Fish drying using different drying methods at different temperatures for fish Tilapia nilotica (Oreochromis niloticus)

Автор: Abdel Moneim babkr, Mortada Elhesain, Omer Osman, Waleed Salih, Yasir Mohamed

Журнал: Вестник Воронежского государственного университета инженерных технологий @vestnik-vsuet

Рубрика: Пищевая биотехнология

Статья в выпуске: 3 (89), 2021 года.

Бесплатный доступ

Тhis study was conducted at the Institute of Agricultural Engineering and Food Processing, Georg-August University, Gottening- Germany during the year 2016. The objectives of the study were to investigate the effect of drying method using three levels of drying temperatures on drying rate and drying time of fish Tilapia nilotica (Oreochromis niloticus). These methods are hot air (oven) drying; Microwave drying and infrared drying. The levels of temperatures were 40, 50 and 60˚C for each of the drying method. The results show that, there is direct relationship between drying temperature and drying rate and inverse relationship between temperature and drying time i.e. as the temperature of the drying increases the drying rate will increase and the drying time will decrease and vice versa. For oven drying method the lowest drying time was obtained at temperature of 60°C (7 hours) and the highest drying time was encountered at temperature 40°C (17 hours). Also the highest drying rate (37.232g water∕100 g of DM ∕hour) was found at temperature of 60°C and the lowest drying rate (14.936 g water∕100 g of DM ∕hour) was obtained at temperature of 40° C. When using Microwave drying method the lowest drying time was obtained at temperature of 60°C (5 hours) and the highest drying time was obtained at temperature 40° C (22 hours) and the highest drying rate (52.208 g water∕100 g of DM ∕hour) was obtained at temperature of 60°C and the lowest drying rate (11.032 g water∕100 g of DM ∕hour was obtained at temperature of 40°C. In case of infrared drying method the low drying time was obtained at temperature of 60°C (8 hours) and the highest drying time was found at temperature 40°C (14 hours) and the highest drying rate (39.589 g water∕100 g of DM ∕hour) was obtained at temperature of 60°C and the lowest drying rate (18.009 g water∕100 g of DM ∕hour) was obtained at temperature of 40°C. Statistical analysis using Eviews program show that microwave gives better results.

Fish Tilapia, Drying methods, Drying time, Drying rate, Microwave, Infrared, Hot air, oven drying

Короткий адрес: https://sciup.org/140259870

IDR: 140259870 | УДК: 66.047.3 | DOI: 10.20914/2310-1202-2021-3-115-120

Текст научной статьи Fish drying using different drying methods at different temperatures for fish Tilapia nilotica (Oreochromis niloticus)

DOI:

Fish provides a good source of high quality protein and contains many vitamins and minerals; which are almost cheaper than any other type of meat and therefore available for large number of people (Fellows and Hamptum, 1992). Rural areas depend mainly on fish in their diet; the husbandry of fish is not expensive when compared to other types of animals raised for meat production. Every year, large quantities of meat have been lost because of inadequate preservation and storage of meat. This is due to the high moisture content present in meat and consequently the rate of growth and development of micro-organisms; insects and mites increase very rapidly. Fish is an extremely perishable food, and both quantity and quality will be reduced after catching the fish. For example most fish become inedible within 12 hours at tropical temperatures; spoilage begins as soon as the fish dies (Fellows and Hamptum, 1992). The traditional methods of fish preservation and storage include, under direct sun drying salting and smoking. These processes are neither effective nor economical and they are not possible under adverse conditions. These processes can be done under unhealthy conditions. Drying is one of the oldest methods of food preservation, and is a difficult food processing operation mainly because of undesirable changes in the quality of the dried product and it is one of the most common processes used to improve food stability. It decreases the water activity of the product, reduces microbiological activity and minimizes physical and chemical changes during storage (Mayor and Sereno, 2004). Long shelf life, product diversity and substantial volume reduction are reasons for popularity of dried products, and this could be expanded further in improvement in product quality and process application. These improvements could increase the current degree of acceptance of dehydration foods in the market

This is an open access article distributed under the terms of the Creative Commons Attribution 4.0 International License

