Fuel pumps plunger pairs chrometitanium plating regimes justification

Автор: Abbasov E.

Журнал: Science, Education and Innovations in the Context of Modern Problems @imcra

Статья в выпуске: 6 vol.8, 2025 года.

Бесплатный доступ

The article presents the results of research on the corrosion of high-pressure parts of fuel pumps. given and their restoration for diffusion chrometitanium plating regimes choice justified. Certain done that diffusion saturation from the period original as plunger diameter important varies to a certain extent. It should be noted that the material of the part, its initial and subsequent heat treatment, and the plunger to swell has an important impact.

Fuel pump, plunger pair, chromotitanization, nitriding, swelling, diffusion saturation

Короткий адрес: https://sciup.org/16010811

IDR: 16010811 | DOI: 10.56334/sei/8.6.74

Текст научной статьи Fuel pumps plunger pairs chrometitanium plating regimes justification

Abbasov E. (2025). Fuel pumps plunger pairs chrometitanium plating regimes justification. Science, Education and Innovations in the Context ofModern Problems, 8(6), 683-687; doi:10.56352/sei/8.6.74.

Micrometering of the details of the plunger pairs shows that the guiding part of the grooveand the maximum wear of the plunger is 0.5 -1.0 μ m . Unlike general wear, precession Local erosion located in different areas of the surfaces has different values. Exploited and Analysis of the circular diagrams of the extracted parts shows that the local wear of the plunger (section IV) is 14 μ m, of the engraving (cut I) - 20 μ m, of the dispenser (cut XII) - 5 μ m. Local minimal wear of parts From 2 6 μ m It is as much. Results obtained [1-3] to the results of the work suitable.

A study of plunger pairs for the repair fund shows that many of them are corroded, resulting in 20-30% of plunger pairs sent for repair fail due to corrosion damage to the precession surfaces. fuel pumps wedged and 35% until repair fund details plunger and to carve corrosionto injuries according to for repair not useful [4]

Plunger transmitter surfaces exploitation It is eaten unevenly in the process. As a rule the most small wear on the transmission surfaces of the rotating plunger and the toothed groove at the junction with themobserved on precession surfaces. Analysis of the precession surfaces of 150 plungers showed that the mean square Ifthe deviation δ =0.054 mm and the coefficient of variation V=0.33, the average amount of wear is 0.165 mm. did. This eating road to be given knowing of the field at the limit is located and pump reputable to work cannot have a significant effect. The wear of individual plungers (8%) is 0.6 -1.5 mm. Gear The nature and quantity of the erosion of the surface of the groove completely corresponds to the indicators of the plunger. The most big of being eaten price of the meeting of work character with closed, because here touching forcesThe wear of the surface of the bottom plate at the junction with the plunger heel is the mean square deviation δ =0.18 mm and coefficient of variation When V=0.47, the consumption average price 0.38 mm. Initial information that is not for plunger heel of being eaten certain making possible It doesn't happen. However, probability can be done that its price your plate eating comparison with can be done.

Metallographic analysis shows that the thickness of the nitrided layer on the plungers is 3-5 times, i.e. 0.2...0.10

mm decreases, and in the plates the thickness of the layer (cyanated layer) is - 0.2-0.3 mm. This shows that that for repair to be eaten in the details sent resistant surface layer no.

Thus, the analysis showed that the greatest wear among the precessional surfaces was caused by the plunger groove, the most to the little one while - dispenser exposed remains. Plunger transmitter surfaces between the most less square surface eaten.The average wear of the surface of the plate at the junction with the plunger is 0.38 mm. Research data certain to do opportunity gives that plunger pairs refusals basics precession surfaces local eating and is corrosion damage.

The effect of diffusion titanization and chromium plating on the change in dimensions of parts. Nitrogen-For the removal of the effect of changes in linear dimensions of parts made of 25X5MA steel initial diffusion without titanization and using chrome plating has been done.

