Epoxy composites modified with coal tar

Автор: Erofeev V.T., Bogatov A.D., Kondakova I.E., Ivlev V.I., Yudin V.A., Afonin V.V.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Construction materials science

Статья в выпуске: 6 Vol.16, 2024 года.

Бесплатный доступ

Introduction. Despite significant progress in the creation of high quality polymer composites with a unique combination of key indicators, some issues in this area have not been fully studied. This paper presents the results of research on the structure of materials based on epoxy-coal binder and analysis of physical and mechanical properties at the microstructure level, which are influenced by various factors: the quantitative content of modifying additives and various fillers, the degree of particle dispersion, their size and shape. It has been revealed that nanoscale particles are one of the potential modifiers of the microstructure of composites. Materials and methods. As part of the experiment, composites were studied, in which ED-16 epoxy resin modified with coal tar was used as the main binder. Polyethylene polyamine served as a hardener. Reduction of viscosity and plasticization of compositions was achieved through the use of gasoline, acetone, turpentine, white spirit, dibutylphthalate, etc. Quartz sand, fine powders of brick, marble, glass, limestone, and in addition, Portland cement were used as fillers. Two nano additives were used: carbon black and carbon nanotubes. Standard techniques were used to reveal the mechanical characteristics. Physicochemical investigations were carried out by IR spectroscopy. Tests of samples for fungus resistance and fungicidal properties were carried out in accordance with the State Standard (SS) 9049-91. Results. The results of composite tests are presented in the form of spectrograms, graphical dependencies, and tabular data. Discussion. The results of analyzing the obtained experimental data are presented. The optimum content of polyethylene polyamine for curing of epoxy-coal compositions has been determined. The following has been established: the physical and mechanical properties of composites depend to a great extent on the nature of the solvent, and changes in wide ranges have been recorded. It has been determined that the properties of composite materials are seriously influenced by the dispersity and quantitative content of the filler. The expediency of nano-additives application in epoxy compositions has been revealed. In the course of the experiment the dependences of the change of chemical resistance and biological resistance of composites on the type and quantitative content of the modifying additive, on the nature of the filler were determined. Conclusions. Modified epoxy-coal composites with the use of multilevel fillers and additives have been developed. This makes it possible to increase the strength, increase the deformability and crack resistance of building materials composites for operation, which is very important under the influence of chemical and biological aggressive environment.

Polymer composites, epoxy resin, coal tar, solvents, fillers, nanoparticles, strength, deformability, chemical and biological resistance, durability

Короткий адрес: https://sciup.org/142242745

IDR: 142242745 | DOI: 10.15828/2075-8545-2024-16-6-533-548

Текст научной статьи Epoxy composites modified with coal tar

Review article

V arious polymeric materials are widely used in the construction industry, the increase in the use of which is achieved through the synthesis of new and modification of large-tonnage polymers already mastered by the industry [1, 2, 3, 4].

A large number of works by Russian and foreign authors are devoted to the theoretical issues of creating, evaluating the properties and predicting the durability of polymer materials [5, 6, 7, 8, 9]. Thus, the monograph [5] analyzed various structures, including cluster, lattice and framework structures, of polymer composite materials based on synergetic, which is a new discipline related to

CONSTRUCTION MATERIALS SCIENCE the study of self-organizing temporal and spatial formations in complex disordered systems of different nature and mechanics of composite materials. Finite element modeling of interfacial bonding of polymer concrete components was performed in the study [7]. In the boundary layers, the polymer forms a structure and properties different from those in the volume, which are heterogeneous in thickness of these layers. This causes hardening of the polymer adhesion to the filler surface [1]. The paper [6] presents the results of research on studying the resistance of composites to aggressive environments and the development of ways to increase it. Expressions allowing to estimate the resistance of composites to the action of the environment during their manufacture and operation depending on time, product dimensions, permeability and chemical interaction parameters have been obtained. The theoretical foundations of the proposed methods of protecting composites from the impact of aggressive environment have also been developed. The paper [10] presents the most complete theoretical issues related to the research of bio-damage and methods of increasing the biostability of materials, including consideration of destruction mechanisms, modeling of biodegradation, and predicting the durability of materials.

It is known that the most effective application of polymeric building materials is achieved when their increased chemical resistance is required [8, 11, 12].

In buildings with aggressive environments the most durable are polymer concretes, anti-corrosion protective coatings, etc. are the most durable. [6, 13, 14, 15, 16, 17].

Of the wide class of binders used to make polymer concretes, epoxy resins are the most in demand [19, 20, 21, 22, 23]. Polymer composites created on their basis have universal resistance to active chemical exposure [24, 25, 26]. It is important to note that significant problems during operation are caused by the increased brittleness of these materials, which is associated with the formation of a dense spatial grid during curing. Reducing the density of crosslinking is possible due to the introduction of modifiers containing flexible long chains into the composite [27, 28,

29]. Rubbers, phthalates, bitumen, coal tar, etc. are used as modifiers [30].

As protective coatings on concrete, reinforced concrete and metal surfaces epoxy-coal composites have demonstrated reliability and rather high efficiency. This problem is in the center of attention of researchers, but at the same time the structure formation, optimization of compositions and technology of manufacturing of these composites are studied in insufficient degree. The solution of these problems will allow to expand the practice of application of these materials. A very important quality of anticorrosive coatings is the resistance of materials in chemically and biologically aggressive environments. In the current situation, the improvement of polymer composite materials is associated with the study of objects created according to the principle of multicomponent structures at various dimensional levels [7, 31, 32, 33]. The study of the role of special additives in the plasticization of epoxy compositions in the framework of our research was carried out in combination with various fillers. One of the potential microstructure modifiers is nanoscale particles [9, 34, 35].

MATERIALS AND METHODS

Binders, hardeners, modifiers

Epoxy resin of the ED-16 brand (GOST 10587-84). Polyethylene polyamine (PEPA) (Technical Requirement (TR)-6-02-594-85) was used as an epoxy resin hardener, and coal tar (SS 4492-65) was used as a modifier.

Solvents, plasticizers

Gasoline (SS 2084-77), acetone (SS 2768-84), solvent 646 (SS 18188-72), diesel fuel (SS 305-82), turpentine (SS 1571-82), white spirit (SS 3134-78), dibutyl phthalate (SS 8728-66).

The fillers used in the experimental studies are presented in Tables 1 and 2.

