From ore to metal: exploitation of the Novotemirsky mine, Southern Trans-Urals, in the second millennium BC

Автор: Ankusheva P.S., Alaeva I.P., Ankushev M.N., Blinov I.A., Fomichev A.V., Zazovskaya E.P.

Журнал: Archaeology, Ethnology & Anthropology of Eurasia @journal-aeae-en

Рубрика: The metal ages and medieval period

Статья в выпуске: 1 т.49, 2021 года.

Бесплатный доступ

Короткий адрес: https://sciup.org/145146227

IDR: 145146227

Текст статьи From ore to metal: exploitation of the Novotemirsky mine, Southern Trans-Urals, in the second millennium BC

Territorial distribution of the metal-producing cultures reached an unprecedented scale in the Eurasian Metallurgical Province of the Late Bronze Age. At the stage of its emergence, its western fringe was in the Southern Trans-Urals, with the Sintashta center of metallurgy (Chernykh, 2008: 47–49; Bochkarev, 2010: 52–53). Development of metal production in the second millennium BC is a debated issue. Some scholars argue for a clan-oriented organization of miners and metallurgists inhabiting the fortified settlements (ca 2100–1900 BC) and degradation of metal production in the “traditional” cattle-breeding society of the Alakul period (ca 1900–1500 BC) (Vinogradov, 2018). On the contrary, other scholars consider the scale of the Sintashta metallurgy to be exaggerated and specialization to have emerged at the subsequent stages of the Late Bronze Age, associated, among other factors, with changes in ore procurement and development of richer sources (Grigoriev, 2013: 263, 481; Chechushkov, Petrov, 2021).

We suggest that this contradiction may be resolved by taking a closer look at mining as a component of metal production outside the settlements. The object of research is the ancient Novotemirsky mine—one of the three mines (along with Vorovskaya Yama and Novonikolaevsky) known in the Southern Trans-Urals, which have been reliably dated to the Bronze Age (Zaykov et al., 2005; Ankushev et al., 2018) (Fig. 1). In the course of archaeological works, fundamentally new data on metallurgical processes at copper deposits of the region in the second millennium BC have been obtained. These processes are analyzed in this article.

