Exploring the Surface Chemistry for the Stabilization of Bismuth Titanate Fine Particle Suspensions in Cement Systems

Автор: Svetlana V. Samchenko, Irina V. Kozlova, Olga V. Zemskova, Marina O. Dudareva

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Construction materials science

Статья в выпуске: 5 Vol.15, 2023 года.

Бесплатный доступ

Introduction. The evolution of the construction industry in its current stage calls for the alteration of traditional building materials through the incorporation of nano- and fine-dispersed additives. These additions confer new, unique attributes to cement-based construction materials, enabling control over structure formation processes. Consequently, this allows for the creation of materials with specifically defined characteristics. Additives can be introduced into the cement composite during the joint grinding with clinker minerals, as a component of dry building mixture, or in the form of a suspension instead of mixing water. Therefore, it is essential to obtain fine particles suspensions resistant to aggregation and sedimentation. Thus, the purpose of this study is to obtain stabilized suspensions of bismuth titanate fine particles for cement systems and to study the properties of modified cement stone. Materials and methods. The purpose of this work was to establish the optimal concentration of polycarboxylate plasticizer in industrial water, necessary for the stabilization of fine bismuth titanate suspensions using surface tension and conductometric determination methods, the sedimentation stability of the obtained suspensions and the effect of ultrasonic exposure, as well as the physical and mechanical characteristics of cement stone modified with the obtained suspensions. Results and discussion. In order to establish the optimal concentration of the plasticizer necessary to obtain stable suspensions of bismuth titanate particles, the critical micelle concentration (CMC) for the plasticizer was determined with tap water as the dispersed medium. The CMC value was 1.3 g/l. If the concentration exceeds CMC, the process of micelle formation begins. In the micellar form, the plasticizer no longer provides stabilizing effect on the additive particles, therefore, the concentration of the plasticizer should be lower than the CMC. It was also found that ultrasound exposure increases the sedimentation stability of suspensions. The resulting stabilized suspensions were used instead of mixing water to obtain modified cement stone samples. There is an increase in the compressive strength of cement stone samples obtained after the introduction of fine bismuth titanate into the cement composite in the form of water suspensions stabilized by ultrasonic treatment with concentrations of 10, 30 and 50 g/l. The increase in compressive strength of modified samples compared to reference sample was from 24 to 33 MPa at first day age (by 13, 25 and 38% respectively), and from 80 to 93 MPa at 28 days age (by 4, 9 and 16%). Compressive strength of samples modified with bismuth titanate suspensions after ultrasonication compared to reference sample with plasticizer increased mostly at the first and third days age: from 29 to 42 MPa (by 31, 38 and 45%) and from 53 to 70 MPa (by 28, 30 and 32%) respectively. Conclusion. As a result of the research carried out in this study, the Critical Micelle Concentration (CMC) of a polycarboxylate plasticizer was determined, optimal for stabilizing fine-dispersed additive of bismuth titanate for cement systems, the effectiveness of ultrasonic treatment to achieve sedimentation stability of the obtained suspensions of the additive was confirmed, an increase in the strength characteristics of modified cement stone samples was established both in the initial hardening periods and at 28 days age. The results allow to consider a cement composite with fine bismuth titanate as a basis for obtaining building materials of new generation.

Fine additive, plasticizer, bismuth titanate, critical micelle concentration, aggregative and sedimentation stability, factors of aggregative stability, adsorption, gel-like films, strength

Короткий адрес: https://sciup.org/142238319

IDR: 142238319 | DOI: 10.15828/2075-8545-2023-15-5-397-407

Текст научной статьи Exploring the Surface Chemistry for the Stabilization of Bismuth Titanate Fine Particle Suspensions in Cement Systems

Original article

T he development of building materials science nowadays involves the development of a wide range of new construction, finishing, insulation, repair and other building materials that would exceed the characteristics of traditional materials based on concrete, ceramics and metals, wood and polymer materials, would be eco-friendly and safe for humans. Such materials with unique properties include, for example, “smart” materials – self-healing concretes, photocatalytic coatings, multilayer composites based on polymers and wood raw materials, carbon structures, aerogels of various composition and structure [1–5]. A special role in the development and production of such structures with unique characteristics is assigned to the modification of traditional building materials with nano- and fine-dispersed additives. Introducing such additives even in small quantities (up to 5% by weight) can significantly affect the properties of the material [6–8]. For example, the introduction of nanoscale titanium dioxide particles into the composition of a cement composite can provide the concrete surface with the ability to oxidize adsorbed organic pollutants and nitrogen oxides due to the photocatalytic reactions and the ability to selfcleaning due to an increase in the hydrophilicity of the surface [9, 10]. Carbon nanostructured objects increase the crack resistance of concrete, the strength and density of cement stone, acting as crystallization centers for hydration products forming during the hardening of cement paste [11, 12]. Nano- and fine-dispersed components of fly ash, ground granulated blast furnace slag, metakaolin also intensify the hydration processes of clinker minerals, and due to the pozzolanic reaction, provide the material with increased corrosion resistance [13, 14].

