High-performance nano-modified concrete of increased strength and durability

Автор: Sergey P. Kasatkin, Valentina Y. Soloviova, Irina V. Stepanova, Dmitry V. Kuznetsov, Dmitry A. Sinitsin

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Application of nanomaterials and nanotechnologies in construction

Статья в выпуске: 6 Vol.14, 2022 года.

Бесплатный доступ

Introduction. To create concrete with a set of physical and mechanical characteristics, a rational selection of the components of the concrete mix is required, including the use of finely dispersed fillers, including those based on recyclable materials, and a highly effective chemical additive of a certain nature and reactive action, which has a complex effect on concrete system. Methods and materials. The effectiveness of the components in used additive was assessed by changing the indicators of compressive strength, tensile strength in bending, the assessment of which was carried out according to GOST 10180-2012 “Concrete. Methods for determining the strength of control samples. For carrying out scientific and experimental studies, the following materials were used: Portland cement CEM I 42.5N; natural sand; fine microsilica; complex chemical additive with increased plasticizing and reactive effects. Results. The combination of polycarboxylate polymers and nanodispersions of silicon hydroxide enhances the effectiveness of each component, which is reflected in a significant increase in the coefficient of crack resistance of concrete at high compressive strength. It has been established that when using a complex nanopolymer chemical additive, the increase in tensile strength in bending is 67% and it exceeds the increase in compressive strength by more than 30%. Discussion. An increase in hydration activity in the presence of a nanopolymer additive has a positive effect on the compaction of the emerging concrete structure. Confirmation of the formation of a dense and strong structure during the hardening of nanomodified concrete is an increase in the water resistance of concrete by 2.5 times and its frost resistance by more than 2.5 times. Conclusion. The advantage of nanomodified concrete is its increased chemical resistance to carbon dioxide and magnesia corrosion and, in accordance with the index of chemical resistance coefficient, CCSт> 0.8, and GOST R 58895-2020, the developed nanomodified concrete belongs to chemically highly resistant concretes. It is advisable to recommend nanopolymer concrete with high physical and mechanical properties for the manufacture of structures for overhead power transmission lines (OPL).

High-strength concrete, tensile strength at bending, durability, chemical additive, nano-dispersion, plasticizing effect, reaction activity, overhead power line (OPL) constructions

Короткий адрес: https://sciup.org/142235789

IDR: 142235789 | DOI: 10.15828/2075-8545-2022-14-6-493-500

Текст научной статьи High-performance nano-modified concrete of increased strength and durability

Original article

C oncrete is one of the most common and unique construction materials, as its properties such as strength, cracking resistance, hardness and frost resistance can be purposefully controlled, improving each of the required parameters, as a result of the use of a certain component composition or the creation and use of high-performance complex of chemical additives of a certain nature.

The concrete manufacturing technology is quite simple, it consists of precise metering and careful mixing of

rationally selected components in order to obtain concrete mixture of a certain mobility, which is used to make products of different shapes and configurations.

The concrete mixture is hardened and formed spontaneously under natural conditions at an above-zero temperature of about +5 до +25оС. During the hardening process of the concrete mixture, hydration processes take place and complex hydrate joints of different composition, different crystalline structure, which influences the formation of artificial stone (concrete) with certain physical and mechanical properties [1–10].

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Concrete is used in various areas of construction, for example, in motor roads, airfields and railroads construction to create a high-strength surface, used in the creation of nuclear power plants for the manufacture of dense seamless structures, as well as in high-rise buildings, when creating unique buildings such as Lahta-Center with a height of 462 m in Saint-Petersburg or buildings with a height of 268 m in the Moscow-City complex in Moscow, in addition, demand and require improvement of the design for OPL (overhead power line), which help to provide electricity to towns and cities in the center of the country and in the most outlying areas.

