Evaluating the Feasibility of a Photovoltaic-Fuel Cell Hybrid Energy System for the Ice Cream Factory in Fukuoka City, Japan: An Economic and Technical Analysis

Автор: Md. Ahsan Habib, Sumon Kumar Debnath, Md. Shahin Parvej, Jannatun Ferdous, Md. Ali Asgar, Md. Ahasan Habib, Md. Asaduzzaman Jemy

Журнал: International Journal of Education and Management Engineering @ijeme

Статья в выпуске: 4 vol.14, 2024 года.

Бесплатный доступ

This paper is dedicated to a comprehensive analysis of hybrid energy options, with a specific focus on exploring their economic and environmental advantages within the context of an ice cream factory located in Fukuoka, Japan. The study takes a holistic approach, delving into various facets such as power generation, energy expenses, and related factors to uncover the potential benefits associated with specific configurations of hybrid energy solutions. The analysis presented in this study serves as a valuable tool for assessing the impact of different power generation technologies and energy management strategies. It sheds light on how these choices can influence not only the factory's operational costs but also its environmental footprint. By quantifying these effects, the study provides critical insights that can guide decision-makers toward more sustainable and economically sound energy solutions. As a forward-looking application approach, this research envisions the utilization of a PV-wind-diesel-grid-electrolyzer power system. This hybrid configuration serves as a versatile platform for conducting simulation studies, allowing for the exploration of a wide spectrum of potentially viable solutions. The insights derived from these simulations not only facilitate informed decision-making but also pave the way for anticipating and strategically planning future energy implementations. In essence, this study represents a proactive and data-driven approach to energy optimization, offering the ice cream factory in Fukuoka a roadmap to harnessing the benefits of hybrid energy systems, ultimately contributing to both economic efficiency and environmental sustainability. So, at a cost of energy (COE) of 18.313¥ per kWh, this arrangement stands out as an economically advantageous and environmentally friendly solution for the electrification of the ice cream factory.

Solar energy, Wind energy, Hybrid energy, Economic analysis, Fukuoka

Короткий адрес: https://sciup.org/15019319

IDR: 15019319 | DOI: 10.5815/ijeme.2024.04.03

Текст научной статьи Evaluating the Feasibility of a Photovoltaic-Fuel Cell Hybrid Energy System for the Ice Cream Factory in Fukuoka City, Japan: An Economic and Technical Analysis

Going through the proverb-"Necessity is the mother of invention" which reflects how the increasing energy demand has driven the search for alternative, sustainable energy sources like renewables. The rapid increase in energy demand over recent decades has been primarily driven by factors such as urbanization, the integration of new technologies into our daily lives, and the growing consumption of various forms of energy. Currently, nuclear energy and fossil fuels, including coal, oil, and natural gas, stand as the dominant sources for generating electricity on a global scale. The price spike triggered by the conflict in Ukraine and the subsequent sanctions against Russia has exposed the inherent unreliability of fossil fuels [1]. The widespread use of fossil fuels across multiple sectors, ranging from manufacturing to transportation, has had far-reaching and serious adverse effects on many nations, with a particularly pronounced impact on developing nations [2]. The cost of living and the global inflation rate have experienced substantial and simultaneous increases on a global scale. This phenomenon reflects the challenges that individuals and economies face as prices for essential goods and services surge, impacting everything from household budgets to macroeconomic stability. However, the reliance on these conventional energy sources has led to various forms of environmental pollution, including air and water pollution, as well as contributing to climate change through greenhouse gas emissions. Recognizing the environmental challenges posed by these conventional sources, there is a growing consensus that renewable energy sources hold the key to a sustainable and environmentally friendly energy future. Renewable energy resources, such as solar, wind, hydro, and geothermal power, are not only considered environmentally friendly but also abundant and sustainable. Their contribution to the world's energy mix has steadily increased and currently stands at approximately 13.5% [3], showcasing their growing significance. Hybrid Renewable Energy Systems (HRES) have emerged as a solution to enhance the reliability and efficiency of renewable energy sources. These systems, which combine different energy sources, can operate in both off-grid (standalone) and grid-connected modes, providing flexibility in meeting energy demands [4]. The effectiveness of HRES depends on various factors, including their reliability [5], ability to reduce emissions, economic viability, overall efficiency [6], and so forth [7-8]. Despite the global push for renewable energy sources and sustainable practices, many countries continue to heavily rely on fossil fuels to meet their electrical energy needs.

The current state-of-the-art in electricity generation has recognized the strategic establishment of a community microgrid as an effective means to cultivate a positive energy community [9]. However, this approach also exposes significant weaknesses, particularly in addressing the challenges of intermittent energy sources. To mitigate these weaknesses and ensure a constant and reliable electricity supply, there is a recognized imperative for adopting a hybrid energy system [10]. This integrated approach, encompassing photovoltaic [11], wind, and hydropower, aims to overcome the intermittent nature of solar and wind energy, but it still faces challenges. In addressing the weaknesses of the hybrid energy system, the Hybrid Optimization of Multiple Energy Resources (HOMER) modeling tool has emerged as a preeminent choice, supported by a robust body of research [12-17]. Yet, despite its widespread adoption and effectiveness, certain weaknesses persist in fully addressing the complexities of hybrid systems. Therefore, proposed strategies are essential to cure these weaknesses and further enhance the reliability and efficiency of hybrid renewable energy systems. The collaborative potential of hybrid renewable energy systems in electricity production has been substantiated across diverse settings, offering promising solutions. So, notable research persists, particularly in Bangladesh areas [18], and in Japan [19-20]. These research works are not limited confined space like our research such as ice-cream factory. Our focused endeavours, which may be confined by spatial constraints or specific parameters, these broader research domains explore a more expansive landscape, allowing for a comprehensive examination of the subject matter from various perspectives and dimensions.