Materials and methods

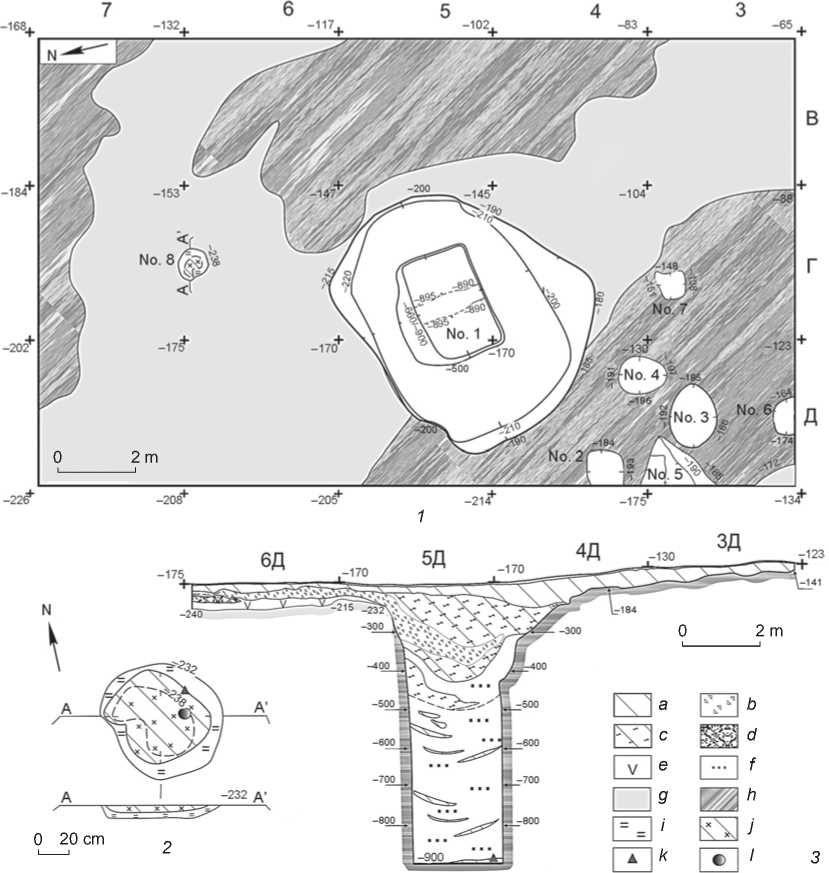

The Novotemirsky ore occurrence is located in the Chesmensky District of the Chelyabinsk Region. It is confined to the Kulikovsky ultrabasic massif at the contact of apoharzburgite serpentinites with rodingites. The primary copper ores are represented by chalcopyrite and bornite. Chrysocolla, malachite, azurite, less frequently delafossite, covellite, chalcosine, and native copper occur in the oxidation zone. At the first survey in 2014, the mine looked like an oval-shaped swampy quarry, with slightly slanting bottom measuring 30 × 20 m and reaching 2.5 m in depth, surrounded by crescent-shaped sodded dumps (Yuminov, Ankushev, Rassomakhin, 2015). In 2017–2019, the expedition of the South Ural Humanitarian Pedagogical University and Institute of Mineralogy of the South Urals Research Center of Mineralogy and Geoecology of the Ural Branch of the Russian Academy of Sciences conducted archaeological excavations, and geological, mineralogical, and geophysical works. In the northern half of the site, V.V. Noskevich carried out a ground penetrating radar survey (Medvedeva et al., 2019); two excavation pits were made in the southern half of the site over a total area of 400 m2 (Fig. 2, 1 ). The cultural layer of the investigated area consisted mainly of waste

Fig. 1 . Location of archaeological sites of the Bronze Age mentioned in this article, in the Ural-Mugodzhary region. a – mine; b – settlement.

Fig. 2 . Orthophotomap of the Novotemirsky mine, showing the boundaries of the excavation in 2018–2019 ( 1 ) and bottom part of mine No. 1 ( 2 ).

a – outline of mine No. 1; b – excavation grid marks.

dumps of various thickness poured over the buried soil: up to 0.6 m in the southeastern part and up to 1.6 m in the southwestern part of the site. The cultural layer contained extremely scarce finds, which consisted mostly of fragments of stone mining tools from imported (sandstone) and local (serpentinite, rodingite) rock. Pottery is represented by isolated specimens, its overwhelming majority coming from deepened objects. The osteological complex, which was also dispersed in the filling of the dumps and deepened objects, included 112 fragments of animal bones with a total weight of 1.11 kg. There were no signs of dwelling structures in the excavated area.

Owing to low presence of artifacts and other remains of human activities in the layer, radiocarbon analysis was chosen as the main dating method, taking into account the stratigraphic context. The age of the samples was established using accelerator mass spectrometry at the Center for Collective Use “Laboratory of Radiocarbon Dating and Electron Microscopy” of the Institute of Geography RAS (Moscow, Russia) and Center for Applied Isotope Studies at the University of Georgia (Athens, USA). Conventional 14C dates were calibrated using the OxCal 4.2.3 software (Bronk Ramsey, 2017) and the IntCal13 calibration curve (Reimer et al., 2013).

Evidence for various stages of metal production at the Novotemirsky mine

Mining . The present-day appearance of the site does not reflect the real morphology of the shafts, because they were filled with waste in ancient times. Geophysical methods revealed a more sophisticated structure of the main quarry as opposed to its current bowl-like shape with a smooth, silty center. A ground penetrating radar survey in the northern part of the site revealed the bottom of the quarry at a depth of 1.5–2.0 m under muddy sediments, as well as several vertical shafts with a width of 0.5–1.5 m extending deeper than 4 m (Medvedeva et al., 2019).

Mine No. 1 was chosen as the main object of excavation. It was a vertical shaft in the southeastern part of the site visually with no raised waste dumps. At the level of the present-day surface, the mine looked like an oval depression with a diameter of 16 m and depth of 0.5 m, sodded with green moisture-loving vegetation. A bush grew in the center. On the level of the virgin soil, the mine had the form of a subrectangular area measuring 6 × 4 m and oriented along the NW–SE line (Fig. 3, 1). Starting from a level of –500 cm (approximately 4 m from the present-day surface), the mine acquired a regular rectangular outline measuring 2.6 × 1.7 m and retained this shape with strictly vertical walls to the very bottom, which was found at a level of –910 cm (8.0–8.5 m depth from the present-day surface). The bottom was flat, with a small (up to 10 cm high) rise of the middle transverse (see Fig. 2, 2).

