Features of processes of high-speed milling with a complex profile tool in the processing of aluminum alloys and composite materials

Автор: M.S. Vakulin, Yu.I. Gordeev, V.B. Yasinsky, A.S. Binchurov, P.V. Timoshev

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Technological processes and material science

Статья в выпуске: 3 vol.24, 2023 года.

Бесплатный доступ

Complex computational and experimental studies substantiate rational modes of milling of complex contour equiaxed surfaces with high accuracy of shape, dimensions and roughness parameters. Bars made of nanostructured carbide composite (produced by extrusion of WC-Co-Al2O3 bimodal powder mixtures) with increased strength, crack resistance and heat resistance were used as a workpiece material for the manufacture of new original tool designs. The combination of these properties is a necessary prerequisite for the effective operation of the developed designs of multi-blade cutters at high cutting speeds and under conditions of variable cyclic loads. A more complex kinematics of the joint rotational movement of the tool during milling dictates the need for new approaches when assigning rational cutting modes. To obtain reliable calculation formulae, numerical experiments were previously carried out, including simulation of the machining process using the VisualStudio integrated development environment, which supports Windows- Forms technology. The ability to display graphical 3D objects was implemented using an additional software product in the form of the Open CASCADE geometric core. Numerical experiments using MathCAD software products and based on the analytical provisions proposed in the work made it possible to evaluate the influence of cutting conditions, geometric parameters of the cutting part of the tool (profile and number of teeth), kinematics of relative movement in the “tool – part” system on the shape of surfaces and contour parameters (roughness) obtained during milling. A technique, algorithm and program for the automated calculation of cutting conditions have been developed, which have been verified during full-scale experiments and the manufacture of complex profile parts from aluminum alloys for drives of aerospace products (in the form of an equiaxial profile and parts of a pinion transmission of guidance mechanisms). At the same time, on the basis of a 3D model of products, control programs for CNC machines were created using MasterCAM. The practical significance and technical and economic efficiency of the proposed design and technological solutions is to increase productivity and reduce the complexity of processing (in comparison with the basic options) through the use of new multi-edge carbide tools for high-speed milling (including when processing composite materials).

Milling, hard metal tools, mathematical modeling, complex surfaces, aluminum and titanium alloys, composites, processing quality

Короткий адрес: https://sciup.org/148329701

IDR: 148329701 | УДК: 621.9 | DOI: 10.31772/2712-8970-2023-24-3-570-588

Текст научной статьи Features of processes of high-speed milling with a complex profile tool in the processing of aluminum alloys and composite materials

The active use of modern 3-5-axis multi-tasking CNC machines gives the expanded technology op-portunitites for processing complex-profile parts with high productivity and accuracy. At the same time, these digital technologies dictate the need to develop methods corresponding to their level of new tool and equipment designs for the effective implementation of high-speed precision machining processes. Solving these complex problems is of particular importance when processing complex-profile products for the aerospace industry, obtained from materials that are difficult to deform during cutting, such as composites, titanium and aluminum alloys. Increased demands are placed on the parts made from these materials on the quality of processing (accuracy of dimensions and relative position of surfaces, roughness), reliability and durability.

Therefore, it is necessary to take into account that the shaping processes during high-speed cutting on multi-purpose machines (milling, turn-milling, turning) have a number of features associated with the so-called size effect [1–3]. When assigning cutting modes, in addition to the known parameters generally accepted in theory and practice (cutting angles and material of the cutting part of the tool, properties of the workpiece material, shrinkage amount, angle of inclination of shear surfaces, cutting forces, etc.), it is necessary to take into consideration other characteristics [1; 4]. The majority of researchers recognize that one of the most informative indicators in the analytical description of micromilling processes is the specific cutting force [5; 6] in the deformation zone. To a large extent, its value depends on the geometry of the cutting part of a multi-blade tool, as well as the profile of the surface obtained during processing, the height of micro-irregularities in the form of shape deviations, and roughness [1]. Nevertheless, the use of well-known analytical calculation methods based on geometric and stereological models [6; 7] when designing multi-edge complex-contour cutters is limited, since they do not take into account the increased intensity and speed of deformation processes. Therefore, the preferred solution is the integrated use of analytical and numerical methods of finite element analysis. For example, in the papers [8; 9] these methods determined the minimum thickness of the cut layer of structural steels, estimated depending on the radius of the cutting edge (r e ) by the ratio h min = (0,14 – 0,43) r e , at which the required processing quality is ensured. Similar values were determined experimentally when studying size effects and features of micromilling [10; 11]. But it is not enough to take into account only the scale factor when describing the features of deformation processes of high-speed processing [12; 13]. An increase in cutting speed (spindle speed on multi-purpose machines reaches 40,000 rpm) and feed speed leads to a significant change in the kinematic cutting angles. In particular, a large negative-rake angle may appear [14; 15] and, as a result, a “ploughing” effect occurs (instead of cutting off the surface layer) [1; 6; 13]. This leads to an increase in the specific energy concentrated in the cutting zone, which is also characteristic of high-speed micropocessing [4; 8; 9; 11; 14; 15]. In this case, elastic deformation predominates, and finely crushed chips are formed in the layer being cut. The differences in fracture mechanisms during high-speed cutting can be indirectly assessed by the shape and size of the chips: the sizes of undeformed layers (fragments) of chips can vary from 0.1 to 900 μm [8; 9; 14]. With increasing cutting depth, the material is plastically deformed, but before reaching a very certain threshold value [16]. A characteristic feature of microprocessing is also the increased intensity of cyclic deformation processes, the frequency of formation of surfaces, shear elements, and the formation of submicron lamellae in the chip cross-section [1]. The theoretical and analytical description of the mechanisms of their formation, modeling and calculation of kinematic parameters under which various shaping mechanisms are realized are necessary conditions for determining rational cutting conditions and ensuring the required processing quality. In particular, theoretically and experimentally substantiated methods of high-speed rotational turning, turn-milling and milling allow increasing the intensity of deformation processes and ensuring effective crushing of chips down to micron and submicron sizes. At the same time, it is possible to improve the quality of processing surfaces according to roughness parameters [11; 14; 15]. The papers [16–20] present the analysis of problems and research results that allow various methods to increase the efficiency of highspeed processing of aluminum alloys: by choosing the correct milling strategy [16], assigning rational cutting modes [17], combining micro-milling and electrophysical methods [18], applying a protective coating to the surface of a cutting tool [19], optimizing the geometric parameters of cutters [20].