One of the factors determining the increase in mechanical characteristics of cement stone modified with a fine additive is the uniformity of distribution of additive particles throughout the cement composite. The introduction of nano- and fine-dispersed component into the composition of an inorganic binder can be carried out by various methods: by joint grinding of clinker and additive particles, as a component of dry building mixture, or in the form of a suspension instead of mixing water. All these processes, however, are associated with certain difficulties, primarily due to the fact that fine particles have a highly developed surface area, and, consequently, excessive surface energy, which leads to the tendency of particles to form agglomerates. When obtaining suspensions, which are thermodynamically unstable systems, the particles of the additive spontaneously enlarge and then settle, that is, the process of destruction occurs: the dispersed system loses aggregate and sedimentation stability. If such suspension is introduced into the cement system instead of mixing water, its particles won’t be uniformly distributed throughout the cement composite. Thus, it is necessary to achieve stabilization of fine-dispersed additive suspension, which will subsequently allow to obtain a cement stone with increased mechanical, functional and special properties.

Suspensions of most finely dispersed additives are thermodynamically unstable lyophobic colloidal systems that rapidly lose their aggregative and sedimentation stability, tend to reduce the surface area and decrease the excess surface energy of the system. The concept of aggregative stability of lyophobic colloidal systems, the formation of electric double layer and adsorption processes on the surface of colloidal particles is well explained by the DLVO theory developed in 1935–1940 by Soviet scientists B.V. Derjaguin and L.D. Landau and independently by Dutch physicists E. Verwey and Th. Overbeek. Since nano- and fine-dispersed objects and their applications in various fields of science and technology are currently being actively studied by scientists in many countries, the DLVO theory is becoming increasingly relevant, in particular, in the construction industry and especially in construction materials science [15–17].

The system is stable if there is a balance in repulsion and attraction forces between particles. The repulsion energy decreases with distance exponentially and contributes to the electrostatic component of the disjoining pressure. The disjoining pressure occurs when the thickness of the film (interlayer) between the two particles of the dispersed phase decreases as the particles get closer and their surface layers overlap. The energy of attraction is due to intermolecular van der Waals attractive forces. It is inversely proportional to the square of the distance between the particles.

Factors of aggregate stability can be classified as 1) thermodynamic, which include electrostatic attraction and repulsion forces, the interaction between the dispersed phase and the dispersed medium, resulting in the formation of solvent molecules layers surrounding colloidal particles and entropic repulsion, which promotes the particles to be the uniformly distributed throughout the dispersed medium and 2) kinetic – and hydrodynamic, resulting in formation of viscous interlayers of dispersed medium between the particles, the formation of elastic protective layers of adsorbed macromolecules, preventing the particles from agglomeration.

The last factor consists in the formation of strong thick elastic films of surfactants and high-molecular compounds adsorbed on the surface of colloidal particles, which prevent them from coagulation when they collide. This factor can be called one of the determining factors for the stabilization of admixture suspensions for cement systems, where polymer chemical compounds are used, increasing the aggregative and sedimentation stability of the dispersed system. Surfactants are compounds with diphilic structure, that is, they have a hydrophilic part and long hydrophobic nonpolar hydrocarbon tail in their

CONSTRUCTION MATERIAL SCIENCE structure. Due to the structural features, surfactant molecules can adsorb on the surface of the admixture particles, forming a thick elastic layer on their surface, which serves as a structural and mechanical barrier preventing coagulation and further settling of particles. During the aggregation of particles, a process of self-organization occurs, accompanied by the formation of agglomerates, which leads to the decrease of entropy of the system. Consequently, the introduction of surfactants into the admixture suspension not only increases the structural and mechanical barrier, but also leads to an increase in the entropy, contributing to the stabilization of the suspension and, as a result, to the uniform distribution of the additive particles throughout the cement composite and, consequently, obtaining a denser and stronger cement stone structure with improved physical and mechanical properties.

