Foundries at Stary Tartas-5-an early bronze age site in the Baraba forest-steppe

Автор: Durakov I.A., Mylnikova L.N.

Журнал: Archaeology, Ethnology & Anthropology of Eurasia @journal-aeae-en

Рубрика: The metal ages and medieval period

Статья в выпуске: 4 т.48, 2020 года.

Бесплатный доступ

This study focuses on areas evidencing bronze casting at the Odino culture site, Stary Tartas-5, in the Baraba foreststeppe. One such area is within dwelling 1 and has a smelting hearth and pits situated nearby; the other, outside the dwelling, has a smelting kiln. We provide characteristics of these areas and their archaeological context. Each artifact from the foundries is described in detail, parallels are listed, and results of binocular microscopy of the molding compound are outlined. Based on fi ndings of thermogravimetric studies, we assess the functions of technical pottery represented by fragments, and the number of times various items of the casting set could have been used. Previously, crucibles shaped as straight-walled jars have not been found at Odino sites, with the exception of a single intact specimen from burial 286 at the Tartas-1 cemetery. Dwelling 1 at Tartas-5 and the workshop associated with it were apparently parts of a single household. The Odino bronze casting tradition was retained by the Krotovo population, who supplemented it with innovations, such as the use of oval cups with thicker bottoms adapted to their own casting practices. The Odino sites in the Baraba forest-steppe date to the fi rst half of the third millennium BC. It is concluded that the evidence of the bronze casting industry found at Stary Tartas-5 is the earliest in that region, and that its level in the Odino culture was high.

Odino culture, Baraba forest-steppe, Stary Tartas-5, bronze casting areas, crucibles, nozzles, molds

Короткий адрес: https://sciup.org/145146044

IDR: 145146044 | DOI: 10.17746/1563-0110.2020.48.4.084-094

Текст статьи Foundries at Stary Tartas-5-an early bronze age site in the Baraba forest-steppe

The Early Bronze Age brought several innovations to human society. Some scholars consider this period to be extremely important (Hansen, 2019: 28), or momentous (Tsivilizatsionnye tsentry…, 2013: 3), or the time of radical changes and transformations (Hansen, 2011), which played a crucial role in ancient history. Such innovations included production of copper and bronze. In the Baraba forest-steppe, the Odino culture is considered the earliest culture with proven bronze casting. Yet, until recently, it was unclear what level of metalworking was reached among the carriers of that culture. In the course of many years of field work by the team of V.I. Molodin at the sites of the Odino culture in the region (Markovo-2 (Molodin, 1981), Sopka-2 (Molodin, Grishin, 2019), Tartas-1 (Molodin, Mylnikova, Novikova et al., 2011), Stary Tartas-5 (Molodin, Nesterova, Mylnikova, 2014)), smelting furnaces, tool sets, and various kinds of complexes have been identified, which can be described as economic complexes associated with bronze casting. However, information about them has not yet been

summarized. The sources accumulated to date make it possible to do this. The purpose of this article is to present the features of bronze casting areas of the Odino culture based on the analysis of the evidence from the settlement of Stary Tartas-5.

This site is located 1 km south of the village of Stary Tartas, in Vengerovsky District of Novosibirsk Region (Fig. 1). It was discovered by V.I. Molodin in 1994 (Molodin, Novikov, 1998: 57) and appears as eleven visually noticeable depressions remaining from dwellings and located in two parallel rows (Molodin, Nesterova, Mylnikova, 2014: 111, fig. 1). During the excavations at the site carried out by the expedition from the Institute of Archaeology and Ethnography of the SB RAS in 2012– 2013, deposits were unearthed over an area of 307 m 2 , and four housing structures were examined (Molodin, Mylnikova, Nesterova et al., 2013: 283). Pottery with the features of mostly classical Odino culture was found at the settlement (Molodin, Nesterova, Mylnikova, 2014: 118–121, fig. 10, 11). Foundry waste in the form of small fragments of molds, crucibles, and slagged clay occurred over the entire territory. Taking into account these finds, scholars suggested that the settlement had smelting furnaces associated with bronze casting, and specialized production areas (Molodin, Nesterova, Mylnikova, 2014: 114, 116). The results of our analysis of the smelting furnaces and utility pits, as well as correlation with the above-mentioned finds make it possible to identify two bronze casting areas on the territory of the excavated zone of the settlement.