OPL represented by poles, foundations are absolutely not protected from the influence of such external factors as wind and precipitations. The main requirement for the construction of such structures is to increase their working life. The solution to this problem can be achieved by creating a concrete with increased tensile strength at bending at the same time at high compressive strength, which should improve the resistance of the concrete structure to cracking. It is advisable and effective to increase the density of concrete in order to increase the chemical and frost resistance and waterproof, which should have a positive impact on increasing the durability of OPL [11–14].

In order to create concrete with a set of above mentioned physical and mechanical characteristics it is required a rational selection of components of the concrete mixture, and specifically it is advisable to consider the use of fine fillers, and also it is required a highly effective chemical additive of a certain nature and reactive action, which has a complex effect on the concrete system.

This research deals with the solution of the abovementioned issues and creating high-performance concrete.

METHODS AND MATERIALS

The materials presented below were used for the scientific and experimental studies.

-

1. Portland cement CEM I 42,5Н GOST 31108-2020 «Standard cement. General specifications». Physical and mechanical characteristics of Portland cement: – normal density of the cement dough (%) – 25,8;

-

– start cement setting, minute – 165;

-

– finish cement setting, minute – 257;

-

– compressive cylinder strength of concrete at 28 days, МPа – 53,5.

-

2. Sand for construction works GOST 8736-2014 «Sand for construction works. General specifications »: - particle size module Mk = 2.6,;

-

- dust and clay particles – 1,37 %;

-

- clay lump content – no.

-

3. Crushed granite as per GOST 8267-93 in fractions of 5–10 mm. «Crushed stone and gravel from dense rock for construction works. General specifications»

-

- dust and clay particles – 0,93 %;

-

- clay lump content – no.

-

4. The microsilica (SiO2) MK-85 GOST R 588942020 was considered as a filler.

-

5. To increase reactive activity of the system, a complex chemical additive was used, which has increased plasticizing and reactive action effects. The additive was based on polycarboxylate polymer combined with colloidal solution based on nanodispersions of silica hydroxide SiO2•nH2O, with particle size – (50–70) nm, and additionally as modifiers used substances of organic and inorganic nature, providing moderate air involvement (in the range of 4–6%) on the concrete mixture.

The effectiveness of the components of the additive used relative to the components of the concrete mixture was evaluated by changing of compression and flexible strength, wich was estimated according to GOST 101802012 «Concrete. Methods of strength determination by control samples».

To determine the strength parameters, samples-cubes with an edge of 100 mm and samples-prisms of 100×100×400 mm were manufactured. Concrete samples were hardened under normal conditions at temperature (20±2)оС and humidity W ≥ 95 %.

The ratio of flexible strength to compressive strength characterizes the resistance of concrete to cracking, which is essential for centrifugal poles of OPL, which have a height of up to 26 m at a wall thickness of up to 85 mm. As mentioned earlier, to increase the durability of structures, it is advisable to increase the density of the structure of the concrete used for the construction of poles of OPL.

The water absorption of concrete was determined according to GOST 12730.378 “Concrete. Methods for determining water absorption».

The durability of concrete was assessed by the indicators of frost resistance and chemical resistance, which were determined by standard methods in accordance with GOST 10060-2012 «Concrete. Methods of determination of frost resistance», GOST 12730.5-2018 «Con-crete. Methods of determination of water resistance» and GOST R 58896-2020 «Сhemically resistant concrete. Test methods».

RESULTS

The main objective of this study is to create concrete with the increased resistance to cracking. It can be achieved by the formation of hydrosilicates with elevated SiO2 content in the hardening process, which are low-base hydrosilicates and have a fibrous or needle-like structure, which has a microreinforcing effect on the forming structure of concrete, positively influencing its tensile strength during bending. To achieve this, comparative studies were carried out on the use of the microsilica (SiO2) and the

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION nanodispersions of silica hydroxide SiO2•nH2O which is part of the additive.

