Formation of porous structures in production technology of construction materials based on building gypsum plaster

Автор: Anna I. Kurmangalieva, Lyubov A. Anikanova, Aleksander I. Kudyakov, Aleksey B. Steshenko, Aleksander F. Buryanov, Nadezhda A. Lukyanova, Aleksander S. Inozemtsev, Segey S. Inozemtsev

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Construction materials science

Статья в выпуске: 4 Vol.15, 2023 года.

Бесплатный доступ

Introduction. This article presents the results of the research works on formation of building gypsum plaster porous structure with the use of recovered anhydrite raw materials and chemical additives, and describes a method for production of wall materials. The relevance of this paper is stipulated by the need to expand the range and increase the manufacture of heat-insulating and structural-heat-insulating products based on gypsum binders and local mineral raw materials, as well as the development of technologies to ensure the production of gypsum materials with improved performance. The authors proposed certain methods for forming the porous structure of building gypsum plaster and improving its performance in terms of porosity and thermal conductivity through the use of modified recovered raw materials and chemical additives of calcium chloride and sodium carbonate. Materials and methods. The study of the effect of modifying additives on the properties of the mixture was carried out using gypsum paste of normal consistency (NC = 55%). The preparation of samples and testing were performed according to the methods specified in the national standards with the use of porous additives of calcium carbonate, fluoroanhydrite and chemical additives for the rheological properties of the mixture, average density and strength of the samples, the patterns and mechanism of the processes of gypsum stone structure formation were established. Results. The application of fluoroanhydrite modified in the disintegrator with an equimolar amount of calcium carbonate leads to a decrease in the average density of the samples to 40% with evenly distributed pores. The analysis of the microstructure of heat-insulating material samples with a density of 550 kg/m3 showed that the average diameter of micropores is 0.45 mm, while the thermal conductivity of samples with complex chemical additives has the thermal conductivity coefficient of 0.25 W/m°C, which is 30% lower than the thermal conductivity of samples without complex additives. Conclusions. The results obtained create the basis for using recovery raw materials and domestic modifying additives as a pore-forming agent, which allow regulating the structure of gypsum stone in order to produce effective wall materials.

Gypsum matrix, pore-forming additives, structure formation, compressive resistance, average density

Короткий адрес: https://sciup.org/142238302

IDR: 142238302 | DOI: 10.15828/2075-8545-2023-15-4-319-327

Текст научной статьи Formation of porous structures in production technology of construction materials based on building gypsum plaster

Research article

The strategic development of the construction industry in Russia until 2035 is based on the implementation of effective measures and tools to provide sites with high quality construction materials made with the maximum use of local raw materials, including industrial waste. A great attention is paid to technologies for production of wall materials ensuring the consistently required load-bearing capacity, thermal protection during operation and low cost of buildings. In connection with changes in desires and requirements of the popula-

CONSTRUCTION MATERIALS SCIENCE tion for the comfort of living, special attention is paid to the resource provision of wall materials in private house building (PHB). The main controlled requirements for the quality of wall materials used, which ensure the safety and energy efficiency of a building, include compressive resistance and thermal conductivity. The choice of wall materials and components for their manufacture depends on the construction technology – prefabricated or monolithic. Most often, when manufacturing products to form a porous matrix, mineral binders and various pore-gas-forming additives, and fillers – dense porous mineral or organic granular materials of various sizes – are used [1–5]. The quality of wall materials depends on the strength of interpore partitions (type of the binder), as well as the size, content and distribution of pores in the volume. Therefore, studies on controlling the process of formation and preservation of the porous structure of wall materials, depending on the type of the raw material used and operating conditions throughout the entire life cycle of products, are in demand and of scientific interest for the development of new technologies.