Table 1

Chemical composition of fillers

|

№ |

Type of filler or aggregate |

Chemical composition |

||||||

|

SiO 2 |

Al 2 O 3 |

Fe 2 O 3 |

СaO |

MgO |

SO 3 |

Other compounds |

||

|

1 |

Quartz sand |

91.93 |

5.36 |

0.56 |

0.04 |

0.9 |

0.2 |

1.01 |

|

2 |

Brick rubble |

55–80 |

5–15 |

3–15 |

25 |

3 |

3 |

15 |

|

3 |

Limestone sand |

3.1–8.2 |

1.9–3.6 |

0.4–3.0 |

49–50 |

0.6–1.3 |

– |

– |

|

4 |

Marble powder |

26 |

– |

0.05–0.8 |

40.6–55.5 |

10 |

0.5 |

32 |

|

5 |

Crushed glass |

68.5–72.9 |

1.0–1.5 |

– |

5.0–6.0 |

3.2–3.7 |

– |

16.8–22.3 |

|

6 |

Portland cement |

23.08 |

5.45 |

2.99 |

66.91 |

1.42 |

0.15 |

– |

CONSTRUCTION MATERIALS SCIENCE

Table 2

Values of filler densities

|

№ |

Type of filler or aggregate |

True density, g/cm3 |

Bulk density, g/cm3 |

|

1 |

Quartz sand |

2.56 |

1.45 |

|

2 |

Brick rubble |

1.6–1.8 |

1.3 |

|

3 |

Limestone sand |

1.8 |

1.23 |

|

4 |

Marble powder |

2.6–2.8 |

1.4–1.55 |

|

5 |

Crushed glass |

2.4–2.6 |

0.82–0.95 |

|

6 |

Portland cement |

3.1 |

1.1 |

Nanoscale fillers: carbon black (soot) of the P234 brand and carbon nanotubes “Tuanit-M” manufactured by Nanotechcenter LLC. The structure of the cured compositions was studied by the method of semi-quantitative Fourier-IR spectroscopy (it makes it possible to estimate the change in reactive groups in the polymer structure by changing the optical density at the characteristic absorption bands of bonds). The IR spectra of the samples were recorded on the Fourier spectrometer InfraLUM FT-02. A universal Autograph Shimadzu AG-X series testing machine with a load-strain diagram was used for mechanical testing of samples. Parameters such as compressive strength, bending strength, and modulus of elasticity were determined using standard methods. The control of the test process and the preliminary processing of the obtained data were carried out using TRAPEZIUM X×1 software. The samples were tested for fungal resistance and the presence of fungicidal properties in accordance with SS 9049-91. Species of micromycetes used as test organisms: Asperqillus oryzae (Ahiburq) Cohn, Asperqil-lus niqer vqn Tieqhem, Asperqillus terreus Thom, Chae-tomium qlobosum Kunze, Paecilomyces varioti Bainier, Penicillium funiculosum Thom, Penicillium chrysoqe-num Thom, Penicillium cyclopium Westlinq, Tricho-derma viride Pcis, ex Fr. Methods 1 and 3 were used in the tests. Accelerated tests on the biostability of polymer composites were carried out in a model microbiological environment including aqueous solution of citric acid and hydrogen peroxide of various concentrations according to [10].

RESULTS AND DISCUSSION

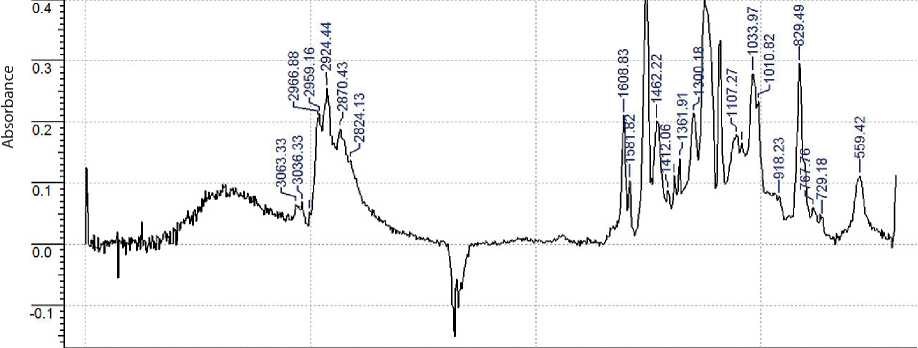

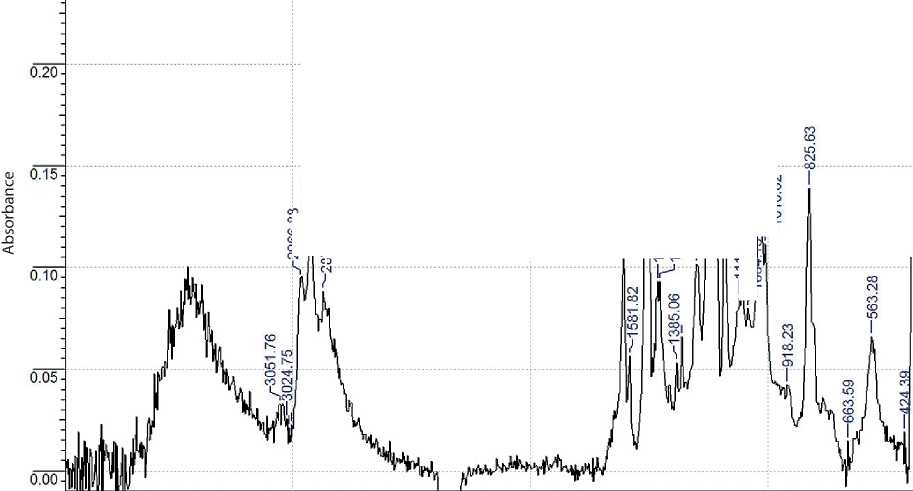

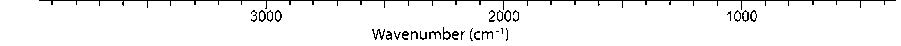

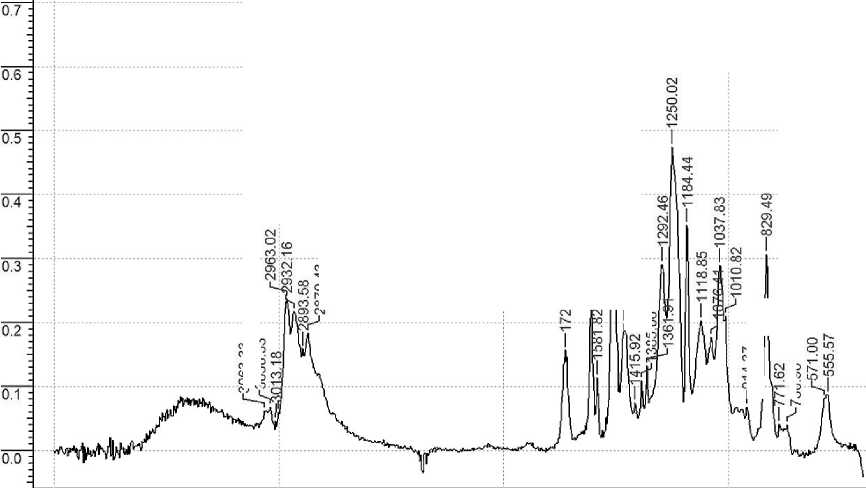

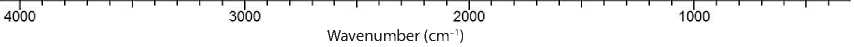

According to the results of studies conducted by IR spectroscopy (Fig. 1–3), it was concluded that when coal tar and bitumen were introduced into epoxy resin and cured with polyethylene polyamine, no qualitative changes in the IR spectra of the cured samples were observed. In the samples with dibutyl phthalate, the appearance of a new absorption band at 1724 cm-1 which characterizes the absorption of carbonyl group in the ester group of dibutyl phthalate itself, was recorded.

In order to quantitatively compare the obtained spectra, the intensities of the most characteristic band for the epoxy group at 3001 cm–1 (bands at 914 and 864 cm–1 are less characteristic, since in these areas absorption of skeletal vibrations of the polymer may be superimposed) using the absorption of “pulsation” vibrations of the aromatic ring at 1508 cm–1 as an internal standard. The results are shown in Table 3.

It follows from the data of the presented table that when dibutyl phthalate is used, the intensity of the absorption band at 3001 cm–1, characterizing the content of free epoxy groups in the cured composite, increases in comparison with the composite without additives (0.050 and 0.046 respectively), which is evidence of the reduction of spatial cross-links in the presence of dibutyl phthalate. Additionally, due to the introduction of coal tar and bitumen in the composite, the density of spatial crosslinking is reduced.