Thus, it is necessary to choose the optimal concentration of plasticizer to obtain a fine component suspension resistant to coagulation and sedimentation due to the formation of surfactant macromolecules layer and subsequent increase of entropic repulsion factor.

In accordance with literature review, the purpose of the study was formulated, which is to obtain stabilized suspensions of bismuth titanate fine particles for cement systems and to study the properties of the modified cement stone.

2. MATERIALS AND EXPERIMENTAL METHODS

The object of the study is stabilized suspensions of bismuth titanate for cement systems. The subject of the study is surface chemistry aspects of stabilization of fine bismuth titanate suspensions.

The following materials were used in the work:

– synthesized fine-dispersed additive of bismuth titanate, obtained on the basis of the TiO2–Bi2O3 system by citrate method.

– polycarboxylate plasticizer Melflux 5581F (BASF, Germany) (hereinafter – Sp) for stabilization of bismuth titanate fine particles

– ordinari portland cement CEM 0 LLC “Holcim (Rus) Building Materials” (hereinafter – OPC), the chemical and mineralogical composition is presented in Tables 1 and 2.

The synthesis of the bismuth titanate additive was carried out by the citrate-based method from titanium and bismuth salts in a solution of citric acid, similar to the classical Pechini citrate method [18]. To obtain the additive particles, titanium tetrachloride (99,9%, ρ (TiCl4) = 1.72 g/ml), bismuth oxide (99.99%), hydrochloric acid solution (1:1), citric acid monohydrate were used. The required amount of titanium tetrachloride was introduced into ice distilled water with constant stirring to form the products of TiOCl2 hydrolysis (solution 1). The corresponding amount of bismuth oxide was dissolved in hydrochloric acid, the required amount of citric acid was added to this solution and slowly added to the solution (1) with intensive stirring for 30 minutes for homogenization. The resulting solution was evaporated in a water bath at 100oC until a yellow gel-like residue was formed, which was decomposed in a muffle furnace at 400oC (15 minutes) to remove the organic component, and then annealed in a muffle furnace at a temperature of 700оC until the final fine flake-like reaction product was formed (Fig. 1).

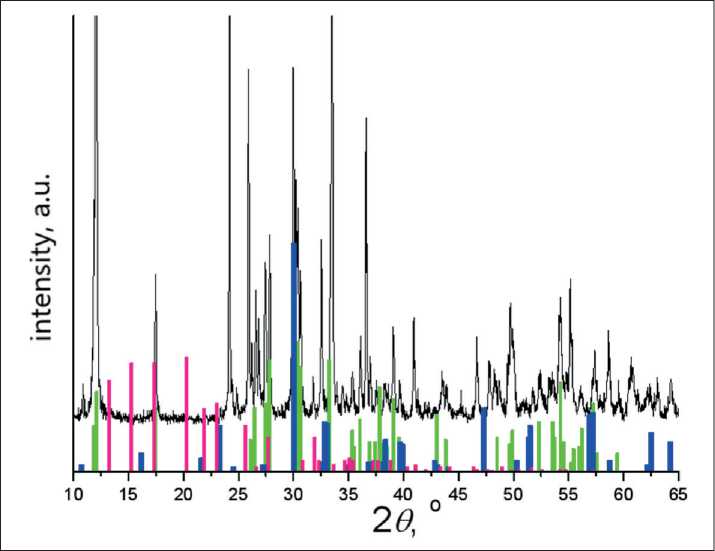

The phase composition of the bismuth titanate additive was studied using X–ray phase analysis, which was carried out using an X-ray diffractometer D8 ADVANCE Bruker AXS CuKa radiation (graphite monochromator), λCuKa = 1.54056 Å. The patterns were processed using the Match! software.