The works [21–26] analyze the main problems that arise when processing various composites (delamination, stretching of composite fibers, chipping and non-cutting of composite fibers); recommen- dations were given on the geometry of the cutting part and the design of tools [21–24], the choice of methods and technological modes of processing of composites [25; 26]. The advantageous performance differences of high-speed milling do not always guarantee the required quality of surfaces, especially when processing products based on difficult-to-deform materials (aluminum and titanium alloys, fiber composites). There are objective restrictions on cutting modes and design of the tool when processing complex surfaces. The existing problems can be largely solved through the expanded use of milling methods and new original designs of multi-edge milling cutters for their implementation on CNC machines [27–29]. Milling with high geometric complexity of the tool allows reducing the volume of the cut layer (chip size) and cutting forces, as well as produce three-dimensional microcomponents from a wide range of metallic and non-metallic materials, including composites. In addition, longitudinal turning using a top cutting tool can be replaced by milling, which improves processing productivity by combining the rotational movements of the workpiece and the tool while simultaneously improving surface quality. With high-speed milling, in addition to reducing the volume of chips (the thickness of the cut layer can be comparable to the radius of the tool edge), the mechanisms of destruction of the workpiece material also change - destruction occurs mainly in the elastic zone without significant plastic deformation. There are some known methods for mathematical modeling and studying the influence of the kinematics of relative movement in the “tool – workpiece” system on the shape of bodies of rotation obtained during processing of complex surfaces (equiaxial contours) [30].

Moreover, by specifying the geometry of the tool, cutting modes and the trajectory of the relative movement of the points of the tool and the workpiece, one can control the shape of the resulting surface of the part [31]. But the problems of developing new designs of cutters and methods for numerical assessment of deformation processes in the cut layer based on the finite element method (FEM), in relation to milling and high-speed precision milling methods, require solutions in the same way as the problems of creating control programs for CNC machines. The problems of mathematical description of the kinematics of milling processes, assignment and optimization of cutting modes remain insufficiently studied, both theoretically and experimentally.

The purpose of the work is to theoretically and experimentally substantiate the kinematic parameters and modes of high-speed milling to increase the productivity and quality of processing complex surfaces of parts.

Methods and equipment of research

The experimental studies on milling were carried out on a CNC turning and milling machine (DMG MORI CTX 310 model) with a live tool (Fig. 1, a ). Round rolled products made of aluminum alloy D16 GOST 4784-97 and steel 45 GOST 1050-2013 were used as workpieces during testing. The study of high-speed milling of composite materials based on carbon fabric UT - 900 - 3 and epoxy resin Etal - 200M was carried out on a Kuka KR 90 R3100 extra HA 9 robotic manipulator with an H6161H0902 spindle installed on it (Fig. 1, b ).

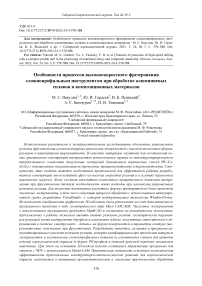

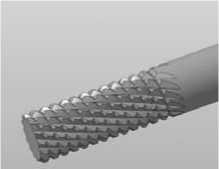

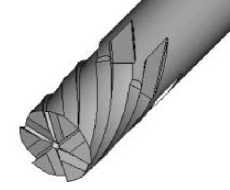

The tools being used were our own original designs of multi-blade router cutters [31] (Fig. 1 c, d ), used during testing in comparison with analogues from ISCAR (Israel) and SANDVIK (Sweden). Analog milling cutter 2P350 – 1000 – OA O12M (Sandvik).

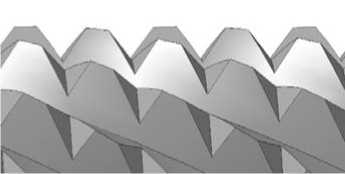

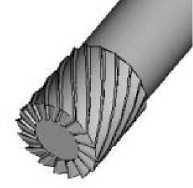

To study the machinability of aluminum alloys, multipoint end mills were additionally designed, the 3D models of which are shown in Fig. 1 d, f.

