Northern regions have a very unusual function in the system of geographical division of labor – they are a “testing ground” for new equipment and some innovative technologies. The reasons for this are extreme climatic conditions and many other environmental characteristics, which require special engineering solutions to adapt to. Sometimes such solutions are used in places with a more favorable climate. For instance, the experience of using arches in building and construction to preserve permafrost is brought into action in large cities to obtain additional parking areas or for other purposes. A good example is the architectural design of the arctic rotation villages, integrating the complex of utility and office spaces with covered walkways, winter gardens and other recreational areas. This kind of architecture is useful, for example, in the organization of a therapeutic resort in any territories where there are appropriate prerequisites for its development. Other northern innovations of interregional importance are connected with transport, economic use of snow and ice, organization of underground storage, medical adaptation techniques, etc.

As a rule, the “testing ground” function of northern regions is auxiliary to traditional farming, mining and processing of minerals, forestry, taiga agriculture and life support systems. But at certain stages of development, the performers of this function become valuable as attractor structures, i.e. they act as a key link in strategic qualitative transformations. Currently most regions of the North of Russia are in this very stage, when the classical forms of organization of mass (large-scale) production become problematic there both in terms of efficiency of capital investments and socio-ecology.

The “scale of production” problems are, of course, solvable, but this requires appropriate resources and time for thorough technical preparation. In addition, it is necessary to overcome the “arctic syndrome”, when a significant investment in the declared projects of the RF Arctic Zone is considered as a sign of the “correct” economic behavior of a corporation (firm), allegedly following common geopolitical guidelines. But more often, arctic zeal is explained by the hope of government subsidies for business projects, as well as gaining a positive reputation.

In modern conditions of national economic development, the other thing is relevant – the use of less expensive “miniature” physico-chemical and biochemical technologies, the creation of new materials and composites from mineral resources, the design and testing of “northern” technology. We are no longer talking about individual achievements in adapting to the difficult northern conditions, but about the scientific-and-experimental form of organization of production and the economy as a whole.