Description of the specialized bronze casting areas

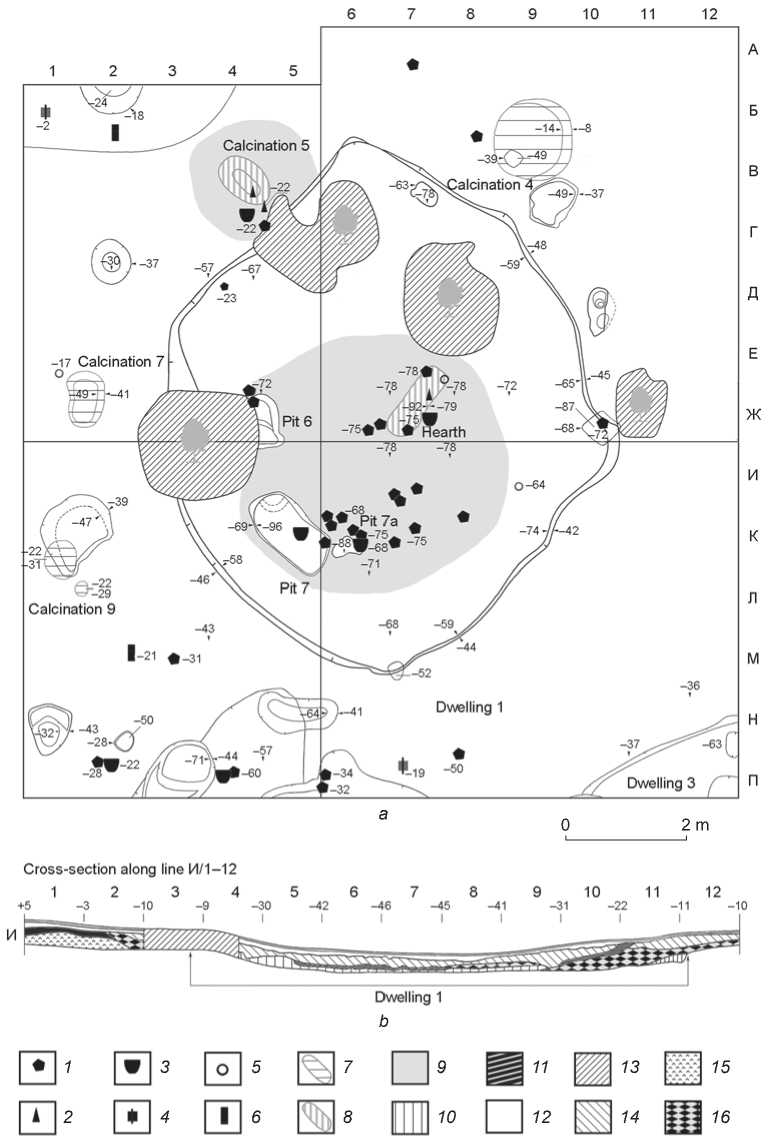

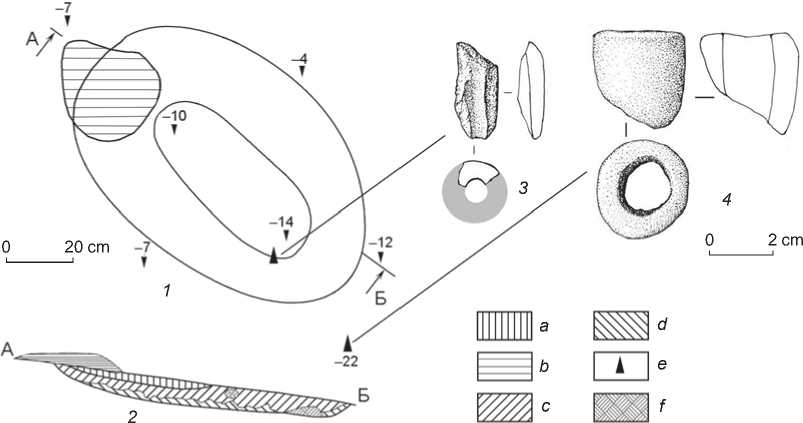

One production area was identified at the floor level of the pit remaining from dwelling 1 (Fig. 2), which was a subrectangular semi-dugout, oriented with its corners to the cardinal points. The size of the pit was 7.7 × 7.1 m; its area was 54.67 m 2 . The walls were steep. The depth in the center of the dwelling was 0.33–0.34 m; the depth at the walls was 0.12–0.2 m. The bottom was uneven, sloping from the walls towards the center of the dwelling, where a horizontal platform around the hearth was located. Absence of posts suggests that the structure was made of logs. The production area in the dwelling had a smelting hearth and three pits.

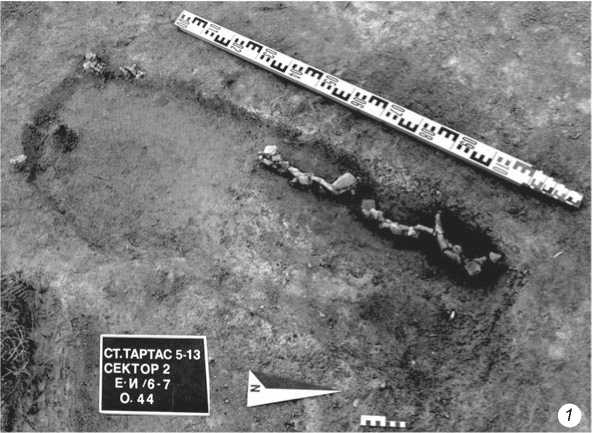

Hearth . The hearth was located in the center of the dwelling pit (Molodin, Nesterova, Mylnikova, 2014: 114, fig. 4), and was a rectangle pit with its long side oriented along the NE-SW line, with strongly smoothed corners (Fig. 3). The pit was 1.32 m long and 0.35–0.45 m wide. The walls were sloping; the bottom was uneven with its depth reaching 12 cm in the southeastern part, 10 cm in the northeastern part, and 5 cm in the central part.

