Experimental experience of tape drying dishes

Автор: Abbasov B.

Журнал: Science, Education and Innovations in the Context of Modern Problems @imcra

Статья в выпуске: 4 vol.8, 2025 года.

Бесплатный доступ

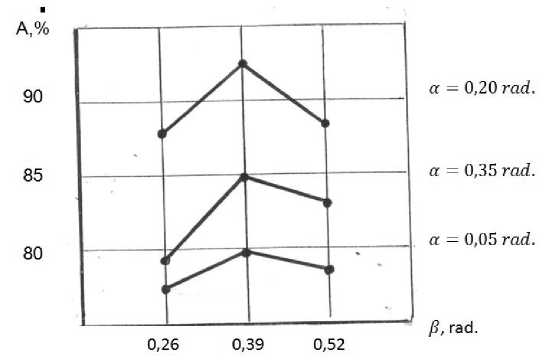

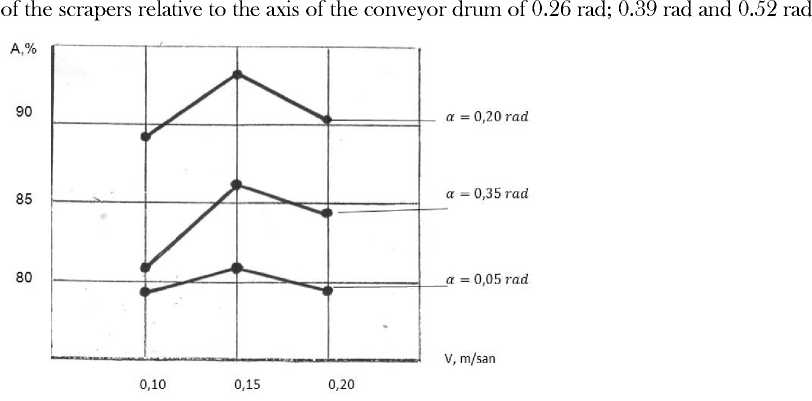

The article covers grain materials, including hazelnut kernels, beans, peas, etc. is devoted to the development and experimental research of a device for sorting food raw materials. The relevance and great importance of the use of the device for sorting granular materials developed at the level of invention in modern heavy and light industrial production, as well as in the agricultural sector was demonstrated. It has been established that belt conveyors are one of the devices with the highest specific weight among the technical means used in light industry, agricultural production, as well as in heavy industry. A graphical description of the sorting indicators during the sorting of hazelnut kernels is given. Analysis of the graphical description of experimental studies shows that during studies related to the sorting of hazelnut kernels, β = 0.39 rad; v_l=0.15 m/sec, as well as α = 0.20 rad, the sorting values of food raw materials are higher than other indicators.

Food raw material, hazelnuts, ribbon sorter, device, research

Короткий адрес: https://sciup.org/16010614

IDR: 16010614 | DOI: 10.56334/sei/8.4.53

Текст научной статьи Experimental experience of tape drying dishes

E-mail: ,

Introduction world economy, the relevance of methods and means with high economic and operational indicators for sorting food raw materials is beyond doubt. Sorting food raw materials by mass and volume allows you to improve the quality indicators of both sowing materials in agriculture and food products in the food industry. The fact that the technical means currently used for this purpose are expensive, energy and resource-intensive, as well as the costs of production in foreign countries and their import does not exclude the relevance of the problem posed [1 .„5].

of numerous analytical studies, it is known that among the technical means used in food, light industry, agricultural production, as well as in heavy industry, one of the devices with the largest specific gravity is belt conveyors. The purpose of using the aforementioned conveyors in transporting various types of cargo vertically, horizontally, at short and long distances, as well as at different angles to the horizontal plane is to:

-

- their simple construction and easy operation;

-

- one place to another and put into operational condition;

-

- because it can be quickly and easily dismantled;

-

- that less labor is required for its exploitation, etc.

above , belt conveyors are currently used to sort various granular food raw materials with flowability, making their relevance even more apparent.

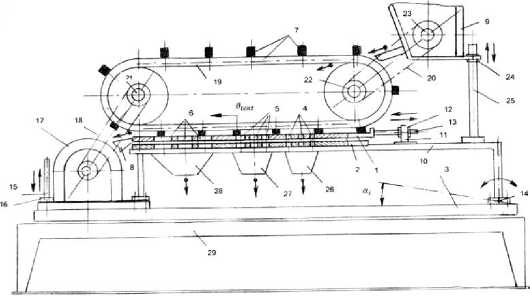

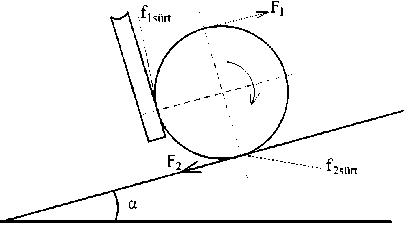

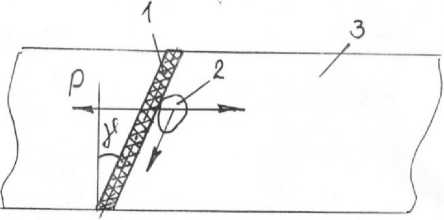

The technological scheme of the proposed belt conveyor device for sorting of food raw materials is shown in Figure 1, the side and top views of the sorter belt are shown in Figures 2 and 3, and the graphical description of the experimental research is shown in Figures 4-5 .