Titanization of nitrided 25X5MA steel with diameters of 8 and 9 shows that at 950-1150 0 C temperature and storage time up to 12 hours, the diameter growth is 22-25 μ m. This is swell into account taking enough to recover is not.

That one made of steel plungers chrome plating 1150 0 C temperature and 8 clock storage during The linear dimensions can be increased up to 180 μ m. However, negative aspects are revealed: surface hardness uneven distributed and diffusion fold thickness 70-80 mkm when exceeded then cracks arises.

It has been determined through experiments that if titanation of nitrided steel is applied to the plunger pair, If it does not allow the restoration of the details of the chrome, then when the above deficiencies are eliminated, packing process used for their recovery be can.

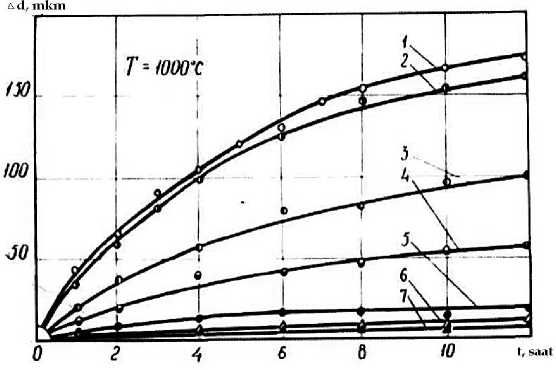

Note done that reactive in the mix ferrotitanium amount increase with (from 25% very) The increase in size decreases sharply (Figure 1) and spots appear on the surface. The ratio of chromium to ferrotitanium in the alloy The change in linear dimensions at 20:80 (% by mass) is comparable to their change during titanization. is done.

Nitrification unattainable 25X5MA branded made of steel details titanization and Chromization shows other results. Non-nitriding steel linear dimensions when chrome plated the change is slightly higher than in titanization (15-20%), but less than in nitrided steel. significantly less. The greater thickness of the nitrogen diffusion layer in the surface layer of 25X5MA steel to be purchased and in this regard details linear dimensions to change opportunity gives.

Contact gas-phase absorption in the process details swelling. In containers plunger pairs diffusion processing shows that of the swell price is different. The most small swelling at the price dispenser (0-1 mkm, ) to the largest while plunger (70 μ m) until) has.

Table 1. Diffusion when chromed (1000 0 C, 6 hours; 150 0 C/h) various from steel plunger swelling

|

/N |

Steelbrand |

Without chrome plating front thermal process and chemical thermal process type |

Without chrome platingthen bending, mkm |

Without chrome plating then thermal process type |

Without chrome plating andthermal from processing then bending,mkm |

|

45 |

- |

48.5 |

Volume persistence+ reflection |

61 |

|

|

45 |

to the tray |

41.0 |

-“- |

55.5 |

|

|

Y8 |

to the table+ reflection |

35.0 |

-“- |

39.5 |

|

|

ShX-15 |

- |

12.5 |

-“- |

19.5 |

|

ShX-15 |

to the tray |

8.5 |

-“- |

16.0 |

|

|

XBG |

- |

5.0 |

-“- |

14.0 |

|

|

XBG |

- |

9.2 |

-“- |

14.0 |

|

|

25X5MA |

nitrification |

9.0 |

-“- |

12.5 |

|

|

25X5MA |

- |

3.5 |

-“- |

3.5 |

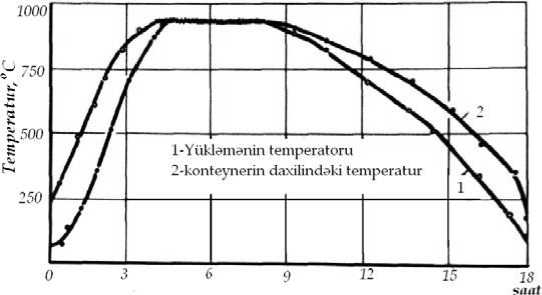

The bulge of the parts depends on many factors. It has been confirmed that the plunger and the groove are vertical It also experiences less swelling when processed in a vertical position . For example, details are processed in cassettes in a vertical position. when done of the swell quantity average count 3-5 to mm until down falls. Details bending The size of the container also affects the price. For example, as the size of a container increases, the volume inside ittemperature relative to the stove more slowly rising (picture 2). Across the cross section of this container temperature creates a difference, which affects the swell. Details of the thermal conductivity of the absorbent mixture It is important to note the effect of the loaded container on the heating rate. According to experimental data, more mixture for titanizing for high thermal conductivity, mixture for chromium plating for low thermal conductivity has.