(Maskan, 2001); Akpinar, E.K. et al. (2003). Sun drying is the most common method used to preserve food products in the world. It is easy method and with low cost. Despite the popularity of this method, it has some problems related to the contamination with dust, soil, sand particles and insects, and being weather dependent. Also, the required drying time can be quite long. Therefore drying process should be under taken in close equipment’s to improve the quality of the final products (Erekin and Yaldiz, 2004). The main aim of drying products is to allow longer period of storage, minimize packaging requirements and reduce shipping weights (Okos, etal.1992). Several drying methods are commercially available and the selection of optimum method is determined by quality requirements, raw materials characteristics and economic factors. The application of microwave energy to dry materials may be a good approach to overcome the problems of conventional drying techniques, infrared drying is an effective method of dehydration. Infrared is used to heat or to dry moist materials, the radiation reached the exposed materials penetrates it and the energy of radiation converts into sensible heat. Since the materials are heated intensely, the temperature gradient in the material reduces within the short period. Therefore, energy consumption in infrared drying process is relatively lesser, (Ginzburg, A.S., 1969; Hebbar and Rostagi, 2001). The temperature had a significant effect on drying time and drying rate of food materials. The drying rate was highly dependent on drying temperatures resulting in faster drying. Therefore, the aim of this study is to:

Determine the effect of different temperatures on drying rate and drying time of fish (Tilapia) using hot air (oven), microwave and infrared drying methods at temperatures of 40, 50, and 60 °C .

Materials and methods

Materials and equipment

Fresh fish Tilapia nilotica (Oreochromis niloticus) of the same age and treated with the same conditions, were brought from the Institute of Animal Husbandry and Genetics, Georg-August University, Gottening – Germany for running the experiments. The average growth weight of fish (samples) was about 180 grams for each. Head and tail were cut and removed using stainless steel knife. Then the fish were cut longitudinally and all internal parts of gut, liver, gall bladder and fats were removed (fats become rancid easily and will spoil the dried fish). The split fish were thoroughly cleaned and weighed for initial moisture content determination and running the experiments. These fish (fresh) were then sealed into double layer polyethylene bags and stored in a refrigerator (below 5 ̊C) until the time of running the experiments and measuring. The required Samples were removed from storage refrigerator one day prior the test and kept overnight in double-layer plastic bags at room temperature (to maintain the normal temperature of fish at time of drying).

Initial moisture content determination

Moisture content was determined according to AOAC, (1995) and AOAC, (2007). A representative sample was taken, weighed and put in an oven at 105 °C for overnight, then the final weight was recorded (bone dry weight).

The moisture content was determined using the fallowing equation:

MC (w. b.) = ×100 (1)

MC (d. b.) = ×100 (2)

where MC (w. b.) = moisture content on wet basis, grams; MC (d. b.) = moisture content on dry basis, grams; Ww = weight of water, grams; Wd = weight of dry, grams.

The duplicated samples were used then an average was taken.

Drying rate calculation

The drying rate was calculated using the fallowing equation (Akpinar, E.K. etal, 2003).

DR = Mt + dt – M. 100 (3)

dt v 7

where DR = drying rate, g of water / 100 g of dry matter/hour; Mt + dt = moisture content at time t + dt dry basis (percentage); Mt = moisture content at time t dry basis (percentage); dt = the time interval, hours.

Drying experiments

After preparation of fish as mentioned above, three methods of drying were applied; these are namely hot air (oven), microwave and infrared drying methods. These methods were done, using three temperatures 40, 50 and 60 C for each method of drying. The decrease in dried sample weight was recorded every one hour interval using sensitive balance (SATRIUS GMBH, Tyoe L 610 D, Fabr. – Nr. 35110073, Germany).with maximum capacity of 600 grams; accuracy of the balance was ± 0.001 g. the drying experiments were continued till the final weight at which the targeted moisture content was achieved, was reached. It is about 13 % (w.b.) as shown by Prabhu, P.V. and Balachandran, K.k. (1982).

-

(i) Hot air oven drying method:

Heracus Oven D. 6450 Hanau. Type UT 6120, Temperature 300 ̊ C and AC 230 volt was used for three different temperatures 40, 50 and 60 ̊C. The experiments were run and the weight losses in fish were recorded every one hour interval using sensitive balance till the weight equivalent to the target moisture content (13 % w.b.) was attained

Two replicates for each drying temperature were carried out then an average was taken for each temperature measurement.