It follows from the data of this table that in the presence of dibutyl phthalate the intensity of the absorption band at 3001 cm–1, characterizing the content of free epoxy groups in the cured composite, increases compared to the composite without additives (0.050 and 0.046, respectively). This indicates a decrease in spatial cross-linking in the presence of dibutyl phthalate. The introduction of coal tar and bitumen into the composite additionally decreases the density of spatial crosslinking.

These facts indicate that the additives used in epoxy compositions at low-temperature amine curing perform the role of plasticizers, distributing between the elements of the epoxy composition structure and thus facilitating the mutual movement of macromolecule aggregates. Plasticizing ability increases in the following series: dibutyl phthalate < coal tar < bitumen. The results of mechanical tests of samples show that the studied additives increase the elasticity but decrease the strength of epoxy composites in the above series. This fully confirms the conclusions obtained in the present study.

In order to establish the optimum hardener content in epoxy-coal composites, studies were carried out using mathematical planning method of experiment. The Kono plan including 9 experiments was used as a planning matrix, which is a full factorial experiment 32. The fol-

CONSTRUCTION MATERIALS SCIENCE

Fig. 1. IR spectrum of ED-16 epoxy resin modified with coal tar (10 wt.h.) and cured with PEP (10 wt.h.) (Area 500–4000 cm–1)

B8ZLIOL—h

NOogzL—

805Л 88№І^ ^4 後/

9BCO 二 L—

й.ол-т

8Ld0gL—

0gw9》L CCZ9W

S.§T

寻OZ8Z omcoz6fh 8CO.996Z

Fig. 2. IR spectrum of ED-16 epoxy resin modified with bitumen (10 wt.h.) and cured with PEP (10 wt.h.) (Area 500–4000 cm–1)

CONSTRUCTION MATERIALS SCIENCE cgcdogL—

ecnabrosbA

90 98E

06 92

芻 Z9WII

88CO09L—

COF0ZCOZ

ЕЕ 9E0E

Fig. 3. IR spectrum of ED-16 epoxy resin modified with dibutyl phthalate (10 wt.h.) and cured with PEP (10 wt.h.) (Area 500–4000 cm–1)

Table 3

In the framework of the experimental study composites were considered, where as the main binder was used the epoxy resin of ED-16 brand modified with coal tar in the amount from 5 to 15%. The filler was quartz sand in the amount of 300 wt.h. per 100 wt.h. of epoxy resin. The hardener – polyethylene polyamine – was introduced into the composition in the amounts of 7.5; 10; 12.5 wt.% per 100 wt.% of epoxy resin.

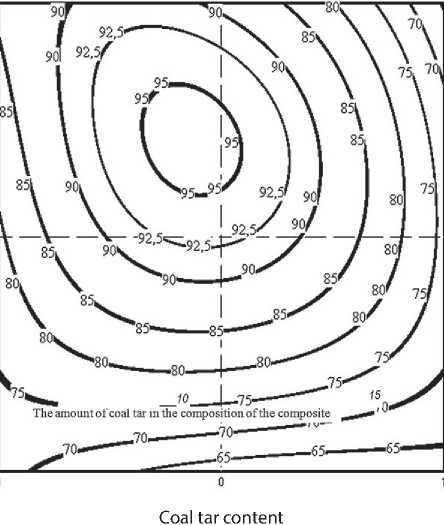

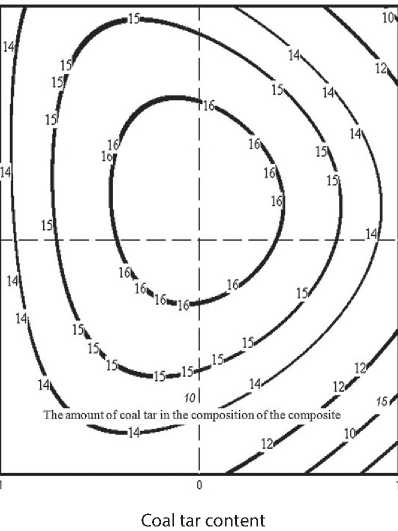

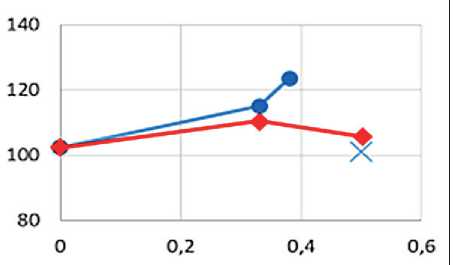

Based on the analysis of the results of studies of the strength properties of epoxy-carboniferous composites, the optimal content of PEP for curing epoxy-carboniferous composition was determined: 10–11 wt.h. (Fig. 4).

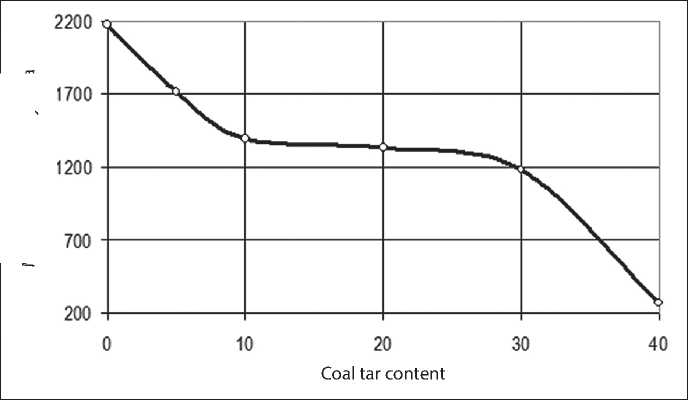

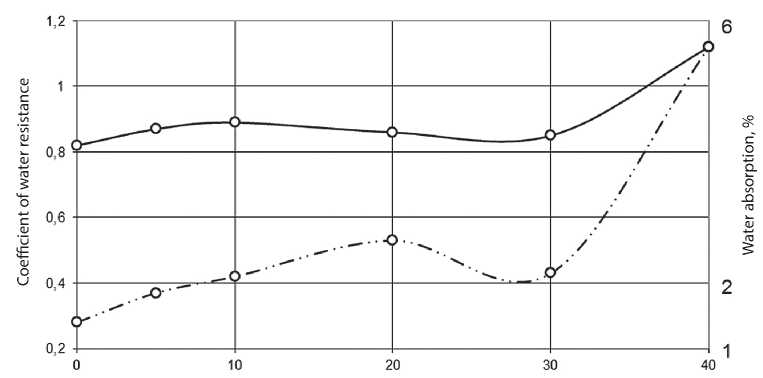

To determine the change in the modulus of elasticity of epoxy-coal composites, samples with the content of coal tar from 0 to 40 wt% per 100 wt% of epoxy resin were used. Quartz sand of 0.315–0.63 mm coarseness was used as a filler, the quantitative content of which was assumed to be 300 wt.hr. According to the results of the experiment, it was concluded that the elastic modulus decreased 8 times with increasing the modifier content from 0 to 40% (Fig. 5).

Experimental studies of mechanical properties of ep-oxy-coal composites using quartz sand and finely ground marble as fillers have been carried out. The following factors were considered as variable factors: quantitative content of hardener (polyethylene polyamine), coal tar content, filler size, degree of filling and a factor taking into account the degree of interaction (type and ratio) of fillers. The listed factors and their variation levels are given in Table 4, the planning matrix and the experimental results are given in Table 5.