Previous studies have demonstrated that the optimization of a hybrid renewable energy system is a multifaceted challenge. Its complexity arises from its inherent site-specific nature, heavily reliant on factors such as geographical location, economic considerations, environmental parameters, the unique load demand of the system, and the availability of renewable energy resources. In essence, each location presents a distinct set of variables and constraints that must be carefully considered when designing and optimizing a hybrid renewable energy system. These variables encompass the local climate, renewable energy potential, financial resources, and the specific energy demands of the area. Consequently, the optimization process becomes a highly nuanced task, tailored to address the precise conditions and requirements of each individual site. Hence, this paper takes a significant step forward by focusing on the unique case of an ice-cream factory in Fukuoka, Japan. This innovative application showcases the versatility of HRES in addressing energy needs across diverse industries. Furthermore, the paper delves into the various sizing methods tailored specifically for HRES systems. These methods play a pivotal role in achieving the right balance between capital investment and system reliability, a critical consideration for any renewable energy implementation. Moreover, the paper doesn't stop at sizing alone; it also explores optimization techniques designed to compare the cost of energy across different HRES system configurations. So, this paper not only reviews the applications of HRES in diverse global settings but also narrows its focus to an intriguing case on an ice-cream factory in Fukuoka, Japan. It highlights the importance of sizing methods for HRES systems, showcasing their role in optimizing capital investment and ensuring reliability. Additionally, the paper explores optimization techniques that contribute to a deeper understanding of the cost-effectiveness of different HRES configurations through simulation analysis. So, this paper is used to perform a comprehensive techno-economic analysis of a hybrid energy system designed to address the prevailing electricity challenges. This analysis will delve into both the technical feasibility and the economic viability of the proposed hybrid system, shedding light on its potential to provide reliable and sustainable solutions to the electricity challenges.

The paper is categorised into the following sections; section 2 indicates the material and methods, section 3 shows the results and discussion and section 4 represents the conclusion.

2. Material and Methods

This section serves as a crucial reference for researchers who want to understand how a study was conducted and potentially build upon or validate its findings.

-

2.1 Study area

The region, in which the system was presumed for the economical optimization would be performed, that was chosen as the ice-cream factory, Fukuoka, Kyushu island, Japan. Fukuoka prefecture is the southern part of Japan which is located at 33.5902°N and 130.4017°E [21].

-

2.2 HOMER/ Simulation Configuration

The HOMER software framework comprises three integral components: simulation, optimization, and sensitivity analysis, collectively employed to meticulously calculate the energy balance throughout each season of the year. Through the simulation component, HOMER replicates the behavior of various energy configurations, providing a dynamic model of energy production and consumption. After balancing calculations for each configuration by HOMER, feasible solutions over lifetime span are determined. HOMER is the optimization model which is developed by the National Renewable Energy Laboratory (NREL), U.S.A. [22]. It can be utilized for a variety of application as for grid-connected and off-grid power system. It receives inputs to simulate the different system configurations, or combinations of different components, and as a result that can be presumed as a list of feasible configurations. The simulation results are expressed as different tables and graphs for comparing configurations [23]and evaluating them based on economic[24] and technical supports [25].The Renewable deployment projects with long operational life have the economic analysis that is related to assessment of the feasibility with different configuration such as the net present value (NPV); it makes compare initial investment with present value of all the future cash flows, the payback period (PP); it shows number of the years which are needed to recover initial investment from the future cash flow, and the internal rate of return (IRR); it provides the overall rate of saving from initial investment. Furthermore, the additional factor as levelized cost of energy (LCOE) is often calculated regarding the energy system. Following the relation for calculation of NPC is as-

NP^i + ^^y)^]

I is the initial investment, n is the life span of project, Cy is yearly cost (including O(Operation) & M(Maintenance) and replacement), d is the discount rate. The levelized cost of energy is expressed as-

COE =

NPC

^^)[^]

Ey is yearly served electricity.

-

2.3 Configuration of the proposed system

-

2.3.1 PV array

-

2.3.2 Wind turbine

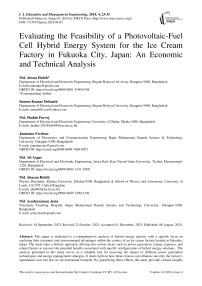

The proposed configuration system is displayed in Fig. 1 in which PV source, wind turbine, diesel generator, electrolyzer, hydrogen tank, fuel cell, converter, and loads are available. The detailed specifications of them is depicted here.

The PV array forms a critical component of the energy system, constituting the interconnection of individual PV modules. These modules work in unison to harness solar energy and convert it into direct current (DC), establishing a fundamental power source within the overall system. The detailed technical description of PV system is shown in Table 1. The HOMER software evaluates the power of PV array by using following equation-

P pv = f pv' P pVT ' (3)

Where, fpv is PV derating factor, Ypv represents the rated capacity of PV array (KW), IT introduces global solar radiation (beam plus diffuse) incident on surface of PV array (KW/m 2 ), and Is is standard radiation rate (KW/ m2 ).Different size of PV panels [ 0 , 1, 100, 150, 200, 250, 300, 350, 400, 450, 500, and 550 KW] are included for the optimization . Here only day time is considered due to the day-time working in the ice-cream factory, Fukuoka, Japan. Consequently, battery is not required for this system.