Fig. 1 . Location of the Stary Tartas-5 settlement and other sites with the objects of the Odino culture.

1 – Stary Tartas-5; 2 – Tartas-1; 3 – Sopka-2; 4 – Ust-Tartas-2;

5 – Markovo-2.

Two rows of vertically set large fragments of pottery (parts of a single vessel) were found along the western wall of the hearth (Fig. 3). Fragments of the vessel’s bottom and the part adjacent to it were in the middle of the hearth. Remains of an inner lining made of pottery fragments survived also in the southwestern corner of the hearth depression. All fragments were inserted into a shallow groove (3–5 cm deep) in order to keep them in a vertical position.

The northeastern part of the hearth was a saturated carbonaceous area of dark gray, sandy loam (Fig. 3, 2 ). In its filling, the fragment of a ceramic nozzle and a clay ball with a barely noticeable groove were found. Fragments of casting molds were discovered near the southern and northern walls (Fig. 4, 1 , 2 , 8–11 ).

Taking into account the technical characteristics (the walls were covered with fragments of vessels), as well as waste from bronze casting (fragments of molds, crucibles, and a clay nozzle), which was found in the filling and on the adjacent territory (see Fig. 2), this object should be considered a smelting furnace. Note that subsequently such smelting structures were a part of foundry production in Western Siberia for a long time. For example, smelting kilns with inner walls lined with fragments of vessels have been found at the sites of the Krotovo culture. At the settlement of Vengerovo-2 (Baraba forest-steppe), in dwelling 10, three hearths were discovered. One of the hearths had a similar lining on its southern wall (Molodin, Mylnikova, Nesterova et al., 2017: 371). Three types of smelting furnaces were found

Fig. 2 . Ground plan of bronze casting areas with objects and technical pottery ( a ), and cross-section ( b ) of dwelling 1 at Stary Tartas-5.

1 – fragment of a casting mold; 2 – fragment of a nozzle; 3 – fragment of a crucible; 4 – item made on a ceramic fragment; 5 – ceramic ball; 6 – fragment of a bronze product (fragment of a knife?); 7 – calcination; 8 – smelting kiln; 9 – territory of bronze casting area; 10 – dense, mixed, gray-brown sandy loam with inclusion of carbonaceous lenses; 11 – black, carbonaceous, humic sandy loam; 12 – gray, humic sandy loam; 13 – areas occupied by trees; 14 – whitish-gray, fine sandy loam; 15 – mixed black-brown, lumpy sandy loam; 16 – gray sandy loam with ferruginous inclusions.

in dwelling 7 at the same site. One of these furnaces had its inner walls covered with pottery fragments (Molodin, Durakov, Mylnikova et al., 2018: 54–55, fig. 9). The same smelting furnace was discovered in dwelling 3 (hearth 8) at the settlement of Stary Tartas-5 (Molodin, Nesterova, Mylnikova, 2014: Fig. 1).

Utility pits were associated with the smelting furnace in dwelling 1.