For production of wall materials, the use of composite gypsum binders is considered effective and promising. Expansion of the range and increase in manufacture of heat-insulating and structural-heat-insulating products based on gypsum binders and local mineral raw materials is a promising task, especially for the Siberian region. In regions where there are no deposits of gypsum stone – the raw material for production of building gypsum, recovered raw materials consisting of various modifications of calcium sulfate can be used as an alternative. Fluoroanhydrite – a by-product of hydrofluoric acid production, consisting mainly of anhydrous calcium sulfate – can be used as such raw material. The annual volume of fluoroanhydrite recovered raw materials of the Siberian

Chemical Plant (Tomsk) is 25 thous. tons, Halopolymer, CJSC – 70 thous. tons [6–8].

As noted in the Resolution of the Ministry of Construction, Housing and Utilities “Use of secondary resources and recovered raw materials in the field of construction, housing and utilities for 2020–2030”, the effective use of recovered resources in the production of building materials is a solution to the problem of the integrated use of natural resources, reducing the alienation of land for storage waste and pollution of the human environment.

Fluoroanhydrite is not yet widely used in the manufacture of gypsum wall materials, due to insufficient information about the patterns of formation of a stable porous structure, properties and production technologies. Based on the material composition of fluoroanhydrite, consisting of soluble and insoluble anhydrite and residual sulfuric acid adsorbed on its grains, it is proposed to use acid as a gas-forming component in a hardening building gypsum anhydrite composition.

MATERIALS AND METHODS

When conducting studies on gypsum anhydrite porous compositions, the following materials were used:

-

- building gypsum plaster of Г-5АII grade (GOST 125-2018), with the main characteristics presented in Table 1.

-

- fluoroanhydrite, composition and quality characteristics are given in Table 2. The chemical composition of recovered raw materials depends on the temperature of formation of the main product, while the furnace exit temperature can be 170–280оC. The paper specifies the fluoroanhydrite with a furnace exit temperature of 180оC, which is represented mainly by insoluble anhydrite, with residual sulfuric acid adsorbed on its

Table 1

Physical and mechanical characteristics of gypsum

|

Normal consistency, % |

Times of setting, min |

Ultimate working capacity, MPa |

Gypsum grade |

||

|

Start |

End |

Bend |

Tension |

||

|

55 |

not earlier than 6 |

not later than 30 |

2.5 |

5 |

Г — 5 А II |

Table 2

Composition and quality characteristics acid fluoroanhydrite of natural grading

|

Fluoroanhydrite furnace exit temperature |

Fluoroanhydrite chemical composition, wt. % |

Grain-size composition, partial residuals on sieves, % |

True density, kg/m3 |

Average density, kg/m3 |

||||||||

|

CaSO4p |

CaSO4н |

CaF2 |

H2SO4 |

HF |

2.5…5 |

1.25… 2.5 |

0.63… 1.25 |

0.315… 0.63 |

0.16… 0.315 |

|||

|

180о |

15 |

81.3 |

0.5 |

3.0 |

0.2 |

8.4 |

11.0 |

4.2 |

40.7 |

35.7 |

2570 |

1470 |

CONSTRUCTION MATERIALS SCIENCE grains. To conduct the studies of porous gypsum materials, the fluoroanhydrite of natural granulometry and crushed in the disintegrator to a specific surface of 300 m2/kg was used.

-

- limestone meal (GOST 14050-93) represented mainly by calcium carbonate (85%), with a specific surface area of 300 m2/kg,

-

- citric acid (GOST 31726-2012), anhydrous, specified in this paper as the gypsum anhydrite binder retarder, - chemical modifying additives – calcium chloride

(GOST 450-77) and sodium carbonate (GOST 510085).

Tests of samples taken from binders, including building gypsum plaster, fluoroanhydrite and modifying additives, were carried out in accordance with GOST 23789-2018, and the quality assessment was carried out in accordance with GOST 125-2018.

