Features of organizational and technological solutions for the construction and installation of large-span buildings

Автор: Kuzmina T.K., Bolshakov A.N., Lukyanova N.A., Puzikova A.V.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: In related sectors

Статья в выпуске: 3 Vol.17, 2025 года.

Бесплатный доступ

Introduction. Cable-stayed structures occupy a special place in the modern construction industry due to their unique characteristics and wide application possibilities. They allow to convey architectural expression of large span buildings and to ensure high efficiency and minimal weight of structures. Systems with cross arranged cables and arch cable-stayed combined solutions, including "tensegrity" structures, are of particular interest nowadays. Materials and methods. The study is based on an analysis of regulatory documents, scientific and technical literature reflecting the installation of cable-stayed structures, including requirements for the quality of materials, installation processes and structural reliability control. A comparative analysis of various types of cable-stayed systems (parallel, radial and cross arranged) is carried out, and examples of their practical application are considered. Results and discussion. Based on the analysis of regulatory documents and scientific and technical literature review, cable-stayed structures were classified into various categories, reflecting their design features and applications. The advantages and disadvantages of each type of cable-stayed coverings were analyze as well as progressive methods of installations were revealed. Conclusion. The use of cable-stayed coverings, especially with cross-arranged cables and "tensegrity" structures are a promising direction in modern construction. These structures allow to create complex architectural solutions, creating lightweight, aesthetically attractive coverings. At the same time, the design and installation of cable-stayed structures require consideration of all their disadvantages and limitations to ensure the strength and durability of buildings and structures.

Cable-stayed coverings, installation of cable-stayed coverings

Короткий адрес: https://sciup.org/142244837

IDR: 142244837 | DOI: 10.15828/2075-8545-2025-17-3-339-346

Текст научной статьи Features of organizational and technological solutions for the construction and installation of large-span buildings

Review article

Cable-stayed structures stand out due to their exceptional characteristics and wide application possibilities in the modern construction industry. These systems consist of flexible steel cables which are strong in tension, as well as supporting structures that accept loads from these elements. The cables can be implemented in the form of tendons, ropes or bundles of high-strength wire. Such structures are an important tool in the development of architectural solutions, allow to crate buildings with complex spatial shapes, as well as large span structures. They are an effective solution for long-span buildings [1]. They are also actively used in the construction of shopping malls, exhibition halls, sports complexes, as well as industrial facilities, ensuring reliability and cost-effectiveness when covering significant spaces. Their widespread use is explained by the ability to effectively use the bearing properties of materials, ensuring minimal weight of the structure and high efficiency. Cable-stayed coverings are one of the key types of spatial structures that most accurately reflect the tectonics of the structure [2]. Their main advantage over the rigid structures is the minimum weight per square meter of the covered area, as well as the most efficient use of metal, the main structural material. In hanging cable-stayed constructions metal elements only work under tensile, which makes it possible to fully utilize their strength characteristics. According to V.E. Dolgopo-lov and his colleagues data, “the rational use of materials in cable-stayed structures reduces the cost of materials and installation, which is especially important for unique structures” [3].

The greatest interest in recent years, both in Russia and abroad, has been caused by structures with crossarranged cables, as well as arch cable-stayed combined systems. These structures are actively developing and are considered one of the most progressive solutions in modern construction. Their use opens up great opportunities for creating lightweight, cost-effective and architecturally expressive coverings. Combined cable-stayed structures include a large group of systems known as “tensegrity” [4]. In such systems, continuous stretched cables are combined with few short struts. Habibi T. and co-authors indicate that “prestressing is a key factor ensuring the stability and efficiency of tensegrity structures” [5]. One of the varieties of “tensegrity” systems are cable-stayed trusses which consist of high-strength belts (flexible cables) and vertical ties. To ensure the stability of the cable-stayed belts when exposed to alternating external loads, pre-tensioning is used. P.G. Eremeev emphasizes that “tensegrity systems open up new horizons in architectural design, allowing to create lightweight and cost-effective structures” [6].

Innovative technologies for the construction of unique buildings and structures in order to increase productivity in the construction industry are also being actively discussed.

MATERIALS AND METHODS

The installation of cable-stayed structures is covered by a set of regulatory documents that specify both the general requirements for construction and the specific features of working with highly pre-tensioned elements. The key areas of rationing are:

IN RELATED SECTORS

Requirements for the quality of materials and products.

Technological processes of installation.

Inspecting the strength and reliability of structures after installation.

Safety of work during installation.