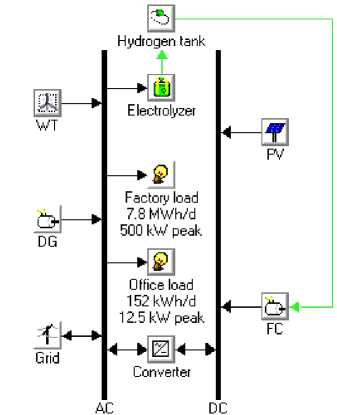

The wind turbine plays a pivotal role within the system, serving as a vital means to harness the mechanical energy derived from the force of the wind and efficiently convert it into electricity. This specific wind turbine is seamlessly integrated into the system, connecting directly with the AC bus. Its design features a robust 20-year operational lifespan, ensuring long-term reliability and energy production. Additionally, the turbine boasts a hub height of 25 meters above ground level, strategically positioned to capture optimal wind speeds for efficient electricity generation. In terms of cost-effectiveness, the capital investment required for this wind turbine is approximately 2,50,723¥. Remarkably, the operation and maintenance costs associated with this turbine are negligible, further enhancing its economic appeal as a sustainable and dependable energy source. After that wind power is optimized by HOMER which is displayed in Fig.2.

Fig.1. Configuration of the proposed hybrid system at Fukuoka, Japan.

Table 1. Technical details of the PV system [6]

|

Parameter |

Value |

Parameter |

Value |

|

Rated power capacity |

1 |

Temperature coefficient of power [% /0C] |

- 0.258 |

|

PV derating factor |

0.9 |

PV cell temperature under standard test conditions [250C] |

25 |

|

Maximum efficiency |

0.217 |

Nominal operating cell temperature |

44 |

|

Incident radiation at standard test conditions [ KW/m 2] |

1 |

Nominal ambient temperature [0C] |

20 |

Fig.2. Power output from wind speed.

-

2.3.3 Diesel Generator

To ensure a consistent and uninterrupted power supply, a 20 KW diesel generator has been integrated into this energy scheme. This generator serves as a dependable and traditional fossil fuel source, effectively meeting the system's load demand.The specifications of the diesel generator include an annual fuel consumption of 5000 liters per year, with a presumed operational lifetime of 15,000 operating hours. Additionally, it is important to note that the average price of diesel fuel over the years from 2017 to 2022 stands at approximately ¥134.9 per liter, as indicated in reference [26]. By incorporating this diesel generator, the system gains an essential backup power source, contributing to its reliability and resilience in the face of variable energy production from renewable sources. This ensures that power can be continuously supplied, even during periods of low renewable energy generation or unexpected disruptions in the primary energy sources.

-

2.3.4 Fuel cell

-

2.3.5 Converter

-

2.3.6 Loads

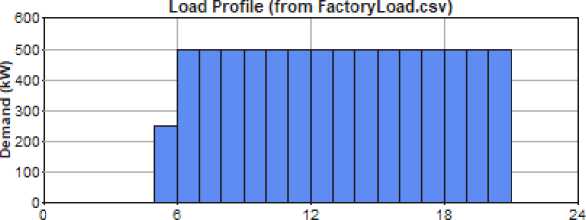

Fig.4 provides a valuable insight into the duration of average loads for the ice cream factory located in Fukuoka, Japan, spanning the years from 2017 to 2022. Notably, the graph illustrates the distinct load patterns experienced by the factory during this time frame, shedding light on the energy consumption dynamics that are crucial for system design and optimization. One noteworthy observation is that the factory operates during daytime hours, indicating that its energy demand aligns with the availability of solar power from the PV system. As a result, the need for energy storage in the form of batteries is rendered unnecessary, further simplifying the system configuration and emphasizing the compatibility of the energy supply with the factory's working hours. This data-driven approach to understanding load profiles is pivotal for designing an energy system that can efficiently meet the factory's electricity needs while minimizing costs and environmental impact. It ensures that the energy solution is precisely tailored to the factory's operational schedule and reinforces the practicality of utilizing renewable energy sources like solar power in a seamless manner.

The fuel cell plays a pivotal role within the energy system, acting as a transformative element that converts chemical energy, in the form of hydrogen, into electricity. In this setup, the generator is supplied with stored hydrogen, which serves as a reliable and efficient means of energy storage. For the installation and replacement of the fuel cell system, the costs have been thoughtfully selected, amounting to 400,000¥ for a 1KW system. This investment accounts for the initial setup and any potential future replacements, ensuring the sustained operation of the fuel cell system. Additionally, the choice of a DC system connection further optimizes the efficiency of the energy conversion process, aligning with the overall design philosophy of the energy scheme. One notable advantage of incorporating fuel cells into the system is the remarkably low operation and maintenance cost, making it a financially appealing choice. Moreover, the flexibility of the system design allows for variations in the size of fuel cells, ranging from 0 to 600 KW, accommodating the specific energy demands and scalability requirements of the model. In essence, the fuel cell technology within this setup represents a reliable, efficient, and cost-effective means of generating electricity while offering versatility in system size and negligible maintenance expenses, further enhancing the overall energy scheme's sustainability and economic viability.