In order to clarify the maximum and minimum mechanical properties of the investigated composite, a model planning matrix was created taking into account the first four factors, as well as their possible interactions. The

CONSTRUCTION MATERIALS SCIENCE

PEP eht fo tnetnoC а

PEP eht fo tnetnoC

戸 5

Fig. 4. Dependence of compressive strength (a) and flexural tensile strength (b) of composites on the quantitative content of coal tar and hardener aPM yticitsale fo suludo

Fig. 5. Dependence of elastic modulus of epoxy-coal composites on the coal tar content computer programme [36] was used to determine the coefficients of the regression equation taking into account the interaction of factors. The notation of factors and their interactions is as follows:

Х0, Х1, Х2, Х3, Х4, (Х1•Х2), (Х1•Х3), (Х1•Х4), (Х2•Х3), (Х2•Х4), (Х3•Х4), (Х1•Х2•Х3), (Х1•Х2•Х4), (Х1•Х3•Х4), (Х2•Х3•Х4), (Х1•Х3•Х4), (Х2•Х3•Х4), (Х1•Х2•Х3•Х4), where X0 is identically equal to one.

After deriving the regression equations for Rcompr, Rbend., Eelast.. using [36], cubic interpolation (Makima method) of the regression equations was performed. This made it possible to determine more accurate maximum values of the compressive strength (Rcompr), bending strength (Rbend) and modulus of elasticity (Eelast.). The results of calculations are presented in Table 6.

According to the results of ranking of average values of all considered indicators it was concluded that the effect of factor X4 is insignificant for all indicators, factor X1 is insignificant for compressive strength, tensile strength in

CONSTRUCTION MATERIALS SCIENCE

Table 4

Factors and levels of their variation

|

№ |

Factors |

Denominations |

Factor levels |

|

|

+1 |

–1 |

|||

|

1 |

Hardener content, (wt.h.) |

Х 1 |

10 |

5 |

|

2 |

Coal tar content, (wt.h.) |

Х 2 |

20 |

0 |

|

3 |

Filler coarseness |

Х 3 |

0.315–0.63 |

0.14–0.315 |

|

4 |

Binder filling degree |

Х 4 |

1:3 |

1:1 |

|

5 |

Factor considering the degree of interaction, (type and ratio) of filler material |

Х 5 |

А: quartz sand 100% В: marble-based sand 100%, С: А-75%, В-25%, Д: А-50%, В-50%. |

|

Table 5

Planning matrix and experiment results

|

№ п/п |

Planning matrix |

Physical and technical properties in MPa |

||||||

|

Х 1 |

Х 2 |

Х 3 |

Х 4 |

Х 5 |

Rcompr. |

Rbend., |

E, elact |

|

|

1 |

+1 |

+1 |

+1 |

+1 |

А |

49.7 |

14.9 |

50.6 |

|

2 |

–1 |

+1 |

+1 |

+1 |

С |

57.6 |

15.0 |

173.8 |

|

3 |

+1 |

–1 |

+1 |

+1 |

В |

35.2 |

8.5 |

118.4 |

|

4 |

–1 |

–1 |

+1 |

+1 |

Д |

52.7 |

8.2 |

42.63 |

|

5 |

+1 |

+1 |

–1 |

+1 |

В |

39.2 |

11.7 |

51.2 |

|

6 |

–1 |

+1 |

–1 |

+1 |

Д |

54.9 |

11.7 |

145.3 |

|

7 |

+1 |

–1 |

–1 |

+1 |

С |

29.6 |

8.0 |

55.0 |

|

8 |

–1 |

–1 |

–1 |

+1 |

А |

30.6 |

6.1 |

69.3 |

|

9 |

+1 |

+1 |

+1 |

–1 |

С |

57.9 |

13.5 |

126.9 |

|

10 |

–1 |

+1 |

+1 |

–1 |

А |

41.9 |

11.2 |

157.8 |

|

11 |

+1 |

–1 |

+1 |

–1 |

Д |

35.3 |

5.6 |

159.5 |

|

12 |

–1 |

–1 |

+1 |

–1 |

В |

44.8 |

7.4 |

117.4 |

|

13 |

+1 |

+1 |

–1 |

–1 |

Д |

54.6 |

14.9 |

177.1 |

|

14 |

–1 |

+1 |

–1 |

–1 |

В |

27.6 |

6.9 |

95.7 |

|

15 |

+1 |

–1 |

–1 |

–1 |

А |

20.5 |

2.9 |

61.4 |

|

16 |

–1 |

–1 |

–1 |

–1 |

С |

27.8 |

4.8 |

54.5 |

Table 6

Results of determination of maximum physical and technical properties of the composite

|

Maximum physical and technical properties |

Maximum values for the matrix planning effects-wise interaction, MPA |

Coded values factors of the planning matrix taking into account interaction effects |

|

Maximum R сж |

58,4827 |

1 1 1 1 –1 1 1 –1 1 –1 –1 1 –1 –1 –1 –1 |

|

Maximum R изг. |

15,6863 |

1 –1 1 1 1 –1 –1 –1 1 1 1 –1 –1 –1 1 –1 |

|

Maximum Е упр. |

177,2901 |

1 1 1 –1 –1 1 –1 –1 –1 –1 1 –1 –1 1 1 1 |

CONSTRUCTION MATERIALS SCIENCE bending, X3 is insignificant for modulus of elasticity. The effects of other factors for all indicators are significant.

The use of quartz sand as filler in combination with marble powder in the ratio of 50% by 50% causes improvement of contact interaction of epoxy binder modified with coal tar, with coal tar content of 20%. The introduction of coal tar increases the deformability, the modulus of elasticity decreases by 13.5%. Modified polymer concretes have rather high strength properties. In particular, the compressive strength is 54.6 MPa, and the tensile strength in bending is 14.9 MPa.

In addition, we have conducted studies of the influence of the quantitative content of the modifier – coal tar on the mechanical properties of epoxy-coal polymer concretes, as well as the effect of solvents and fillers on them.

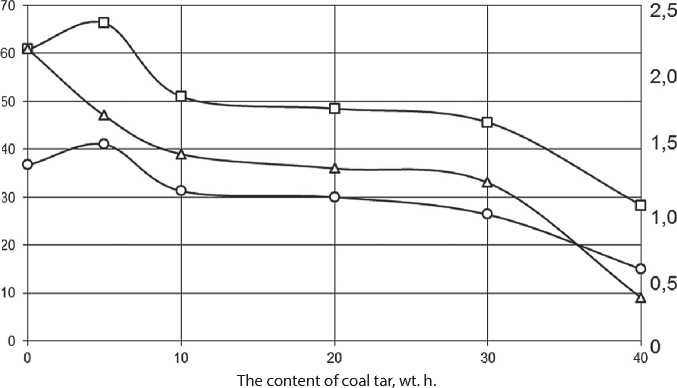

The subject of the study were epoxy-coal composites with coal tar in the binder from 5 to 40 wt.h. per 100 wt.h. of epoxy resin. Quartz sand of 0,315–0,63 mm coarseness was chosen as a filler. The content of hardener – polyethylene polyamine was taken at the rate of 10% of epoxy resin weight. The effect of coal tar content on the properties of epoxy composites was analyzed by testing prisms of size 1×1×3. The test results are shown in the graphs (Fig. 6).

Based on the analysis of the obtained dependences it can be concluded that the introduction of coal tar in the amount of up to 5% causes an increase in compressive and tensile strength in bending. The strength decreases with the increase of the content volume. The addition leads to a decrease in the modulus of elasticity of epoxy-

– ○ – Bending strength – ■ – Compressive strength – ▲ – Modulus of elasticity

b

The content of coal tar, wt. h.