The following cutting mode parameters were taken as independent variables: So – longitudinal tool feed per revolution of the shaft being processed, 0.15–1.2 mm/rev; n з – number of revolutions of the workpiece, 50–1000 rpm; υ р – cutting speed, 310–933 m/min; n c – cutter speed, 6000–18000 rpm; t - cutting depth, 0.1–1.5 mm. The quality of the processed surface of the samples was assessed by two height parameters of roughness Ra , Rz on a profilometer model Tr 220 (China), measurement range 160 µm (from –80 to +80 µm). The analysis of the sample microstructure and chip morphology was carried out using HITACHI TM 1000 and JEOL JSM-7001F scanning electron microscopes.

a

b

c

d

e

f

Рис. 1. Оборудование и оснастка для проведения экспериментов:

а – токарно-фрезерный станок с ЧПУ DMG MORI CTX 310; б – робот Kuka KR 90 R3100 extra HA (Япония) и шпиндель H6161H0902; в , г – 3D-модель новой конструкции многолезвийной фрезы-роутера EMC-D10-90-1 и профиль зубьев; д , е – геометрия режущей части концевых фрез для обработки алюминиевых сплавов

-

Fig. 1. Equipment and tool set for experiments:

a – CNC turning and milling machine DMG MORI CTX 310; b – robot Kuka KR 90 R3100 extra HA (Japan) and spindle H6161H0902; c , d – 3D model of a new design of the EMC-D10-90-1 multipoint cutter-router and tooth profile; e , f – geometry of the cutting part of end mills for processing aluminum alloys

The production of solid carbide milling cutters was carried out on an ANCA RX7 grinding machine using specially developed control programs, taking into account all the design parameters of the designed cutters (Fig. 2). Rods made of nanostructured carbide composite (obtained by extrusion of bimodal WC-Co-Al2O3 powder mixtures) with increased strength, crack resistance and heat resistance were used as a workpiece material for the manufacture of the tools [32; 33].

The combination of these properties is a necessary prerequisite for the effective operation of the developed multipoint cutter design at high cutting speeds and under conditions of variable cyclic loads. The developed new designs of cutters made of carbide composite have an expanded scope and correspond to groups P , N, М and S according to the ISO 513:2012 standard.

Simulating milling processes

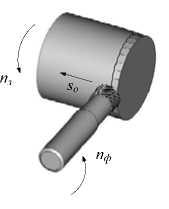

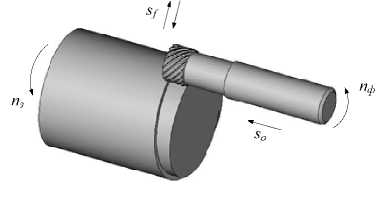

When processing a part using the milling method, the tool makes two movements: progressive motion along the axis of the part (so) and rotational motion around its own axis (nc); and the workpiece being processed rotates around its own axis (nд). It is possible to have both a perpendicular position (Fig. 3, a) of the cutter rotation axis relative to the workpiece rotation axis, and a coaxial position (Fig. 3, b). In the first case, an end processing scheme is implemented, and in the second – a contour one.

Рис. 2. Образцы новых конструкций твердосплавных фрез для проведения испытаний

Fig. 2. Samples of new designs of carbide milling cutters for testing

a

Рис. 3. Схемы обработки поверхностей при фрезоточении

Fig. 3. Schemes of surface machining during milling

A necessary condition for achieving high accuracy and productivity when processing parts by milling is the assignment of optimal cutting conditions.

The more complex kinematics of the joint rotational motion of the tool during milling imlicitly influences the methodology for calculating cutting conditions. To obtain reliable calculation formulae, numerical experiments were previously carried out, including simulation of processing using the integrated development environment VisualStudio, which supports WindowsForms technology. The ability to display 3D graphic objects was implemented using an additional software product in the form of the Open CASCADE geometric kernel (Fig. 4).

Рис. 4. Кинематическая схема и профиль поверхности при торцевом фрезоточении

Fig. 4. Kinematic scheme and surface profile during face milling

Based on the results of numerical estimates for the first scheme of face milling, a comprehensive methodology and calculation formulae were developed for determining the main cutting conditions (1–6) given below.

The diameter of the workpiece being processed is determined by the following formula:

D m = D W – 2 · a p ,

where a p – cutting depth. Step offset angle:

0 = arctg

x

. 3,14 - D,

where x – a helix pitch.

Workpiece rotation speed, mm/rev:

_ z - fz • nt , x where z – number of cutter teeth, fz – feed per tooth, nt – tool revolution speed.

The feed per tooth and feed in the axial direction are determined by the formulae (4), (5):

f _ f/ - x - cos(0)

!z 3,14 - Dm ’ f / _ 3,14 - Dm • nw z z - cos (0)- nt ’

And finally, the speed of the cutter along the spiral path:

V _ П - D m ' n w f / cos ( 0 ) ,

The calculations using the formulae (1)–(6) show a significant increase (up to 2 times) in cutting speed and productivity in terms of the volume of the material being cut compared to a turning process.

The additional feed motion of the cutter ( s f ) with a contour processing scheme (Fig. 3, b ) also provides the ability to process complex surfaces, such as equiaxed contours with a regular profile, cycloidal, helical, etc.

When modeling coaxial milling processes and in the experimental part of the work, an original design of a multi-edge tool was used, which combines elements of “conventional” cutting of a layer of material and a router. Increased intensity and frequency of surface layer cutting cycles imply increased productivity and quality of surface treatment of the part. This is precisely what explains the effectiveness of using high-speed precision milling according to the scheme presented in Fig. 3, b . The numerical experiments using MathCAD software products, based on the analytical principles proposed in the work, made it possible to evaluate the influence of cutting modes, geometric parameters of the cutting part of the tool (profile and number of teeth), kinematics of relative motion in the “tool-workpiece” system on the shape of surfaces and parameters contour (roughness obtained during milling).