According to the design data for poles of OPL, most often required concrete is B30 with a brand for the workability of the concrete mixture – P3. The most rational material consumption per 1 m3 of concrete mixture has been determined on the basis of pre-selected concrete compositions:

-

- Portland cement PC CEM 42.5H – 390 kg;

-

- Sand with МК=2,25- 845 kg;

-

- Crushed stone fraction (5-10) mm - 950 kg;

-

- W/C ratio – 0,52.

In the first stage, the studies made a comparative assessment of the action efficiency of the microsilica (SiO2) and the nanodispersions of silica hydroxide SiO2•nH2O in the presence of an aqueous solution of a polycarboxylate polymer with a density ρ = 1,027 г/см3 and a value of hydrogen pH = 6.5. The effectiveness evaluation was carried out on changing the mobility of the concrete mixture and on the index of compressive strength. The results of studies are presented in table 1.

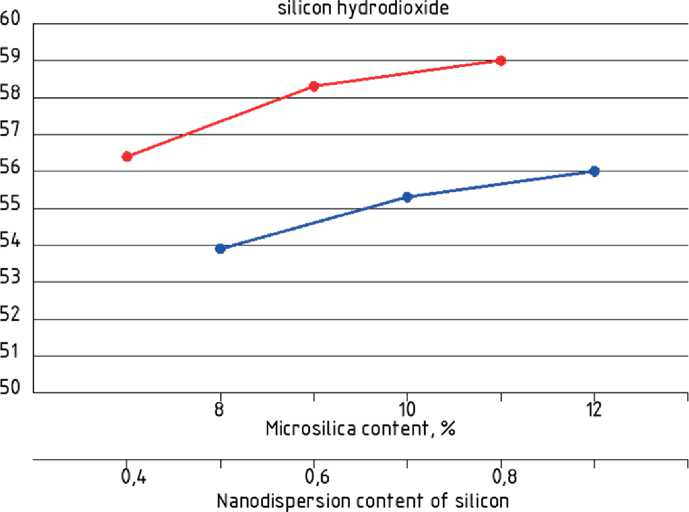

An analysis of the data presented in Table 1 shows that the action efficiency of the microsilica (SiO2) is lower than that of the nanodispersions of silica hydroxide SiO2•nH2O, which is confirmed by the absence of a plasticizing effect in the microsilica, and at the same time the increase in compressive strength in the presence

of a microcstrap is 11% against the concrete modified by a polycarboxylate polymer, while in the presence of

silicon hydroxide nanodispersions, the strength increase is 17% (Fig. 1) and there is an increase in the mobility of the concrete mixture, as evidenced by a slight decrease in the W/C ratio in the range (5–7)%.

For thin-walled high-rise constructions, their resis-

tance to cracking is essential, which is evaluated by the

index of tensile strength at bending or fracture resistance

coefficient, С fr = R tensile strength at bending

/ R сompressive strength

as

well as important for all concrete structures, especially

for those that are not protected from possible external adverse effects, to which OPL constructions may be assigned, has a durability that is to some extent correlated with the density of the emerging structure of concrete.

During further scientific and experimental studies, a comparative assessment of fracture resistance and density was made when using in a rational amount of the microsilica (SiO2) and the nanodispersions of silica hydroxide SiO2•nH2O in combination with a polycarboxylate polymer. The results of the studies are presented in table 2.

The data presented in Table 2 confirm the high efficiency of the combined action of polycarboxylate polymer and nanodispersions of silica hydroxide, resulting in a significant increase in the fracture resistance coefficient at increased compressive strength, and at the same time,

