Geotextile-reinforced soils in a modernized irrigation system

Автор: Ismoilova Sabida Isroilovna, Loginov Pavel Viktorovich, Khamidov Saidjon Sobitjon Ugli, Kumakov Jakhongir Xamzayevich, Khazratova Tulganoy Yashin Kizi

Журнал: Строительство уникальных зданий и сооружений @unistroy

Статья в выпуске: 3 (88), 2020 года.

Бесплатный доступ

The use in irrigation construction of geotextile soils reinforced (strengthened) with fibrous materials, including cotton fibers waste of textile materials, requires strength assessment of these soils under tension and bending. Due to the low tensile and bending strength of soil, the load is born by the fibers reinforcing the soil. Direct methods to test tensile and bending geotextile soils are complex. It was proposed to evaluate the strength of geotextile materials through the strength characteristics of their components. Soils reinforced with textile waste cotton fibers are considered in the paper. To determine the strength of cotton fibers experimentally under the action of friction force only, a tensile test of cotton yarn consisting of cotton fibers was conducted. The diagrams of cotton yarn stretching obtained experimentally and the known diagrams of sandy soil compression are given in the paper. It was found that in the process of strain, both cotton yarn and soil change structurally. These changes are described by the change functions of their strain moduli, determined from considered experimental results in the form of graphs. Based on them, a method for assessing the strength of geotextile soils based on the general law of cotton yarn and soil strain is proposed. The possibility of using the formula obtained from this law for a particular case when determining and evaluating the strength of cotton yarns under tensile forces is shown. Therefore, it is recommended to use this formula in calculating the tensile strength of geotextile soils reinforced (strengthened) with waste textile materials used in innovative and modernized construction of irrigation reservoirs, canals, ditches, and reservoirs.

Geotextiles, soils, fiber, strength, irrigation construction

Короткий адрес: https://sciup.org/143172520

IDR: 143172520 | УДК: 69 | DOI: 10.18720/CUBS.88.5

Текст научной статьи Geotextile-reinforced soils in a modernized irrigation system

One of the innovative building materials of our time is geotextile. Geotextiles are the materials consisting of soil and textile fibers. In the case under consideration, textile fibers are the wastes of textile production and other wastes in the form of fibrous materials. At that, strength and other mechanical characteristics of geotextile materials are of great interest. The determination of mechanical characteristics of building materials reinforced with textile fibers and materials has been the subject of many publications [1 - 27]. In [6], geosynthetic clay (clay reinforced with synthetic fibers) was considered as an anti-filtration material in irrigation reservoirs. The strength and filtration characteristics of the material were determined in [6]. Geosynthetic material inevitably includes the interconnected behavior of various materials and fibers [7]. Dependences of strength characteristics of the geosynthetic material on mechanical properties of reinforcing additive are determined by moisture-content, stress-strain state, chemical, and thermal conditions of fibers [7]. The strength characteristics of the concrete reinforced with recycled textile waste (old clothes, jeans, etc.) were studied in [8]. It was found that the strength of the concrete improved up to 40% under compression and up to 7% under bending compared with unreinforced concrete [8].

The strength of black cotton soil, reinforced with the addition of processed sawdust and lime, was studied in [9]. The strength of the reinforced soil with nylon fibers 15-20 mm long was defined in [10]. The influence of the reinforcement type on the behavior of sand stratum was considered in [11].

The strength of geotextiles reinforced with various fibrous materials was considered in [13–16]. Environmental issues of geotextile materials were investigated in [16, 17]. The effect of jute fiber on the mechanical properties of concrete was determined in [18]. Mechanical and chemical properties of geomaterials reinforced with textile and other fibers were investigated in [19-21]. Dynamic properties of geotextile materials were studied in [22, 23].

The use of innovative geotextiles to protect the banks of drainage channels and ditches was considered in [24]. Seismic characteristics of geosynthetic sand (longitudinal wave propagation and seismic strength) were determined in [25]. The stability of dumps reinforced with textile fibers waste was investigated in [26]. A wide review of publications on geotextile materials devoted to the study and determination of their mechanical and strength characteristics under static and dynamic loads was given in [27].