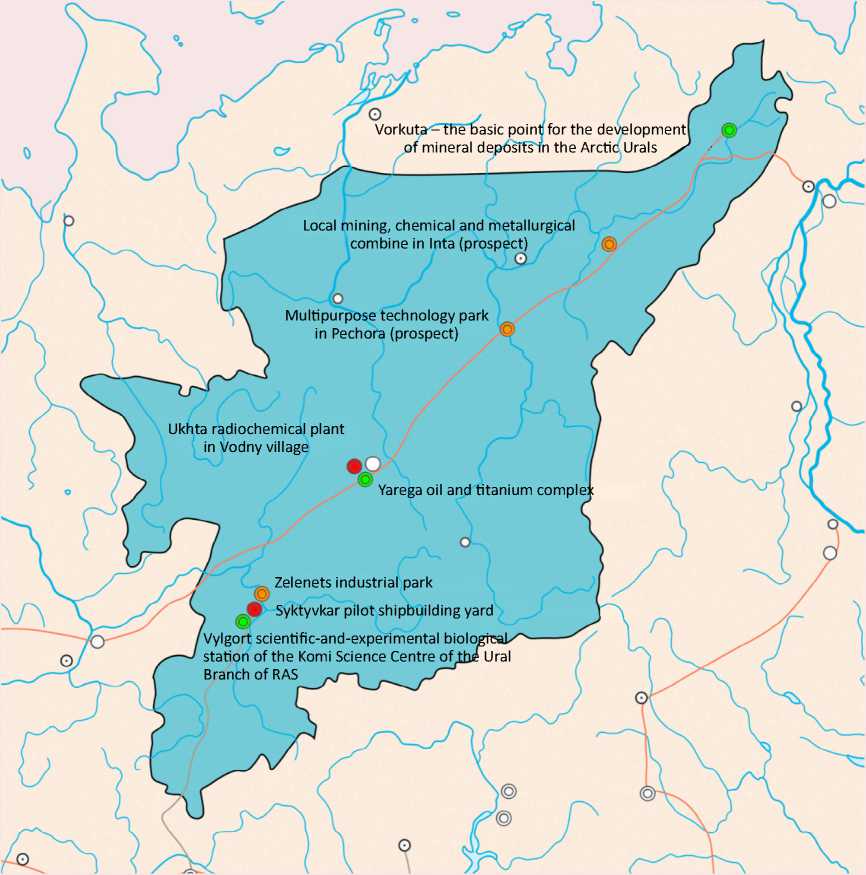

The facilities of scientific-and-experimental production working in the past and currently, as well as promising ones considered in the article, are shown in the Figure .

Three examples of the experimental approach to the production engineering in the Komi Republic

Let us refer to the historical experience of enterprises engineering similar to modern (scientific-and-experimental). These facilities were urgently created to solve practical problems, and theoretical understanding of the northern regions’ position in the geographical division of labor was not taken into account. At the same time, they serve as an example of a creative approach to using advanced scientific achievements and obtaining an original result based on domestic research.

Syktyvkar pilot shipbuilding yard. This example is interesting in the context of this article as there is a shift from a purely practical, “routine” activity to an experimental, creative approach. The former is due to the great influence of river transport on the pioneering development of the northern

Scientific-and-production facilities in the Komi Republic (red sign – facilities active in the past; green sign – active currently; brown sign – proposed for creation)

Vorkut e basic

– mineral de

Zelenets industrial/park

Ukhta radiochemical plant in Vodny village

Yarega oil and titanium comple

Ural

Local mining, chemical and metallurgical combine in Inta (prospect)

Multipurpose technology park / in Pechora (prospect) л

territories; the latter is due to the integration of the Komi Republic into the national river shipbuilding system. The yard’s development stages: forge and mechanical yards (1930) – ship-repairing yards (1934) – shipbuilding and ship-repairing yard (1941) – ship-repairing yard (1954) – pilot shipbuilding yard (1969–1995)2. Eventually, the yard became a developer of new technology for highly relevant technological operations, such as coastal timber bundling, piece-by-piece unloading of timber from the water, and lifting timber (that has been drowned and lying at the river-bed for years). The latter allowed not only revitalizing the rivers, but also obtaining valuable wood with special physico-chemical properties. It is appropriate to note here the achievements of the research designers L.F. Koyushev, F.G. Kukovitskii, Yu.A. Latkin, M.P. Sivkov.

The yard’s design bureau was aimed at creating and testing prototypes of novel equipment, followed by their “replication” at the country’s shipyards. It is this direction of production engineering that corresponds to the economic and geographical specifics of the northern region. The closing and liquidation of the yard, which could not withstand the devastating impact of the “reforms” of the 1990s, is a great loss for the Komi Republic. Now we are not talking about restoring the yard, but only about using the method of its activity, which simultaneously includes the republic’s participation in solving the problem of reviving northern river navigation and interregional cooperation within the framework of specific science and technology programs.

Ukhta radiochemical plant in Vodny village. From 1931 to 1956, a unique radiochemical plant operated in Vodny village near Ukhta, the only enterprise in the world where radium was isolated from mineralized groundwaters. A new branch of science was born there – radiogeochemistry of groundwater.

A review of online materials3 shows that a radiochemical laboratory, a radium concentrate processing plant, 12 radiochemical plants and three individual water treatment plants operated in Vodny village. About 150 wells were constantly in use. The company’s production facilities were situated within a radius of 40 km. Settlements for independent workers and prisoners were located near the plant producing radium concentrates and large water processing plants. As of August 1, 1940, 2756 prisoners and 573 independent workers were engaged in this field. In 1951, due to new technologies in radium production, the extraction and processing of radium waters were completely stopped, three chemical plants were closed, and the radium concentrate processing plant was reconstructed and converted to processing uranium waste. In 1956, the radium industry in Vodny village was completely closed.