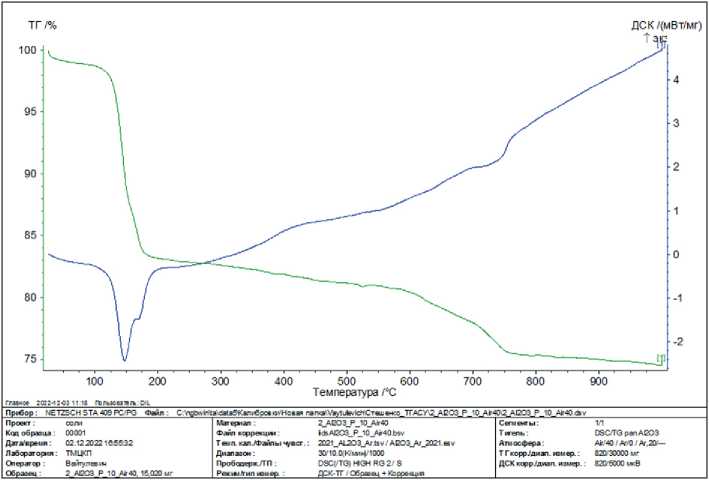

Determination of the phase composition for the components of the building gypsum plaster composition was carried out using the X-ray phase analysis performed on the XRD -6000 diffractometer (Shimadzu, Japan) with the method of powder diffraction patterns. The differential thermal analysis was carried out with the use of the Netzsch STA 409 PC/PG derivatograph (Netzsch, Germany). The programmed heating was carried out up to 1000оС at a rate of 10оС/min.

RESULTS

By analyzing the material composition of fluoroanhydrite and various mechanisms of pore formation of building materials, a working hypothesis was developed on the possibility of pore formation as a result of gas evolution during the interaction of residual sulfuric acid of fluoroanhydrite with mineral additives and control of porosity in production of wall building materials and products with increased heat-protection properties. The processes of modifying fluoroanhydrite at the stage of the manufacture of a porous wall material was studied. The controlled processes of structure formation are based on chemical reactions of neutralization of residual sulfuric acid on the grains of fluoroanhydrite with gas generation and formation of pores uniformly distributed in the volume of the material matrix. The required strength of the wall material is provided by hydration of the gypsum binder and soluble anhydrite in the recovered raw materials. Gas generation occurs according to the following chemical reaction:

CaCO3 + H2SO4 = CaSO4 + CO2 + H2О.

The swelling of the fluoroanhydrite mixture takes place due to the released carbon dioxide. The use of recovered raw materials makes it possible to significantly reduce the cost of gypsum materials. Establishment of

Table 3

Grain-size composition of fluoroanhydrite activated in the disintegrator

The main ingredients and their quantity are selected considering the equimolar ratios for complete neutralization of the residual acid of fluoroanhydrite grains with calcium and sodium carbonates. The rationally selected compositions and properties of porous gypsum anhydrite binders using the crushed fluoroanhydrite of natural grain size are presented in Tables 4 and 5.

The maximum results in terms of the compressive strength of the samples were obtained at a pH value corresponding to a neutral medium, with the use of the maximum amount of the recovered product, which is 20–25 wt.%. The minimum value of the average density of the samples, which is 690 kg/m3, is achieved with equal ratios of building gypsum plaster, fluoroanhydrite and limestone flour, while ensuring the minimum thermal conductivity coefficient, respectively, providing increased thermal performance. The ingredients and properties of the porous gypsum anhydrite binders using fluoroanhydrite crushed in the disintegrator are presented in Table 5.

For production of heat-insulating materials with low density, according to the results in Table 5, it is rational

CONSTRUCTION MATERIALS SCIENCE

Table 4

Ingredient composition and properties of porous materials using fluoroanhydrite of natural granulometry