____ Coefficient of water resistance – .. – Water absorption, %

Fig. 6. Dependence of compressive strength, flexural tensile strength and modulus of elasticity (a) and coefficient of resistance, water absorption (b) on the quantitative content of coal tar in epoxy binder

CONSTRUCTION MATERIALS SCIENCE coal composites. With the increase of coal tar content up to 40% the water resistance coefficient increases by 1.28 times in comparison with the control composition. This occurs, in all probability, due to the processes of interaction between epoxy and coal tar, contributing to the increase in hydrolytic stability.

The study analyses how the nature of the solvent affects the properties of epoxy-coal binder. Solvents: acetone, petrol, diesel fuel, turpentine, solvent 646, white spirit. The compositions on epoxy resin without modifying additive and on epoxy-coal binder without solvent became the control ones in relation to the compositions consisting of epoxy-coal binder with solvent inclusion (Table 7).

According to the results of the test it is possible to draw a conclusion about change in wide ranges of physical and mechanical properties of composites - depending on the nature of the solvent. At that, the best indicators of compressive strength demonstrate compositions with the use of solvent 646, turpentine and petrol, and tensile strength at bending – acetone, solvent 646, turpentine. The use of solvents is justified also from the technological point of view – it makes it possible to exclude preliminary heating of components from the process of preparation of epoxy-coal composites.

The nature of the filler plays a key role in the creation of composite materials. The highest values of strength and durability are in composites obtained by combination of certain ‘binder–filler’ pairs. To determine the influence of the nature of mineral fillers on the properties of filled epoxy-coal composites, comparative studies were carried out. The following fillers were used: quartz sand and crushed powders of limestone, crushed glass, marble and ceramic bricks. The coarseness of the filler was assumed to be 0.315–0.63 mm. The amount of introduced filler provided the ratio of binder/filler – 1/1. Information about strength properties of composites is presented in Table 8.

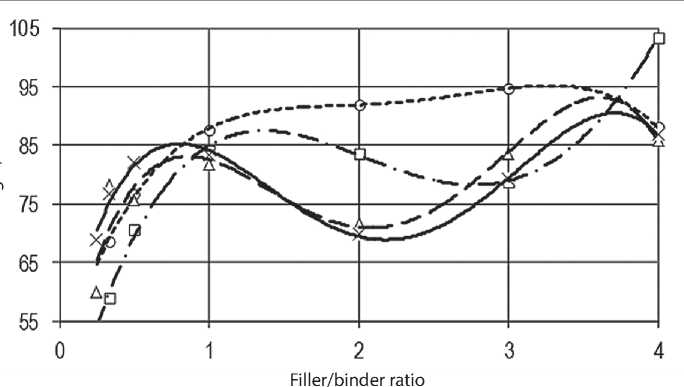

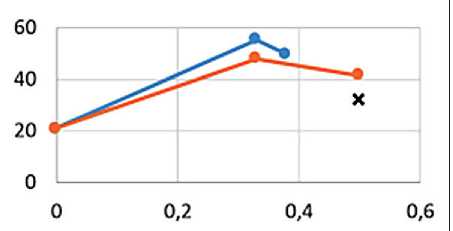

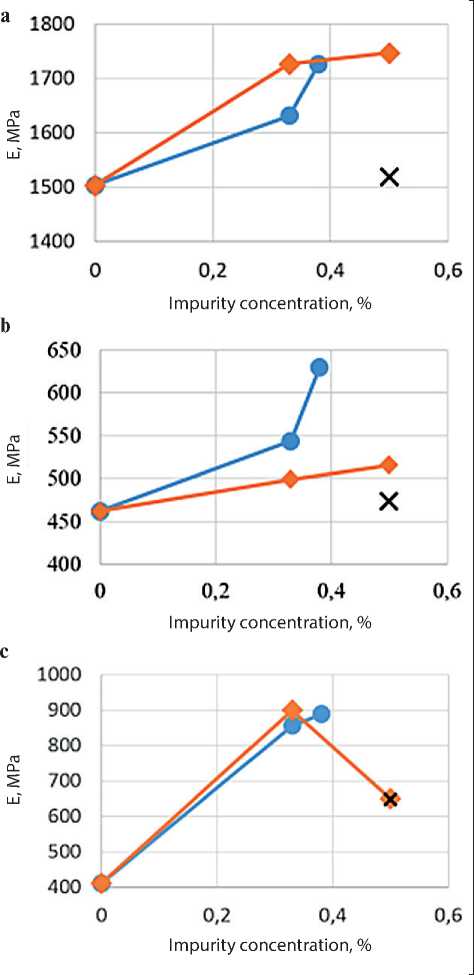

In the course of the study it was determined that among the considered epoxy-coal filled composites the greatest strength in compression and tensile strength in bending is peculiar to composites filled with limestone. It should be noted that the dispersity and quantitative content of the filler has a significant influence on the properties of composite materials (Fig. 7).

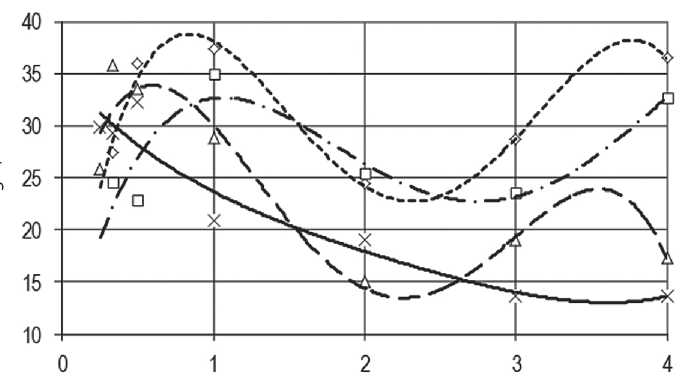

The greatest strength is inherent in composites filled with powders of high dispersity (fraction < 0.071 mm). Notable effects were obtained when using nano-additives as fillers – furnace soot and carbon nanotubes ‘Tuanit-M’ [37]. Moreover, the additives were introduced both sepa-

Table 7

Strength of epoxy-coal composites

|

№ Composition |

Solvent type in modified formulations |

Strength limit in compression, MPa |

Tensile strength under bending, MPa |

|

1 |

No modifier |

104,7 |

78,5 |

|

2 |

Acetone |

77,5 |

72,4 |

|

3 |

Petrol |

89,2 |

52,3 |

|

4 |

Acetone + petrol (1:1) |

85,0 |

57,4 |

|

5 |

Diesel fuel |

87,0 |

51,8 |

|

6 |

Solvent 646 |

96,4 |

68,6 |

|

7 |

Turpentine |

90,7 |

65,0 |

|

8 |

White spirit |

84,4 |

56,9 |

|

9 |

No solvent |

96,7 |

63,5 |

Table 8

Strength of epoxy-carboniferous composites on various fillers

|

№ |

Filler type |

Strength limit, MPa |

|

|

in compression |

tensile in bending |

||

|

1 |

No filler |

68.7 |

9.2 |

|

2 |

Quartz sand |

83.2 |

20.9 |

|

3 |

Limestone |

140.8 |

22.7 |

|

4 |

Marble |

133.9 |

17.0 |

|

5 |

Brick rubble |

117.3 |

21.4 |

|

6 |

Crushed glass |

111.1 |

20.9 |

CONSTRUCTION MATERIALS SCIENCE

aPM ,htgnert

Filler/binder ratio

---- Fraction < 0.071 mm

– – – Fraction 0.14–0.315 mm

– . – Fraction 0.071–0.14 mm

____ Fraction 0.315–0.63 mm

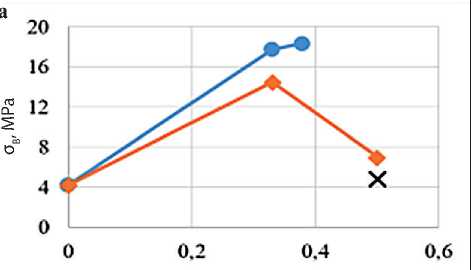

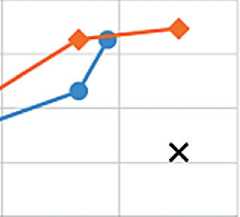

Fig. 7. Dependence of compressive strength and flexural tensile strength of epoxy-coal composites on filler content and dispersity rately and jointly. In some cases, the joint effect of several nano-additives caused an improvement in the properties of polymer composites [35, 38] (Figs. 8–10).