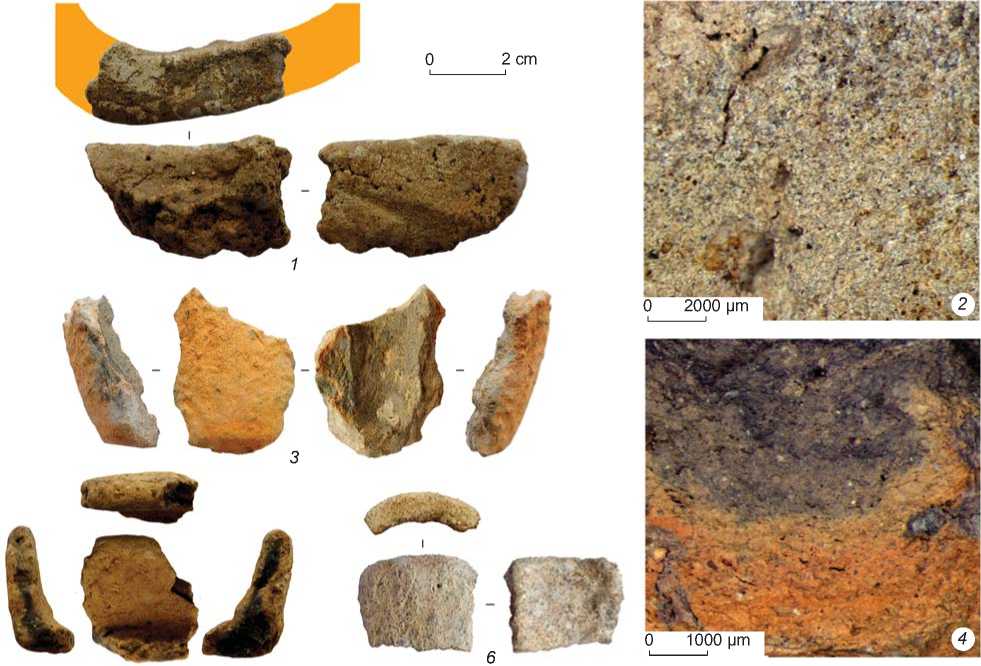

Pit 7 was located 2 m to the northwest of the smelting kiln. It was of subrectangular shape, had rounded corners, and was oriented along the NW-SE line (Fig. 5, 1 ). The size of the pit was 1.6 × 0.81 m. Its northern wall was 8–12 cm lower than the southern wall. The maximum depth from the floor of the dwelling reached 0.32 m. The bottom and walls were covered with a layer of carbonaceous soil of rich black color (up to 0.12 m thick) (Fig. 5, 2 ). Inclusions of ash and lumps of fired clay occurred in the filling, which also contained the fragment of a crucible.

Pit 7a was located 0.45 m to the east of pit 7. It had the shape of an irregular triangle with strongly rounded corners (Fig. 6, 1 ). The size of the pit was 0.72 × × 0.78 m; the depth from the floor of the dwelling was 0.11–0.12 m. The filling of the pit in its western part was a lens of reddish-brown soil. The central part and bottom of the pit were covered with mixed reddish-brown and black soil; the eastern part was filled with deep black carbonaceous soil (Fig. 6, 2 ).

Pit 6 was located 2 m to the north of pit 7 and was a depression in the form of a rectangle elongated along the N-S line, with strongly rounded corners. The western part of the pit was under a tree. The size of the excavated part was 1.0 × 0.4–0.8 m; the depth was 0.1 m. The walls were inclined; the bottom was stepped. The pit was filled with mixed black-brown soil.

Thus, the production complex of dwelling 1 consisted of four objects located in a small area in the central and southwestern part of the pit (see Fig. 2). A hearth was in the center of the area; a large number of small fragments of baked clay were found on the southern side of the hearth in addition to waste of bronze casting. The filling of the pits (ashy soil) and finds in the pits indicate their use as collectors of waste after cleaning the hearth.

The second bronze casting area of the settlement was located in the space between the dwellings, near the

Fig. 3 . Smelting hearth in dwelling 1.

1 – photo after removal of the filling; 2 – ground plan and cross-section. a – dense carbonaceous soil of rich black color; b – calcined reddish-brown soil; c – calcined red soil; d – pottery fragments; e – fragment of a nozzle; f – fragment of a casting mold.

northwestern wall of dwelling 1 (see Fig. 2). The place for the main production activities was the area around a smelting hearth (calcination 5). Fragments of technical pottery, including fragments of two nozzles, a crucible, and casting mold (Fig. 7), were found there.

The hearth consisted of an oval depression oriented with its long axis along the NW-SE line (Fig. 7, 1 ), measuring 0.98 × 0.61 m, with a depth of 0.1 m. The walls were inclined; the bottom was even. In accordance with the topography, the eastern edge of the pit was 0.09 m lower than the western edge. Over a depression in the northwestern part of the hearth, the remains of a vault in the form of a lens of lumpy, orange, baked clay were found. The size of the preserved part of the

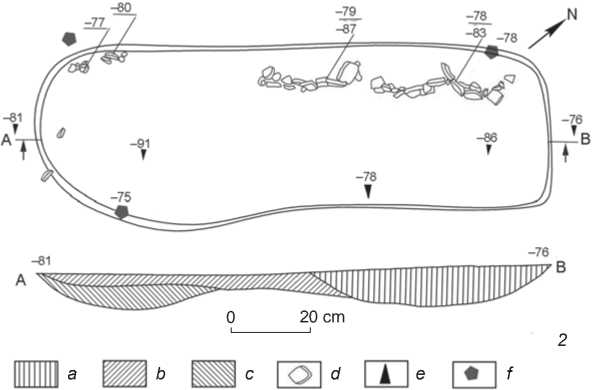

Fig 4 . Fragments of casting molds ( 1 , 3–10 ), a casting core ( 2 ), and ball ( 11 , 12 ).

1 – sq. Ж/18; 2 – sq. П/2; 3 – production area 2, sq. Г/5; 4 – sq. Б/14; 5 – sq. С/8; 6 – sq. Д/13; 7 – sq. Ж/16; 8 , 9 – production area 1, sq. К/6; 10 – sq. И/15; 11 – sq. Е/1; 12 – filling of the kiln in dwelling 1, sq. Е/7.