-

(II) A Microwave EMG. Engineering, Ruthen – Hemmern, 2001, Type No. 222801, 400 volt, 50Hz, 12 A, with a maximum output of 1200 W was used for drying experiments.

The dimensions of microwaves cavity were 600 mm • 600mm • 600mm. In the roof of drying chamber or cavity there is a fan which is used to cool the system. Three drying temperatures 40, 50, 60 ̊C were investigated in the drying experiments at microwave power of 120 W. Moisture losses were recorded every one hour interval during the drying by removing the sample from the microwave and placing it in a digital sensitive balance, The microwave power was applied until the mass of the sample was reduced to a level corresponding to the target moisture content (13 % w.b.). Two replicates for each drying temperature were carried out then an average was taken for each temperature measurements.

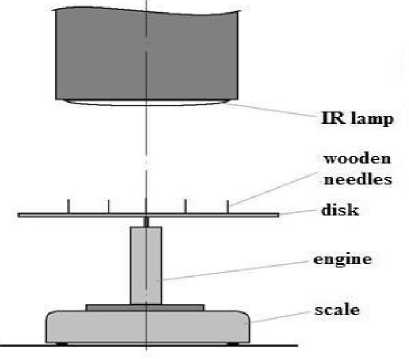

Fig 1 shows the schematic diagram for the instruction of microwave device. The microwave operated or works by conversion the high voltage of electricity to electromagnetic waves using a migration. The electromagnetic was used as an energy for fish drying.

Figure 1. Schematic diagram of a microwave device

-

(III) Infrared drying methods:

In this study a Radiator, 220/230 V ELS TEEN FSR 1300 W, Germany made. Transmit electromagnetic radiation in the range of medium to short wave infra radiation was used as drying equipment. The experiment was carried out for 40, 50, 60 ̊C drying temperatures, the loss in weight (moisture content losses) of the sample was recorded every one hour interval by removing the sample from the Radiator and placing it in digital sensitive balance till we reach the weight corresponding to the target moisture content(13 % w.b.). Two replicates were run then an average was taken.

Temperature measurements:

The three temperature 40, 50, 60 ̊C was measured using thermometer and sensors (Luxtron 790 Fluoropic thermometer with SIW-2 Sensors, U.S.A.). This was done for all the three drying methods.

Fig 2 shows the schematic diagram for the instruction of infrared device. As show in the diagram the engine convert electricity power to light using an infrared lamp. This light was used for fish drying.

Figure 2. Schematic view of the experimental drying infrared device

Statistical Analysis

Statistical Analysis using Eviews program version 8 was used to show the best method of the drying.

Results and Discussions

Fish Tilapia, drying started with an initial moisture content of 76 % (w.b.)and continued to final moisture content of about 13 % (w.b.) using different drying methods (microwave, infrared and oven drying method) at different temperatures of 40, 50 and 60 ℃ for each method.

Table 1 shows an average drying rate (g water / 100 g DM / h) with drying time using different drying methods at different temperatures. As, it was observed, increasing the drying temperature caused significant increase in the drying rate, thus the drying time is decreased. In general, the highest drying rate was obtained at 60 ℃ and the lowest at 40 ℃ for all the drying methods.

Table 1.

Drying rate versus drying time using different drying methods at different temperatures for fish Tilapia

|

Drying Methods |

Drying Temperature (°C) |

Drying time (hours) |

Average Drying Rate (g water-100 g of DM)/hour |

|

Microwave drying |

40 |

22 |

11.032 |

|

Infrared drying |

40 |

14 |

18.009 |

|

Oven drying |

40 |

17 |

14.936 |

|

Microwave drying |

50 |

8 |

31.465 |

|

Infrared drying |

50 |

12 |

21.037 |

|

Oven drying |

50 |

10 |

25.104 |

|

Microwave drying |

60 |

5 |

52.208 |

|

Infrared drying |

60 |

8 |

39.584 |

|

Oven drying |

60 |

7 |

37.232 |

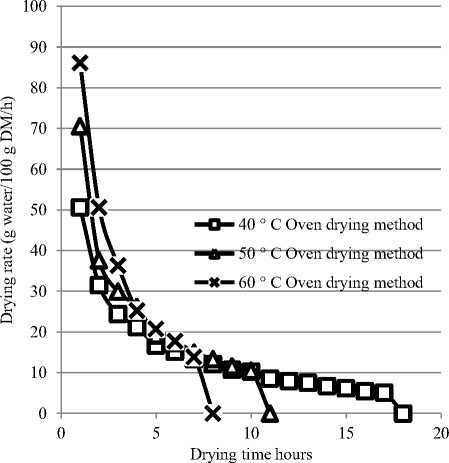

Figure 3. Variation of drying rate with time at the same method of dring (oven drying) at different drying temperatures