As can be seen from the above brief analysis, the strength of geotextile materials was mainly evaluated through testing of soils reinforced with textile or other fibers. They are widely used in irrigation construction.

It is obvious, that the strength of reinforced soil directly depends on the strength of fibers.

The purpose of this work is to develop the methods for determining and evaluating the strength of geotextile material components that serve as the tools to improve the strength of soils and building materials used in irrigation systems.

The objectives of the study are:

-

• to determine the basic indices of the strength of soils and textile fibers and materials used in geotextiles;

-

• to determine experimentally and theoretically the strength of soils, textile fibers and materials;

-

• to develop a method for determining the strength of geotextile materials used in irrigation systems.

2 Methods and materials

The basis of geotextile material is soil. To strengthen the geomaterials, many varieties of textile fibers are used. In this paper, cotton fibers and soils are the objects of study. With the addition of cotton fibers obtained from textile waste into soil, the strength of soil increases [19-21]. As is well known, soils work in compression. They practically cannot bear tensile loads.

Cotton fibers added to soil increase the tensile strength of soil. Obviously, the tensile strength of the soil is mainly determined by the fiber strength under tensile loads.

The fiber arrangement in soil is randomly chaotic. The main forces acting on fiber are the friction forces that occur between the fiber and soil. Under tension or bending, the fibers in soil stretch due to friction. The greater the amount of fibers in soil, the more tensile it is. The maximum strength of fibrous materials is achieved in a yarn consisting of fibers interlaced in a complex manner.

A similar situation is with a cotton yarn. In a yarn, the fibers are also randomly arranged [28-32]. Under cotton yarn stretching, the fiber is exposed to an external friction force between the fibers [28]. Mechanical behavior of fibers in soil and a cotton yarn is similar. The strength and mechanical characteristics of yarn were studied in [29-32]. The friction forces between the soil and the rigid body were investigated in [33].

Here, based on the mechanical characteristics of cotton yarn and soil, we consider the actual problem of determining and predicting the strength of geotextile material.

3 Results and their analysis

Using the method of experimental study of the yarn strength [29-32] and the interaction forces between the fibers [28] in a rigid body and soil [33], we determine the tensile strength of cotton fibers under friction.

To conduct experiments on stretching, a ready-made cotton yarn with a linear density of N/m was selected. The experiments were carried out at the factory installation "Statimat C", designed for tensile testing of textile yarns.

-

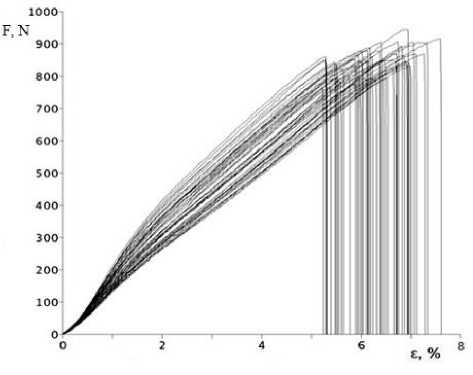

3.1 shows the results of experiments on cotton yarn stretching to a break as a dependence of tensile strength on strain. The tensile strain rate was 0.015 s-1. The replication of experiments shown in 3.1 is 50. The spread of experimental data in 3.1 is about 30%. According to the curves in 3.1, the yarn strain occurs nonlinearly.

Figure 3.1 – Dependence of tensile stresses on the relative strain of cotton yarn

According to 3.1, the value of the maximum load at which the cotton yarn breaks off is F y max = 9.5

N. The linear density of cotton fibers which compose the yarn is /у = 1.1-10-5 N/m. The breaking load of a cotton fiber is Ff max = 0.35 H [32]. The strength of materials is characterized by specific stresses, determined from the formula

F y max Г = ~- yS

Ff f max

S

(3.1)

where Sy is the cross section of a cotton yarn, Sf is the cross section of the cotton fibers which compose the yarn ( S y = 5 - 10 - 8 m2, S f = 10 - 9 m2).