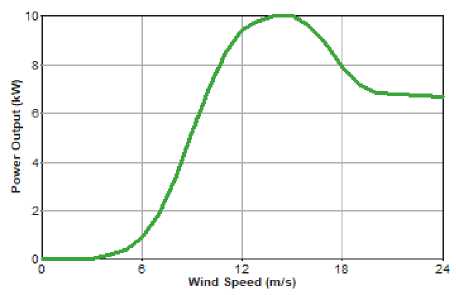

The converter, encompassing both a rectifier and an inverter, assumes a pivotal and multifaceted role within the energy system. Its functionality dynamically adapts to the operational state of the photovoltaic (PV) system. When the PV system is actively generating power, the rectifier takes centre stage, efficiently converting AC energy to DC. This DC power is then utilized to charge the batteries, maximizing power delivery and energy storage. Additionally, a solar converter or inverter, often referred to as a PV inverter, serves as a crucial component in the system. Its primary function is to convert DC energy generated by the PV system into AC, making it suitable for feeding into a commercial grid or for local consumption within an off-grid electrical network. The associated costs for the converter, including installation and potential replacements, have been thoughtfully set at 400,000 ¥ per kilowatt (kW), ensuring the unit's reliability throughout its assumed 25-years lifetime. Furthermore, the converter boasts an impressive 90% efficiency rating, emphasizing its role in optimizing energy conversion within the system. The versatility of the proposed inverter is a notable feature, with its power capacity ranging from 0 to 700 kW, as visually depicted in Fig.3. This flexibility allows for the adaptation of the inverter's size to meet the specific power demands of the system, underscoring its importance in maintaining overall system efficiency and performance. So, the converter, with its rectifier and inverter components, is a cornerstone of the energy system, dynamically managing energy conversion as per operational needs. Its efficiency, longevity, and adaptability make it an integral part of the scheme, contributing to optimal energy utilization and grid compatibility.

Fig.3. Converter cost curve

Hour

Fig.4. Average factory loads in ice-cream factory, Fukuoka, Japan, 2017-2022.

-

2.3.7 Electrolyzer

The electrolyzer assumes a crucial role within the energy system, serving as the means to convert electricity into hydrogen through the process of electrolysis. In this electrochemical process, electrical energy is employed to split water molecules into hydrogen and oxygen gases, with hydrogen being a valuable energy carrier. For the optimization of the electrolyzer's capacity, a search space ranging from 0 to 3500 KW; has been defined and fed into the HOMER software. This search space allows HOMER to explore various electrolyzer sizes and configurations, seeking the optimal selection that aligns with the system's specific requirements and objectives. The selected parameters for the electrolyzer include a presumed operational lifetime of 10 years, ensuring a sustained and cost-effective hydrogen production process. Moreover, the electrolyzer operates with a commendable efficiency of 85%, maximizing the conversion of electrical energy into hydrogen gas. This dynamic approach to electrolyzer sizing underscores the importance of tailoring the system to efficiently produce hydrogen, which can be utilized for various energy applications, including fuel cells or energy storage, contributing to the overall sustainability and resilience of the energy scheme.

-

2.3.8 Hydrogen Tank

The hydrogen tank assumes a pivotal role within the energy system, functioning as a storage facility for the hydrogen produced. To optimize the storage capacity, a search space ranging from 0 to 3500 kg has been defined, allowing for a diverse range of hydrogen tank sizes to be considered. Each hydrogen tank within this range boasts an impressive operational lifespan of 20 years, ensuring the long-term viability of hydrogen storage as a key component of the system. These tanks are designed to safely store hydrogen for extended periods, making them integral to the overall energy scheme. The cost considerations for these hydrogen tanks are characterized by a capital cost of 150,000 yen per kilogram (kg) of storage capacity. Additionally, the operation and maintenance costs associated with these tanks are

-

2.3.9 Resource assessment

-

2.3.9.1 Solar resource

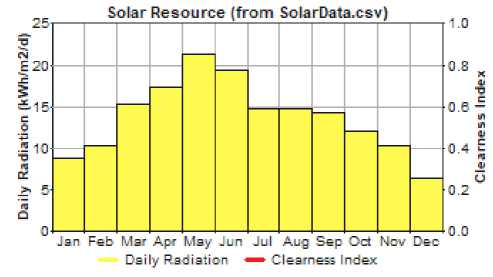

Fig. 5 provides a comprehensive overview of the average solar irradiation levels experienced in the Fukuoka prefecture, Japan, spanning the years from 2017 to 2022 [27]. This data is instrumental in understanding the region's solar energy potential and forms a critical component of the energy system design. Remarkably, the calculated scaled annual average radiation stands at an impressive 13.8 kWh/m2/day. This figure signifies the amount of solar energy that can be harnessed on a daily basis, serving as a pivotal metric for estimating the solar power generation capacity in the region. This solar irradiation data underscores the feasibility and viability of utilizing solar power as a significant energy source within the system. It reaffirms that the region's solar energy potential can be effectively leveraged to meet energy demands, promoting sustainability and reducing reliance on conventional energy sources. In essence, the solar irradiation data represented in Fig.5 forms a foundational element in the system's resource assessment, highlighting the substantial solar power generation capacity available in the Fukuoka prefecture and validating its inclusion in the energy scheme.

-

2.3.9.2 Wind resource

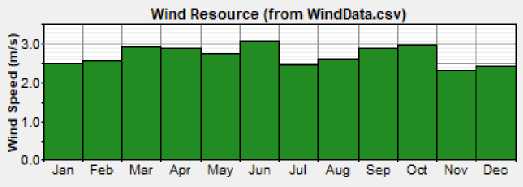

Fig.6 presents a comprehensive dataset detailing the average wind speed in the Fukuoka prefecture, Japan, spanning the years 2017 to 2022 [27]. This wind speed data is a crucial component of the system's resource assessment, offering valuable insights into the region's wind energy potential. Remarkably, the calculated scaled annual average wind speed stands at 2.71 kWh/m2/day. This metric signifies the amount of wind energy available per square meter each day, underlining the region's potential for harnessing wind power as a renewable energy source. The inclusion of wind energy in the resource assessment further diversifies the energy mix, enhancing the system's overall resilience and sustainability. It validates the feasibility of incorporating wind power into the energy scheme, complementing the solar energy resources and contributing to a balanced and reliable energy supply. So, the wind speed data showcased in Fig. 6 is instrumental in understanding the Fukuoka prefecture's wind energy potential, and the calculated annual wind energy levels reinforce the viability of wind power as a valuable addition to the region's energy landscape.