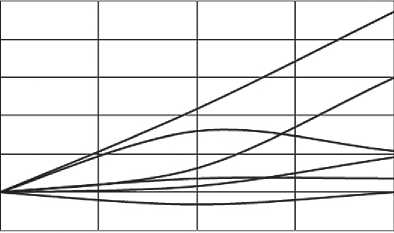

The presented graphs show a significant effect of nano-additives on the mechanical properties of the cured resin. Thus, tensile strength increased almost 5 times and bending strength increased 3 times. At the same time, the effect of nanotubes introduction in most cases turned out to be slightly less than that when soot was used

Among the most effective binders that make it possible to create construction materials with increased physical and mechanical properties and universal resistance in solutions of acids, alkalis and salts are polymers, in particular epoxy resins. It is essential that modifying additives do not cause a decrease in the resistance of materials in aggressive environments [39, 41, 42]. To establish the influence of coal tar additive on chemical and biological resistance of epoxy composites, we have conducted studies of epoxy-coal composites with coal tar content varying from 5 to 40%. Powders based on crushed glass and limestone, quartz sand and Portland cement were used as fillers. The coarseness of the fillers was assumed to be 0.315–0.63 mm, and the dispersity of Portland cement was assumed to be 3100 cm2/g. The compositions used are shown in Table 9.

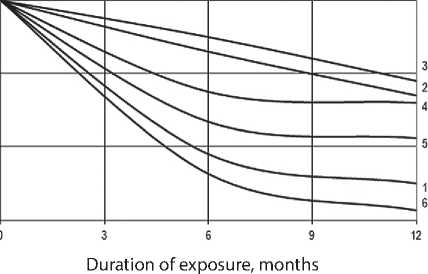

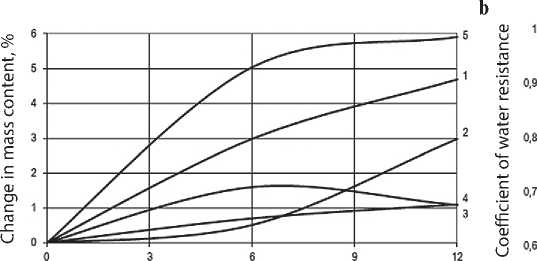

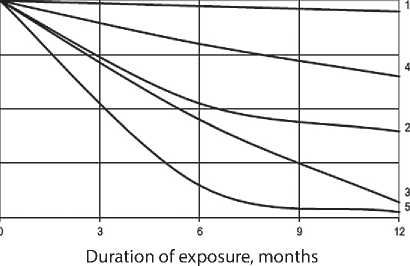

In the course of the experiment the dependences of chemical resistance of composites on the type and quantitative content of modifying additive, nature of filler when kept in water, aqueous solutions of alkalis and acids were determined. Dependences of mass content and resistance coefficient of epoxy-coal composites on the duration of soaking in water are shown in Fig. 11 and 12.

CONSTRUCTION MATERIALS SCIENCE

Impurity concentration, %

b

c

та І

Impurity concentration, %

та І

Impurity concentration, %

Fig. 9. Dependence of the change in the effective modulus during the tensile test (a), compression (b) and bending (c) on the type and content of nano-additives:

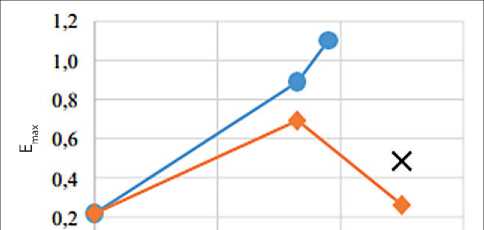

• – soot, ♦ – CNTs, × – soot + CNT

Fig. 8. Dependence of tensile (a), compressive (b) and flexural (c) strength variation on the type and content of nano-additives: • – soot, ♦ – CNTs, × – soot + CNTs

0,0

О 0,2 0,4 0,6

Volume of the additive, %

Fig. 10. The maximum total deformation depending on the additive value obtained during tensile tests:

• – soot, ♦ – CNTs, × – soot + CNTs

CONSTRUCTION MATERIALS SCIENCE

3 6 9

Duration of exposure, months

Table 9

Compositions used for chemical resistance tests

|

Components |

Content of mass parts in the compositions |

|||||||||

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

|

|

Epoxy resin of ED-16 brand |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

|

Polyethylenepolyamine |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

|

Coal tar |

– |

5 |

10 |

20 |

30 |

40 |

20 |

20 |

20 |

20 |

|

Quartz sand |

300 |

300 |

300 |

300 |

300 |

300 |

||||

|

Portland cement |

300 |

|||||||||

|

Limestone |

300 |

|||||||||

|

Crushed glass |

300 |

|||||||||

Fig. 11. Dependence of change of mass content (a) and resistance coefficient (b) of epoxy-coal composites on the quantitative content of coal tar and duration of soaking in water: 1 – no coal tar; 2–5% coal tar in the binder; 3–10% coal tar; 4–20% coal tar; 5–30% coal tar; 6–40% coal tar

а

Duration of exposure, months

Fig. 12. Dependence of change of mass content (a) and resistance coefficient (b) of epoxy-coal composites on the type of filler and duration of holding in water: 1 – no filler; 2 – Portland cement; 3 – limestone; 4 – sand; 5 – crushed glass

It has been experimentally established that the introduction of coal tar increases the water resistance of epoxy composites. Water resistance increases by 20% in comparison with composites on unmodified binder at

the content of coal tar in the amount of 10%. Maximum water resistance is at composites filled with quartz sand. It was determined that modification of epoxy binder with coal tar in the amount up to 40% increases resistance in

CONSTRUCTION MATERIALS SCIENCE acid solutions by almost 40%. In the course of 6-month tests it was found that the compositions filled with quartz sand have the highest resistance in acid solutions. The graphs also show the positive influence of coal tar on the chemical resistance of epoxy-coal binders in caustic soda solutions. The resistance of modified composites exceeds the similar index of unmodified ones by 15%. The greatest resistance in caustic soda solutions of 10% concentration is inherent to compositions filled with quartz sand.

Nowadays, researchers have paid much attention to the study of biodegradation and biosecurity of various materials [17, 43, 44, 45].

Studies of biological resistance of epoxy-coal composites depending on the type of fungicidal additives and the content of coal tar (5–10%) in the binder have been carried out. In the course of the experiment, quartz sand was used as a filler, introduced in the quantitative ratio of

1:1 to the binder. The tests were carried out on samples in the form of prisms with the size of 1×1×3. At the first stage the tests were carried out in a model biological environment, at the second stage – in a standard environment of mycelial fungi. In the first stage, the problem was solved by implementing a rototable matrix, the variable factors on which were the content of citric acid (0.1–10%) and hydrogen peroxide (0.03–3%) in aqueous solution (products of microbial metabolism). The compositions of aggressive media and their concentrations were determined taking into account the conditions of application of polymer concretes in industrial and agricultural construction (Tables 10 and 11). The compositions of aggressive environments and their concentrations were determined taking into account the conditions of polymer concrete application in industrial and agricultural construction (Tables 10 and 11).