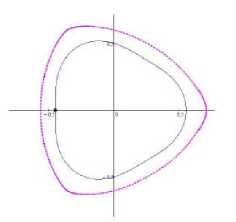

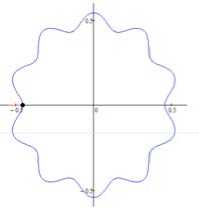

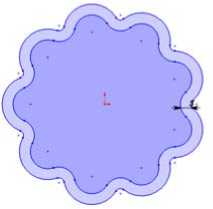

The theoretical study of the possibilities of using milling processes to obtain more complex surfaces such as equiaxed contours (Fig. 5) required the development of more complex mathematical models using specialized CAD systems.

б

Рис. 5. Результаты моделирования профилей поверхностей деталей: а – профиль треугольника Рело; б – циклоида; в – многогранник

Fig. 5. The results of modeling the profiles of the surfaces of parts: a – profile of the Reuleaux triangle; b – cycloid; c – polyhedron

The angular velocities of the tool and the workpiece were specified as input data in the milling process model to determine the profile of the machined surface; and these parameters and their correlations varied when determining the required trajectory. Tool cutting surfaces are formed as a result of the intersection of the plane of the front surface with the generating surface of the cutter. The description of the motions of the tool and the part is presented in the form of a system of equations (7) and a part rotation matrix (8). For example, with the ratio of angular velocities of 1/3: ω I = 2π3, ω D = –2π, where ω I are angular velocities of the tool, ω D are angular velocities of the part.

г ( t , 5ф ) =

^ r IO cos( s It + 5ф ) + s^

ч гю cos( s it + 8ф) ?

^ cos( ro Dt )

M Z ( t ) = sin( ro Dt )

- sin( ro Dt ) 0 ' cos( ro Dt ) 0

0 1,

where r I – coordinates of tool motion points; δφ – distance between cutting edges; ε –ratio of the radii of a cutter and a workpiece.

The discreteness of the calculations was specified by the step of the parameter t . Depending on the number of cutting edges of the cutter N and the pitch between the teeth K , the rotation angle δφ changes - formula (10) and the contour of the surface being machined (9):

r ( t , δφ) = M Z ( t ) r I ( t , δφ),

&P k =

360 ■ deg

K

The simulation results show that milling allows obtaining different profiles on the part (Fig. 5). The examples of profiles and surface roughness obtained by milling at different values of the number of teeth N , angular velocities of the tool ω I and workpiece ω D , and the distances between the tool axis and the workpiece s are presented in Fig. 5. For example, for an equiaxial contour in the shape of a Reuleaux triangle (Fig. 5, a ), the coordinates of the points (change in the angle of the equilateral figure) can be determined by the formulae p ( t ) = 9 – cos (3 t ).

The description of an equally wide curve in accordance with the model is made by determining the coordinates of points x and y using the formulae (11) and (12).

x (t) = I p(t)cos(t)

+ d- p ( t ) sin ( t ) l 0,07,

У ( t ) = I P ( t ) sin ( t )

+ dtp ( t ) cos ( t ) l 0,07,

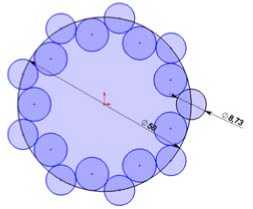

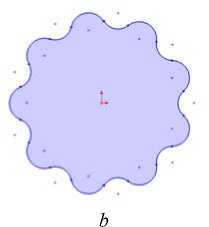

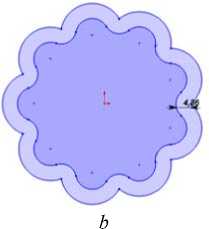

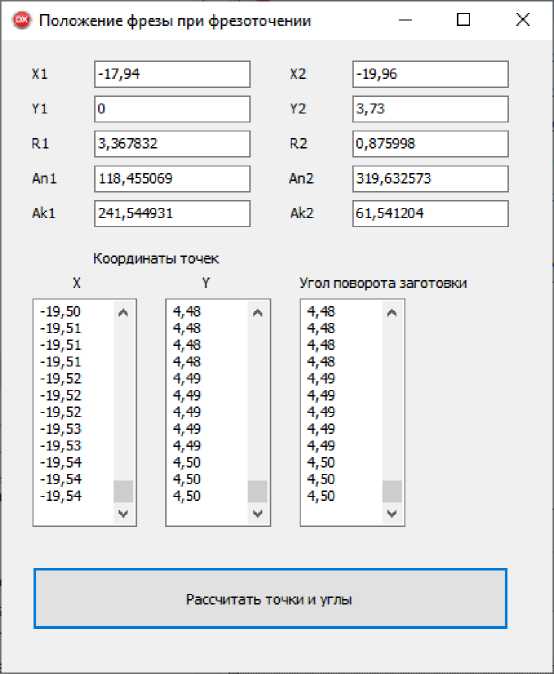

Based on the above formulae describing the process of forming an equiaxial contour, an algorithm was developed and a calculation program was created to automate the procedure for determining the coordinates of points. The construction of the pin-gear wheel profile is carried out after calculating the main initial parameters. For example, for a gearbox part with a gear ratio of 8 and a nominal race diameter of 50 mm, the wheel diameter will be 44.444 mm and the pin diameter will be 8.73 mm. After auxiliary constructions with superimposition of the contours of the workpiece and the tool, we obtain an array of intermediate circles (Fig. 6, a ) and the contour of the pin-gear wheel (Fig. 6, b ).

a

Рис. 6. Построение контура цевочного колеса: а – массив промежуточных окружностей; б – профиль детали

Fig. 6. Constructing the outline of the lantern wheel: a – аrray of intermediate circles; b – part profile

To obtain the trajectory of the cutter, it is necessary to perform the “object displacement” operation. The amount of displacement should be equal to the radius of the cutter, and the trajectory is a closed contour of arcs of two different radii (Fig. 7, a ). If the diameter of the cutter is equal to the diameter of the pin, the trajectory will consist of arcs of the same radius (Fig. 7, b ).