-

2.3.9.3 Economic and constraints

notably negligible, enhancing their economic attractiveness as a means of storing surplus hydrogen generated by the electrolyzer. So, the hydrogen tanks play a pivotal role in enabling efficient energy storage, offering a wide range of storage capacities to accommodate varying production levels. Their extended operational lifespan, coupled with reasonable capital costs and minimal maintenance expenses, further solidify their importance within the energy system.

The HOMER model serves as the cornerstone of this study, enabling the exploration of various combinations of energy resources, including solar, wind, and existing power lines. Its primary objective is to discern the most suitable and feasible solution for the system's configuration, aligning with the specific requirements and goals of the project. The resource assessment process, facilitated by the HOMER model, represents a systematic approach to designing and optimizing the energy system. It involves a meticulous evaluation of the available resources, taking into account factors such as solar irradiance, wind speeds, and the reliability of existing power infrastructure. This comprehensive assessment allows for the identification of the most promising energy resource combinations, offering a clear roadmap for the optimal configuration of the system. It serves as a valuable tool for decision-makers and engineers, ensuring that the chosen energy mix is both economically viable and capable of meeting the energy demands while adhering to sustainability and environmental objectives.

Fig.5. The average solar radiation data for fukuoka, Japan, 2017-2022. [27]

Fig.6. The average wind speed data for fukuoka, Japan, 2017-2022. [27]

The study adopts a project lifetime assumption of 20 years, reflecting a long-term perspective on the energy system's sustainability and economic feasibility. Furthermore, a conservative annual interest rate of 3% has been factored into the financial analysis, accounting for the time value of money and investment considerations. Importantly, there are no maximum annual capacity shortages imposed on the system, allowing for flexibility in accommodating varying energy production levels from renewable sources. In the context of renewable energy output, prudent operating reserves of 80% and 40% have been allocated for solar and wind energy, respectively. These reserves are essential for ensuring grid stability and reliability, especially in the face of intermittent energy generation patterns associated with renewables. It's worth noting that this study does not take into account any cost subsidies, emphasizing a realistic and self-sustainable economic model for the energy system. All these key parameters and considerations are meticulously detailed in Table 2, providing a transparent and comprehensive foundation for the techno-economic analysis and optimization of the proposed energy configurations.

Table 2. Economic data for equipment for the optimization of system

|

Equipment with capacity unit[KW] |

Lifetime (years) |

Initial cost(yen) |

Operations & Maintenance (Yen/year) |

Reference |

|

PV |

20 |

230000 |

11500 |

[6] |

|

WT |

20 |

250723 |

7740 |

[7,24] |

|

DG |

15000 hours |

32703 |

55/(hr) |

[6] |

|

H 2 Tank |

20 |

150000 |

9000 |

[6] |

|

Electrolyzer |

10 |

170000 |

3000 |

[6] |

|

Fuel cell |

10 |

400000 |

4000 |

[6] |

|

Inverter |

25 |

4228 |

1051 |

[8] |

|

Parameter |

Value |

|||

|

Discount rate [%] |

0.30 |

|||

|

Expected Inflation rate [ %] |

0.98 |

|||

3. Results and Discussion

The simulation work presented in this study goes beyond merely identifying the best solution; instead, it provides a comprehensive sensitivity and optimization analysis. This approach aims to shed light on how different factors impact the design outcomes of the proposed system. The simulation results, which are detailed in Table 3, play a pivotal role in supporting the optimization cases. They offer valuable insights into the various parameters' effects on the system's performance. It's important to note that when analyzing the proposed system based on these results, the discount rate becomes a critical factor. An increased discount rate suggests greater uncertainty in future cash flows, which can influence decision-making regarding the system's design. Conversely, a higher photovoltaic (PV) capacity can enhance the reliability of power supply while reducing uncertainty, particularly when the discount rate is lower. In cases where cost constraints necessitate a decrease in the installed PV capacity, this adjustment becomes feasible but should be carefully considered in light of the higher discount rate. This study's simulation work not only highlights the best solution but also provides a nuanced understanding of how various factors influence the system's design. The discount rate and PV capacity emerge as crucial considerations, with their interplay impacting the system's reliability and costeffectiveness.

In the evaluation of different power system combinations using HOMER, our primary focus is on assessing their economic and operational characteristics. These combinations encompass a range of technologies, each contributing to the overall performance. From Table 3, one of the hybrid options; PV-wind-diesel-grid-electrolyzer combination is considered, which offers a versatile energy solution by integrating both conventional and non-conventional energy resources. Within this hybrid power system, the calculated cost of energy (COE) per kWh is 18.313¥, demonstrating its competitive edge in terms of affordability and efficiency. This configuration leverages the combined strengths of photovoltaic (PV) and wind energy, augmented by the reliability of a diesel generator and grid connection. Moreover, the inclusion of an electrolyzer plays a pivotal role in energy storage and conversion, further enhancing the system's adaptability. In contrast, the wind-grid-diesel generator-fuel cell-electrolyzer-inverter hybrid option closely trails with a