From patterns shown in Fig. 2, it can be concluded that the value of the angles 2θ and the intensities of the synthesized additive corresponds to the Bi2Ti4O11 from the JCPDS-ICDD PDF-2 database. Thus, it has been

Table 1

Chemical composition of clinker LLC “Holcim (Rus) Building Materials”

|

Components |

Mass loss after calcination, % |

CaO |

SiO2 |

Al2O3 |

Fe2O3 |

MgO |

SO3 |

R2O |

|

Clinker |

1.12 |

63.89 |

20.63 |

5.62 |

5.15 |

3.68 |

0.59 |

1.36 |

Table 2

Mineralogical composition of clinker LLC “Holсim (Rus) Building Materials”

|

Mileral content, % |

|||

|

C3S |

C2S |

C3A |

C4AF |

|

63.0 |

11.0 |

6.00 |

15.00 |

CONSTRUCTION MATERIAL SCIENCE

Fig. 1. Photo of bismuth titanate additive immediately after synthesis established that the predominant phase is bismuth titanate of the composition Bi2Ti4O11 (PDF#83-0673), however, there is also a phase of the composition Bi4Ti3O12 (PDF#72-1019) with the structure of perovskite and a metastable [19, 20] phase of the composition Bi2Ti2O7 (PDF#32-0118) with the structure of pyrochlore.

The next step in this study was to obtain a stabilized suspension of bismuth titanate additive particles.

To achieve this, it is necessary to determine the optimal amount of plasticizer, which can provide aggregative and sedimentation stability. In accordance with the studies described in [21], the authors established the critical micelle concentration (CMC) for the selected plasticizer in tap water. CMC was determined by two methods: by surface tension and conductometric methods.

The surface tension method is based on comparing the number of drops of the test solution and the standard liquid (tap water) flowing from the burette.

For highly dilute solutions of plasticizer Sp, the surface tension was calculated by the formula:

σ(Sp) = σ(H2O)•n(H2O)/n(Sp), (2)

where σ(Sp) is the surface tension of the investigated plasticizer solution, N/m;

σ(H2O) is the surface tension of the solvent, N/m;

n(H2O) is the number of drops of solvent;

n(Sp) is the number of drops of the studied plasticizer solution.

According to the obtained data, surface tension isotherms for the plasticizer solutions were plotted, the CMC of the Sp was found from the curve.

Measurements of the electrical conductivity of the plasticizer solution using a conductivity meter were carried out by immersing the detector of the device into the plasticizer solutions at a level of 3–4 cm and after establishing a constant data on the display, the value of the

Fig. 2. X-ray diffraction pattern of bismuth titanate additive: ■ experimental data; ■ Bi2Ti4O11; ■ Bi4Ti3O12; ■ Bi2Ti2O7

CONSTRUCTION MATERIAL SCIENCE electrical conductivity of the solution was fixed. According to this data, the dependence of the logarithm of electrical conductivity on the logarithm of concentration were plotted, and CMC was found from the curve.

To enhance the stabilizing effect of the plasticizer and to promrote its adsorption on the surface of bismuth titanate particles, ultrasonic treatment of bismuth titanate suspensions containing Sp was carried out on the UZDN-1 device. Dispersion parameters: ultrasonic vibration frequency – 44 kHz, temperature control temperature –25 ± 2оC, exposure time – 20 minutes.

Studies have been conducted to establish the sedimentation stability of bismuth titanate suspensions (10, 30, 50 g/l) without and after ultrasonication, as well as in the presence of Sp. The prepared suspensions were transferred into cylinders and the process of settling was observed.

The strength characteristics of modified cement stone was assessed at cube samples with sides of 20×20×20 mm. The cement powder was mixed with stabilized suspensions instead of mixing water. The values of the compressive strength of the samples was measured at Controls laboratory hydraulic press at 1, 3, 7 and 28 days age.

The study of the cement grains hydration process was carried out on the thermal analyzer “SDT Q-600” (TA Instruments, USA) using TG/DTA methods in the air atmosphere in the temperature range of 25÷900оC. The rate of temperature change was v = 10о/min.

3. RESULTS AND DISCUSSION

The stabilizing effect of Sp is mainly explained by the formation of strong gel-like plasticizer films on the surface of fine particles, thereby causing their stabilization. The stabilized particles are evenly distributed throughout the dispersed medium and the cement stone.

However, there is a limitation: Sp should not be introduced into the suspension in concentrations exceeding the CMC value. Otherwise, the stabilizer molecules are involved into the micelle formation process and the true solution of ionogenic surfactant transforms into micellar with the formation of classical spherical, and then cylindrical and disc-shaped micelles. In this case, the stabilizing effect of the plasticizer will not be achieved. This aspect is discussed in details in [21]. So at the first stage of this study the authors determined of the CMC of the stabilizer Sp in tap water using the surface tension method. A series of stabilizer solutions with a concentrations of 2.5; 2; 1.5; 1.3; 1.13; 1; 0.89; 0.76; 0.63; 0.31; 0.16; 0.078; 0.039 g/l.