Table 10

Compositions used for biological resistance testing

|

Components |

The content of mass parts in the compositions |

||||||||

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

|

|

Epoxy resin ED-16 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

|

Polyethylenepolyamine |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

|

Coal tar |

– |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

|

Quartz sand |

100 |

100 |

50 |

||||||

|

Crushed glass |

100 |

||||||||

|

Limestone |

100 |

||||||||

|

Marble |

50 |

100 |

|||||||

|

Brick rubble |

100 |

||||||||

|

Portland cement |

100 |

||||||||

Table 11

Physical and technical parameters of epoxy-coal composites in biologically aggressive environments

|

№ Composition |

Maximum value |

Minimum value |

||||

|

№ Environment |

Compression strength, MPa |

Tensile strength at bending, MPa |

№ Environment |

Compression strength, MPa |

Tensile strength at bending, MPa |

|

|

1 |

3 |

70.8 |

24.2 |

1 |

45.63 |

15 |

|

2 |

2 |

70.2 |

19.3 |

5 |

55.87 |

19.2 |

|

3 |

7 |

65.1 |

24.4 |

1 |

47.76 |

11.8 |

|

4 |

7 |

45.7 |

13.6 |

3 |

35.3 |

13.3 |

|

5 |

7 |

73.5 |

15.9 |

9 |

62.9 |

23.3 |

|

6 |

2 |

67.1 |

18.9 |

1 |

43.5 |

17.6 |

|

7 |

1 |

67.6 |

20.3 |

2 |

57.7 |

20.8 |

|

8 |

7 |

75.7 |

26.5 |

5 |

62.4 |

30.4 |

|

9 |

7 |

56.4 |

9.86 |

8 |

28.8 |

13.8 |

CONSTRUCTION MATERIALS SCIENCE

Table 11 contains physical and technical parameters of epoxy-coal composites after testing in biologically aggressive environments: the most aggressive is environment No. 1 (content of citric acid 1%, hydrogen peroxide 0.3%) and No. 8 (content of citric acid 0.1%, hydrogen peroxide 0.3%).

Solutions of nitrofungin and “Teflex” were used as fungicidal additives in epoxy-coal composites. Studies have shown that the introduction of 2% nitrofungin has no effect on the increase of fungus resistance. Increasing the content of nitrofungin up to 5% increases the fungicide resistance for the composition filled with brick rubble and unfilled compositions, further increase in the content of nitrofungin leads to a decrease in its fungicidal effect. The use of “Teflex” is more effective: its addition in the amount of 2% has a positive effect on fungicidal properties, 10% and more – its addition in the amount of 2%

positively affects fungicidal properties, 10% and more – fungicidal properties. The use of fungicidal compositions prevents microorganisms from infesting building structures and helps to improve the environmental situation in buildings and structures.

CONCLUSIONS

Thus, based on the results of the experimental research carried out by the authors using methods of mathematical planning, measurement of mechanical properties, and IR spectroscopy, modified epoxy-coal composites with increased mechanical properties, chemical and biological resistance have been developed, allowing to use products made of them for operation under conditions of exposure to water, aqueous solutions of acids, and alkalis, salts, mineral fertilizers and microscopic organisms.

Список литературы Epoxy composites modified with coal tar

- Khozin V.G. Strengthening of epoxy polymers. Kazan: House of Printing; 2004.

- R. Bedi, R. Chandra, S.P. Singh. Reviewing some properties of polymer concrete. Indian Concr. J. 2014; 88: 47-68.

- S. Daghash, R. Tarefder, M. Reda Taha, A New Class of Polymer Concrete with Improved Fatigue Strength Using Carbon Nanotubes, 2015. https://doi.org/10.1007/978-3-319-17088-6_37

- Y. Feng, Y. Su, N. Lu, S. Shah. Meta concrete: exploring novel functionality of concrete using nanotechnology. Eng. Sci. 2020. https://doi.org/10.30919/es8d816

- Bobryshev A.N. Physics and synergetics of dispersed disordered condensed composite systems: monograph / A.N. Bobryshev, V.T. Yerofeev, V.N. Kozomazov. – St. Petersburg: Nauka; 2012.

- Fedortsov A.P. Physico-chemical resistance of building composites and ways to increase it. Saransk: Publishing House of the Mordovian University; 2015.

- J. Wang, Y. Fan, C. Zhu, S. Lu, J. Liu. Mesoscopic finite element simulation on the interfacial bonding performance of functionally gradient concrete. ES Mater. Manuf. 2020. https://doi.org/10.30919/esmm5f810

- J.P. Gorninski, C.de S. Kazmierczak. Evaluation of the chemical strength of polymeric concretes in aggressive environments. Ambiente Construído. 2008; 8:105-113.

- B. Fiedler, F.H. Gojny, M.H.G. Wichmann, M.C.M. Nolte, K. Schulte. Fundamental aspects of nano-reinforced composites. Compos. Sci. Technol. 2006; 6: 3115-3125, 10.1016/j.compscitech.2005.01.014

- Solomatov V.I. Biological resistance of materials: monograph / V.I. Solomatov, V.T. Erofeev, V.F. Smirnov, etc. Saransk: Publishing House of Mordovia. Unita; 2001.

- Erofeev, V., Gubanov, D., Bogatov, A., Bulgakov, A. Frame polymerbetons based on fillers of different nature. Materials Science Forum, 2020;1011: 164–170. https://doi.org/10.4028/www.scientific.net/MSF.1011.164

- Thomas, C., Lombillo, I., Polanco, J.A. Polymeric and cementitious mortars for the reconstruction of natural stone structures exposed to marine environments. Composites Part B: Engineering. 2010; 41(8): 663-672. https://doi.org/10.1016/j.compositesb.2010.08.007

- Berndt, M.L. Evaluation of coatings, mortars and mix design for protection of concrete against sulphur oxidizing bacteria. Construction and Building Materials. 2011; 25(10):3893-3902. https://doi.org/10.1016/j.conbuildmat.2011.04.014

- Valix, M., Zamri, D., Mineyama, H. Microbiologically induced corrosion of concrete and protective coatings in gravity sewers. Chinese Journal of Chemical Engineering. 2012; 20 (3):433-438. https://doi.org/10.1016/S1004-9541(11)60150-X

- Vipulanandan, C., Parihar, A., Issac, M. Testing and Modeling Composite Coatings with Silanes for Protecting Reinforced Concrete in Saltwater Environment. Journal of Materials in Civil Engineering. 2011; 23(12): 1602-1608. https://doi.org/10.1061/ (ASCE)MT.1943-5533.0000330

- Hua, W., Jiang, H., Zhou, Z. Resistance to nitric acid corrosion of latex modified sulphoaluminate cement mortar. Advanced Materials Research, 2012; 382: 404-407. https://doi.org/10.4028/www.scientific.net/AMR.382.404

- Bertron, A., Duchesne, J. Attack of cementitious materials by organic acids in agricultural and agrofood effluents.RILEM State-of-theArt Reports. 2013; 10: 131-173. https://doi.org/10.1007/978-94-007-5413-3_6

- Vipulanandan, C, Liu, J. Polymer Coatings for Concrete Surfaces: Testing and Modeling. Handbook of Environmental Degradation of Materials: Second Edition. September 24. 2012; 12: 621-653. https://doi.org/10.1016/B978-1-4377-3455-3.00021-3