Many well-known scientists were involved in the engineering of these radiogeochemical industries4: I.Ya. Bashilov, Chemical Engineer, Doctor of Sciences (Engineering), one of the founders of the radiochemical and rare earth industry in the USSR; I.I. Ginzburg, head of the radiochemical laboratory, Doctor of Sciences (Geology and Mineralogy), Professor of Geochemistry; M.D. Krasheninnikov – Chief Engineer of the industry; A.V. Kulevskii – Chief Geologist of the plant; G.A. Razuvaev – Production Superintendent of the concentrate plant, Doctor of Sciences (Chemistry), USSR Academy of Sciences Academician, laureate of the Lenin and State Prizes of the USSR, Hero of Socialist Labor; S.P. Sudarikov – Senior Chemist; F.A. Toropov – head of the core chemical laboratory, Chemical Engineer, Doctor of Sciences (Engineering).

At its core, the radiochemical plant in Vodny was a research-and-production enterprise, and formally it looked like a “sharashka”5, where politically convicted scientists and engineers worked under the control of security agencies. They have solved the strategically important task of providing Soviet science and industry with radium, the only material for sealed sources of ionizing radiation at that time.

Without referring to the Gulag forms of labor organization, we highlight the knowledge-intensive nature of production there. The USSR Academy of Sciences performed expert and advisory functions in the development of this field. In 1933, the Pechora team of the Polar committee of the USSR Academy of Sciences headed by Academician A.P. Karpinskii6 visited the industry, and in March 1940, a special academic expedition of the USSR Academy of Sciences headed by Academician A.E Fersman visited the industry. This expedition consisted of Academicians V.G. Khlopin and D.S. Rozhdestvenskii, Professors V.I. Baranov, V.N. Vasil’ev, L.V. Komlev, N.N. Slavyanov, A.A. Chernov, and Researcher E.M. Rozhanskaya. Since the 1960s, ecological aspects have been studied in Vodny, the essence of which (the effect of small doses of radiation on living organisms and vegetation) has been revealed by the staff of the Department of Radioecology at the Institute of Biology of the Komi Science Centre of RAS with the academic advising of Candidate of Sciences (Biology) V.I. Maslov and Candidate of Sciences (Biology) A.I. Taskaev.

The radiogeochemistry of groundwater, created in the 1930s at the facility in Vodny, was subsequently developed into a wide range of geochemical methods for extracting minerals from mineralized edge water. One example of the studies on geochemistry is the research on methods for obtaining magnesium from mineralized edge water from oil fields and gas condensate reservoirs in the Komi Republic (Lanina et al., 2010).

In 1957, the plant named “Komielektrosteatit” was founded in Vodny village. In 1966, it was renamed “Progress”, and in 1997 it was renamed OAO Ukhta “Progress” plant. Its specialization is the production of electro-ceramic, radio-ceramic materials, high-voltage ceramic capacitors, as well as sonar equipment-specific technological complexes for the intensification of hydrocarbon production. Scientific work and experimental tests on semiconductor devices, hydroacoustics, condensation, and corundum ceramics are conducted there7.

Yarega oil and titanium complex. In terms of research-and-production engineering, this complex is the most interesting and yet the most problematic in the Komi Republic. Its uniqueness is in the thermoshaft method of heavy oil extraction, suitable for producing insulating, white technical and medicinal oils, grahamite and varnished bitumen, arctic diesel, etc.; in the presence of titanium in oil-bearing sandstones and underlying ore bodies, the reserves of which make this deposit large for the production of titanium metal and titanium dioxide, the raw materials for the production of paints and varnishes; in the non-standard technical and technological solutions to the commingled production of oil and titanium ore.