Below there is an algorithm and fragments of the implementation of a control program for the manufacture of drive parts for the cycloid transmission of satellite communication control mechanisms. To obtain trajectory coordinates, one can use the built-in tools of the CAD environment API to transform curves into a set of points and then obtain the dependence of the rotation angle of the part on the trajectory point. The CAD environment provides the ability to obtain curve parameters through the interface with subsequent processing in lateral software products (Fig. 8).

Рис. 7. Траектория для фрезы диаметром, равным диаметру цевок: а – замкнутый контур из дуг двух различных радиусов; б – траектория из дуг одного радиуса

Fig. 7. Trajectory for a cutter with a diameter equal to the diameter of the pins: a – closed contour of arcs of two different radii; b – trajectory of arcs of the same radius

|

Параметры |

||

|

(о |

-20.20164185 |

А |

|

4 X |

V |

|

|

0.00 |

А |

|

|

V |

||

|

Сх |

-23,00258587 |

А |

|

V |

||

|

7.27798752 |

А |

|

|

V |

||

|

-23.00258587 |

А |

|

|

' X |

V |

|

|

-7.27798752 |

А |

|

|

V |

||

|

7.79835815 |

А |

|

|

V |

||

|

137.90141509’ |

А V |

|

b

Рис. 8. Получение характеристик дуги в SolidWorks ( а ) и интерфейс приложения ( б )

a

Fig. 8. Obtaining arc characteristics in SolidWorks ( a ) and Application interface ( b )

Since during milling the cutter moves only along one coordinate, the sets of points of the X coordinate and the angle of rotation of the workpiece are selected to form the trajectory (Table 1).

Moreover, to obtain a profile using milling methods, it is necessary to make appropriate adjustments for the rotation of the workpiece. This procedure can be performed on the basis of a 3D model of products when creating control programs for CNC machines using the MasterCAM software product.

Таблица 1

The correlation between the position of the cutter and the angle of rotation of the workpiece

|

№ |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

|

Position of the cutter relative to the workpiece, mm |

–19.57 |

–19.59 |

–19.6 |

–19.62 |

–19.63 |

–19.65 |

–19.66 |

–19.68 |

–19.69 |

–19.71 |

–19.72 |

|

Angle of rotation of the workpiece, degrees |

2.94 |

2.94 |

2.93 |

2.92 |

2.91 |

2.9 |

2.89 |

2.89 |

2.88 |

2.87 |

2.86 |

Experimental studies of high-speed milling processes. Results and discussions

The assignment of cutting parameters during milling to obtain complex-contour equiaxed surfaces of aerospace products was carried out using control programs for CNC machines. As the main parameters for verifying the modeling results during experimental studies, the values of the accuracy of the dimensions and shape of equiaxed contours, the roughness of the surface machined by milling during the manufacture of real parts in production conditions were used. As a result, it was possible to produce parts in the form of an equiaxed contour profile (Reuleaux triangle) with high accuracy of dimensions, shape and the required quality of the surface layer (Fig. 9, a). The step-by-step processing when obtaining the contour of a part for the pin-gear drive is presented in Fig. 9, b–d.

a

b

c

Рис. 9. Сложноконтурные поверхности деталей, полученные фрезоточением: а – треугольник Рело; б – схема наладки при фрезоточении; в – профиль циклоиды для цевочной передачи; г – готовая деталь

d

Fig.9. Complex contour surfaces of parts obtained by milling: a – Reuleaux triangle; b – setup diagram for milling; c – cycloid profile for pin-gear drive; d – finished part