0 20 cm

A

vault was 0.28 × 0.31 m; the thickness was at least 5 cm. The vault was made of ferruginous clay with the addition of sand.

The pit was filled with rich, calcined orange and brick-red soil. The underlying layer was mixed graybrown, sandy loam interspersed with calcined soil (Fig. 7, 2 ). Fragments of two ceramic nozzles (see Fig. 7, 3 , 4 ) and the fragment of a casting mold were found near the southern wall, which makes it possible to link this object with the bronze casting industry.

Analysis of technical pottery

The investigated territory of the settlement revealed some items related to the foundry collection of production

-68 T

а

b

c

Fig. 5 . Ground plan ( 1 ) and cross-section ( 2 ) of utility pit 7. a – gray-black, mixed, ashy sandy loam; b – black, carbonaceous sandy loam; c – ferruginous, reddish-brown loam.

Fig. 6 . Ground plan ( 1 ) and cross-section ( 2 ) of utility pit 7a. a – carbonaceous soil of rich black color; b – mixed reddish-brown and black soil; c – reddish-brown soil.

-71 Т

equipment, including nozzles, fragments of casting molds and crucibles.

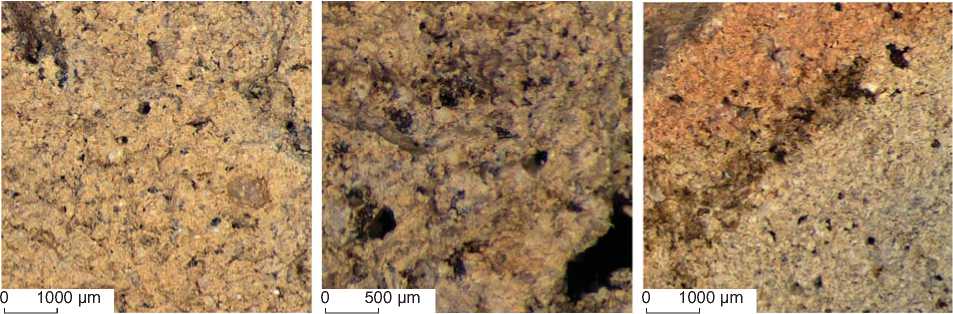

Casting molds . Forty four fragments have been studied, of which 32 were discovered in the immediate vicinity of the above-mentioned bronze casting areas, and 12 were scattered over the rest of the settlement. The remains of the working chambers were preserved in nine fragments (see Fig. 4, 1 , 3–10 ). Due to the fragmented nature of the finds, it is not possible to completely reconstruct the cast items. Some of the molds might have been intended for casting strips having lenticular or trapezoidal crosssection (see Fig. 4, 5 , 9 ). The width of the items did not exceed 1.0–1.5 cm. Molds for casting such items widely appear among the materials of the Early Bronze Age in Western Siberia (Molodin, 1977: Pl. XLIX, 5 ; LXI, 1 , 2 ; LXII, 2 ; Molodin, Durakov, Mylnikova et al., 2012: 115– 117, fig. 13, 14). According to scholars, the artifacts cast in such molds were later forged into strips, rods, staples, etc. (Molodin, Polosmak, 1978: 24–25). For example, an oval-shaped rod was cast in the mold shown in Fig. 4, 1 . This mold was one-piece and disposable; most likely, it was damaged when the casting was being removed. The imprint of a wood structure inside the working chamber suggests that a whittled stick served as a model.

Two molds (see Fig. 4, 3 , 4 ) were intended for casting strips having wedge-shaped cross-section (knife blades?), with thickness of the butt reaching at least 0.2– 0.3 cm. The same series includes the mold for casting

-76

т

20 cm

-71

-76

а

b

c

an object in the form of a subtriangular strip at least 2.5 cm wide, with two convex ridges on the surface. It is impossible to reconstruct the complete shape of the cast product; a distant parallel with distinctive ridges along the blade, which could have resulted from casting in such molds, might have been the fragment of a knife from the settlement of Berezovaya Luka (Kiryushin, Maloletko, Tishkin, 2005: 129, fig. 69, 2 ).

Three molds were used for casting rods or tubes, round in cross-section, with diameter of 1.5 to 3.0 cm (see Fig. 4, 6–8 ). Fragments of two casting rods (see Fig. 4, 2 ) were also found at the settlement, which suggests manufacturing hollow castings.

Thus, judging by the working chambers in the molds, it can be concluded that mostly simple products such

Fig. 7 . Ground plan ( 1 ) and cross-section ( 2 ) of the smelting hearth (calcination 5), fragments of nozzles from its filling ( 3 , 4 ).

a – lumpy, orange burnt soil; b – red-orange, baked clay (coating); c – saturated brick-orange, calcined sandy loam; d – mixed gray and reddish-brown sandy loam; e – fragment of a nozzle; f – tree roots.