The upper filling of the mine (see Fig. 3, 3) consisted of an organo-mineral soil horizon formed in the depression after abandoning the site. Underneath was located a loose, reddish brown layer with largesized rubble of serpentinite and fragments of copper-magnetite ores—dumped waste that “slipped” into the mine from the adjacent area. The main filling of the shaft, starting from a level of –350 cm to the bottom, was yellow, sandy loam with serpentinite rubble, which included dark, humic interlayers arranged en echelon. Large rock fragments (15–20 cm in size)

Fig. 3 . Mining and metallurgical objects of excavation A: No. 1 – mine; No. 2–7 – pits; No. 8 – metallurgical furnace. 1 – general plan of the excavation at the level of the virgin soil; 2 – plan and cross-section of the metallurgical furnace; 3 – eastern profile of mine No. 1.

a – dark gray, humic sandy loam; b – brown, humic sandy loam with large (up to 26 cm; on average 5–10 cm) serpentinite rubble; c – gray, humic sandy loam with small (3–5 cm) serpentinite rubble; d – light gray, small (2–4 cm) serpentinite ruble; e – buried soil; f – yellow sandy loam with small (1–3 cm) serpentinite rubble and isolated, large rock fragments; g – virgin soil of yellow sand with rubble; h – virgin soil of light gray bedrock outcrops of serpentinite; i – reddish calcined sandy loam; j – dark gray ashy soil with charcoal, small fragments of animal bones, ceramics, and slag; k – location of pottery fragments; l – location of large pieces of metallurgical slag.

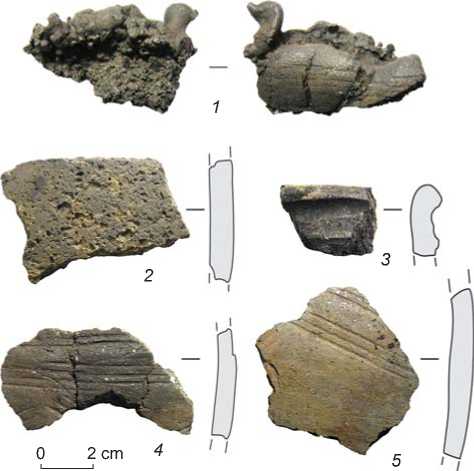

Fig. 4 . Metallurgical slag ( 1 ) and pottery fragments of the Bronze Age ( 2–5 ).

occasionally occurred in the layer. This filling resulted from collapsed walls in the upper layers of the mine at the level of the weathering crust. Fragments of wood and cattle bones, as well as two stone tools (a pick-hoe made of sandstone and counterweight of serpentinite), were found in its bottom part. Pottery fragments of the Alakul culture of the Bronze Age (Fig. 4, 4 , 5 ) were discovered in the southeastern part of the mine bottom.

There were also some shafts of different morphology. Six pits of various shapes with diameter reaching 1.5 m and depth up to 1 m, made in serpentinite and filled with humic, sandy loam with rubble, were found in the immediate vicinity of mine No. 1. These pits remained after mining thin ore veinlets. A shaft of yet another type (conventionally called a “winding manhole”) was found while unearthing a dump on the southern slope of the quarry. Based on the results of the GPR survey, it is possible to assume the presence of similar mines corresponding to the shape of the ore body, in the northern part of the quarry (Ibid.).

Smelting metals from ores. A unique find for the Bronze Age of the Southern Trans-Urals was a metallurgical furnace located directly at the deposit. It was located 4 m north of the northwestern corner of the mine No. 1, in the buried soil, partially cutting through the virgin soil. The furnace looked like a bowl-shaped depression reaching 0.2 m in depth, with a flattened bottom. At the level of the virgin soil, the diameter of the furnace was 0.6 m. The object had black, ashy filling surrounded by a red-colored, calcined rim and contained pottery fragments, small burnt animal bones, metallurgical slag, and pieces of oxidized copper ore.

Pottery fragments (21 pieces) were most likely parts of a single undecorated vessel. Its outer and inner sides were carefully smoothened; their thickness was up to 1 cm; their color was light brown. The clay compound contained abundant admixture of shells burnt on the outer surfaces from the impact of high temperatures (Fig. 4, 2 ).