The historical role of the development of this deposit and the engineering of the production of frost-resistant engine oil for refueling tanks during military operations in winter is as significant as the Vodny radium industry for the production of packaged radiation sources. There, from the very beginning, scientific experiment was considered as a necessary element of production work (Kalinina, Kalinin, 2013; Aginei, 2022). An example of this is the research activity of Professor, Doctor of Sciences (Geology and Mineralogy) N.N. Tikhonovich, who in 1934 (while exiled to Ukhta) put forward the idea of opening an oil reservoir with a mine; Professor, Doctor of Sciences (Geology and Mineralogy), twice awarded the State Prize, Hero of Socialist Labor A.Ya. Krems (repressed and exiled to Ukhta in 1939, rehabilitated in 1956) – developed the scientific foundations of mining heavy oil; a number of other geologists and engineers (Zhangabalov, 2020).

But the history of Yarega also has negative manifestations: due to inter-corporate disagreements, integrated development is deliberately delayed. The improvement of thermoshaft production is carried out by PAO Lukoil, which does not deal with titanium ores. The latter was the subject of OAO Yarega-Ruda, but this company placed financial interests above production and technology. It has been lawfully deprived of its license to develop titanium ores. Such upheaval is relevant to the subject of our article only in one aspect – how to be “unique” in market conditions?

Strategically, the answer to this question should be looked for in the issues of public-private partnership, regulation of inter-corporate relations, and management by objective. Instead, the experimental approach to the engineering of complex productions is more related to the current circumstances. Taking them into account, it seems very promising that Ukhta State Technical University recommends to organize an educational production laboratory in an oil mine, where in natural conditions it is possible to study the geological structure of the reservoir, the mechanism of oil recovery, to work out various drilling technologies and configurations of wells; to organize basic work-study sites in the mine and on the surface for testing modern technologies and facilities, internships and training of qualified personnel in the field of resource development (Ruzin, 2010). It is also advisable to include experimental studies on the enrichment processing of titanium oxide raw material using carbothermy, autoclave processing and flotation (Roshchevskii, Timonin, 1994; Ryabkov et al., 2013).

There is a growing social recognition of the uniqueness of Yarega. The increased interest of academic science, higher education and the population of the Komi Republic in its problems can have a positive impact on the development of a mining and chemical complex there with an integrated scientific-and-educational center.

Promising areas of the experimental approach to the engineering and siting of new industries

The basic technologies for the further development of the natural resource economy of the Komi Republic are the following:

– processing of primary hydrocarbons to produce chemical products;

– new methods of mining ore minerals, their enrichment and processing using geomechanical, hydrometallurgical, nuclear, physical and biochemical methods, X-ray separation of ores, etc.;

– production of natural materials with high consumer properties and qualities;

– chemical processing of wood greenery, waste from logging and woodworking, the use of biochemical technologies in agriculture.

These areas of technological development are considered fundamental in many other regions of Russia, though it is necessary to consider special geological, geographical and socio-economic circumstances of their implementation in the Komi Republic:

– geological and geographical – the characteristics of territorial combinations of minerals, identified in the republic, require to find new technologies for their integrated development and use (Askhabov et al., 2015);

– socio-economic – the republic has no other way of balanced and prosperous development, except for the diversification of the structure of the natural resource economy with the creation of high-tech and high-income jobs (Lazhentsev, 2020).

Hydrocarbon chemistry. Due to the problems of the structural transformation of the global energy sector and Russia’s technological sovereignty, the multipurpose use of coal is becoming increasingly relevant, including the production of coke, liquid fuels, adsorbents, carbon-graphite materials, and thermo-graphite. The complex use of oil and gas has a similar motivation, because their components – ethane, butane, propane, hydrogen sulfide – are raw materials for the production of PVC, plastics, sulfur dioxide, mineral fertilizers, whereas liquid asphalt and petroleum residue – for the production of oil coke and other products. The set of mining and chemical raw materials also includes peat and shale.