Based on the data obtained from surface tension method, the surface tension isotherm for Sp σ = f(C υ) was plotted, where υ is the stoichiometric coefficient of the electrolyte (Fig. 3a). For Sp υ = 2, since the number of positive and negative ions turn out to be equal to 1. Also, according to the results of calculations obtained from Sp surface tension isotherms, the Gibbs adsorption isotherm G = f (cν) was plotted (Fig. 3b).

The CMC of the plasticizer Sp was found from the curve in Fig. 3a which corresponds to a value of 1.3 g/l, and the maximum Gibbs adsorption is G = 9.3 mol/m2. The obtained results allow us to conclude that the plasticizer Sp not only adsorbs at the interface of the water-air phases, but also adsorbs on the surface of the additive particles, forming a structural and mechanical barrier preventing coagulation and further settling of particles, enhancing the stabilization of suspension.

The CMC of Sp was also determined using the conductometric method, measuring electrical conductivity of a series of prepared solutions. According to the obtained data a dependence lg ( ϗ ) = f (lg C) was plotted (Fig. 4).

Fig. 3. Surface tension (a) and Gibbs adsorption (b) isotherms of plasticizer Sp

CONSTRUCTION MATERIAL SCIENCE

Fig. 4. Dependence of electrical conductivity on the concentration of Sp solutions

The CMC value of Sp obtained by the conductometric method is also in the range of 1.3 g/l, which is in good agreement with the data of the surface tension method.

Thus, from the data obtained from surface tension and conductometric methods, it can be concluded that the CMC value corresponds to 1.3 g/l. To stabilize the fine-dispersed additive, the concentration of Sp should not exceed this value, therefore, for further studies, the concentration of Sp below the CMC region was selected, which is 1.2 g/l.

To stabilize the particles of the finely dispersed component throughout the dispersed medium, ultrasonic processing of the suspensions was carried out, which contributes to additional particle grinding, separation of the formed agglomerates, as well as capable of improving the adsorption of Sp macromolecules on the surface of bismuth titanate particles.

In order to confirm the possibility of stabilization of bismuth titanate additive particles using a plasticizer, sedimentation stability of suspensions was evaluated. Table 3 presents data on the settling rate of bismuth titanate particles in water and water-polymer medium without and after ultrasonic treatment.

The process of sedimentation of additive particles in water dispersed medium can be divided into three main periods. During the first period, the largest and heaviest particles settle to the bottom of the cylinder, so the entire mass of particles divides into fractions. Since the settling of large particles occurs very quickly, the first period can be neglected, and therefore there is no data on it in Table 3. During the second period fine fraction of additive is suspended throughout the dispersed medium, at the end of the third period complete deposition of particles to the bottom of the cylinder is observed, the dispersion medium becomes transparent.

The studies demonstrate that suspensions of bismuth titanate after ultrasonication are more stable than without: it demonstrates the effectiveness of ultrasonic processing of fine component suspensions, which significantly prolongs the settling time of particles. It is remarkable that with an increase in the concentration of particles, their settling rate increases. This is probably due to the fact that in a more concentrated suspension the particles collide more often than in a diluted one. Large particles collide with each other and with the walls of the cylinder and settle fast. Smaller and lighter particles settle together with large ones.

The use of Sp in concentration of 1.2 g/l and ultrasonication makes it difficult to visually estimate the sedimen-

Table 3

Sedimentation stability of bismuth titanate suspension in an water dispersed medium

|

No. |

Method of homogenization |

Concentration of additive, (g/l) |

Period of settling |

|||

|

II |

III |

|||||

|

Settling time, min |

Settling rate, 10–5 m/s |

Settling time, h-min |

Settling rate, 10–5 m/s |

|||

|

1 |

Without ultrasonic exposure |

10 |

40 |

7.08 |

5-33 |

0.85 |

|

2 |

30 |

30 |

17.8 |

4-05 |

1.09 |

|

|

3 |

50 |

20 |

13.3 |

3-30 |

1.26 |

|

|

4 |

After ultrasonic exposure |

10 |

100 |

2.7 |

46-00 |

0.01 |

|

5 |

30 |

80 |

3.1 |

42-30 |

0.88 |

|

|

6 |

50 |

65 |

3.9 |

30-00 |

0.36 |

|

CONSTRUCTION MATERIAL SCIENCE

Fig. 5. Sedimentation process of bismuth titanate particles with a concentration of 50 g/l in a suspension stabilized with a plasticizer (C(Sp) = 1.2 g/l) and ultrasonic processing: a) immediately after ultrasonication b) 14 days after ultrasonication tation rate of bismuth titanate particles: after 14 days there was no complete sedimentation of particles to the bottom of the cylinder, we observed a gradual separation of particles into fractions by size (Fig. 5).