|

No. |

Mass ratio, % |

Mixture pH |

ρ, m kg/m |

R, comp. MPa |

||||

|

Gypsum |

Fluoroanhydrite |

Limestone flour |

Citric acid |

Water |

||||

|

1 |

32 |

31.6 |

4.8 |

– |

31.6 |

1 |

1280 |

3.0 |

|

2 |

47.3 |

15.5 |

3.2 |

– |

34 |

4 |

1170 |

4.2 |

|

3 |

46.2 |

9.3 |

7.5 |

– |

37 |

7 |

1200 |

3.5 |

|

4 |

40 |

8 |

12 |

– |

40 |

9 |

1100 |

3.2 |

|

5 |

34.09 |

21.59 |

21.59 |

– |

22.73 |

7 |

1660 |

6.0 |

|

6 |

31.00 |

20.00 |

19.00 |

– |

30.00 |

7 |

1570 |

4.9 |

|

7 |

32/26 |

20.43 |

20.43 |

0.03 |

26.85 |

7 |

1360 |

3.2 |

|

8 |

25.68 |

25.68 |

25.68 |

0.02 |

22.94 |

7 |

690 |

2.5 |

Table 5

Ingredients and properties of porous materials using fluoroanhydrite crushed in the disintegrator

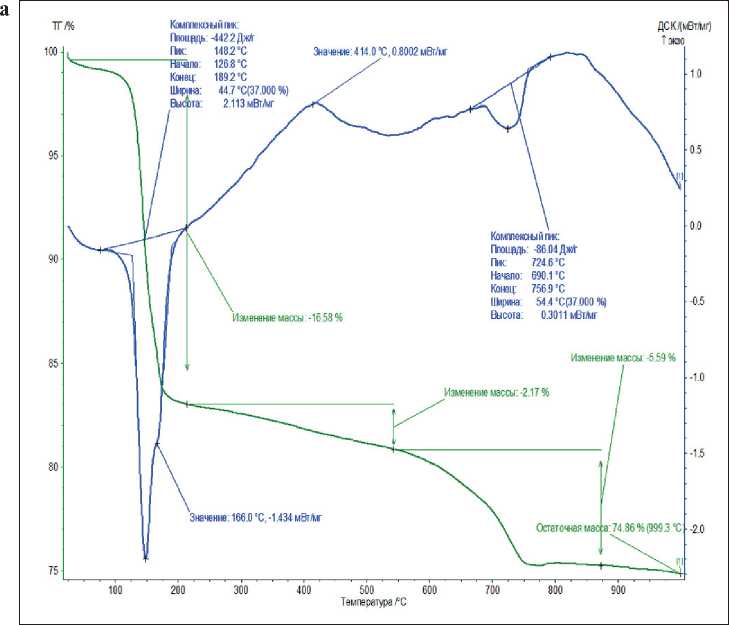

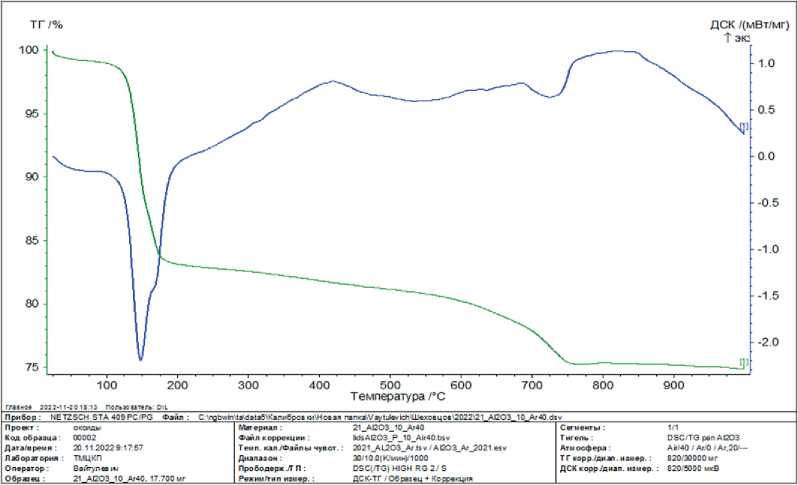

The results of physical and chemical studies of samples using calcium carbonate and fluoroanhydrite are shown in Figure 1.

According to the results of thermal analysis, it was found that on the DTA curve of the age of 7 days, there were endoeffects at temperatures of 150, 750, 400–600оC, which is associated with the processes of dehydration of gypsum dihydrate, rearrangement of the anhydrite crystal lattice and dissociation of calcium carbonate. At the age of 28 days, endoeffects at temperatures of 400–600 and 750оC practically vanish, which indicates to complete hydration of the soluble anhydrite and binding of the calcium carbonate.