Fig. 3 show the variation of drying rate for fish Tilapia using an oven drying method at different temperatures 40, 50 and 60 °C. It is clear, that as the temperature of drying increases the drying time will decrease and the drying rate will increase for oven drying method. The lowest drying time was obtained at temperature of 60 °C (7 hours). Also the highest drying time was attained at temperature 40 °C (17 hours). It is apparent that, the drying rate decreases continuously with drying time. There is no constant-rate drying period in the curve and all the drying operations seemed to occur in the falling rate period.

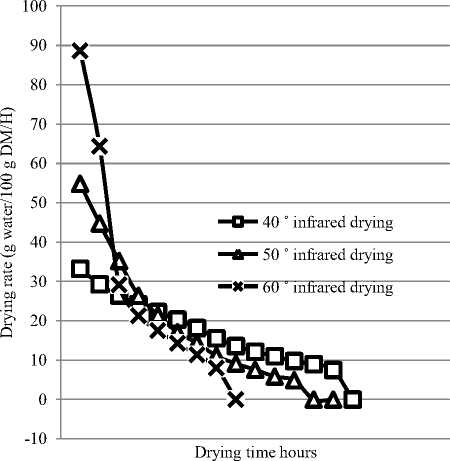

Fig. 4 shows the variation of drying rate for fish Tilapia using infrared drying method at different temperatures 40, 50 and 60 °C. It is clear that as the temperature of drying increases, the drying time will decrease and the drying rate will increase for infrared drying method. The lowest drying time was obtained at temperature of 60 °C (8 hours) and the highest drying time will obtained at temperature 40 °C (14 hours). Also it is apparent that, drying rate decreases continuously with drying time. There is no constant-rate drying period in the curve and all the drying operations occurred in the falling rate period.

Figure 4. Variation of drying rate with drying time using the same method (infrared drying) at different temperatures

X 5 10

Figure 5. Variation of drying rate with drying time using the same drying method (microwave) at different drying temperatures

—D— 40 C ° microwave drying )

A 60 C ° microwave drying )

50 C ° microwave drying )

Fig. 5 show the variation of drying rate for fish Tilapia using microwave drying method at different drying temperatures 40, 50 and 60 °C. It is clear that as the temperature of drying increase the drying time will decrease and the drying rate will increase for microwave drying method. The low drying time were obtained at temperature of 60 °C (5 hours), and the highest drying time will obtained at temperature 40 °C (22 hours). It is apparent that drying rate decreases continuously with drying time. There is no constant-rate drying period in the curve and all the drying operations are seen to occur in the falling rate period. These result are in good agreement as compared to the earlier observations (Kaymak-Ertekin, 2002; Passa-mai and Saravia, 1997a, b;Togrul and Pehlivan, 2002; Yaldiz and Ertekin, 2001 ; Yaldiz et al 2001).