Metallurgical slag amounted to 249 specimens with a total weight of 264 g. It was able to reconstruct slag of flattened shape with protruding edges from several large fragments (Fig. 4, 1 ). The inner surface (adjacent to the metal) was bumpy; the outer surface was relatively smooth, with grass imprints. By using optical and electron microscopy, it was established that the metallurgical slag of the ancient mine belonged to the Cr-rich spinel of olivine type, similar to the Sintashta settlements (Grigoriev, 2013: 123; Ankushev et al., 2021). Such slag emerges during processing of oxidized copper ores confined to ultrabasites, which is confirmed by the presence of serpentinite and Cr-rich spinels remains. The slag from the Novotemirsky mine contains neogenic sulfides, which has also been observed at the Abashevo settlements (Grigoriev, 2013: 270), indicating the use of mixed oxide-sulfide ores by ancient metallurgists.

Metalworking. A stone mold for casting a mining tool was found 2.9 m southeast of mine No. 1, in the field of waste dump. It consisted of two parts—the matrix and cover (Fig. 5), both made of

0 10 cm

Fig. 5 . Chloritolite bivalve casting mold of a pickaxe.

chloritolite. The matrix had a rectangular shape and measured 22.9 × 11.3 × 6.0 cm. A T-shaped negative of a pickaxe, consisting of a “beak” (15.5 × 2.0 to 4.0 × 2.0 cm in size) and plate for forming an open socket (11.3 × 5.0 to 1.0 × 2.0 cm in size) was carved in the matrix. Traces of high-temperature impact in the form of black calcined edging, penetrating to a depth of 0.3–0.5 cm were found along the edges of the negative recess. The size of the cover was 23.3 × 12.0 × 5.6 cm. Traces of use were also visible in the area adjacent to the negative recess in the form of a black outline with a reddish, calcined filling (0.5–1.0 cm thick) from the product blank. The adjoining surfaces of the mold parts were carefully polished; the outer surfaces were given a correct shape using the pecking technique.

ф С

Е

8 Ф

Ф > Ф £

Ф X

Thus, all stages of metal production, including mining (shafts of various morphologies and waste dumps), smelting of metals from ores (metallurgical furnace with slags and technological ceramics), and metalworking (parts of a casting mold with traces of use) were found at the Novotemirsky mine.

ф

л

л

Ф

Л

Е ©

Chronology of the structures

Discovery of evidence manifesting all stages of metal production at the mine leads to the problem of its exact dating and correlating with stages and cultural entities of the Bronze Age. Various carbon-containing samples, such as animal bones from the filling of the mine and dumps around it, as well as charcoal from the furnace, were taken for radiocarbon analysis (see Table ).

5 ^5

0£ с ф

^

‘ф

ф

We can confidently speak about mining and metallurgical processes at the Novotemirsky mine since the turn of the third–second millennium BC and during the first half of the second millennium BC. The metallurgical furnace with artifacts found in it was the earliest object of the site (21st–20th centuries BC). Preliminarily, it can be attributed to the Sintashta or Abashevo culture, based on similar morphological and mineralogical-geochemical features of slag from the settlements of these cultures (Grigoriev, 2013: 270; Ankushev et al., 2021), and based on the composition of clay compound in ceramics with artificial addition of shells, which was mostly typical of the early stages of the Late Bronze Age in the region (Dubovtseva, Kiseleva, Panteleeva, 2016: 107), as well as location of the mine in the immediate area of the Sintashta fortified settlements.

Mine No. 1 was built later, in the 17th– 16th centuries BC. Fragments of the Alakul pottery that were found at the bottom indicate its cultural identity. The cultural layer of that period, where animal bones of the same time were found in intermediate buried soil between two layers of dumps, was determined to be north of the mine. The casting mold of the pickaxe, whose age was established from the stratigraphic position and similarity to a typologically similar object from the Gorny I settlement in the Kargaly mining and metallurgical center (Kargaly, 2004: 135, fig. 5.1) could probably have belonged to the same period.

The last stage in the development of the deposit in the Bronze Age might have coincided with the final stage of that period: the 15th–13th centuries BC. This date was obtained from a tooth in a crushed animal jaw, which was found in the northern dump. However, owing to the lack of metallurgical objects with dating evidence from the final stage of the Bronze Age, it is premature to speak about ore mining in that period.

In total, the set of artifacts indicates that people have visited the deposit since the 21st century BC to the present day. Currently, there is no industrial activity at the mine. However, according to the local residents, the lake that was formed in the center of the quarry still attracts shepherds as a watering place for livestock, which explains the presence of the cultural layer of the Modern Age and Contemporary Period.