The tensile strength of cotton yarn and fiber, according to (3.1), in this case, are try = 190 MPa and г f = 350 MPa, respectively. The strength of yarn is almost twice less (45.7%) than the strength of cotton fiber. This means that under cotton yarn stretching, the fiber does not tear, but slips out of the yarn. A similar situation occurs at the tension and bending of geotextile materials. Depending on the moisture-content (wetness) of geotextile materials under stretching or bending, the strength of the fiber-reinforced material is equal to the fiber strength or the half of the fiber strength. The first case occurs when the reinforcing fiber has sufficiently strong bonds with soil along its entire length and under stretching and bending, it breaks. Since the bonds between the soil particles are weaker than between the particles of the reinforcing fiber, the strength of the geotextile material is equal to the fiber strength.

The second case occurs when the reinforcing fibers slip out of soil. In this case, the fibers do not break and the strength of the geotextile material is determined by the value of friction force between the fiber and soil particles along the entire length of the fiber. These options naturally depend on the density of reinforcing fibers in soil. The maximum density of the fiber material is achieved when the entire material consists of reinforcing fibers, i.e. in yarn. Therefore, the yarn strength is the maximum that can be achieved for geotextile soil.

It should be noted that the yarn strength depends also on the technology of its manufacturing. Depending on the manufacturing methods and the types of cotton fiber yarn, its strength ranges from 150 MPa to 200 MPa [30, 31]. When assessing the strength of a geotextile material, it is necessary to use the lower limit of the yarn tensile strength.

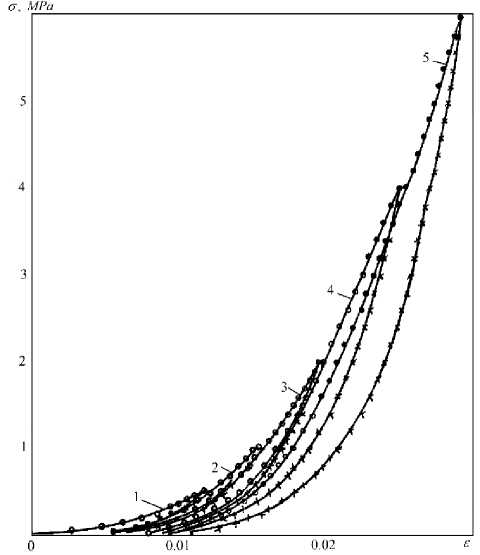

Now consider the results of experiments on strain in fine sandy soil with a density of y g = 1.63 - 10 4 N/m3 and moisture-content W = 4.8% under uniaxial cyclic compression [34]. In reliable experiments [34], the loading of a sample of sandy soil was of static nature. As can be seen from 3.2, the compression of the soil sample occurs nonlinearly. Repeated loadings occur along the parallel trajectories (curves 15, 3.2) . The maximum load under sand compression reaches 6 MPa. Note that soil unloading also occurs along the curved trajectories (3.2) .

Figure 3.2 – Dependences of compressive stresses on the relative displacements of fine sandy soil

A comparative analysis of curves in 3.1 and 3.2 shows that the trajectories of cotton yarn stretching and sandy soil compression differ qualitatively. In the first case (3.1) , the material softening occurs, and in the second case (3.2) , the reinforcement occurs. However, as noted in [29], the nonlinearity of diagrams is caused by a change in soil structure under strain. In the case of cotton yarn, its structure begins to change under stretching and finally breaks. And in the case of soil under compression, its structure changes before reinforcement.

In both cases, following [29,30], the laws of yarn and soil strain can be described by the equation da

ED d t

a d s

+ Ц --=--+ ЦS

(3.2)

ESdt where a is the longitudinal (axial) stress, s is the longitudinal (axial) strain, ED is the dynamic deformation modulus at ds[dt ^^ , ES is the static deformation modulus at ds[dt ^ 0 , ц is the volume viscosity parameter (internal friction), t is the time.

The volume viscosity parameter is determined from the relation

(3.3)

(ED -ES)n where n is the coefficient of volume viscosity.

Equation (3.2) is a well-known law of a viscoelastic standard linear body [29]. It applies to the description of the straining process in both cotton yarn and soil. However, it is necessary in law (3.2) to take into account the difference in their strains.

Obviously, under strain, the structure consisting of the fibers of cotton yarn and the structure consisting of particles of sand change. Therefore, their physicomechanical and mechanical properties change: density, deformation moduli ES and E D , and viscosity coefficient 7 . Based on the diagrams

(3.1 and 3.2), it is possible to determine the changes in the secant deformation modulus ES under the yarn strain. Methods for determining the secant modulus ES and the actual modulus ESF are discussed in [35-37].