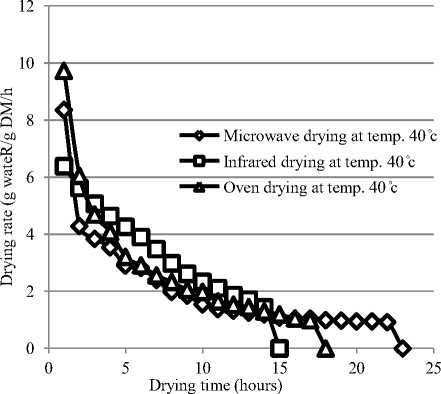

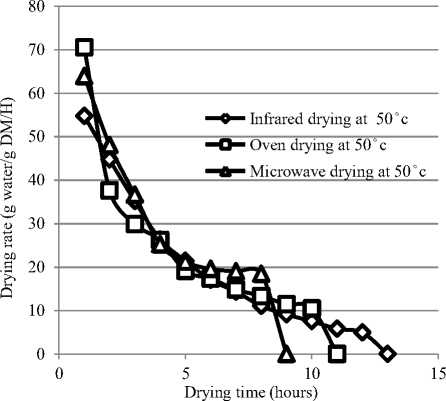

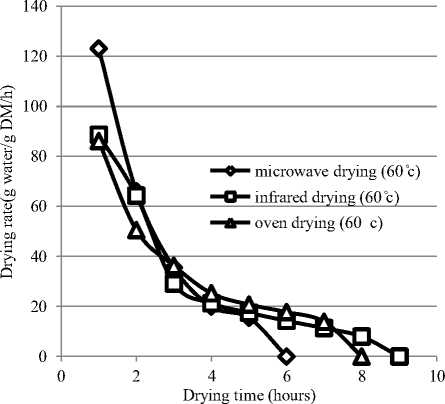

Figures 6, 7 and 8 show the comparison between the drying rate and the drying time using different drying methods (microwave, infrared and oven drying) with the same temperature for each method. Three levels of temperature were used, these are 40, 50 and 60 °C as shown in Figures 4.5 and 6 respectively. Microwave drying show a significant effect When using low temperature (40 °C), there is an increase in drying time (22 hours) and decrease in drying rate (11.032 g water/100 g DM / h). but for the high temperature (60 °C), there is a significant increase in drying rate (52.208 g water / 100 g DM / h) and low drying time (5 hours). For the others two drying methods (oven and infrared drying methods) there were an increase and decrease in drying rate and drying time respectively, with high temperature 60 °C. Generally there is an increase in drying rate and decrease in drying time when the temperature of the drying increase regardless of the drying method used, but microwave show more responses when compared to others two drying methods i.e gives high drying rate and low drying time when using high and medium temperatures.

Figure 6. Comparison between drying rate and drying time using different drying methods at the same tempearture. 40 ℃

Figure 7. Comparison between drying rate and drying time using different drying methods at the same tempearture. 50 ℃

Figure 8. Comparison between drying rate and drying time using different drying methods at the same temp. 60 ℃

Table 2.

The results of statistical analysis for, Mean, Std. Dev. and Probability at different temperatures for fish Tilapia

|

Method of drying |

Temp. of drying (Co) |

Mean |

Std. Dev. |

Probability |

|

Oven |

40 |

11.54086 |

12.08028 |

0.000046 |

|

50 |

11.41100 |

17.48618 |

0.000001 |

|

|

60 |

11.39200 |

21.83248 |

0.000000 |

|

|

Microwave |

40 |

11.03223 |

9.037603 |

0.000000 |

|

50 |

11.44227 |

18.23260 |

0.005248 |

|

|

60 |

11.82295 |

29.55629 |

0.000000 |

|

|

Infrared |

40 |

11.45759 |

10.93544 |

0.432711 |

|

50 |

11.47495 |

15.91761 |

0.011710 |

|

|

60 |

11.56491 |

22.94372 |

0.000000 |

From the table 2 it’s clear that the level of significant for microwave methods is far less than p ≤ 0.05. So that microwave drying gives the best results and can be considered at the best method of drying.

Conclusion

Fish Tilapia nilotica (Oreochromis niloticus) were dried using three drying methods (hot air oven, microwave and infrared) at three levels of temperatures (40, 50, and 60 °C) for each method. The results show that, as the temperature of drying increase, drying rate will increase and the drying time will decrease for all methods of drying. Statistical analysis using Eviews program shows that microwave method is better than two others methods of drying.

Список литературы Fish drying using different drying methods at different temperatures for fish Tilapia nilotica (Oreochromis niloticus)

- Adeyeye S.A.O. An overview of fish drying kinetics. Nutrition & Food Science. 2019. doi: 10.1108/NFS-10-2018-0296

- AOAC. Official methods of analysis. Washington, USA, Association of Official Agricultural Chemists, 1995.

- AOAC. Official methods of analysis 20ed. Washington, USA, Association of Official Agricultural Chemists, 2007.