Table 1

Comparison of the microsilica (SiO2) and the nanodispersions of silica hydroxide SiO2 • nH2O efficiency on concrete mix and concrete properties

|

No. n/a |

ф ф н ф tc с с © ф — я Й 05. а £ 3 И Q |

ф Ф 8 ф ф © 1 u S С Ф Ф О |

8 1111 h ф а «2 Л Ф § С 8 а. |

3 2 8 g^ 8 S1 |

я О а ф С Ф ■i^i^ Ф Ф ХО ° ф £ .ос Z ■= s |

I |

ф и |

Ф Я ф Е |

5 ОС та ф О |

|

1 |

ОС si 0 2 |

390 |

– |

– |

– |

203 |

0.52 |

13 |

39.2 |

|

2 |

390 |

0.8 |

– |

– |

168 |

0.43 |

14 |

46.8 |

|

|

3 |

390 |

1.0 |

– |

– |

160 |

0.41 |

15 |

49.8 |

|

|

4 |

390 |

1.2 |

– |

156 |

0.40 |

15 |

50.4 |

||

|

5 |

390 |

1.0 |

8.0 |

– |

176 |

0.45 |

14 |

53.9 |

|

|

6 |

390 |

1.0 |

10.0 |

– |

179 |

0.46 |

14 |

55.3 |

|

|

7 |

390 |

1.0 |

12.0 |

– |

187 |

0.48 |

13 |

56.0 |

|

|

8 |

390 |

1.0 |

0.4 |

158 |

0.41 |

14 |

56.4 |

||

|

9 |

390 |

1.0 |

0.6 |

152 |

0.39 |

14 |

58.3 |

||

|

10 |

390 |

1.0 |

0.8 |

148 |

0.38 |

15 |

59.0 |

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Dependence of the strength of concrete samples on the amount of microsilicon additive and nanodispersion of

hydrodioxide, %

Fig. 1. Effect of microsilica and nanodispersions of silicon hydroxide on the compressive strength nanomodified concrete

Table 2

Comparison of fracture and density of concrete in the presence of the microsilica (SiO2) and the nanodispersions of silica hydroxide SiO2 • nH2O

|

No. n/a |

8 a oc & ф ф Q |

!| о S о £ .2 8 I = U w |

Ф те = 25 ° £ 8 < is |

Al © |

2 £q,i § ? 8 О о |

и ^ |

Рн ОС S |

Strength, МPа |

5 5 2 я 6 £ *pf o’ |

a о. ф |

|

|

5 ф и |

2 с3 013 S ф |

||||||||||

|

1 |

II ^ % II й ад о ^ 94s 1 94 m o' m |

390 |

— |

0.52 |

P3 |

39.2 |

4.6 |

0.117 |

4.2 |

||

|

2 |

390 |

1.0 |

– |

– |

0.41 |

P3 |

49.8 |

6.0 |

0.120 |

3.9 |

|

|

3 |

390 |

1.0 |

10.0 |

– |

0.46 |

P3 |

55.3 |

6.8 |

0.123 |

3.6 |

|

|

4 |

390 |

1.0 |

— |

0.6 |

0.39 |

P3 |

58.3 |

7.6 |

0.130 |

3.3 |

|

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION the water absorption of the hardened concrete is reduced, which may be due to a decrease in the W/C ratio and an increase in the hydration degree, because the increase in tensile strength at bending is usually due not to compaction of the concrete structure, but to the formation of hydrosilicates, SiO2, i.e. low-core, which have a fibrous structure and microreinforcing effect on the forming concrete structure.

The microsilica relative to the nanodispersions of silica hydroxide appears to have less reactive activity and less action to increase the fracture resistance of the concrete.

Therefore, further studies to assess the durability of the modified high-strength concrete were carried out with an additive based on polycarboxylate polymers modified by nanodispersions of silica hydroxide combined with an air-inducing component, ensuring rational air uptake within 4–6%.

The chemical resistance of modified concrete to carbon dioxide and magnesium corrosion was identified as the main durability parameters. To this end, modified concrete samples were treated in 5% Na2CO3 solution and 5% MgCl2 solution for 360 days. The results of the studies are presented in table 3.

The data presented in Table 3 show that concrete modified with aqueous polycarboxylate polymer solution has increased compressive strength and chemical resistance, which seems to be due not only to the sealing of the concrete structure, due to the plasticizing effect of polycarboxylate polymer, but also to an increase in hydration activity of the components of the concrete mixture.