These results show the effectiveness of stabilization of the fine-dispersed bismuth titanate additive using an integrated approach: the use of a plasticizer and ultrasonic processing.

The macromolecules of Sp are adsorbed on the surface of bismuth titanate fine particles, forming strong dense gel-like films, which prevent the particles from sticking together as they approach, keeping the dispersed system stable longer without coagulation and further settling. Ultrasonic exposure contributes to additional particles size reduction, intensifies the Sp adsorption process on the particles surface, and also promotes the entropy factor, making the stabilized bismuth titanate particles to stay suspended throughout the dispersed water-polymer medium longer. In this case, we can talk about the synergetic effect of Sp and ultrasonication in the studied dispersed system.

The next step in this study was the introduction of fine additive into the cement composition and the study of physical and mechanical characteristics of obtained cement stone (Fig. 6).

The strength characteristics of modified cement samples indicate that synthesized fine bismuth titanate can be considered as a structure-forming additive for cement systems, which intensifies the hydration processes of cement clinker and contributing to an increase in compressive strength.

Thus, when fine bismuth titanate is introduced into the cement composition in the form of water suspensions stabilized by ultrasonic processing with a concentration of a fine additive of 10, 30 and 50 g/l (Fig. 6a), there is an increase in the compressive strength from 24 to 33 MPa compared to the non-additive sample (by 13, 25 and 38%, respectively) at the first day age, and from 80 to 93 MPa (by 4, 9 and 16%) at 28 days age. The maximum increase in strength is observed on the first day of hardening. Probably, this can be explained by the fact that bismuth titanate particles, being an inert additive that does not exhibit its own hydraulic activity, act as crystallization centers for the formation of hydration products of clinker minerals, thereby intensifying hydration processes. This

hydration time, days

□ reference OPC □ OPC+10 g/l additive □ OPC+30 g/l additive □ OPC+50 g/l additive

hydration time, days

□ reference OPC+Sp □ OPC+10 g/l additive+Sp

□ OPC+30 g/l additive+Sp О OPC+50 g/l additive+Sp

Fig. 6. Compressive strength of samples with a fine additive of bismuth titanate: a) without Sp; b) with 1.2 g/l of Sp

CONSTRUCTION MATERIAL SCIENCE also confirms the uniformity of the additive distribution throughout the cement composite. A similar situation is observed for the samples modified with stabilized water-polymer suspensions of the additive after ultrasonic exposure (Fig. 6b). The maximum increase in compressive strength is observed at first and third days age from 29 to 42 MPa (by 31, 38 and 45%) and from 53 to 70 MPa (by 28, 30 and 32%), respectively, compared with the reference sample with plasticizer.

This fact is confirmed by the results obtained using the SDT Q-600 thermal analyzer. According the thermograms (two of them are shown as an example in Fig. 7) the dependence of calcination losses on the hydration time of the samples were plotted (Fig. 8).

The graphs in Fig. 8 show that the mass loss after calcination of cement stone modified with bismuth titanate water suspensions after ultrasonication increases with hydration time and has maximum values for samples with 50 g/l of additive. Similar situation is observed for cement samples modified with water-polymer suspensions after ultrasonic exposure.

Thus, it can be concluded that an integrated approach to the stabilization of suspensions makes it possible to obtain cement composites with higher strength values both in the initial hardening periods and at 28 days age. These characteristics allow the authors further studies such properties as biocidity and photocatalytic activity in order to obtain building material of new generation.

Fig. 7. Thermograms of the reference sample (a) and with 30 g/l of bismuth titanate (b) at 3 days age with Sp

CONSTRUCTION MATERIAL SCIENCE

Fig. 8. The hydration degree of cement stone samples modified with stabilized water (a) and water polymer (b) suspensions of bismuth titanate

CONCLUSION

The study allows to obtain the following results. The optimal value of the plasticizer for fine bismuth titanate additive was determined using surface tension and conductometric methods: the CMC value for polycarboxylate superplasticizer is 1.3 g/l. Thus, in order to stabilize suspensions, it is necessary to choose a concentration of plasticizer less than the CMC point.