The main documents regulating these aspects include Russian standards:

Building regulations SNiP 3.03.01-87 “Load-bearing and separating constructions” – establishes general requirements for the quality of assembling and installation of building structures, including cable-stayed systems.

Building regulations SP 64.13330.2016 “Loads and actions” – contains methods for calculating loads that must be taken into account when designing and installing cable-stayed coverings.

Building regulations GOST R 52969-2008 “Steel structures. Methods of quality control of welded joints” – defines the requirements for quality control of welded joints, which are often used in cable-stayed systems.

The quality of the materials directly affects the durability and reliability of the cable-stayed coverings. The installation of cable-stayed coverings is a complex technological process that requires precise following the sequence of operations and tension parameters control. After the installation of the cable-stayed coverings is completed, it is necessary to verify their reliability and compliance with the design parameters. Safety during installation of cable-stayed coverings is crucial due to high-altitude work and the use of highly stressed elements.

The building regulatory framework in the field of installation of cable-stayed coverings is quite extensive and covers all stages of work, from the selection of materials to the final tests. Strict observance of these standards ensures high quality of installation, durability of structures and safety of facilities operation. The development of technologies and new materials creation require constant improvement of existing regulatory documents, as well as the development of additional standards taking into account the specifics of modern solutions.

Based on the analysis, including regulatory materials, a number of indisputable advantages of cable-stayed systems can be identified in comparison with traditional steel structures:

Low weight of the structure: due to the use of high-strength steels and efficient load distribution in stretched elements, the cables fully utilize their cross-sectional area, which significantly reduces the overall weight of the structure.

Simple installation process: in most cases, the installation of cable-stayed coverings does not require scaffolding, which reduces labor intensity and speeds up the construction process.

Mobility: due to the possibility of folding the cables into compact coils, their transportation becomes much easier and less costly, which simplifies delivery to construction sites.

The possibility of covering large spans: cable-stayed systems allow the implementation of structures with large spans without intermediate columns which is especially important for objects with open spaces.

Economic efficiency: these structures provide financial benefits, since the weight of the supporting elements remains minimal, which reduces the overall materials cost.

Aesthetic expressiveness: the unique geometry of the cable-stayed structures provide buildings with modern dynamic exterior, turning them into a splendid element of any landscape or urban environment.

Comfort of the building’s interior: сable-stayed coverings improve the acoustic characteristics of rooms, increase the level of natural lighting and expand the visibility zones.

Strength and durability: cable-stayed structures ensure stable operation of structures for a long period under high loads and external factors.

It is also worth highlighting the disadvantages of cable-stayed structures.

High deformability: this is the main disadvantage of this type of structure. It is necessary to develop additional solutions to increase the rigidity of cable-stayed structures and to correct deformability.

Cost increase: cable-stayed structures application leads to an increase in the project budget due to the use of special support structures and building materials.

Complexity in the organization of drainage system: it is necessary to develop additional solutions for efficient outflow of water, taking into account the geometry of cable-stayed structures [7].

The production of cables is a complex technological process. At the same time, the use of structural solutions with long horizontal or slightly inclined cables turns out to be non-optimal, since structures can significantly increase deformations and worsen the overall efficiency of the system. Thus, the design and operation of such systems require special attention to detail to ensure their reliability and durability [8].

The low material consumption of the structural elements is justified by the fact that they work mainly under tension. In these structures, the problem of compressed elements stability has been solved – they can be massive and carry a maximum load over a large area, which allows the material to be used most efficiently. Modern construction methods suggest the possibility of improving cable-stayed roofs by the application of carbon fibers instead of steel. Carbon materials have a low weight with a high strength and rigidity, heat and corrosion resistance. A water-resistant tarpaulin is assumed to be the direct enclosing material. Such coverings can be assembled like sails on a ship, and deployed to the design position in hot or rainy weather.

IN RELATED SECTORS

The concrete plays an essential role in the design and construction of structures. The strength and reliability of structures as a whole will depend on it [9, 10]. When building using cable-stayed structures, modified types of concrete can be used, for example, high-strength lightweight concrete to optimize the consumption of reinforcing steel and concrete, or concrete of medium density D1500-D1700 with expanded clay aggregate and strength class B25-B30 using expanded clay gravel and modifying additives. Lightweight concretes made from highly mobile mixtures are obtained using inexpensive raw materials with cone slump test class P4-P5, which are effectively used in construction [11]. An additional economic effect is achieved due to lower thermal conductivity coefficients, as well as reduced costs during the operation of the building [12,13]. It is worth noting that the rapidly developing field of nanotechnology is also implemented in the construction industry. New materials are constantly appearing with exceptional and sometimes contradictory indicators. For example, for the first time, Russian scientists A.N. Ponomarev and M.E. Yudovich created lightweight nanofibre concrete. This is ordinary concrete based on B25 concrete with the addition of a complex additive, including components processed using nanotechnology. The strength of nanoconcrete is 45–60 MPa, specific gravity is 1.4–1.6 t/m3, frost resistance is W20 [14].