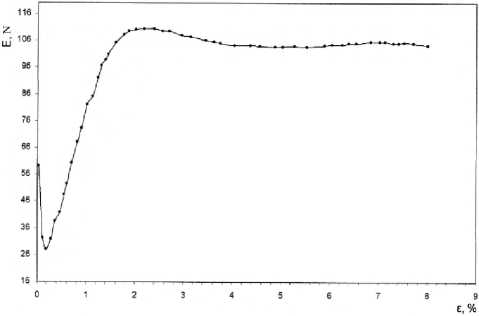

Figure 3.3 – Changes in the secant tensile modulus of cotton yarn depending on the value of tensile strain

-

3.3 shows the change in the secant modulus Es depending on the tensile strain values £ defined from the diagram in 3.1. As can be seen from 3.2, the change in the modulus E of cotton yarn under stretching is quite complicated. At the beginning of the deformation process, the modulus E decreases rapidly, and then increases to a maximum and remains almost constant until the yarn breaks.

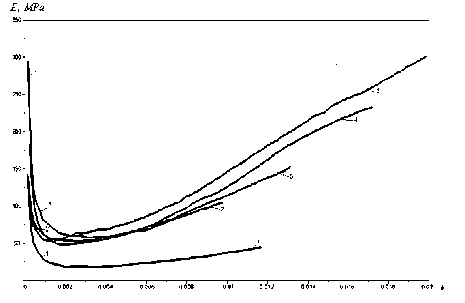

A similar dependence is shown in 3.4 for sandy soil. Here, also at the beginning of the deformation process, the modulus E drops and then grows. In all loading cycles, with the exception of the first one, the change in modulus can be considered almost the same.

Figure 3.4 – Changes in the secant modulus of deformation of sandy soil caused by compression strain

In the first cycle, there is a more intensive change in the soil structure and, accordingly, a change in module ES differs from other cases.

According to the results shown in 3.3 and 3.4, the modulus ES for cotton yarn and soil is a complex nonlinear function of the form Es = Es (s). Determining the specific form of these functions for the curves in 3.3 and 3.4 is a matter of perspective. In this study, it is proposed to use equations (3.2) to describe the process of geotextile soil tension and compression. However, under tension and bending, the functions Es (s), Ed (s) and u(s) are determined from the tensile diagrams of cotton yarn, and under compression - from the compression diagrams of soil. Further, the strength of geotextile material is determined based on the law of strain. In the simplest case, the strength of a geotextile material is evaluated as follows. For permissible strain £ = £K, the secant modulus of cotton yarn or soil is

E S = Esk . Edk = Y KESK , and the value of ek is determined from (3.3), at n = n K • From equation (3.2)

at s = sk and dsjdt = const, the formula for determining cotton yarn tensile strength is obtained in the form

(d£, , )1 - exP (-M K / K t K )

(3.1)

" v = E SK I 37 + Ek £ k I----------------

Vdt J Ek where YD = Edk !ESK .

Based on the analysis of experimental results on yarns stretching, the values of parameters entering equation (3.4) are proposed for determining the strength of geotextile soil reinforced with cotton fiber waste: E SK = 2 ⋅ 103 МPа; µ = 100 s-1; ε = 0.05 ; γ = 2 ; t = 3.5 s. The value of strain rate under tension d ε d t is set depending on the load acting on geotextile soil.

According to (3.4), the maximum strength of geotextile soil reinforced with cotton fiber wastes under tensile loads is determined taking into account the rate of stretching (the strain).

In cases of using geotextile materials reinforced with cotton fiber wastes in irrigation engineering, when reinforcing the sides of reservoirs, canals, ditches, and reducing the filtration properties of soil, it is proposed to have a safety margin of two for reinforced soil. In this case, the tensile strength of geotextile soil at the safety factor K = 0.5 is determined by the formula

σ Z = K Z σ y (3.5)

Similarly, the strength of geotextile material under compression is determined by the formula (3.4). In this case, the values of parameters E , µ , ε , γ , t and d ε d t are determined for soils.