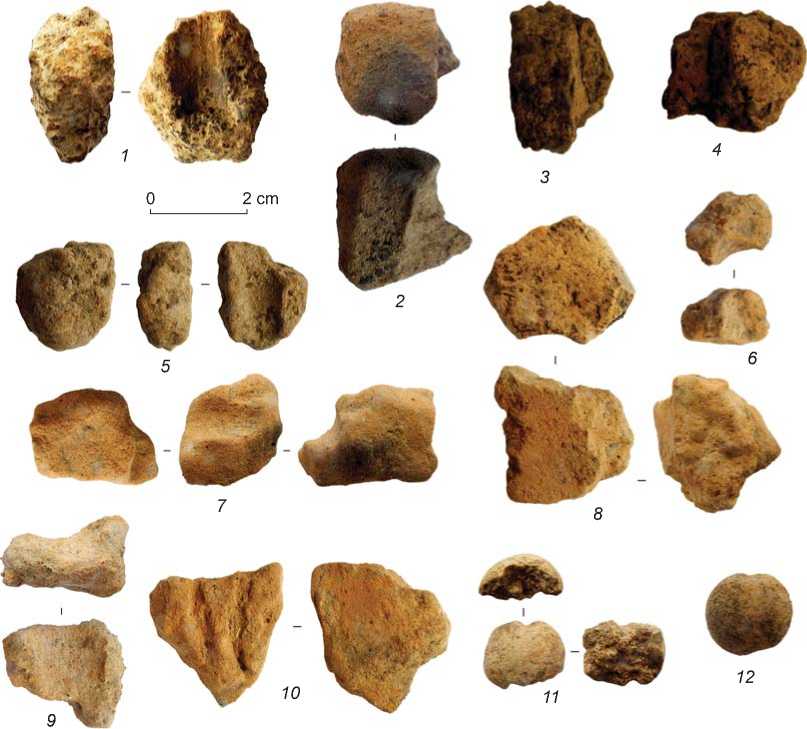

as rods and strips were cast at the settlement of Stary Tartas-5. The molds were made of compounds consisting of ferruginous clay and uncalibrated river sand, with the addition of a small amount of organic matter (dry grass?) (Fig. 8, 1 , 2 ). All molds underwent reduction firing. Undoubtedly, some of them were disposable, one-piece molds.

Thermogravimetric studies of the main body of the molds and surfaces of the working chambers have revealed insignificant differences in weight loss (see Table ) and consequently, in the thermal impact on these objects (Fig. 9). Usually, such a ratio of indicators corresponds to short-term use of the mold: due to short-term impact of metal on the working chamber, a difference in weight loss would accumulate only as a result of multiple repetitions of the pouring cycle (Molodin, Mylnikova, Shtertser et al., 2019: 121–122).

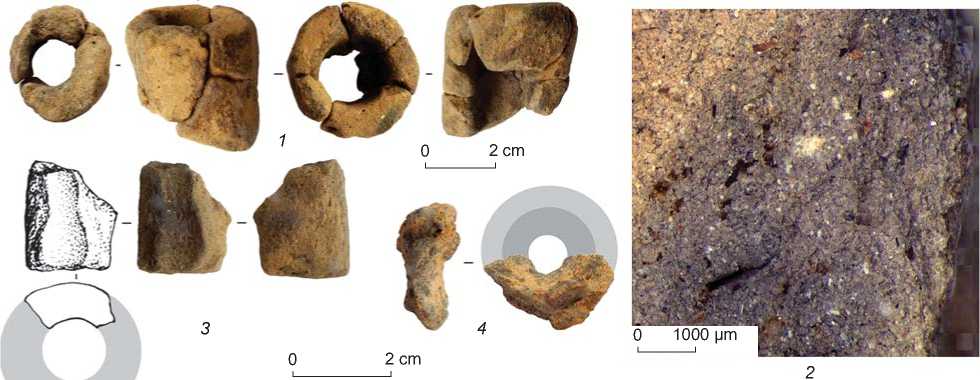

Nozzles. These consisted of a series of four fragments. The best-preserved item was found at the edge of the hearth (calcination 5) in production area 2 (sq. Г/5) (see Fig. 2). It was the end part of a conical ceramic tube (Fig. 10, 1 ). The length of the surviving part was 3.4 cm; the thickness of the walls was 0.6–0.8 cm. The diameter of the tube along the outer edge was 3.0–3.3 cm. The diameter of the air duct was 1.8 cm along the outer edge and 1.3 cm along the inner edge. The object was made of a clay band rolled into a spiral. The compound consisted of clay with additions of sand, organic matter (dry grass), and a small amount of dry clay (Fig. 10, 2 ).

The second nozzle was also associated with the smelting hearth (calcination 5) in production area 2, found in the filling of the hearth (see Fig. 7, 3 ). A fragment of the wall with the air duct survived. Its length was over 3.0 cm; its wall thickness was 0.6–0.65 cm. The diameter along the outer edge was at least 2.0 cm. The diameter of the tube channel hole was 0.7–0.8 cm.