In the previously studied porous mineral mixtures in the form of calcium carbonate and “acidic” fluoroanhydrite, due to insufficiently high dispersion, a large-pore structure with an uneven distribution of pores in the volume is formed. The microporous structure in such materials can be obtained using chemical components that are introduced directly into gypsum mixtures and, when interacting with each other, form pores in the gypsum matrix of the material. Additives of sodium carbonate (technical soda) and calcium chloride are proposed as such additives, which, when interacting, form calcium carbonate. When the calcium carbonate interacts with the sulfuric acid, the carbon dioxide is released, which forms pores in the gypsum matrix.

Na2CO3 + CaCl2 = 2NaCl + CaCO3.

H2SO4 + СаСО3 = CaSO4 + H2O + CO2.

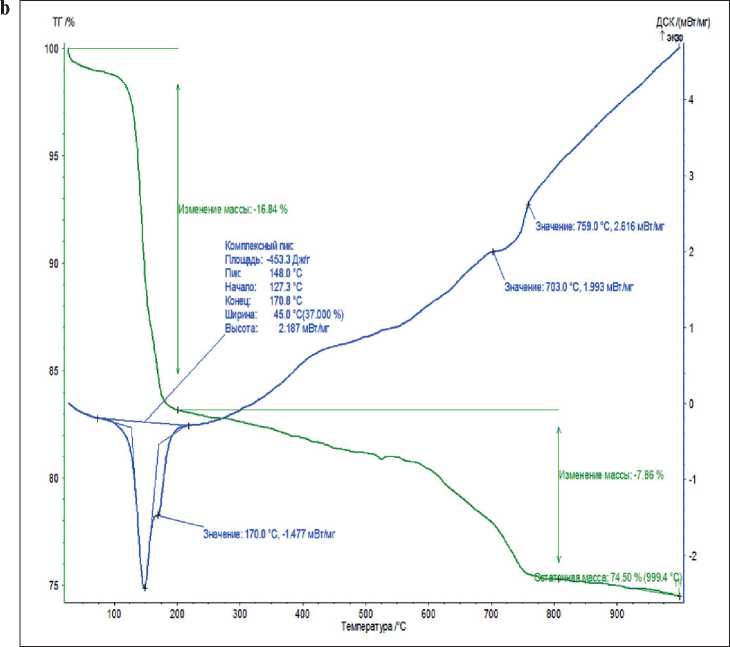

A highly dispersed phase with a particle size of no more than 7 nm is formed from the resulting calcium carbonate, and over time, the formation of amorphous calcium carbonate and gelation are observed, which does not contradict the literature data [16–22]. (Fig. 2a).

According to the results of electron microscopic analysis, it was found that the hydration process ends by the 7th day, then a disordered structure of prismatic and lamellar crystals of gypsum dihydrate is formed, with crystals of insoluble anhydrite and small particles of unbound calcium between. At this, samples with a finely porous structure are formed.