- Nazemi, M.K., Valix, M. Evaluation of acid diffusion behaviour of amine-cured epoxy coatings by accelerated permeation testing method and prediction of their service life. Progress in Organic Coatings. 2016; 97: 307-312. https://doi.org/10.1016/j.porgcoat.2016.04.025

- Roghanian, N., Banthia, N. Development of a sustainable coating and repair material to prevent bio-corrosion in concrete sewer and waste-water pipes. Cement and Concrete Composites. 2019; 100: 99-107. https://doi.org/10.1016/j.cemconcomp.2019.03.026

- Herisson, J., Guéguen-Minerbe, M., van Hullebusch, E.D. Influence of the binder on the behaviour of mortars exposed to H2S in sewer networks: a long-term durability study. Materials and Structures/Materiaux et Constructions. 2017; 50(1): 8. https://doi.org/10.1617/s11527-016-0919-0

- Vipulanandan, C., Liu, J. Polymer Coatings for Concrete Surfaces: Testing and Modeling. Handbook of Environmental Degradation of Materials: Second Edition. 2012: 621-653. https://doi.org/10.1016/B978-1-4377-3455-3.00021-3

- Nazemi, M.K.,Valix, M. Evaluation of acid diffusion behavior of amine-cured epoxy coatings by accelerated permeation testing method and prediction of their service life. Progress in Organic Coatings. 1 August 2016; (97): 307-312. https://doi.org/10.1016/j.porgcoat.2016.04.025

- Benosman, A.S., Mouli, M., Taibi, H. Resistance of polymer (PET)-mortar composites to aggressive solutions. International Journal of Engineering Research in Africa. 2011; 5: 1-15. https://doi.org/10.4028/www.scientific.net/JERA.5.1

- Valix, M., Mineyama, H., Chen, C. Effect of film thickness and filler properties on sulphuric acid permeation in various commercially available epoxy mortar coatings. Water Science and Technology. 2011; 64 (9): 1864-1869. https://doi.org/10.2166/wst.2011.743

- Gutarowska, B., Kotynia, R., Bieliński, D. New sulfur organic polymer-concrete composites containing waste materials: Mechanical characteristics and resistance to biocorrosion. Materials, 2019; 12 (16): 2602. https://doi.org/10.3390/ma12162602

- Pereyra, A.M., Gonzalez, M.R., Rodrigues,T.A. Enhancement of biocorrosion resistance of epoxy coating by addition of Ag/Zn exchanged a zeolite. Surface and Coatings Technology. 270, 25 May 2015; 284-289. https://doi.org/10.1016/j.surfcoat.2015.02.044

- Amin, M., Bassuoni, M.T. Response of concrete with blended binders and nanoparticles to sulfuric acid attack. Magazine of Concrete Research. 2018; 70(12): 617-632. https://doi.org/10.1680/jmacr.17.0008

- Achchige, R.S., Vitanage, D., Bustamante, H. The effect of moisture on bonding behaviour of epoxy on concrete. Proceedings of the 4th Asia-Pacific Conference on FRP in Structures, APFIS; 2013.

- Sokolova Yu.A. Modified epoxy adhesives and coatings in construction / Yu.A. Sokolova, E.M. Gottlieb. M.: Stroyizdat; 1990.

- D. Dutta, S. Ghosh. Comparative study on the performance of blended and nonblended fly ash geopolymer composites as durable construction materials. Adv. Civ. Eng. 2018; 1-12. https://doi.org/10.1155/2018/2940169

- M. Muthukumar, D. Mohan/ Studies on polymer concretes based on optimized aggregate mix proportion. Eur. Polym. J. 2004; 40: 2167-2177. https://doi.org/10.1016/j.eurpolymj.2004.05.004

- H. Xie, B. Liu, Q. Sun, Z. Yuan, J. Shen, R. Cheng. Cure kinetic study of carbon nanofibers/epoxy composites by isothermal DSC. J. Appl. Polym. Sci. 2005; 96 (2): 329-335.

- M.R. Taha, U.F. Kandil, E. Soliman, Generation of polymer concretes incorporating carbon nanotubes. US8426501B1, 2011. https://patentimages.storage.googleapis.com/1f/fa/46/d81db94052624e/US8426501.pdf (accessed August 30, 2021).

- X.-L. Xie, Y.-W. Mai, X.-P. Zhou. Dispersion and alignment of carbon nanotubes in polymer matrix: A review. Mater. Sci. Eng.: R: Rep. 2005; 49: 89-112. https://doi.org/10.1016/j.mser.2005.04.002

- Yerofeev V.T., Afonin V.V., Yerofeeva I.V., Maksimova I.N., Al Dulaimi Salman Daoud Salman, Al Kadhimii Zinah Ali Hassan Any Regression. Application No. 2021614937 dated 04/09/2021. Certificate of state registration of the computer program No. 2021615823. Publication date and bulletin number: 04/13/2021: 4.

- Erofeev V.T., Ivlev V.I., Sigachyov A.F., Fomin N.E., Yudin V.A., Blohin A.N., Yel’chishcheva T.F., Suhorukov A.K., Tkachev A.G. Mechanical properties of epoxy resin with additives soot and nanotubes. Materials Physics and Mechanics. 2021; 47(1): 20-30.

- Q. Wang, J. Zhang, Z. Zhang, Y. Hao, K. Bi. Enhanced dielectric properties and energy storage density of PVDF nanocomposites by co-loading of BaTiO3 and CoFe2O4 nanoparticles. Adv. Compos. Hybrid Mater. 2020; 3 (1): 58-65. https://doi.org/10.1007/s42114-020-00138-4

- Kong L., Fang J., Zhou X. Assessment of coatings for protection of cement paste against microbial induced deterioration through image analysis. Construction and Building Materials, 2018; 91: 342-353. https://doi.org/10.1016/j.conbuildmat.2018.10.04

- Berndt M.L. Evaluation of coatings, mortars and mix designfor protection of concrete against sulphur oxidizing bacteria. Construction and Buijding Materials. October. 2011; 25(10): 3893-3902. https://doi.org/10.1016/j.conbuildmat.2011.04.014

- Valix M., Zamri D., Mineyama H., Cheung W.H., Shi J., Bustamante H. Microbiologically induced corrosion of concrete and protective coatings in gravity sewers. Chinese Journal of Chemical Engineering. June. 2012; 20 (3): 433-438. https://doi.org/10.1016/S1004-9541(11)60150-X

- Pereyra A.M., Gonzalez M.R., Rodrigues T.A. Enhancement of biocorrosion resistance of epoxy coating by addition of Ag/Zn exchanged a zeolite. Surface and Coatings Technology. May. 2015; 270 (25):284-289. https://doi.org/10.1016/j.surfcoat.2015.02.044

- Ribeiro C.C., Da Silva Pinto J.D., Godoy G.C. Microstructural and topographic characterization of concrete protected by acrylic paint. Materials Research, 2013; 16(4): 817-823. https://doi.org/10.1590/S1516-14392013005000042

- Tokach Y.E., Rubanov Y.K., Vasilenko M.I. Design of new approaches and technological solutions of obtaining biocidal compositions to protect industrial and civil buildings and constructions against biodeterioration. Research Journal of Applied Sciences, 2014; 9(11): 774-778. https://doi.org/10.3923/rjasci.2014.774.778

- Pazoki M., Abdoli M.A., Ghasemzade R. Comparative evaluation of poly urethane and poly vinyl chloride in lining concrete sewer pipes for preventing biological corrosion. International Journal of Environmental Research, 2016; 10(2): 305-312.