Chemical processing of hydrocarbons has a lot of potential in the Komi Republic (Burtsev et al., 2015; Burtsev et al., 2016). It was shown that it is possible and attractive to process coal from the Pechora basin with semi-coking and gasification methods to produce valuable fuels (sulfur-free and high energy) and raw materials for chemical processing to produce synthetic liquid fuels, sorbents, and high-carbon materials, such as fullerenes (like graphite or diamond); to produce lignin-alkaline reagents, coal-humic preparations and lignitic material from brown coals containing up to 40–50% humic acids (organic substances that increase soil fertility); to process shale coal to produce shale oil, fuel gas and shale ash.

In our opinion, this complex should be expanded by the production of needle coke, a carbon product obtained from petroleum and coal raw materials and used to produce a wide range of graphite materials. This product is extremely scarce in Russia, relatively new to its economy; it can be produced from alternative sources and according to various technological schemes. The chemical and technological principles of needle coke formation continue to be improved and also require experimental verification (Obukhova et al., 2024).

Each field of hydrocarbon chemistry can be considered separately as an experiment, for example, coal chemistry in Vorkuta. However, their integrated engineering is not excluded either. One of the options for such a combination is the creation of an integrated technology park operating under the rules and regulations established for special economic zones. It could be sited in Pechora, a city equidistant from the main sources of hydrocarbon chemistry (Vorkuta and Inta coal, Ukhta and Usinsk petroleum products and promising shale coal deposits) and having a convenient location for transportation, as well as a lot of energy.

Physico-chemical and economic innovations in mining and processing of ore minerals. There are many ore deposits in the Komi Republic, but only two of them – Vezhayu-Vorykvinskoe and Verkhne-Shchugorskoe (OAO Boksit Timana) – are being developed and make a significant contribution to the growth of the aluminum industry in Russia (the volume of bauxite production is about 3 million tons per year). The third deposit, Pizhemskoe (the largest in Russia and the world in terms of resources and reserves of titanium and quartz raw materials), is being prepared for development. Scientific and technological innovations in bauxite area are carried out by the Integrated Company Rusal, and in titanium and quartz area – by the Rustitan group of companies. Everything else (chromium, manganese, barite, gold, gangue quartz, pure quartz, potash-magnesium salt, etc.) is unallocated mineral resources, and the question, whether they are included in the economy of Russia and the Komi Republic or not, largely depends on an assessment of the possibilities of applying physico-chemical geotechnologies and special forms of territorial organization of mining.

Geotechnology is a comprehensive term and includes a lot of aspects. This is not accidental, since the development of each specific deposit is based not only on standard patterns, but also on “individual” mining methods. They contribute to such novelties as underground dissolution and solvent extraction, hydraulic mining by boreholes, the influence of a thermal field on a rock mass, extraction of minerals from groundwater, microbiological methods for mineral raw materials enrichment, electric and magnetic separation of feebly magnetic ores, etc. It is often necessary to combine various physico-chemical methods of ore extraction and enrichment.

The specifics of the selection of geotechnologies are particularly evident in the development of mineral deposits sited in isolated territories, such as the Arctic (Nether-Polar and Polar) Urals. The Tsentral’noe chromite deposit of the Rai-Iz geological mass is being intensively developed there (sited in Yamal-Nenets Autonomous Area, 35 km from the Kharp – Severnoe Siyanie railway station), while the Zapadnoe, Voikaro-Cyn’inskoe, Saum-Keu and Laptopaiskoe chromite deposits are also considered promising for development; The Parnokskoe manganese deposit has been studied in detail, reserves of iron-skarn ores (Yun’yaginskoe), tantalum, niobium and rare earths (Tai-Keu), barite (Khoilinskoe), polymetals (Saureiskoe, Kharbeiskoe, Lekyn-Tal’beiskoe, etc.), gold and silver (Petropavlovskoe), gangue and pure quartz (Zhelannoe) (Brusnitsyn, 2015; Vikentiev, 2020). Regarding experimental approach, it is indicative that the researchers studying the mineral resource base of this problematic region consider that not only mineral reserves are valuable, but also the uniqueness of the natural site itself, which gives the opportunity to improve geological science and mining (Vakhrusheva et al., 2023).