Thus, based on the analysis of experimental studies results to determine the tensile strength of cotton yarns and soil under compression, calculation formulas are proposed for determining the strength of geotextile soil reinforced with cotton fiber waste. The proposed formulas can be used to assess the strength of soils reinforced with cotton fibers under tension and bending.

4 Conclusions

-

1. Based on the analysis of strength characteristics of soils and textile yarns, the similar character of mechanical behavior of cotton fibers in the soil as in a geotextile material and cotton yarn consisting of cotton fibers was established.

-

2. The causes of strength loss in geotextile soils under tension and bending were analyzed. It has been established that due to the low strength of soils under tension and bending, the strength of geotextile soils is determined by strength characteristics of reinforcing cotton fibers.

-

3. To use geotextile soils reinforced with waste textile materials from cotton and to evaluate their tensile and bending strengths in modernized irrigation engineering, a calculation formula was proposed that takes into account the loading rate (the strain) of external load.

Список литературы Geotextile-reinforced soils in a modernized irrigation system

- Ponomaryov, A., Zolotozubov, D. Several approaches for the design of reinforced bases on karst areas. Geotextiles and Geomembranes. 2014. 42(1). Pp. 48-51. 10.1016/j.geotexmem.2013.12.002. URL: https://linkinghub.elsevier.com/retrieve/pii/S0266114413001076. DOI: 10.1016/j.geotexmem.2013.12.002.URL

- Petrukhin, A.B., Zakrevskaya, L. V., Gandelsman, A.I. Hardening of the soil basis for constructions by nonwoven geotextile fabric and foam glass gravel. Izvestiya Vysshikh Uchebnykh Zavedenii, Seriya Teknologiya Tekstil'noi Promyshlennosti. 2016. 2016-Janua(6). Pp. 277-280.

- Ponomaryov, A.B., Sychkina, E.N., Kleveko, V.I. Use of marl as ground base for embankment. Geotechnics Fundamentals and Applications in Construction: New Materials, Structures, Technologies and Calculations - Proceedings of the International Conference on Geotechnics Fundamentals and Applications in Construction: New Materials, Structures, Tech. 2019. Pp. 280-283. DOI: 10.1201/9780429058882-55

- Shooshpasha, I., Tavangar, Y., Kharun, M. An experimental evaluation of size effect and bearing capacity of footing on non-woven geotextile-reinforced sand. IOP Conference Series: Materials Science and Engineering. 2019. 675. Pp. 012001. 10.1088/1757-899X/675/1/012001. URL: https://iopscience.iop.org/article/10.1088/1757-899X/675/1/012001. DOI: 10.1088/1757-899X/675/1/012001.URL

- Shenkman, R.I., Ponomaryov, A.B. Calculation of vertical deformations of the rigid foundations on the soft soil improved by geotextile encased stone columns. 16th Asian Regional Conference on Soil Mechanics and Geotechnical Engineering, ARC 2019. 2020.

- Suzuki, M., Koyama, A., Kochi, Y., Urabe, T. Interface shear strength between geosynthetic clay liner and covering soil on the embankment of an irrigation pond and stability evaluation of its widened sections. Soils and Foundations. 2017. 57(2). Pp. 301-314. 10.1016/j.sandf.2017.03.007. URL: https://linkinghub.elsevier.com/retrieve/pii/S0038080617300392.

- DOI: 10.1016/j.sandf.2017.03.007.URL

- Kwak, C.W., Park, I.J., Park, J.B. Evaluation of disturbance function for geosynthetic-soil interface considering chemical reactions based on cyclic direct shear tests. Soils and Foundations. 2013. 53(5). Pp. 720-734. 10.1016/j.sandf.2013.08.010. URL: https://linkinghub.elsevier.com/retrieve/pii/S0038080613000929.

- DOI: 10.1016/j.sandf.2013.08.010.URL

- Peña-Pichardo, P., Martínez-Barrera, G., Martínez-López, M., Ureña-Núñez, F., dos Reis, J.M.L. Recovery of cotton fibers from waste Blue-Jeans and its use in polyester concrete. Construction and Building Materials. 2018. 177. Pp. 409-416. 10.1016/j.conbuildmat.2018.05.137. URL: https://linkinghub.elsevier.com/retrieve/pii/S0950061818312121.