To ensure the durability and reliability of structures, since flexible cable elements are susceptible to atmosphere corrosion, especially in conditions of high humidity, salt deposits and temperature fluctuations, corrosion inhibitors containing synergistic nano-additives are used. The leading place among corrosion inhibitors is occupied by heterocyclic compounds, namely nitrogen-containing compounds, in particular, imidazoline derivatives [15, 16].

Consequently, cable-stayed structures represent a modern and effective solution for the construction of large-scale facilities, however, their application requires careful consideration of all the features and possible limitations [17].

RESULTS AND DISCUSSION

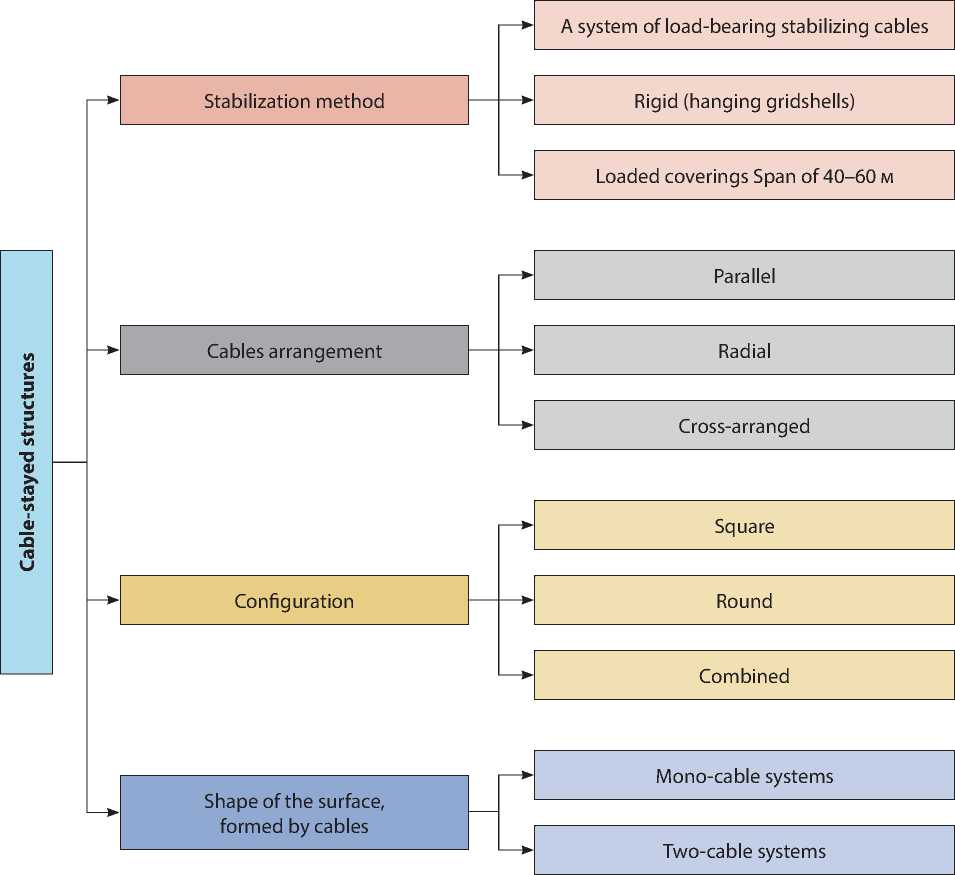

Cable-stayed structures can be classified according to various parameters. However, taking into account that the architectural and spatial organization of buildings with such structures is determined both by the shape of the covering itself and by the features of the supporting contour, it seems most logical to classify them according to these two key characteristics [18]. This approach allows to more accurately describe and systematize the features of these structures, depending on their architectural and construction solutions [19]. Based on the studied information, a scheme was made, which allows to classify cable-stayed structures according to various crite- ria that determine their design features and applications (Figure 1). The scheme includes several main categories revealing specific aspects of cable-stayed structures design and implementation:

A comparative analysis of the cable-stayed coverings was carried out according to the location of the cables (Table 1).