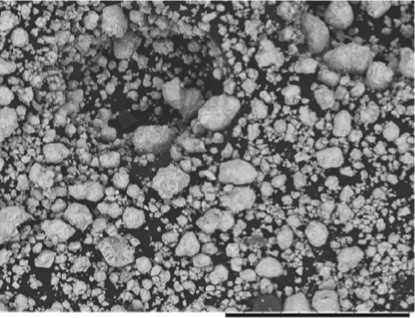

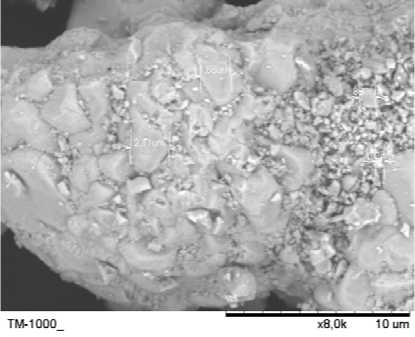

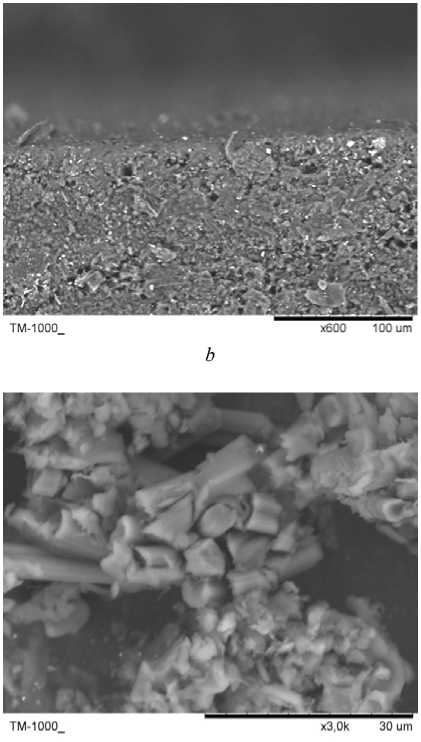

The high intensity of milling processes is confirmed by the results of studying the microstructure of the surface layer. An increase in the microhardness of steel parts to a depth of 80 µm was found to be 2.5 times higher than that of the base, i.e. this cutting method can be used instead of heat treatment. This ensures high surface quality in terms of roughness, which eliminates the need for additional finishing operations. Indirect confirmations of the advantages of high-speed types of milling are the results of electron microscopic studies of the shape and size of the chips. To experimentally verify the numerical results of FEM studies, surface roughness values were used. The morphology of chips obtained by milling an aluminum alloy with a multi-edge contour cutter is illustrated in Fig. 10. The sizes of the chips vary in the range from 2 to 50 microns, and a more detailed study reveals that large types of chips are agglomerates of fragments with sizes of 480–880 nm (Fig. 10, b ).

TM-1000

х400 200 um

a

b

Рис. 10. Морфология алюминиевой стружки, полученной при фрезоточении: а - распределение по размерам, х 400; б - наноструктурированный фрагмент стружки

Fig. 10. Morphology of aluminum chips obtained by milling:

a - size distribution, х 400; b - nanostructured chip fragment

In the process of experimental studies, the possibility of improving the quality of the surfaces of fiber composites during high-speed processing using new original designs of multi-blade router cutters was also confirmed (see Fig. 1, c, d and 2). When conducting the experimental studies of the influence of cutting modes on roughness parameters, carbon-plastic witness samples were used (Fig. 11, a ). They were obtained in parallel from the same material that was used for the manufacture of products (Fig. 11, b ).

а

б

Рис. 11. Образцы для изучения высокоскоростного фрезерования композитов на основе углепластиков: а – образцы для испытаний; б – изделия

-

Fig. 11. Samples for studying high-speed milling of composites based on carbon fiber: a – samples for testing; b – products

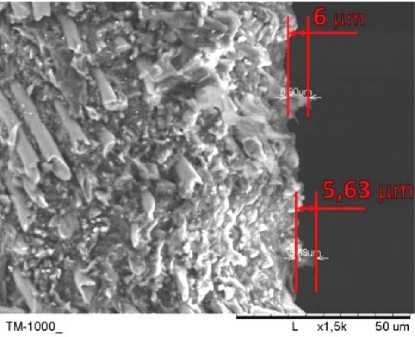

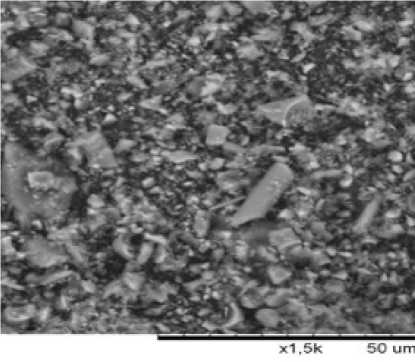

The images of the machined surfaces show that effective cross-section of fibers is ensured (Fig. 12, a, b ). This can be explained by the increased frequency of cutting cycles (up to 4000–6000 s–1). An indirect confirmation of the effectiveness of the tool is the morphology of the chips - its sizes vary in the range from 3 to 8 microns (Fig. 12, c, d ), i.e., they correlate with the roughness of the machined surface (Fig. 12, a ).

a

c

Рис. 12. Результаты электронно-микроскопического исследования:

а – обработанная поверхность стеклопластика; б – обработанная поверхность углепластика; в – морфология стружки стеклопластика; г – морфология стружки углепластика

d

-

Fig. 12. Results of electron microscopic examination:

a – machined surface of fiberglass; b – machined surface of carbon fiber;

c – morphology of fiberglass chips; d – morphology of CFRP chip

The chip crushing coefficient at a milling depth of 0.5 mm and a rotation speed of 4000 rpm is k = 250. This fact indirectly confirms the increase in the productivity of processing and the decrease in the specific cutting force.

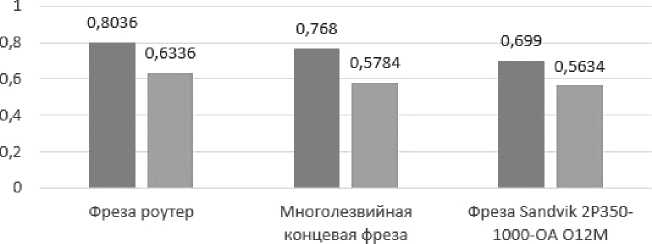

The use of high-speed processing of parts made of composite materials confirms the effectiveness of using new designs of multi-edge milling cutters (the quality of processing corresponds to the characteristics of the world's best analogues). As confirmation, the results of experimental studies are presented in the form of comparative diagrams of measuring the surface roughness of carbon fiber reinforced plastics according to the parameters Ra and Rz using different types of cutters (Fig. 13, 14).