- DOI: 10.1016/j.conbuildmat.2018.05.137.URL

- Ikeagwuani, C.C., Obeta, I.N., Agunwamba, J.C. Stabilization of black cotton soil subgrade using sawdust ash and lime. Soils and Foundations. 2019. 59(1). Pp. 162-175. 10.1016/j.sandf.2018.10.004. URL: https://linkinghub.elsevier.com/retrieve/pii/S0038080618302087.

- DOI: 10.1016/j.sandf.2018.10.004.URL

- Phanikumar, B.R., Singla, R. Swell-consolidation characteristics of fibre-reinforced expansive soils. Soils and Foundations. 2016. 56(1). Pp. 138-143. 10.1016/j.sandf.2016.01.011. URL: https://linkinghub.elsevier.com/retrieve/pii/S0038080616000123.

- DOI: 10.1016/j.sandf.2016.01.011.URL

- Lal, D., Sankar, N., Chandrakaran, S. Effect of reinforcement form on the behaviour of coir geotextile reinforced sand beds. Soils and Foundations. 2017. 57(2). Pp. 227-236. 10.1016/j.sandf.2016.12.001. URL: https://linkinghub.elsevier.com/retrieve/pii/S0038080617300288.

- DOI: 10.1016/j.sandf.2016.12.001.URL

- Sawada, Y., Nakazawa, H., Oda, T., Kobayashi, S., Shibuya, S., Kawabata, T. Seismic performance of small earth dams with sloping core zones and geosynthetic clay liners using full-scale shaking table tests. Soils and Foundations. 2018. 58(3). Pp. 519-533. 10.1016/j.sandf.2018.01.003. URL: https://linkinghub.elsevier.com/retrieve/pii/S0038080618300416.

- DOI: 10.1016/j.sandf.2018.01.003.URL

- Rama Vara Prasad, C., Hari Prasad Reddy, P., Ramana Murthy, V., Sivapullaiah, P.V. Swelling characteristics of soils subjected to acid contamination. Soils and Foundations. 2018. 58(1). Pp. 110-121. 10.1016/j.sandf.2017.11.005. URL: https://linkinghub.elsevier.com/retrieve/pii/S0038080617301580.

- DOI: 10.1016/j.sandf.2017.11.005.URL

- Feng, S.-J., Chen, J.-N., Chen, H.-X., Liu, X., Zhao, T., Zhou, A. Analysis of sand - woven geotextile interface shear behavior using discrete element method (DEM). Canadian Geotechnical Journal. 2020. 57(3). Pp. 433-447. 10.1139/cgj-2018-0703. URL: http://www.nrcresearchpress.com/doi/10.1139/cgj-2018-0703.

- DOI: 10.1139/cgj-2018-0703.URL

- Wongsa, A., Kunthawatwong, R., Naenudon, S., Sata, V., Chindaprasirt, P. Natural fiber reinforced high calcium fly ash geopolymer mortar. Construction and Building Materials. 2020. 241. Pp. 118143. 10.1016/j.conbuildmat.2020.118143. URL: https://linkinghub.elsevier.com/retrieve/pii/S0950061820301483.

- DOI: 10.1016/j.conbuildmat.2020.118143.URL

- Akturk, B., Akca, A.H., Kizilkanat, A.B. Fracture response of fiber-reinforced sodium carbonate activated slag mortars. Construction and Building Materials. 2020. 241. Pp. 118128. 10.1016/j.conbuildmat.2020.118128. URL: https://linkinghub.elsevier.com/retrieve/pii/S0950061820301331.

- DOI: 10.1016/j.conbuildmat.2020.118128.URL

- Senff, L., Novais, R.M., Carvalheiras, J., Labrincha, J.A. Eco-friendly approach to enhance the mechanical performance of geopolymer foams: Using glass fibre waste coming from wind blade production. Construction and Building Materials. 2020. 239. Pp. 117805. 10.1016/j.conbuildmat.2019.117805. URL: https://linkinghub.elsevier.com/retrieve/pii/S0950061819332581.