The analysis of the main characteristics of cable-stayed coverings, depending on the location of the cables, allows us to conclude that each type of such structures has its own advantages and disadvantages. At the same time, structures with cross-arranged cables, as well as archtype cable-stayed combined systems, are actively being improved and are recognized as one of the most advanced in the modern construction industry. The use of such technologies makes it possible to implement lightweight, economical and at the same time aesthetically attractive roof designs.

Combined cable-stayed structures cover a wide class of systems, which are commonly referred to as “tensegrity”. In these systems, the tensioned cables forming a continuous system combine with short and distant from each other support elements – struts. “Tensegrity” structures include cable-stayed structures consisting of strong flexible highly stressed cables and vertical struts. To ensure the stability of the cables systems under variable external loads, the pre-tensioned elements are applied.

The advantages of tensegrity systems include the following features:

-

• The structures are lightweight.

-

• Minimum loads transmitted to the underlying elements.

-

• High rigidity under asymmetric loads.

High resistance to dynamic influences, including seismic ones, due to the built-in damping properties of the system.

The ability to create visually light and transparent designs.

At the same time, these systems are characterized by increased accuracy requirements: it is necessary to strictly maintain the geometry of the elements, control the pretensioning force and the quality of joints. These factors require special attention at the design and installation stages [20].

Here are some examples of "tensegrity" structures:

Mercedes-Benz Stadium (Atlanta, USA). This modern stadium uses elements of "tensegrity" in its roofing system. The coverings consists of mobile panels supported by a network of cables, which ensures the lightness and functionality of the structure.

Tensys Pavilion (Great Britain). Tensys specializes in the design of tensegrity systems. One of their projects is a pavilion where a combination of stretched membranes and cables is applied to create a lightweight and durable structure.

IN RELATED SECTORS

Fig. 1. Classification of cable-stayed structures

Edward Fuller's Domes. Richard Buckminster Fuller, one of the pioneers of the tensegrity concept, created many dome structures based on the principles of stressed integrity. Montreal Biosphere (1967) – geodesic dome for Expo 67, although it is not a classic "tensegrity", but demonstrates the ideas underlying this technology [21].

Examples of the use of "tensegrity" structures show their versatility and potential in various fields: from architecture and construction to medicine and space. These structures combine lightness, stability and aesthetic concept, making them an ideal solution for complex architectural tasks.

Having considered innovative technologies for the construction of unique buildings and structures in order to increase productivity in the construction industry, the authors can highlight a unique method of cable-stayed structures installation using a temporary cable car, proposed by the French company Freissine. This system is a 125-meter-long structure secured by two metal stops on the upper ring of the facility. To minimize the sagging of the cable car, tension force of about 16 tons was created. The whole construction was based on two special metal saddles placed above the upper ring.

This method allows the installation of cable-stayed trusses simultaneously from two opposite sides. The work is carried out from work platforms located at various levels of reinforced concrete rings, which makes it possible to work with both the lower and upper belts of the cables in parallel. Construction cranes deliver the struts of the cable-stayed trusses to the platforms, where they are at-

IN RELATED SECTORS

Table 1. Types of cable-stayed coverings

The finished trusses are moved by cable car using winches and carriages. After reaching the specified position, the trusses are fixed in stationary anchors on reinforced concrete floors. The central ring uses only adjustable anchors to precisely balance the system. During installation, the lower cables are tightened with a force of 14 tons, and the upper ones with a force of 2 tons, which ensures the stability of the structure until the work is completed.

After the installation of all 48 cable-stayed trusses, the pre-tensioning stage of the construction process is carried out. The tension of the upper cables is carried out in stages using jacks with efforts of 14, 35 and 51 tons, respectively. This consistent process guarantees uniform load distribution and high strength of the entire structure [22].

This method demonstrates a high level of technical skills and an innovative approach that significantly improve the productivity and installation quality of complex cable-stayed structures. Computer analysis demonstrates that in order to ensure the stability of the central ring, it is necessary to create a pre-tensioning of two diametrical cable-stayed trusses at all stages of installation. Then pretensioning of the orthogonal trusses is performed, after

IN RELATED SECTORS that the rest. As a result, the pre-tensioning in the loadbearing cables increased from 14 to 37 tons.

CONCLUSION

An analysis of the main characteristics of cable-stayed coverings shows that each type of construction has its advantages and disadvantages. However, coverings with a cross arranged cables and arch cable-stayed combined systems are of the greatest interest. In modern construction, the use of cable-stayed structures is a developing trend. Combined systems, including "tensegrity" structures, are widely used in the construction of various buildings and structures of modern architecture. A promising direction is the designing of strong and durable buildings and structures using modern materials, including nanomaterials.