The third nozzle was represented only by a wall fragment (Fig. 10, 3). Its length was 3.1 cm; the thickness of the walls was 0.3–0.5 cm. The reconstructed outer diameter was 2.3 cm; the diameter of the air duct was 0.6 cm.

The fourth nozzle survived fragmentarily (Fig. 10, 4 ); it was found in the filling of the smelting kiln in production area 1 (sq. Ж/7) (see Fig. 2). The length of the fragment was 2.1 cm; its wall thickness was 0.6 cm. The reconstructed diameter was 2.8 cm, and diameter of the air duct was 1.3 cm.

These nozzles were the earliest among similar items discovered in Western Siberia. According to H.H. Coghlan, bellows were invented in the third millennium BC (1951: 65–66). Almost at the same time they appeared in Siberia; this can be explained either by the rapid spread of this innovation over the vast expanses of Eurasia, or by simultaneous creation of these devices in different regions. The penetration of nozzles to the north, to the Upper Ob region, is probably associated with the Odino production tradition. The earliest nozzles in this region go back to the period when pottery of the Odino-Krokhalevka type emerged (Koksharov, 2014).

Crucibles . Fragments of four items were found. One of them was a fragment of a large, thick-walled (1.6– 1.5 cm), apparently oval, cup (Fig. 11, 1 ). The height of its walls was at least 2.4 cm. The crucible was made of a compound consisting of clay with artificial addition of river sand and organic matter, which could be seen from traces of grass and burnt grains 2.0–2.5 mm in size (Fig. 11, 2 ). Comparative thermogravimetric studies revealed a small loss of mass on both surfaces of samples 5 and 6. Rather good firing indicates the repeated use of the item (see Fig. 9, Table ).

Crucibles in the form of oval cups were typical of the Odino culture and have been found in casting areas of the Markovo-2 and Tartas-1 sites (Baraba forest-steppe). This type of Odino crucible was later adopted by bronze casting artisans of the Krotovo culture (Kondratiev, 1974: Fig. 1, 2; Molodin, Grishin, 2016: Fig. 403–404). They,

Fig. 8 . Microphotographs of parts of the clay compound on casting molds.

1 , 2 – sq. Б/8; 3 – sq. П/2.

Weight loss in the samples of technical pottery at different temperatures, %

|

Sample No. |

Place of discovery |

Item |

Place of sampling |

Temperature, оС |

|||

|

30–350 |

350–600 |

600–850 |

30–850 |

||||

|

1 |

Sq. Г/15 |

Nozzle |

Rim |

2.92 |

1.13 |

0.61 |

4.66 |

|

2 |

Inner surface |

3.09 |

1.41 |

0.57 |

5.07 |

||

|

3 |

Sq. Ж/16, dwelling 2 |

Fragment of casting |

Body |

3.69 |

1.73 |

0.75 |

6.17 |

|

4 |

mold |

Working chamber |

3.12 |

1.34 |

0.60 |

5.06 |

|

|

5 |

Sq. П/2 |

Fragment of crucible |

Outer surface |

4.36 |

2.00 |

1.23 |

7.59 |

|

6 |

Inner surface |

4.65 |

2.23 |

1.2 |

8.08 |

||

|

7 |

Sq. К/6 |

ʺ |

Outer surface |

6.57 |

1.26 |

0.55 |

8.38 |

|

8 |

Inner surface |

9.07 |

1.36 |

0.52 |

10.95 |

||

|

9 |

Sq. К/6 |

Fragment of casting |

Body |

6.96 |

1.58 |

0.64 |

9.18 |

|

10 |

mold |

Working chamber |

6.90 |

1.41 |

0.55 |

8.86 |

|

m

6-

•а О b ■c □d e e о f

#

4-

Fig. 9 . Diagram of weight loss in the samples of technical pottery.

a – nozzle, rim; b – nozzle, inner surface; c – casting mold, working chamber; d – casting mold, body; e – crucible, exterior surface; f – crucible, interior surface.

E

2-

No. 6 о

No. 3

No. 2 о

■ No. 4

No. 1

No . 5

No. 10 No. 7 a

• ■ - - No. 9

о

No . 8

agglomeration

0-

m

Temperature range 30-350 °C, %

for 3 , 4

Fig. 10 . Clay nozzles ( 1 , 3 , 4 ), microphotograph of clay compound on the nozzle ( 2 ).

1 – filling of kiln (calcination 5) in production area 2, sq. Г/5; 2 – sq. Г/5; 3 – sq. Ж/16; 4 – hearth of dwelling 1, sq. Ж/7.

Fig. 11 . Fragments of ceramic crucibles ( 1 , 3 , 5 , 6 ) and microphotographs of part of the clay compound ( 2 , 4 ).