- DOI: 10.1016/j.conbuildmat.2019.117805.URL

- Islam, M.S., Ahmed, S.J. Influence of jute fiber on concrete properties. Construction and Building Materials. 2018. 189. Pp. 768-776. 10.1016/j.conbuildmat.2018.09.048. URL: https://linkinghub.elsevier.com/retrieve/pii/S095006181832227X.

- DOI: 10.1016/j.conbuildmat.2018.09.048.URL

- Wei, L., Chai, S.X., Zhang, H.Y., Shi, Q. Mechanical properties of soil reinforced with both lime and four kinds of fiber. Construction and Building Materials. 2018. 172. Pp. 300-308. 10.1016/j.conbuildmat.2018.03.248. URL: https://linkinghub.elsevier.com/retrieve/pii/S0950061818307530.

- DOI: 10.1016/j.conbuildmat.2018.03.248.URL

- Noolu, V., Mudavath, H., Pillai, R.J., Yantrapalli, S.K. Permanent deformation behaviour of black cotton soil treated with calcium carbide residue. Construction and Building Materials. 2019. 223. Pp. 441-449. 10.1016/j.conbuildmat.2019.07.010. URL: https://linkinghub.elsevier.com/retrieve/pii/S0950061819316733.

- DOI: 10.1016/j.conbuildmat.2019.07.010.URL

- Ramaiah, B.J., Ramana, G.V., Bansal, B.K. Field and large scale laboratory studies on dynamic properties of emplaced municipal solid waste from two dump sites at Delhi, India. Soil Dynamics and Earthquake Engineering. 2016. 90. Pp. 340-357. 10.1016/j.soildyn.2016.09.001. URL: https://linkinghub.elsevier.com/retrieve/pii/S0267726116302238.

- DOI: 10.1016/j.soildyn.2016.09.001.URL

- Jamshidi, R., Towhata, I., Ghiassian, H., Tabarsa, A.R. Experimental evaluation of dynamic deformation characteristics of sheet pile retaining walls with fiber reinforced backfill. Soil Dynamics and Earthquake Engineering. 2010. 30(6). Pp. 438-446. 10.1016/j.soildyn.2009.12.017. URL: https://linkinghub.elsevier.com/retrieve/pii/S0267726109002024.

- DOI: 10.1016/j.soildyn.2009.12.017.URL

- Qu, H.-L., Luo, H., Hu, H.-G., Jia, H.-Y., Zhang, D.-Y. Dynamic response of anchored sheet pile wall under ground motion: Analytical model with experimental validation. Soil Dynamics and Earthquake Engineering. 2018. 115. Pp. 896-906. 10.1016/j.soildyn.2017.09.015. URL: https://linkinghub.elsevier.com/retrieve/pii/S026772611630481X.

- DOI: 10.1016/j.soildyn.2017.09.015.URL

- Broda, J., Gawlowski, A., Laszczak, R., Mitka, A., Przybylo, S., Grzybowska-Pietras, J., Rom, M. Application of innovative meandrically arranged geotextiles for the protection of drainage ditches in the clay ground. Geotextiles and Geomembranes. 2017. 45(1). Pp. 45-53. 10.1016/j.geotexmem.2016.07.003. URL: https://linkinghub.elsevier.com/retrieve/pii/S026611441630084X.

- DOI: 10.1016/j.geotexmem.2016.07.003.URL

- Cristelo, N., Cunha, V.M.C.F., Dias, M., Gomes, A.T., Miranda, T., Araújo, N. Influence of discrete fibre reinforcement on the uniaxial compression response and seismic wave velocity of a cement-stabilised sandy-clay. Geotextiles and Geomembranes. 2015. 43(1). Pp. 1-13. 10.1016/j.geotexmem.2014.11.007. URL: https://linkinghub.elsevier.com/retrieve/pii/S0266114414001022.

- DOI: 10.1016/j.geotexmem.2014.11.007.URL

- Consoli, N.C., Nierwinski, H.P., Peccin da Silva, A., Sosnoski, J. Durability and strength of fiber-reinforced compacted gold tailings-cement blends. Geotextiles and Geomembranes. 2017. 45(2). Pp. 98-102. 10.1016/j.geotexmem.2017.01.001. URL: https://linkinghub.elsevier.com/retrieve/pii/S0266114417300018.