Discussion

The current appearance of the Novotemirsky mine as a quarry surrounded by a ring of collapsed waste dumps significantly differs from its true structure—a system of mining shafts of various depths, shapes, sizes, and the strata of waste dumps of different periods hiding it. In this regard, one should question the hypothesis of an exclusively open-pit method of ore mining in the Ural-Mugodzhary region in the Bronze Age (Zaykov et al., 2013). Shafts and mines, which differed in shape even within the boundaries of the Novotemirsky deposit, were constructed along with quarries. The mine discovered there was the first thoroughly investigated object of the Alakul culture, which has made it possible to clarify the shape and depth of possible shafts, and raise the question of mining systems.

The discovered copper-smelting furnace dating to the turn of the third–second millennium BC gives grounds to assert that metallurgical processes at the mines of the Southern Trans-Urals during this period were not limited only to extraction and primary concentration of copper ore. It has been proven for the first time that a part of the metal was smelted directly at the deposit. Cr-rich spinel containing olivine slag from the furnace were similar to those found at the fortified settlements of the Sintashta culture, such as Ustye I, Kamenny Ambar, Levoberezhnoye, Sarym-Sakly, and Arkaim (Grigoriev, 2013: 123, 125, 129; Ankushev et al., 2021), which suggests that metallurgical procedures for smelting metals from ores were identical at deposits and in settlements.

The next stage of site functioning was associated with the Alakul period, represented by mine No. 1, adjoining dumps, and probably the casting mold of the pickaxe. The discovery of evidence of ore mining by the carriers of the Alakul culture in the Southern TransUrals is extremely important. It confirms the continued use of local copper raw materials in this region during the first half of the second millennium BC, despite almost complete absence of evidence for metal smelting from copper ores in unfortified settlements (Grigoriev, 2013: 438–439; Alaeva, 2014). Moreover, the Novotemirsky mine is an excellent example of using the same deposits in the Alakul period (ca 1900–1500 BC), which followed the Sintashta period (ca 2100–2000 BC). In this regard, the site is comparable with such multicultural sites as the Vorovskaya Yama (Zaykov et al., 2005) and Ishkinino mines (Tkachev, 2019).

The established fact of ore mining both in the Sintashta and Alakul periods makes it possible to speak about functioning of a locality focused on metallurgy as part of the Trans-Urals mining and metallurgical center throughout the entire Late Bronze Age. Accordingly, the sharp decrease in the volume of slag at the unfortified Alakul settlements as compared to the fortified Sintashta settlements cannot be explained by complete cessation of the use of local ore resources and procurement of metal from regions richer in ore deposits. A certain volume of metal smelting operations was carried out directly at the deposits. It is likely that it was limited to the miners’ needs for metal tools.

Nevertheless, with the continued use of local ore sources, it is preferable to speak about an increase in specialization of metal production from the Sintashta culture in the turn of the third–second millennium BC to the Alakul culture of the first half of the second millennium BC. If in the Sintashta period the full cycle of metal production was carried out at each of the fortified settlements, in the Alakul period one may assume transferring a part of metallurgical operations (primarily smelting of metals from ores)

to the settlements located in the immediate vicinity of the deposits. A similar model of organizing metal production is demonstrated by other regions where the Alakul culture was distributed, in particular, its Mugodzhary local version. The Elenovka-Ushkatty, Ishkinino, and Shanshar archaeological microdistricts are the reference areas associated with copper deposits (Tkachev, 2011).

No such complexes have yet been found in the Southern Trans-Urals, which makes micro-regional studies of the areas surrounding the preserved ancient mines all the more important. Nine unfortified settlements of the Bronze Age have been surveyed at a distance of up to 10 km from the Vorovskaya Yama deposit in the valley of the Zingeika River, and metallurgical slags have been found in the test pits in half of them (Ankushev et al., 2016). It is possible that settlements of miner-metallurgists of not only the Sintashta period, but also of the Alakul period will be discovered in that area in the future.

Conclusions

To this day, the Novotemirsky site is the most ancient copper mine in the Southern Trans-Urals. Its study has revealed that the shaft mining method was widely used along with open-pit (quarry) method of ore mining. The development of this deposit throughout the entire second millennium BC by the carriers of different cultures indicates the use of the same ore sources in the Southern Trans-Urals in the Bronze Age. However, obvious changes in the technological components in the communities following the Sintashta may be associated with sophistication and specialization of metallurgy. Further research of mining sites in the Southern Trans-Urals and the associated microdistricts would contribute to better understanding of metallurgical technologies specific for each period, as well as social organization of this sector of the economy.

Acknowledgement

This study was supported by the Russian Foundation for Basic Research, Project No. 18-39-00056 mol_a.