1 , 2 – sq. П/2; 3 , 4 – dwelling 1, sq. K/6; 5 – production area 2, sq. Г/5; 6 – dwelling 1, sq. Ж/7.

however, made the bottom of this type of crucible much thicker, since their production involved much greater thermal impact on that area than was the case with the carriers of the Odino culture. Crucibles with thickened bottoms occur among the materials of the Krotovo culture (Stefanova, 1998: 66, fig. 6, 4 ; Durakov, Kobeleva, 2017).

Three fragments of crucibles indicate that they were flat-bottomed, miniature jars. A part of the wall and bottom in one of them survived (Fig. 11, 3 ). The height of the surviving part was 3.6 cm; the wall thickness was 0.6 cm; the diameter along the upper edge was 4 cm. The reconstructed volume was at least 20–25 cm 3 . The smelting chamber was made of ferruginous sandy clay with addition of organic matter (dry, fine grass) (Fig. 11, 4 ). The diagram clearly shows large differences in weight loss in the inner and outer surfaces of the product (samples 7 and 8) (see Fig. 9). It can be concluded that there was a very large temperature impact on the outer surface of the crucible, which might have led to damage to the object (loss of mass by the inner surface indicates poor-quality firing) (see Fig. 9, Table ). A particularly large thermal impact on the bottom part caused the sand to melt in this place over the entire thickness of the crucible wall.

The third crucible had cylindrical shape (Fig. 11, 5 ); its height was 2.3 cm; its wall thickness was 0.5 cm; the reconstructed volume was 27–30 cm 3 .

The fourth crucible, represented by a part of the wall with the rim, can be partially reconstructed (Fig. 11, 6 ). It was found near the hearth in dwelling 1 (sq. Ж/7) (see Fig. 2). Its diameter along the outer edge was 4.5–5.0 cm; its height was not less than 2.5 cm, and its walls were 0.9 cm thick. Crucibles in the form of straight-walled jars have not previously been found in the complexes of the Odino settlements; they are known only from one intact item from burial 286 at the Tartas-1 cemetery.

Notably, a bronze item (sq. M/2)—a forged rectangular strip (fragment of a knife blade?) 2.7 cm long and 1.7–1.9 cm wide—was discovered for the first time in a layer of the dwelling complex of the Odino culture at Stary Tartas-5.

Conclusions

The settlement of Stary Tartas-5 is undoubtedly one of the sites of Odino culture with signs of bronze casting. Traces of intensive casting activities have been found only in one researched dwelling (No. 1) at the settlement. The same concentration of clear production features has been also discovered at other sites of the Odino culture. For example, at Markovo-2, only one of the three excavated structures revealed the remains of casting production (Molodin, 1981: 70). This can be explained by specialization of production and its specific organization as an individual family occupation (when production required involvement of only two or three people, a group was organized based on an individual family (members of a single household) from among the population of the village (community)). An indirect sign of such specialization is the presence of burials with foundry implements, which have been found at Tartas-1 (burial 286) (Molodin, 2012) and Ust-Tartas-2 (burial 32).

The analysis of different types of smelting furnaces found at the site and such items as nozzles, crucibles, and casting molds, which were a part of the foundry equipment, makes it possible to conclude that there was a high level of specialization in bronze casting among the carriers of the Odino culture. The presence of artifacts of the Seima-Turbino appearance (celts and spears) at the sites of this culture is reliably confirmed by finds from closed complexes (Molodin, 2013: 310–313, fig. 3, 4). The transition to manufacturing sophisticated thin-walled items of the Seima-Turbino type necessitated an increase in the pouring temperature and in the fluidity of the metal. The difficulties that arose in searching for a solution to this problem are manifested by a high share of casting defects in the Seima-Turbino casting. For example, at the Rostovka cemetery (the Irtysh region), 12 objects (4 celts, 8 spears; 54.5 %), out of 22 hollow objects (10 celts, 12 spears) found, had traces of casting defects. At the Turbino-1 cemetery, 28 objects (22 celts, 6 spears; 49.12 %), out of 57 objects (44 celts, 13 spears) found, had blowholes, short runs, and seams (Molodin, Durakov, 2019: 49). The artifacts from the Seima cemetery also had casting defects (Bader, 1970: Fig. 24, 26, 27, 29). The desire of the Odino artisans to resolve this was manifested in covering the inner walls of heating devices with pottery fragments, creation of nozzles, and using devices for artificial inflation of air into the smelting structures, which is evidenced by the production areas at Stary Tartas-5.

Currently, taking into account the calibrated radiocarbon dates (Molodin, Marchenko, Orlova et al., 2012: 238, pl. 1), the Odino complexes of the Baraba forest-steppe can be dated to the first half of the third millennium BC. Accordingly, the traces of metalworking found at Stary Tartas-5 can be considered the earliest in that region.

Acknowledgments

This study was supported by the Russian Foundation for Basic Research (Project No. 18-09-40051).