■ Подача fz - 0,004 мм/зуб; Скорость резания V - 251,2 м/мин

■ Подача fz - 0,001 мм/зуб; Скорость резания V - 376,8 м/мин

Рис. 13. Шероховатость обработанной поверхности Ra после сравнительных испытаний различными конструкциями фрез

Fig. 13. Roughness of the machined surface Ra after comparative tests with different cutter designs

■ Подача fz - 0,004 мм/зуб; Скорость резания V - 251,2 м/мин

■ Подача fz - 0,001 мм/зуб; Скорость резания V - 376,8 м/мин

Рис. 14. Результаты замеров параметра Rz после сравнительных испытаний

-

Fig. 14. Results of measurements of parameter Rz after comparative tests

Conclusion

Based on the results of a complex of computational and experimental studies, the following main conclusions can be made:

-

1. The semi-empirical calculation formulae proposed on the basis of research adequately reflect the results of full-scale experiments and make it possible to determine rational cutting modes for obtaining complex surfaces such as an equiaxed contour.

-

2. Full-scale experiments confirmed the practical significance and technical and economic efficiency of the proposed design and technological solutions: complex drive parts were manufactured by milling, and the processing time was reduced from 6 hours to 18 minutes on a G-64S electrical discharge machine (in the basic version of the technological process).

-

3. The multi-edge design of the new cutter-router with a trapezoidal shape of the cutting edge of the tooth ensures an increase in the quality of processing composite materials, namely, reduction in the roughness and defects of the surface layer (at the level of the world's best analogues).

-

4. The experimental studies made it possible to evaluate the influence of cutting modes, geometric parameters of the cutting part of the tool (profile and number of teeth), kinematics of relative movement in the “tool – workpiece” system on the shape and dimensions of a complex contour surface obtained by milling.

Список литературы Features of processes of high-speed milling with a complex profile tool in the processing of aluminum alloys and composite materials

- De Oliveira F. B. et al. Size effect and minimum chip thickness in micromilling. International Journal of Machine Tools and Manufacture. 2015, Vol. 89, P. 39–54. Doi: https://doi.org/10.1016/j.ijmachtools.2014.11.001.

- Chuzhoy L., Devor R. E., Kapoor S. G. et al. Microstructure-level modeling of ductile iron machining. J. Manuf. Sci. Eng. 2002, Vol. 124, No. 2, P. 162–169. Doi: https://doi.org/10.1115/ 1.1455642.

- Cuba Ramos A., Autenrieth H., Strauß T. et al. Characterization of the transition from ploughing to cutting in micro machining and evaluation of the minimum thickness of cut. J. Mater. Process. Technol. 2012, Vol. 212, No. 3, P. 594–600. Doi: https://doi.org/10.1016/j.jmatprotec.2011.07.007.

- Hideaki O., Koji U., Ippei K. et al. High speed milling processes with long oblique cutting edges. J. Manuf. Process. 2015, Vol. 19, P. 95–101. Doi: https://doi.org/10.1016/j.jmapro.2015.06.004.

- Patraev E. V., Vakulin M. S., Gordeev Yu. I., Yasinsky V. B. [High-speed micro-milling of parts made of composite materials and aluminum alloys]. Proceedings of Universities of Mechanical Engineering. 2021. No. 12 (741), P. 62–72. Doi: doi: 10.18698/0536-1044-2021-12-62-72. Doi: 10.18698/0536-1044-2021-12-62–72.

- Vorontsov A. L., Sultan-Zade N. M., Albagachiev A. Yu. [Development of a new cutting theory. 1. Introduction]. Vestnik Mashinostroeniya. 2008, No. 1, P. 57–67. Doi: https://www.elibrary. ru/item.asp?id=9947574.

- Vogler M. P., Devor R. E., Kapoor S. G. On the modeling and analysis of machining performance in micro-end milling. J. Manuf. Sci. Eng. 2004. vol. 126, no. 4, pp. 685–694, doi: https://doi.org/10.1115/1.1813470.

- Hideaki O, Koji U, Ippei K, Junichi H, Yasuhiro N. High speed processes with long oblique cutting edges. Journal of Manufacturing Processes. 2015, Vol. 19, P. 95–101. Doi: https://doi.org/10.1016/j.jmapro.2015.06.004.

- Furukawa Y., Moronuki N. Effect of material properties on ultra precise cutting processes. Ann. CIRP 1988, Vol. 37 (1), P. 113–116. Doi: https://doi.org/10.1016/S0007-8506(07)61598-4.

- Cheng K., Huo D. Micro-Cutting Fundamentals and Applications, 1th ed., Wiley, United Kingdom, 2013, 348 p.

- Kim J., Kim S. D. Theoretical analysis of micro-cutting characteristics in ultraprecision machining. J. Mater. Process. Technol. 1995, Vol. 49 (3–4), P. 387–398. Doi: https://doi.org/10.1016/0924-0136(94)01345-2.

- Chae J., Park S. S., Freiheit T. Investigation of micro-cutting operations. Int. J. Mach. Tools Manuf. 2006, Vol. 46, P. 313–332. Doi: https://doi.org/10.1016/j.ijmachtools.2005.05.015.

- Wang Z., Kovvuri V., Araujo A. et al. Built-up-edge effects on surface deterioration in micromilling processes. J. Manuf. Process. 2016, Vol. 24, P. 321–327. Doi: https://doi.org/10.1016/j.jmapro.2016.03.016.

- Niu F. Jiao, Cheng K. An innovative investigation on chip formation mechanisms in micromilling using natural diamond and tungsten carbide tools. J. Manuf. Process. 2018, Vol. 31, P. 382–394. Doi: https://doi.org/10.1016/j.jmapro.2017.11.023.