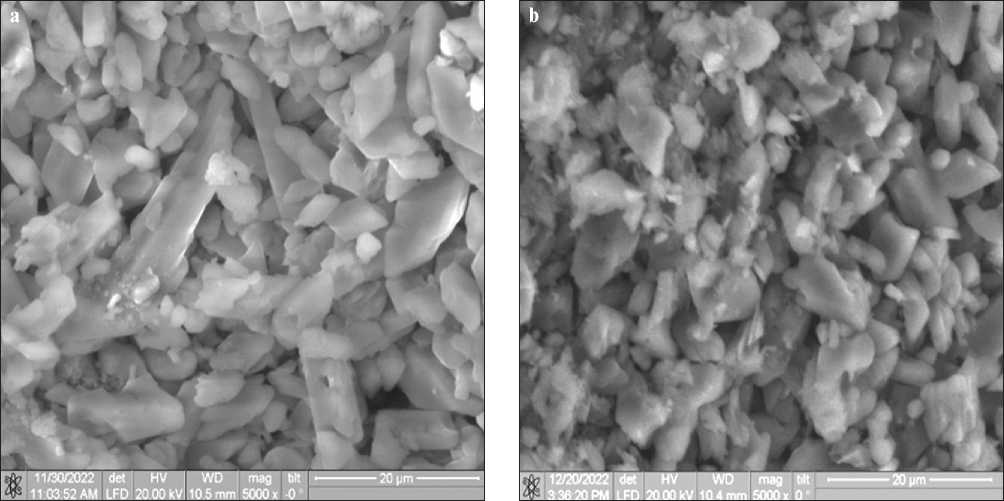

According to the results of the spectrum analysis of the samples with complex additives, calcium dihydrate

CONSTRUCTION MATERIALS SCIENCE

Fig. 1. Derivatograms of gypsum matrix with pore-forming additions of calcium carbonate and fluoroanhydrite aged: 7 and 28 days respectively

CONSTRUCTION MATERIALS SCIENCE

Fig. 2. Microstructure of samples with complex pore forming additives of sodium carbonate and calcium chloride at the age of 7 and 28 days: a — 7 days, b — 28 days, respectively.

decomposes at 150°C (Fig. 3a). There are no endoeffects associated with the rearrangement of the anhydrite crystal lattice at 400–600оC for the samples at the age of 28 days. The calcium carbonate disappears practically in the full scope. When using complex additives, samples with a uniform porous structure are formed. The main indicators of the porous material, such as average density, distribution and pore size, depend on the amount of modifying chemical additives that form the nanodispersed calcium carbonate. According to the results of the microstructure analysis of material samples with a density of 550 kg/m3, the average micropore diameter is 0.45 mm, the thermal conductivity coefficient is 0.25 W/mоC, which is 30% lower than the thermal conductivity of the samples without the use of complex additives.

Based on the chemical composition of the fluoroanhydrite, represented mainly by the insoluble anhydrite, and the results of physical and chemical studies, most of the insoluble anhydrite is not hydrated and acts as a filler in the gypsum anhydrite binder, so the binder can be fully used as a porous gypsum anhydrite material. According to the research results, porous materials belong to light structural and heat-insulating concretes of class B2.5, B5 and can be used in the production of wall blocks, including external walls, provided that the required water resistance is ensured (GOST 25820-2014), as well as for monolithic construction in private house building (PHB).

According to the research results [23–33], the existing technology for the production of porous materials was adjusted. According to well-known technologies, production of porous gypsum wall materials is carried out with a high value of the gypsum paste normal consistency. The formed products have high humidity, and therefore require a long time and additional energy consumption for drying. The technology developed by the authors is based on the production of a dry mechanically activated mixture, including activation of fluoroanhydrite raw materials, joint short-term grinding and mixing with gypsum binders and modifying additives. This approach allows not only grinding the binder, but also creating new chemically active surfaces, which leads to the formation of new compounds in the future. The preparation of porous materials is carried out by mixing the dry mixture with water in a high-speed mixer and pouring the porous mixture into the formwork for hardening under normal conditions. This technology allows to obtain a given density and high early strength in the absence of contraction. Fast curing of gypsum anhydrite wall materials, good thermal insulation properties, no contraction deformation, fire resistance of materials increase the performance of residential buildings.

CONCLUSIONS

Regularities are established for the formation of a porous strong structure of gypsum anhydrite wall materials with complex chemical additives, in which the porous structure is formed at different scale levels due to the occurrence of chemical reactions at the phase boundary: gypsum matrix – fluoroanhydrite. Methods for directed control of structure formation processes of gypsum wall materials with fluoroanhydrite activated in the disintegra-

2023; 15 (4):

319–327

CONSTRUCTION MATERIALS SCIENCE

b

Fig. 3. Results of differential thermal analysis of samples with complex pore forming additives of sodium carbonate and calcium chloride: a — 7 days and b — 28 days

tor and chemical additives are developed. To increase the efficiency of product pore forming, it is recommended to introduce dispersed calcium carbonate and/or complex

chemical additives into the composition of the gypsum mixture with fluoroanhydrite as the main gas-releasing and pore-forming components.