construction , easy working principle, and the possibility of manufacturing in medium-level locksmith workshops indicate that the proposed device has great competitiveness.

single- fiber device makes it possible to use it for sorting food raw materials of various granular shapes by making small adjustments to it.

the device (respectively movable-1 and fixed-2 (Figure 1) can be installed at different angles ( tt j ) on the can 3 allows to increase the quality indicators of the sorting operation. Thus, the angle at which the plate is installed is of particular importance in the passage of the materials to be sorted through the slots corresponding to the sizes (each slot in the device is made in three sizes, respectively small-4, medium-5 and large-6) .(a )

the figures, a small number of larger raw materials that have fallen into the food raw materials to be sorted are removed from the sorter by means of a shovel conveyor 7, which leaves the device, collects them in special containers, and puts them to use for their intended purpose.

the sorter is that the width of the above-mentioned sorting slots can be changed steplessly by changing the position of its plates (1;2) relative to each other in the horizontal plane. This allows the device to sort several different sizes of food raw materials. For this purpose, the movable plate 1 of the sorter is in kinematic connection with a rigidly mounted joint 11 on a support 10 that is rigidly connected to the stationary plate and the hopper 9 of the sorter, and with a nut-screw pair 12; 13. To ensure that the support of the sorter can be positioned at different angles relative to the horizontal plane and to determine its position, a joint 14 and a nut-screw pair 15; 16 were used. The conveyor's transmission mechanism is a combined electric motor, which is transmitted from the reducer 17 to the drive 21, driven 22 and hopper shaft 23 of the sorter through chain drives 18, 19, 20, respectively. Since a block consisting of three sprockets is installed in the sorter's hopper, it is connected to the hopper 9, support 10, and a pair of screws 24, 25 rigidly connected to the nut and support to ensure smooth operation of the chain drive. Funnels are installed 26; 27; 28, respectively, for filling small, medium and large-sized food raw materials leaving the sorter into special bags. The food raw materials sorting device mounted on the can 3 is installed on the table 29.

us and the known belt sorters used in this field is that its scrapers can be set at different angles. To achieve this goal, in order to carry out the sorting process smoothly and with high efficiency, it was considered appropriate to make the scrapers from strip-shaped rubber material and rigidly install the conveyor under the axis of the drum ( F Figure 3).

the technological scheme, the difference of the proposed new belt sorter from the known-analogous devices used in this field is to increase the quality indicators of sorting of granular food raw materials with complex geometric shapes and parameters, such as hazelnut kernels, peas, beans, when they move over the slots opened on the plate of the sorter. During the movement of the belt of such a conveyor, due to the action of scrapers mounted at an angle to the axis of its drum /?, both around its axis of symmetry (Figure 2) and rotating at the angle at which the scraper is mounted, the mentioned raw materials meet the sorting slots with different characteristics, and as we mentioned above, their sorting quality increases.

Figure 1. Technological scheme of a belt conveyor device for sorting granular food raw materials

Figure 2. Reporting scheme of the newly proposed belt conveyor device (side view from picture 1)

Figure 3. Reporting scheme of the newly proposed belt conveyor device (top view in figure 1)

Figure 4. Graphical representation of the dependence of the sorting indicators by size of hazelnut kernels at the linear speed of the new sorter belt of 0.1 m/sec, the inclination angle of the sorting plate relative to the horizontal plane of 0.05 rad; 0.20 rad and 0.35 rad, and the inclination angle

Figure 5. Graphical representation of the dependence of the sorting performance according to the size of hazelnut kernels at the linear speed of the new sorter belt of 0.15 m/sec, the inclination angle of the sorting plate relative to the horizontal plane of 0.05 rad; 0.20 rad and 0.35 rad, and the inclination angle of the scrapers relative to the axis of the conveyor drum of 0.26 rad; 0.39 rad and 0.52 rad new sorter belt of 0.10 m/sec; 0.15 m/sec, 0.20 m/sec, the inclination angle of the sorting plate relative to the horizontal plane of 0.05 rad; 0.20 rad and 0.35 rad, and the inclination angle of the scraper conveyor relative to the axis of the drum of 0.26 rad; 0.39 rad and 0.52 rad (Figures 4,5,6) shows that the sorting indicators are higher compared to previous studies.

experimental studies shows that during studies related to the sorting of hazelnut kernels, when p = 0,39 rad ; V ℓ = 0,15 m/sec, and φ , (X = 0,20 rad the sorting indicators of food raw materials are higher than other indicators (Fig. 4, 5) .