- Binchurov A. S. et al. Influence of cutting modes on power characteristics of rotational turning by multifaceted cutters. IOP Conference Series: Materials Science and Engineering (IOP Publishing 537 No. 3). 2019, P. 032101. Doi: 10.1088/1757-899X/537/3/032101.

- Andryushchenko S. A., Rostovtsev P. A., Roshchupkin S. I. [Experimental study of the influence of machining strategies on surface roughness when milling aluminum alloys with end mills]. Sovremennye tekhnologii: problemy i perspektivy. 2019, P. 11–15 (In Russ.).

- Trusov V. N., Zanov O. I., Shikin V. V. [Investigation of the parameters of the milling process of aluminum alloy D16T]. Vestnik Samarskogo gosudarstvennogo tekhnicheskogo universiteta. Seriya: Tekhnicheskie nauki. 2012, No. 3 (35), P. 155–162 (In Russ).

- Kulikov M. Yu., Inozemtsev V. E., Bocharov A. A. [Study of the process of shaping when combining milling and electrochemical processing of aluminum]. Metalloobrabotka. 2015, No. 6 (90), P. 50–53 (In Russ.).

- Demin A. S., Lavrentiev S. V. [DLC coated cutting tool for aluminum alloy machining]. Problems, prospects and directions of innovative development of science: Sat. articles of the International scientific and practical conference (Omsk, November 24, 2017), Part 3, Sterlitamak, AMI, 2017, P. 116–118 (In Russ.).

- Kovalevsky A. V. [Choice of rational milling modes for processing aluminum alloys]. Omskiy nauchnyy vestnik. 2008, No. 4 (73), P. 64–66 (In Russ.).

- Vavilin V. A., Pasechnik K. A., Pushkarev A. Yu., Amelchenko N. A. [Features of mechanical processing of polymer composite materials]. Aktual'nye problemy aviatsii i kosmonavtiki. 2018, Vol. 1, No. 14, P. 12–14 (In Russ.).

- Abd Halim N. F. H., Ascroft H., Barnes S. Analysis of tool wear, cutting force, surface roughness and machining temperature during finishing operation of ultrasonic assisted milling (UAM) of carbon fibre reinforced plastic (CFRP). Procedia Engineering. 2017, Vol. 184, P. 185–191. Doi: https://doi.org/10.1016/j.proeng.2017.04.084.

- Meshkas A. E., Makarov V. F., Shirinkin V. V. [Technologies to improve the efficiency of processing composite materials by milling]. Izvestiya Tul'skogo gos. un-ta. Tekhnicheskie nauki. 2016, No. 8-2, P. 291–299 (In Russ.).

- Sturov A. A., Chashchin N. S. [Machining of a composite material using a robotic complex based on the Kuka KR210 robot]. Vestnik Irkutskogo gos. tekh. un-ta. 2019. V. 23, no. 4 (147), p. 743–750 (In Russ.).

- Minibaev M. I., Raskutin A. E., Goncharov V. A. Features of the technology for manufacturing samples from PCM on CNC machines (review). Proceedings of VIAM. 2019, No. 1 (73), P. 105–114. Doi: 10.18577/2307-6046-2019-0-1-105-114.

- Raskutin A. E., Khrulkov A. V., Girsh R. I. Technological features of mechanical processing of composite materials in the manufacture of structural parts (review). Proceedings of VIAM. 2016, No. 9 (45), P. 106–118. Doi: 10.18577/2307-6046-2016-0-9-12-12.

- Gordeev Yu. I. et al. [Influence of kinematic and technological parameters of rotary turning by multifaceted cutters on chip formation and surface roughness]. Siberian journal of science and technology. 2017, Vol. 18, No. 2, P. 379–386 (In Russ.).

- Gordeev Y. I., Yasinsky V. B., Spirin E. A. et al. Simulation of high-speed machining processes by multi-edge mills. Journal of Physics: Conference Series. – IOP Publishing, 2022, Vol. 2373, No. 3, P. 032012. Doi: 10.1088/1742-6596/2373/3/032012.

- Binchurov A. S. et al. 2019 Influence of cutting modes on power characteristics of rotational turning by multifaceted cutters. IOP Conference Series: Materials Science and Engineering (IOP Publishing 537 № 3). P. 032101. Doi: 10.1088/1757-899X/537/3/032101.

- Timchenko A. I. Tekhnologiya izgotovleniya detaley profil'nykh besshponochnykh soedineniy [Technology for the manufacture of details of profile keyless joints]. Moscow, VNIITEMR Publ., 1988, 160 p.

- 31.Vakulin M. S., Gordeev Yu. I., Yasinsky V. B. Design of tools with the cutting part of the original profile for high-speed milling. IOP Conference Series: Materials Science and Engineering. 2020, 754(1), P. 012008. Doi: 10.1088/1757-899X/754/1/012008.

- Gordeev Y. I. et al. Investigation of nanostructured hard metal composites obtained from powder mixtures (WC-Co)-Al2O3. Journal of Physics: Conference Series. – IOP Publishing. 2022, Vol. 2373, No. 3, P. 032025. Doi: 10.1088/1757-899X/754/1/012008.

- Gordeev Y. I., Yasinsky V. B., Binchurov A. S. et al. Combined Application of Composite Powders WC-Co and Additives of Nanoparticles as an Effective Method of Improving the Properties of Hard Metals. Key Engineering Materials. 2018, Vol. 769, P. 134–140. Doi: https://doi.org/10.4028/www.scientific.net/KEM.769.134.