Список литературы Formation of porous structures in production technology of construction materials based on building gypsum plaster

- Chernyshov E.M., Potamoshneva N.D., Monastyryov P.V., Yartsev V.P. Construction and technological utilization of man-made waste as the complex systemic environmental and economic problem of the development of territories and urban planning. Questions of modern science and practice. University named after V.I. Vernandskiy. 2016;(4):62:67-86.

- Anikanova L.A., Kudyakov A.I., Pervushina D.M. Fluoroanhydrite binders for manufacture of building composites. Vestnik grazhdanskikh inzhenerov. 2022;(1):73-9. https://doi.org/10.23968/1999-5571-2022-19-1-73-79

- Kudyakov A.I., Radina T.N., Ivanov M.Yu. Granular heat-insulating material based on liquid glass from silica fume and fly ash. Design and Construction in Siberia. 2006;(2):21-2.

- Belov V.V., Buryanov A.F., Yakovlev G.I., Petropavlovskaya V.B., Fisher H.-B., Maeva I.S., Novichenkova T.B. Modification of the structure and properties of building composites based on calcium sulfate. Moscow: De-Nova Publishing House; 2012. 196 p.

- Mashkin N.A., Kudyakov A.I., Bartenyeva E.A. Non-autoclaved foam concrete, dispersed-reinforced with mineral and fibrous additives. Izvestiya vyshikh uchebnikh zavedeniy. Stroitelstvo. 2018;(8):716:58-68.

- Tokarev Yu.V., Yakovlev G.I., Buryanov A.F. Anhydrite compositions modified with ultrafine MgO-based additive. Stroyitelniye materialy. 2012;(7):17-9.

- Ponomarenko A.A., Kapustin F.L. Technology for processing of fluoroanhydrite for use in production of Portland cement. Khimicheskaya tekhnologiya. 2011;(6):323-5.

- Fedorchuk Yu.M. Technogenic anhydrite, its properties, application. Tomsk: TPU; 2005. 110 p.

- Lesovik V.S., Chernyshova N.V., Klimenko V.G. Processes of structure formation of gypsum-containing composites, taking into account the genesis of raw materials. Izvestiya vuzov. Stroitelstvo. 2012;(4):3-11.

- Garkavi M.S., Artamonov A.V., Kolodezhnaya E.V., Nefediev A.P., Khudovekova E.A., Buryanov A.F., Fisher H.B. Activated fillers for gypsum and anhydrite mixtures. Stroyitelniye materialy. 2018;(8):14-7. https://doi.org/10.31659/0585-430X-2018-762-8-14-17

- Kurmangalieva A.I., Anikanova L.A., Volkova O.V., Kudyakov A.I., Sarkisov Yu.S., Abzaev Yu.A. Аctivation of hardening processes of fluorogypsum compositions by chemical additives of sodium salts. Izvestiya vysshikh uchebnykh zavedeniy khimiya khimicheskaya tekhnologiya. 2020;63(8):73-80. DOI: 10.6060/ivkkt.20206308.6137.

- Berdov G.I., Ilyina L.V., Zyryanova V.N., Nikonenko N.I., Sukharenko V.A. Influence of mineral fillers on properties of building materials. Stroyitelniye materialy. 2012;(9):79-83.

- Kudyakov A.I., Kopanitsa N.O., Kasatkina A.V., Prischepa I.A., Sarkisov J.S. Foam concrete of increased strength with the thermomodified peat additives. IOP Conf. Ser.: Mater. Sci. Eng. 2015; 71: 012012. https://doi.org/10.1088/1757-899X/71/1/012012

- Anikanova L.A., Kudyakov A.I., Volkova O.V. Wall and finishing materials using fluoroanhydrite. Papers of Bratsk State University. Series: Natural and Engineering Sciences. 2015; Vol.1:230-4.