The geotechnological aspect of the development of the mineral resources of the Arctic Urals significantly affects the territorial organization of mining, including field methods, seasonal work and a rotational schedule. Earlier, the district method was established as advantageous, when a group of deposits with common infrastructure is developed simultaneously8, and there is a possibility of connecting two or more mines to one separator located in the nearest city or village. In our case, we consider Vorkuta and Inta (Kuznetsov, Lazhentsev, 2025). Now it can be assumed that the enrichment method itself (fragmentation, flotation, gravity concentration, separation etc.) can be polytechnical with additional operations of following up geotechnical products to the conditions necessary for metallurgy, electrochemistry, optical or other engineering, as well as the production of intermediates, for example, by fuming, chloridation, etc.

Such a factory, together with ore and gravel mines, can be considered as a mining, chemical and metallurgical combine with a relatively free location of the factory itself, which is not directly linked to a specific mineral deposit. Given the particularly difficult economic situation of Inta, worsened after the closing of the coal mines, it is advisable to start implementing plans for the introduction of geotechnologies in this city. The construction of a small carborundum and ferrous alloys plant, which could later become part of the mentioned combine, is coming to an end there.

The combined form of production simplifies the manufacturing engineering and testing of new natural materials and composites. The physicochemical structure of some of them was developed at the Institute of Chemistry of the Komi Science Centre of the Ural Branch of RAS under the supervision of Doctor of Sciences (Geology and Mineralogy) B.A. Goldin and Doctor of Sciences (Chemistry) Yu.I. Ryabkov. There is solid evidence of the accelerated development of this area of the Komi Republic’s economy, including the production of composites, sulfur concrete, various ceramics, stone casting, basalt and light-carrying fibers, artificial crystals, and synthetic products (Goldin et al., 2010; Ryabkov et al., 2013; Belyaev et al., 2023).

Organic chemistry in forestry and agriculture. Technologies such as emulsion extraction, hydrolysis, and oxidation allow processing plant resources into valuable bioactive substances and additives. Under the leadership of Academician A.V. Kuchin (Institute of Chemistry of the Komi Science Centre of the Ural Branch of RAS), the scientific work resulted in the production of “VERVA” and “VERVA-EL’” preparations, an emulsion extract from wood greenery, plant protection biopreparations, turpentine oil, and a number of other products9 (Hurshkainen, Kuchin, 2011). Experimental use of some preparations in agriculture has shown their effectiveness (Yudin, 2021). The high demand for biochemical products makes the issues of multipurpose utilization of forest resources and the development of forestry chemistry as a “diverse” branch of the economy relevant for the Komi Republic.

Many areas of organic chemistry are beyond the large-scale wood chemistry (which is represented by Syktyvkarskiy LPK in the Komi Republic) and general agricultural chemicalization processes. Instead, they are integrated into pharmacology and pharmacy, as well as into forestry and productivity increase of small plots of land – gardens and farmland.

Experimental organic chemistry for medicine, veterinary medicine, forestry and local agriculture works mainly with “low doses” and “miniature” technologies, and therefore research and production enterprises themselves can be approximately the same in size and consist of a small number of machines for processing greenery, sawdust, wood shavings, bark. In addition to stationary equipment, it is advisable to include mobile equipment for the primary processing of greenery and wood waste directly at the logging site, covering the entire Sysolo-Vychegodskii forestry district. Syktyvkar and its surroundings will become the center of experimental forestry chemistry (Elyaty place, where the Vylgort experimental scientific biological station of the Komi Science Centre of the Ural Branch of RAS is located, and Zelenets village, where an industrial park is being created).