COE of 18.312¥ per kWh. This configuration showcases the versatility of wind power while maintaining grid connectivity and backup support from a diesel generator. The addition of a fuel cell and electrolyzer underscores the system's potential to harness clean energy sources and efficiently manage power fluctuations. Furthermore, the PV-grid-diesel generator-fuel cell-electrolyzer-inverter hybrid option records a COE of 18.637¥ per kWh, offering a viable alternative for regions where solar energy takes precedence. This configuration capitalizes on solar power generation while maintaining grid and backup support, demonstrating its adaptability to different environmental conditions. The Grid-diesel generator-fuel cell-electrolyzer-inverter hybrid option, with a COE of 18.633¥ per kWh, emphasizes the importance of a stable grid connection alongside backup power sources. The integration of a fuel cell and electrolyzer showcases its potential to bridge the gap between conventional and renewable energy. In contrast, the PV-grid-fuel cellelectrolyzer-inverter hybrid option, with a COE of 21.270¥ per kWh, and the wind-grid-fuel cell-electrolyzer-inverter hybrid option, with a COE of 21.182¥ per kWh, demonstrate higher costs per kWh, reflecting the challenges associated with relying solely on specific energy sources without the robust support of a diesel generator or grid connection. The "Wind-Grid-Diesel Generator Hybrid Option" boasts the lowest COE at 3.386¥ per kWh. This result highlights its costeffectiveness and potential suitability for scenarios where minimizing energy expenses is a paramount concern. Furthermore, the "PV-Grid-Diesel Generator-Inverter Hybrid Option" and the "PV-Wind-Grid-Diesel GeneratorInverter Hybrid Option" achieve COE values of 4.067¥ and 4.07¥ per kWh, respectively. These configurations offer a balanced approach by combining wind and grid power with additional features like diesel generators and inverters, contributing to their competitiveness in terms of cost-effectiveness. Among the different options:(i) the "Wind-Grid-Diesel Generator Hybrid" option has the lowest COE at 3.386¥ per kWh, making it an economically attractive choice and (ii) if environmental sustainability is a priority, configurations with higher proportions of renewable energy sources like PV and wind, such as the "PV-Wind-Grid-Diesel Generator-Inverter Hybrid" and "Wind-Grid-Diesel GeneratorInverter Hybrid" options, might be more appealing due to their reduced greenhouse gas emissions. Consider the availability of energy resources at the project location. For instance, if your site has ample sunlight, the "PV" options may be more favorable, while areas with consistent wind may benefit from "Wind" options.

-

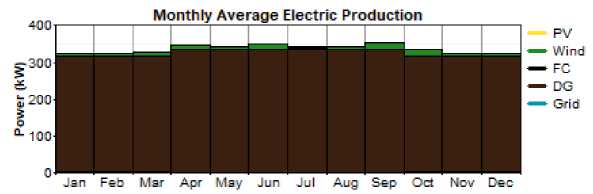

3.1 PV – wind – diesel - grid - electrolyzer power option

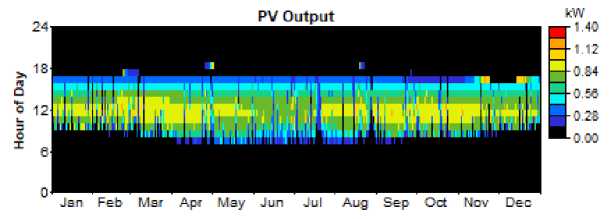

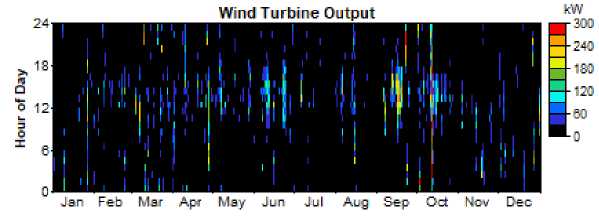

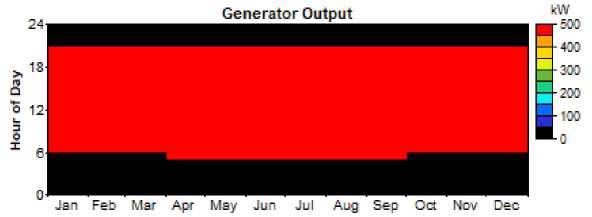

The hybrid power system combining PV, wind, diesel, grid, and an electrolyzer is undoubtedly a standout choice when evaluating various hybrid configurations. What sets it apart is its unique ability to seamlessly integrate both renewable and non-renewable energy sources, making it an incredibly versatile and reliable energy solution. The results obtained from this hybrid system provide valuable insights, especially when examining the monthly average electric production, as showcased in Fig.7. Notably, September emerges as the month with the highest electric production, underscoring the system's remarkable adaptability to varying environmental conditions. Delving further into the system's performance, Fig.8 vividly illustrates the state of PV output. It's evident that whenever solar power is available, the PV system operates efficiently. This results in an impressive estimation of the PV operation at 4,081 hours per year, highlighting its consistent contribution to the overall energy production. Equally significant is the role played by the wind turbine, as depicted in Fig.9. The graph showcases the wind turbine's pivotal role in the hybrid system, with a maximum output of 300 kW and an operational duration of 3,645 hours per year. This consistent performance underscores the system's reliance on wind energy, particularly during periods of wind availability. Turning our attention to the diesel generator (DG), Fig. 10 provides a detailed breakdown of various cost indices and operational characteristics. Notably, the DG exhibits an operational lifetime of 5,658 hours per year, a testament to its crucial role in providing backup power when renewable sources may be limited. Moreover, the DG boasts a maximum electrical output of 500 kW, further enhancing the system's resilience and reliability. The PV-wind-diesel-grid-electrolyzer hybrid power system stands as a remarkable energy solution, seamlessly blending renewable and non-renewable options.