- Petropavlovskaya V.B. Use of mineral ultrafine modifiers based on industrial waste in gypsum composites. Stroyitelniye materialy. 2018;(8):18-23. https://doi.org/10.31659/0585-430X-2018-762-8-18-23

- Anikanova L., Volkova O., Kudyakov A., Sarkisov Y., Tolstov D. Influence of solidification accelerators on structure formation of anhydrite-containing binders. AIP Conference Proceeding. 2016; 1698: 070002. https://doi.org/10.1063/1.4937872

- Anikanova L.A., Volkova O.V., Kudyakov A.I., Kurmangalieva A.I. Activated composite fluoroanhydrite binder. Stroyitelniye materialy. 2019;(1-2):36-42. https://doi.org/10.31659/0585-430X-2019-767-1-2

- Anikanova L.A., Volkova O.V., Kudyakov A.I., Lotov V.A., Pervushina D.M. Analysis of early structure formation of anhydrite binders from secondary raw materials using microcalorimetry. IOP Conf. Ser.: Mater. Sci. Eng. 2020; 911: 012005. https://doi.org/10.1088/1757-899X/911/1/012005

- Anikanova, L., Volkova О., Kurmangalieva А., Mesheulov N. Solving heat engineering problems using the finite element method. Architecture and Engineering. 2021; Vol.6 (3): 3–10. https://doi.org/10.23968/2500-0055-2021-6-3-03-10

- Korolev E.V. Nanotechnology in building materials science. Vestnik of MGSU. 2017;(7):106:711-7. https://doi.org/10.22227/1997-0935.2017.7.711-717

- Korolev E.V. Nanotechnology in building materials science. Analysis of the state and achievements. Ways of development. Stroyitelniye materialy. 2014;(11):47-80.

- Khozin V.G., Abdrakhmanova L.A., Nizamov R.K. General conceptual regularity of nanomodification effects of building materials. Stroyitelniye materialy. 2015;(2):25-33.

- Kalabina D.A., Alexandrov A.M., Yakovlev G.I. Fluoroanhydrite gypsum compositions for manufacture of decorative architectural details and sculptural products. Stroyitelniye materialy. 2021;(11):52-6. https://doi.org/10.31659/0585-430X-2021-797-11-52-56

- Kuzmina V.P. Mechanisms of influence of nanoadditives on gypsum products. Nanotekhnologii v stroitelstve. 2012;4(3):98-106.

- Belov V.V., Buryanov A.F., Yakovlev G.I., Petropavlovskaya V.B., Fisher H.B. Modification of the structure and properties of building composites based on calcium sulfate. Moscow: De Nova; 2012. 196 p.

- Petropavlovskaya V.B., Belov V.V., Novichenkova T.B. Low-energy gypsum building composites. Tver: TGPU; 2014. 136 p.

- Berezkina Yu.V. Technological features in production of gas gypsum. BGTU Vestnik. 2011;(4):11-4.

- Zavadsky V.F., Popov V.A., Deryagin P.P. Technology of building products from cellular concrete. Novosibirsk. 2004; 108 p.

- Khaliullin M.I., Rakhimov R.Z., Gayfullin A.R. Composite gypsum bindings with increased water resistance, containing claydite dust as an active mineral additive. Weimarer gipstagung F.A.Finger – institute fur baustjffkunde. Weimar, 2011; 445–450.

- Anikanova L.A., Volkova O.V., Kudyakov A.I. Dry building mixes with fluoroanhydrite binder. Tomsk: TGASU; 2019. 144 p.

- Kudyakov A.I., Steshenko A.B., Simakova A.S., Latypov A.D. Methods of introduction of glyoxal-containing additives into foam concrete mixture. IOP Conf. Series: Materials Science and Engineering. 2019; 597: 012037. https://doi.org/10.1088/1757-899X/597/1/012037

- Krasinikova N.M., Khozin V.G. New way of making foam concrete. KazGASU Izvestiya. 2009;(1):273-6.

- Kalashnikov V.I., Earakanov O.V. On use of complex additives in new generation concretes. Stroyitelniye materialy. 2017;(1-2):62-7.