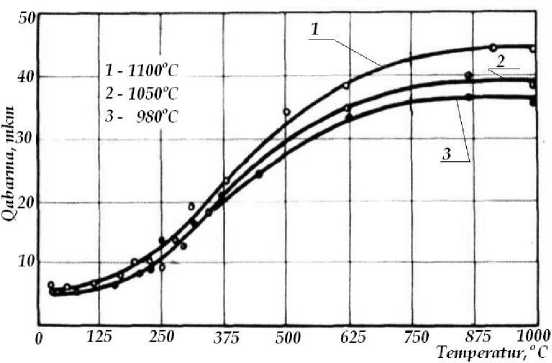

Carving and plunger to swell impact who from factors one container heating and cooling. To the top especially impact who factor container cooling (picture 3). But even very less plunger deflection at cooling rate 5-15 organize mkm does. These quantities are all studied done diffusion processes (titanium plating, chrome plating, chrometitanium plating) for approximately is equal.

Nitrogenized on the cover detail in the material residue tensions existence plungers of the swelling main is the reason. Research show that nitrogenated fold fragility second to the group belongs to.

This time his/her inside residue tensions 600 to MPa enough, mechanical from processing then thickness diversity 10-15 μ m organizes.

Picture 1. Diffusion of satiety from the period dependent as plunger diameter change. In the mix chrome and of titanium ratio (mass in %): 1-100:0; 2- 98:2; 4- 95:45; 5:30:70; 6,7 - initial unnitrified relevant chromed and titanized 25X5MA branded steel.

Picture 2. Diffusion in saturation container and ofloading temperature change

Picture 3. Container cooling from the temperature dependent as plunger swelling

The material of the part, its initial and final heat treatment have a significant impact on the plunger bulge. The table shows the deflection values of plungers made of various steels. Of the bend maximum quantities are observed in the middle part of the plunger. It can be seen from the table that alloyed made of steel details construction and tool from steel to the details relatively more small to swell 45 , U8 , ShX-15, XBG and nitrided 25X5MA steels with chrome plating in details After annealing, heat treatment increases the swelling by 20-40%. Therefore, when high-precision parts are manufactured, it technological should be removed from the process.

Thus, the wear rates of parts, changes in linear dimensions, and nitrogenization Analysis of the swelling during the chrome plating process of 25X5MA steel using this method of plunger pairs of restoration conclusion about the possibility to remove allows

Results:

-

1. With micrometer measurements and profilograms of worn parts included in the repair It was determined that the total wear present in the guide parts of the parts is 0.5 -1.0 μ m. In addition to being, it is also found in local cuisine. This has the following maximum values: -14 μ m on the plunger, in carving 20mkm and in the dispenser - 5 μ m. Plunger transmitter surfaces and with him meeting details The average wear of the plunger square is 0.065 mm, and the wear of the bottom plate is 0.38 mm . It is mm.

-

2. The effects of diffusion chromizing and titanating on the properties and dimensional changes of the coating The study of the effect of the piston pair made of nitrided 25X5MA steel showed that the details of the piston pair restoration for using these two methods It cannot be done.

-

3. Diffusion metallization leads to swelling of parts. The plunger is most susceptible to swelling. The tide price one very from factors depends he including: heating temperature, cooling mode, steel grade, and condition of the part during processing, etc. Maximum deflection for steel 45 is 61 μ m, initial processing not done 25X5MA for branded steel 3.5 mkm organizes.