The studies on the effect of ultrasonic exposure on the stabilization of suspensions and on the sedimentation rate of additive particles in water and water-polymer dispersed media demonstrate that ultrasonication contributes to a slower particle sedimentation process, which is probably explained by the size reduction of large particles into smaller ones and the disintegration of agglomerates, as well as the intensification of adsorption of Sp macromolecules on the particles of the additive.

Studies of the mechanical properties of cement stone modified with bismuth titanate stabilized suspensions indicate an increase in strength characteristics and more intensive hydration processes in modified samples, which indirectly confirms the uniformity of additive particles distribution throughout the cement stone.

Based on our studies, it can be concluded that the stabilization process of additive is achieved by synergistic effect as a result of formation of strong gel-like films of adsorbed plasticizer on the surface of the particles, which prevent the particles from sticking together with subsequent sedimentation of particles. Ultrasonic processing provides increase in entropy which contributes to the uniform distribution of the particles throughout the dispersed medium so that they stay longer suspended in it. Cement powder mixed with stabilized suspensions of fine additive in concentration of 10, 30 and 50 g/l leads to an increase in the in the compressive strength of the samples from 24 to 33 MPa compared to the reference OPC (by 13, 25 and 38%, respectively) at first day age, and from 80 to 93 MPa (by 4, 9 and 16%) at 28 days age. The maximum increase in compressive strength for samples modified with water-polymer suspensions is noted at first and third days age, from 29 to 42 MPa (by 31, 38 and 45%) and from 53 to 70 MPa (by 28, 30 and 32%), respectively, compared to the reference sample OPC+Sp.

The results of our research indicate the possibility of obtaining a cement composite with enhanced properties and expanding the base of new generation building materials.

Список литературы Exploring the Surface Chemistry for the Stabilization of Bismuth Titanate Fine Particle Suspensions in Cement Systems

- Wang D., Zhang W., Han B. New generation of cement-based composites for civil engineering. New Materials in Civil Engineering. 2020; 777-795. https://doi.org/10.1016/B978-0-12-818961-0.00025-9

- Inozemcev A.S., Korolev E.V. Sravnitel’nyj analiz vlijanija nanomodificirovanija i mikrodispersnogo armirovanija na process i parametry razrushenija vysokoprochnyh legkih betonov. Stroitel’nye materialy. 2017; 7: 11-15.

- Luna M., Delgado J.J., Romero I., Montini T., Almoraima Gil M.L., Martínez-López J., Fornasiero P., Mosquera M.J. Photocatalytic TiO2 nanosheets-SiO2 coatings on concrete and limestone: An enhancement of depolluting and self-cleaning properties by nanoparticle design. Construction and Building Materials. 2022; 338. https://doi.org/10.1016/j.conbuildmat.2022.127349

- Tan T.H., Shah S.N., Ng C.C., Putra A., Othman M.N., Mo K.H. Insulating foamed lightweight cementitious composite with co-addition of micro-sized aerogel and hydrogen peroxide. Construction and Building Materials. 2022; 360. https://doi.org/10.1016/j.conbuildmat.2022.129485

- Stepina, I., Sodomon, M., Semenov, V., Kononov, G., Petukhov, V. Compatibility of modified heracleum Sosnovskyi cellulose-based material with some polymers. Cellulose Chem Technol. 2022; 56: 815-826. https://doi.org/10.35812/CelluloseChemTechnol.2022.56.73

- Eisa M.S., Mohamady A., Basiouny M.E., Abdulhamid A., Kim J.R. Mechanical properties of asphalt concrete modified with carbon nanotubes (CNTs). Case Studies in Construction Materials. 2022; 16. https://doi.org/10.1016/j.cscm.2022.e00930

- Grishina A. N., Korolev E.V. Bio- i himicheskaja stojkost’ nanomodificirovannogo kompozicionnogo cementnogo kamnja, soderzhashhego gidrosilikaty metallov. Regional’naja arhitektura i stroitel’stvo. 2023; 1(54): 4-14. https://doi.org/10.54734/20722958_2023_1_4