- DOI: 10.1016/j.geotexmem.2017.01.001.URL

- Saba, N., Jawaid, M., Alothman, O.Y., Paridah, M.T. A review on dynamic mechanical properties of natural fibre reinforced polymer composites. Construction and Building Materials. 2016. 106. Pp. 149-159. 10.1016/j.conbuildmat.2015.12.075. URL: https://linkinghub.elsevier.com/retrieve/pii/S0950061815307479.

- DOI: 10.1016/j.conbuildmat.2015.12.075.URL

- Grechukhin, A.P., Seliverstov, V.Y., Rudovskiy, P.N. The method of determination of yarn bending rigidity and friction factor during interaction of fibers. The Journal of The Textile Institute. 2017. 108(12). Pp. 2067-2072. 10.1080/00405000.2017.1312676. URL: https://www.tandfonline.com/doi/full/10.1080/00405000.2017.1312676.

- DOI: 10.1080/00405000.2017.1312676.URL

- Sultanov, K.S. A non-linear law of the deformation of soft soils. Journal of Applied Mathematics and Mechanics. 1998. 62(3). Pp. 465-472. 10.1016/S0021-8928(98)00058-6. URL: https://linkinghub.elsevier.com/retrieve/pii/S0021892898000586.

- DOI: 10.1016/S0021-8928(98)00058-6.URL

- Sultanov, K.S., Ismailova, S.I., Tulanov, S.E. Experimental regularities of deformation of the cotton yarn at stretching. Izvestiya Vysshikh Uchebnykh Zavedenii, Seriya Teknologiya Tekstil'noi Promyshlennosti. 2016. 364(4) Pp. 63-67 URL:https://ttp.ivgpu.com/wp-content/uploads/2016/11/364_13-4.pdf

- Sultanov, K.S. The attenuation of longitudinal waves in non-linear viscoelastic media. Journal of Applied Mathematics and Mechanics. 2002. 66(1). Pp. 115-122. 10.1016/S0021-8928(02)00015-1. URL: https://linkinghub.elsevier.com/retrieve/pii/S0021892802000151.

- DOI: 10.1016/S0021-8928(02)00015-1.URL

- Sultanov, K.S., Ismailova, S.I. Determination of the strength of the cotton yarn on the basis of nonlinear elasticviscoplastic model of deformation. Izvestiya Vysshikh Uchebnykh Zavedenii, Seriya Teknologiya Tekstil'noi Promyshlennosti. 2018. 375(3). Pp.95-101 URL: https://ttp.ivgpu.com/wp-content/uploads/2018/10/375_18.pdf

- Bakhodirov, A.A., Sultanov, K.S. Waves in a viscoelastic bar surrounded by soils under smooth loading. Mechanics of Solids. 2014. 49(3). Pp. 349-359. 10.3103/S002565441403011X. URL: http://link.springer.com/10.3103/S002565441403011X.

- DOI: 10.3103/S002565441403011X.URL

- Grigoryan S., Studies in soil mechanics. Thesis for a science. Moscow State University, Moscow, 1965.

- Sultanov, K., Loginov, P., Ismoilova, S., Salikhova, Z. Variable moduli of soil strain. E3S Web of Conferences. 2019. 97. Pp. 04013. 10.1051/e3sconf/20199704013. URL: http://www.scopus.com/inward/record.url?eid=2-s2.0-85067279669&partnerID=MN8TOARS.

- DOI: 10.1051/e3sconf/20199704013.URL

- Loginov, P. V., Salikhova, Z.R., Sultanov, K.S. Experimental and Theoretical Method for Determining Mechanical Characteristics of Soils under Dynamic Loads. Mechanics of Solids. 2019. 54(6). Pp. 915-928. 10.3103/S0025654419060074. URL: http://link.springer.com/10.3103/S0025654419060074.

- DOI: 10.3103/S0025654419060074.URL

- Ismailova, S.I., Sultanov, K.S. Nonlinear deformation laws for composite threads in extension. Mechanics of Solids. 2015. 50(5). Pp. 578-590. 10.3103/S002565441505009X. URL: http://link.springer.com/10.3103/S002565441505009X.

- DOI: 10.3103/S002565441505009X.URL