- Mehta P., Samaddar S., Patel P., Markam B. et al. Design and performance analysis of a mixed mode tent-type solar dryer for fish-drying in coastal areas. Solar Energy. 2018. vol. 170. pp. 671-681. doi: 10.1016/j.solener.2018.05.095

- Kubra K., Hoque M.S., Hossen S., Husna A.U. et al. Fish drying and socio-economic condition of dried fish producers in the coastal region of Bangladesh. Middle-East J. Sci. Res. 2020. vol. 28. no. 3. pp. 182-192. doi: 10.5829/idosi.mejsr.2020.182.192

- Richa R., Shahi N.C., Lohani U.C., Kothakota A. et al. Design and development of resistance heating apparatus‐cum‐solar drying system for enhancing fish drying rate. Journal of Food Process Engineering. 2021. pp. e13839. doi: 10.1111/jfpe.13839

- Darvishi H., Azadbakht M., Rezaeiasl A., Farhang A. Drying characteristics of sardine fish dried with microwave heating. Journal of the Saudi Society of Agricultural Sciences. 2013. vol. 12. no. 2. pp. 121-127. doi: 10.1016/j.jssas.2012.09.002

- Aberoumand A., Abad M.K.R. Influences of drying methods processing on nutritional properties of three fish spe-cies Govazym stranded tail, Hamoor and Zeminkan. International Food Research Journal. 2015. vol. 22. no. 6. pp. 2309.

- Yuwana Y., Sidebang B. Performance testing of the hybrid solar-biomass dryer for fish drying. International Jour-nal of Modern Engineering Research. 2016. vol. 6. no. 11. pp. 63-68.

- Aghbashlo M., Mobli H., Madadlou A., Rafiee S. Influence of wall material and inlet drying air temperature on the microencapsulation of fish oil by spray drying. Food and Bioprocess Technology. 2013. vol. 6. no. 6. pp. 1561-1569. doi: 10.1007/s11947-012-0796-7

- Aghbashlo M., Mobli H., Rafiee S., Madadlou A. Energy and exergy analyses of the spray drying process of fish oil microencapsulation. Biosystems Engineering. 2012. vol. 111. no. 2. pp. 229-241. doi: 10.1016/j.biosystemseng.2011.12.001

- Mohod A.G., Khandetod Y.P., Shrirame H.Y. Development and evaluation of solar tunnel dryer for commercial fish dry-ing. Journal of The Institution of Engineers (India): Series A. 2014. vol. 95. no. 1. pp. 1-8. doi: 10.1007/s40030-014-0070-2

- Encina C., Vergara C., Giménez B., Oyarzún-Ampuero F. et al. Conventional spray-drying and future trends for the microencapsulation of fish oil. Trends in Food Science & Technology. 2016. vol. 56. pp. 46-60. doi: 10.1016/j.tifs.2016.07.014

- Janjai S., Bala B. K. Solar drying technology. Food Engineering Reviews. 2012. vol. 4. no. 1. pp. 16-54. doi: 10.1007/s12393-011-9044-6

- Nagwekar N., Tidke V., Thorat B.N. Microbial and biochemical analysis of dried fish and comparative study using different drying methods. Drying Technology. 2017. vol. 35. no. 12. pp. 1481-1491. doi: 10.1080/07373937.2016.1256889

- Kipcak A.S., İsmail O. Microwave drying of fish, chicken and beef samples. Journal of Food Science and Technol-ogy. 2021. vol. 58. pp. 281-291. doi: 10.1007/s13197-020-04540-0

- Hu Y., Que T., Fang Z., Liu W. et al. Effect of different drying methods on the protein and product quality of hair-tail fish meat gel. Drying Technology. 2013. vol. 31. no. 13-14. pp. 1707-1714. doi: 10.1080/07373937.2013.794831

- Ghimire A., Basnet S., Poudel R., Ghimire A. Mathematical modeling of thin layer microwave drying of Jaya fish (Aspi-doparia jaya). Food Science and Technology International. 2021. vol. 27. no. 6. pp. 508-516. doi: 10.1177/1082013220969353

- Storer T., Bannister J., Bennett K., Byrnes E. et al. Influence of discharge regime on the movement and refuge use of a freshwater fish in a drying temperate region. Ecohydrology. 2021. vol. 14. no. 1. pp. e2253. doi: 10.1002/eco.2253

- Ershov A.M., Ershov M.A., Pokholchenko V.A. Similarity effects of dehydration at the processes of fish drying, smoking and frying. Proceedings of International scientific and technical Conference named after Leonardo da Vinci. 2014. vol. 2. pp. 26-35.