Table 3. Cost of energy (COE) of different options

|

S.I |

PV (K W) |

Wind Turbin e (WT) |

Grid (KW) |

DG (KW) |

FC (KW) |

Electr olyzer |

Converte r(Inverte r) |

Initial cost(¥) |

Total NPC(¥) |

COE(¥/ KWh) |

Renewa ble Fraction |

|

1 |

1 |

30 |

1000 |

500 |

10 |

2000 |

100 |

408103200 |

1078207616 |

18.313 |

0.03 |

|

2 |

30 |

1000 |

500 |

10 |

2000 |

100 |

407873184 |

1077930752 |

18.312 |

0.03 |

|

|

3 |

1 |

1000 |

500 |

10 |

2000 |

100 |

400581504 |

1072622400 |

18.637 |

0.00 |

|

|

4 |

1000 |

500 |

10 |

2000 |

100 |

400351488 |

1072380544 |

18.633 |

0.00 |

||

|

5 |

1 |

1000 |

10 |

2000 |

100 |

384230016 |

1224151296 |

21.270 |

0.00 |

||

|

6 |

30 |

1000 |

10 |

2000 |

100 |

391521696 |

1226586240 |

21.182 |

0.03 |

||

|

7 |

1 |

30 |

1000 |

10 |

2000 |

100 |

391751712 |

1226828288 |

21.186 |

0.03 |

|

|

8 |

1 |

30 |

1000 |

100 |

47751688 |

388245984 |

6.705 |

0.03 |

|||

|

9 |

1 |

30 |

1000 |

500 |

100 |

64103188 |

239625312 |

4.07 |

0.03 |

||

|

10 |

1 |

1000 |

500 |

100 |

56581500 |

234040144 |

4.067 |

0.00 |

|||

|

11 |

30 |

1000 |

500 |

16351500 |

199325680 |

3.386 |

0.03 |

Fig.7. Monthly average electric production

Fig.8. Monthly PV output

Fig.9. Monthly wind turbine output

Fig.10. DG generator output

3.2 . Emission

Table 4. Pollution emission

4. Conclusion

Table 4 provides a comprehensive list of all the possible configurations, with a specific focus on their pollutant emissions. These emissions encompass significant contributors such as carbon dioxide (CO2), carbon monoxide (CO), sulfur dioxide, and nitrogen oxide. Notably, the highest emissions among these pollutants are attributed to CO2, with an annual total of 2,458,389 kg/year. This table serves as a crucial reference point for assessing the environmental impact of various system configurations, shedding light on the significance of mitigating CO 2 emissions in pursuit of more sustainable energy solutions.

|

Pollutant |

Emissions(Kg/year) |

|

Carbon dioxide |

24,58,389 |

|

Carbon monoxide |

6068 |

|

Unburned hydrocarbons |

672 |

|

Particular matter |

457 |

|

Sulfur dioxide |

4713 |

|

Nitrogen oxides |

54,006 |

The successful achievement of different optimal power system combinations through the utilization of HOMER represents a significant milestone in the quest to power an ice cream factory in Fukuoka, Japan. This accomplishment has been made possible through a meticulously planned process that involved estimation, design, simulation, and optimization, all tailored to meet the specific energy needs of the factory. Crucial to the success of this endeavor was the preparation of load estimations, which were derived from on-site visits to ensure the accuracy and appropriateness of the design and simulation work. These load estimations served as a foundational element in creating power solutions tailored to the factory's requirements, thereby guaranteeing the most suitable outcomes. Moreover, the inclusion of meteorological data played a pivotal role in generating reliable results. These data sets contributed significantly to the accuracy of the simulations, ensuring that the proposed power systems could adapt to the variable weather conditions of the region. From the extensive array of feasible outcomes, this study not only provides practical solutions but also opens up opportunities for a diverse range of hybrid power options. These options encompass both renewable and non-renewable sources, with a notable example being the PV-wind-diesel-grid-electrolyzer power system. This configuration boasts a cost of energy (COE) of 18.313¥ per kWh, making it an economically viable and environmentally conscious choice for electrifying the ice cream factory. In essence, this study represents a multifaceted approach to addressing the energy needs of the ice cream factory, rooted in meticulous estimation, design, and simulation, and ultimately offering a diverse array of hybrid power options that can serve as a blueprint for sustainable electrification. For projects emphasizing environmental sustainability, options with higher proportions of renewable sources, such as "PV-Wind-Grid-Diesel Generator-Inverter Hybrid" and "Wind-Grid-Diesel Generator-Inverter Hybrid," may be preferred due to their reduced greenhouse gas emissions despite slightly higher costs.

Список литературы Evaluating the Feasibility of a Photovoltaic-Fuel Cell Hybrid Energy System for the Ice Cream Factory in Fukuoka City, Japan: An Economic and Technical Analysis

- Global Data Thematic Research, Offshore Technology, Ukraine conflict highlights the issue of energy dependency, Jun. 27, 2022, https://www.offshoretechnology.com/comment/ukraine-highlights-energy-dependency/. (Accessed 23 Jul 2022).

- IEA, IRENA, UNSD, World Bank, and WHO, tracking SDG 7: The energy progress report 2022, Washington DC, 2022, [Online]. Available: https://www.irena.org/- media/Files/IRENA/Agency/Publication/2022/Jun/ SDG7_Tracking_Progress_2022.pdf. (Accessed 23 Aug 2022).

- A. Bhatt, M. P. Sharma, and R. P. Saini, "Feasibility and sensitivity analysis of an off-grid micro hydro – photovoltaic – biomass and biogas – diesel – battery hybrid energy system for a remote area in Uttarakhand state, India," Renew. Sustain. Energy Rev., vol. 61, pp. 53–69, 2016.

- P. Bajpai and V. Dash, "Hybrid renewable energy systems for power generation in stand-alone applications: A review," Renew Sustain Energy Rev., vol. 16, pp. 2926–2939, 2012.