General conditions of the experimental approach

The general premise of the experimental approach to the engineering and siting of the production facilities discussed in the article in the Komi Republic is cooperation between research institutes and manufacturing enterprises. The basis of cooperation is long-term agreements on the generation of scientific knowledge right at production site in order to meet specific sci-tech or other innovative objectives (Lazhentsev, 2024b).

The experimental approach is also supported by the need for experimental verification of electronic technologies, geoinformatics, mining and geological information systems and remote control when resolving issues of development and use of natural resources of the arctic and northern territories. To do this, first of all, it is desirable to strengthen the role of scientific institutions at enterprises, which have been preserved in places since the Soviet period and significantly contribute to resolving complex issues of technological development.

Interest in the study and development of mineral deposits in the arctic and subarctic territories is usually within the framework of economic feasibility standards. Therefore, it will be correct to focus on selective and staged development, taking into account the real possibilities of introducing new technologies, constructing winter and year-round roads, using special vehicles and rotation villages. In this case, the objective is not the creation of new jobs and population growth, but obtaining extremely scarce products and their rational utilization in the Russian economy system. At the same time, the experience of economic activity in the conditions of extreme climate at the Far North periphery is also gaining value, that is why it is sometimes necessary to incur additional costs.

The author believes that the engineering of experimental production facilities in the North, and even more so in the Arctic, is possible only on the basis of management by objective carried out at the federal level, considering recommendations for the development of projects and programs of a full innovation cycle (Lenchuk, Filatov, 2024) and with a focus on the best performance of technology parks in Russia (Byvshev et al., 2024).

Conclusion

The combination of scientific, experimental and common economic activities in the northern and arctic regions is driven by the logic of technological development of natural resource sectors of the economy. We attempted to show the possibility of such a combination using the example of the Komi Republic, based on three grounds:

– the specific participation of the Komi republic in the Russian economy development, when the experience and result of engineering solutions to adapt to extreme climatic conditions and to resolve the issues of multipurpose utilization of natural raw materials are usefully transferred to other regions of the country;

– there is an urgent need to integrate scarce mineral and biological resources into the Russian economy, a significant part of such resources is located on the territory of the republic and neighboring regions;

– the uniqueness of natural objects, the study and use of which contribute to the development of science itself and generate public interest in learning about the environment.

It follows from the article that plants processing mineral and biological raw materials can be sited in the Komi Republic, release new types of products and also develop research and educational programs, design estimates, patents for discoveries and inventions in the field of relevant technologies. There will be few such enterprises, but they will play the driving role in the qualitative transformation of the Komi Republic’s economy. In the commodity economy system, they could function in the form of small and medium-sized businesses with the organized scientific institutions and an access to the national system of technological cooperation.

The experimental approach to the engineering of new production facilities also has an economic-and-geographical aspect, when the natural resource potential of a particular geological or biological area is achieved through the organization of multipurpose production plants, which is especially relevant for the arctic and northern regions.

The pre-design demonstration of scientific-and-experimental approach advantages in the Komi Republic relate to:

– transformation of the “Yareganeft’” company into the Yarega mining-and-chemical combine with the integrated scientific-and-educational center;

-

– creation of a coal chemical plant on the basis of AO Vorkutaugol;

-

– construction of the Pechora technology park of hydrocarbon chemistry using coal, refined petroleum products, shale and peat;

-

– creation of the Inta mining, chemical and metallurgical combine with the inclusion of a plant producing carborundum and ferrous alloys;

– organization of Syktyvkar experimental forestry combine using the production sites of the Zelenets industrial park and the Vylgort scientific-and-experimental biological station of the Komi Science Centre of the Ural Branch of RAS.

In case these enterprises (fully or partially) receive the approval for design, it is necessary to include them in the Territorial Planning Scheme of the Komi Republic in order to optimize the development of infrastructure and the use of generic storage resources.