- Klapiszewska I., Ławniczak Ł., Balicki S., Gapiński B., Wieczorowski M., Wilk K.A., Jesionowski T., Klapiszewski Ł., Ślosarczyk A. Influence of zinc oxide particles dispersion on the functional and antimicrobial properties of cementitious composites. Journal of Materials Research and Technology. 2023; 24: 2239-2264. https://doi.org/10.1016/j.jmrt.2023.03.131

- Khannyra S., Luna M., Almoraima Gil M.L., Addou M., Mosquera M.J. Self-cleaning durability assessment of TiO2/SiO2 photocatalysts coated concrete: Effect of indoor and outdoor conditions on the photocatalytic activity. Building and Environment. 2022; 211. https://doi.org/10.1016/j.buildenv.2021.108743

- Xue Zhang X., Hui Li H., John T. Harvey J.T., Xiao Liang X., Ning Xie N., Ming Jia M. Purification effect on runoff pollution of porous concrete with nano-TiO2 photocatalytic coating. Transportation Research Part D: Transport and Environment. 2021; 101. https://doi.org/10.1016/j.trd.2021.103101

- Artamonova, O. V., Slavcheva G.S., Shvedova M.A. Jeffektivnost’ primenenija dobavok nanotubuljarnoj morfologii dlja modificirovanija cementnyh sistem. Neorganicheskie materialy. 2020; 56(1): 110-116. https://doi.org/10.31857/S0002337X20010029

- Tolchkov, Ju. N., Mihaleva Z.A., Tkachev A.G. Modificirovanie kompozitov stroitel’nogo naznachenija uglerodnymi nanostrukturami. Vestnik Tambovskogo gosudarstvennogo tehnicheskogo universiteta. 2019; 25(1): 161-172. https://doi.org/10.17277/vestnik.2019.01.pp.161-172

- Hung N.S., L.T. Van., Bulgakov B.I., Aleksandrova O.V., Larsen O.A. Vlijanie soderzhanija zoly-unosa na prochnost’ betonov na osnove sul’fatostojkogo portlandcementa. Promyshlennoe i grazhdanskoe stroitel’stvo. 2021; 1: 51-58. https://doi.org/10.33622/0869-7019.2021.01.51-58

- Samchenko S.V., Kozlova I.V., Zemskova O.V., Dudareva M.O., Shubina E.S. Sravnitel’nyj analiz sposobov modificirovanija shlakoportlandcementa ul’tradispersnym komponentom. Tehnika i tehnologija silikatov. 2020; 27(4): 113-120.

- Sargam Y., Wang K. Influence of dispersants and dispersion on properties of nanosilica modified cement-based materials. Cement and Concrete Composites. 2021; 118. https://doi.org/10.1016/j.cemconcomp.2021.103969

- Guvalov A.A., Kuznecova T.V. Vlijanie modifikatora na svojstva cementnyh suspenzij. Stroitel’nye materialy. 2013; 86-88.

- Vatanparast H., Shahabi F., Bahramian A., Javadi A., Miller R. The Role of Electrostatic Repulsion on Increasing Surface Activity of Anionic Surfactants in the Presence of Hydrophilic Silica Nanoparticles. Scientific reports. 2018; 8: 1-11. https://doi.org/10.1038/s41598-018-25493-7

- Dhage S.R., Khollam Y.B., Dhespande S.B., Potdar H.S., Ravi V. Synthesis of bismuth titanate by citrate method. Materials Research Bulletin. 2004; 39(13):1993-1998. https://doi.org/10.1016/j.materresbull.2004.07.014

- Pijr I.V. Kationzameshhennye titnaty i niobaty vismuta s karkasnoj (tipa pirohlora) i perovskitopodobnoj sloistoj strukturami: kristallohimicheskie, jelektricheskie i magnitnye svojstva. Dissertacija na soiskkanie uchenoj stepeni doktora himicheskih nauk. Syktyvkar; 2016.

- Lelievre J., Marchet P. Structure and properties of Bi2Ti2O7 pyrochlore type phase stabilized by lithium. Journal of Alloys and Compounds. 2018; 732: 178-186. https://doi.org/10.1016/j.jallcom.2017.10.128

- Samchenko S.V., Kozlova I.V, Zemskova O.V, Dudareva M.O. Methodological substantiation of the choice of a stabilizer for bismuth titanate fine particles suspensions. Nanotechnologies in construction. 2023; 15 (2): 97–109. https://doi.org/10.15828/2075-8545-2023-15-2-97-109