- M. M. Rashid, M. A. Habib, and M. M. Hasan, "Design and construction of the solar photovoltaic simulation system with the implementation of MPPT and Boost converter using MATLAB / SIMULINK," Asian J. Curr. Res., vol. 3, pp. 27–36, 2018.

- M. A. Habib, M. A. Kabir, and J. Tanimoto, "Evolutionary Game Analysis for Sustainable Environment Under Two Power Generation Systems," Evergreen, vol. 09, no. 02, pp. 323-341, June 2022.

- O. Erdinc and M. Uzunoglu, "Optimum design of hybrid renewable energy systems: Overview of different approaches," Renew Sustain Energy Rev., vol. 16, pp. 1412–1425, 2012.

- M. A. Habib, "Wind speed data and statistical analysis for Rangpur district in Bangladesh," J. Electr. Eng. Electron. Control Comput. Sci. –JEEECCS, vol. 8, no. 30, pp. 1-10, 2022.

- M. Zeyad, S. M. M. Ahmed, S. Hasan, and D. M. Mahmud, "Community microgrid: an approach towards positive energy community in an urban area of Dhaka, Bangladesh," Clean Energy, vol. 7, no. 4, pp. 926–939, 2023, doi: 10.1093/ce/zkad027.

- M. S. Islam, M. A. Habib, N. A. Noman, "What would be the best Techno-Economic aspects of the feasibility study concerning the proposed PV-Wind-Hydro hybrid system in Nilphamari, Bangladesh?," Int. J. Educ. Manage. Eng., October 2022, doi: 10.5815/ijeme.2022.05.04.

- Y. Huang, Q. Mian, N. Conradi, R. Opoka, A. L. Conroy, S. Namasopo, M. T. Hawkes, "Estimated Cost-effectiveness of Solar-Powered Oxygen Delivery for Pneumonia in Young Children in Low-Resource Settings," JAMA Netw Open, June 1, 2021, doi: 10.1001/jamanetworkopen.2021.14686.

- C. Ghenai, T. Salameh, and A. Merabet, "Technico-economic analysis of off grid solar PV/Fuel cell energy system for residential community in desert region," Int. J. Hydrogen Energy, vol. 45, pp. 11460-70, 2020, doi: 10.1016/j.ijhydene.2018.

- M. M. Rashid, M. M. Rahman, M. A. Habib, and M. M. Hasan, "Study and analysis of hybrid energy options for electricity production in Rangpur, Bangladesh," Asian J. Curr. Res., vol. 3, pp. 9–14, 2018.

- L. Khalil, K. Liaquat Bhatti, M. Arslan Iqbal Awan, M. Riaz, K. Khalil, N. Alwaz, "Optimization and designing of hybrid power system using HOMER pro," Mater. Today Proc., vol. 47, pp. S110–S115, 2021, doi: 10.1016/j.matpr.2020.06.054.

- T. M. I. Riayatsyah, T. A. Geumpana, I. M. Rizwanul Fattah, S. Rizal, T. M. Indra Mahlia, "Techno-economic analysis and optimisation of campus grid-connected hybrid renewable energy system using HOMER grid," Sustainability (Switzerland), vol. 14, no. 13, 2022, doi: 10.3390/su14137735.

- M. Sohail, H. N. Afrouzi, K. Mehranzamir, J. Ahmed, M. B. Mobin Siddique, M. Tabassum, "A comprehensive scientometric analysis on hybrid renewable energy systems in developing regions of the world," Results Eng., vol. 16, 2022, 100481, doi: 10.1016/j.rineng.2022.100481.

- S. K. Nandi, H. R. Ghosh, "A wind–PV-battery hybrid power system at Sitakunda in Bangladesh," Energy Policy, vol. 37, pp. 3659–3664, 2009. DOI: 10.1016/j.enpol.2009.04.039.

- R. Ahmmed et al., "Optimizing Hybrid Power for Manpura Island: A Case Study in Bangladesh," Journal of Energy Engineering and Thermodynamics, vol. 03, no. 01, pp. 20-30, Dec 2022 - Jan 2023. [Online]. Available: http://journal.hmjournals.com/index.php/JEET DOI: 10.55529/jeet.31.20.30.

- N. Takatsu and H. Farzaneh, "Techno-economic analysis of a novel hydrogen-based hybrid renewable energy system for both grid-tied and off-grid power supply in Japan: The case of Fukushima prefecture," Appl. Sci., 2020, doi: 10.3390/APP10124061.

- Y. Yoshida and H. Farzaneh, "Optimal design of a stand-alone residential hybrid microgrid system for enhancing renewable energy deployment in Japan," Energies, vol. 13, 2020, doi: 10.3390/en13071737.

- Fukuoka Wikipedia, Japan.

- The NREL, United States. HOMER Pro. https://www.homerenergy.com/products/pro/docs/index.html.

- B. Escobar et al., "Analytical model as a tool for the sizing of a hydrogen production system based on renewable energy: The Mexican Caribbean as a case of study," Int. J. Hydrog. Energy, vol. 38, no. 28, pp. 12562-9, 2013.

- Sector VP. Wind power green energy technology, 20; 231-56, https://doi.org/10.1007/978-3-642-20951-2_8, 2012.

- N. Noman, M. S. Islam, M. A. Habib, and S. K. Debnath, "The Techno-Economic Feasibility Serves to Optimize the PV-Wind-Hydro Hybrid Power System at Tangail in Bangladesh," Int. J. Educ. Manage. Eng. (IJEME), vol. 13, no. 3, pp. 19-32, 2023, doi: 10.5815/ijeme.2023.03.03.

- Global petrol prices.com

- JMA. weather data