The addition of nanodispersions of silica hydroxide SiO2•nH2O to the polycarboxylate polymer is effective, and has an additional positive effect on the increase of

hydration activity of the concrete mixture. Apparently, the pre-mixing of this components, enhances the own effectiveness of each component increasingly.

In the presence of a complex chemical additive, the compressive strength is increased by about 52%, and the concrete with the additive corresponds to class B47 relative to the design class of concrete B30, the modified concrete relates to high resistance to carbon dioxide and magnesium corrosion in accordance with GOST P 588952020 The concretes are chemically resistant. Technical conditions», while the concrete control composition according to Table 3 is «relatively stable» concrete.

Increasing the chemical resistance of the concrete used for posts or foundations of OPL is of great importance, which must be taken into account when designing these constructions.

The increased strength of concrete is usually accompanied by a decrease in the W/C ratio as a result of the modifier plasticizing effect or the formation of an increased number of new complex hydrate connections, sealing and reinforcing the forming concrete structure by creating new contacts between the concrete components, which should have a positive impact on the durability of the concrete. Scientific and experimental studies have been carried out to confirm these assumptions, the results of which are presented in table 4.

The physical and mechanical performance of modified concrete at the same cement consumption significantly exceeds the strength and durability of the test concrete composition, which leads to the assumption, that the durability of modified concrete will also increase at least twofold and should be 100 years or more, which is economically and environmentally efficient.

Table 3

Comparison of complex of physical and mechanical characteristics of concrete

|

No. n/a |

и § 5 Q ОС © g 75 "© я *я |

& - 5 = 8 © я © 3 © 5 = и ® |

© я Ilf Я © с ""^ о "§D « S |

СУ joj ! ? й 8 А £ |

2 8 су © о у О S |

су Рн 6 OJD © О |

Рн © 75 су ОС © S |

рр "о © о ’ey < |

Chemical resistance coefficient, Ccr |

|

|

© ^ Z ID Я |

а ш о а |

|||||||||

|

1 |

о s |

390 |

— |

— |

— |

39.0 |

P3 |

В30 |

0.46 |

0.43 |

|

2 |

390 |

1.0 |

– |

– |

49.6 |

P3 |

В40 |

0.73 |

0.72 |

|

|

3 |

390 |

1.0 |

0.6 |

— |

58.0 |

P3 |

В46 |

0.87 |

0.84 |

|

|

4 |

390 |

– |

– |

1.0 |

52.2 |

P3 |

В47 |

0.89 |

0.86 |

|

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

DISCUSSION

Concrete structures for OPL, represented by thinwalled poles up to 26 m high, whose diameter reaches 0.8 m, as well as foundations, which are used for fixing and installing poles, are partially in the ground, partly on the surface, are not protected from negative atmospheric influences such as alternate wetting-drying, freezingthawing. Of course, such constructions require a new level of concrete properties, which must simultaneously have a set of improved physical-mechanical characteristics, the most important of which are fracture resistance, chemical resistance, frost resistance, waterproof and increased compressive strength [15–20].

The improvement of the above parameters is possible and is achieved by the use of an effective chemical additive based on highly effective surfactants, represented by a polycarboxylate polymer, which provides a superplasticizing effect. The combination of this type of surfactant with the nanodispersions of silica hydroxide SiO2•nH2O dispersions enhances the plasticizing and water-reducing effects by more than 27%, and the presence of nanodispersions in the additive significantly increases its reactive activity, providing the formation of new hydrate phases of a certain structure, which contributes to a higher growth of tensile strength during bending and, as a result, increased cracking resistance of high-strength concrete [21–27].

The use of a complex chemical additive with nano-structural elements made it possible to solve the tasks in a sufficiently complete manner and to create a concrete with increased reliability and durability, which is expedient to use for the constructions of OPL.

CONCLUSION

It has been determined that it is advisable to use a complex chemical additive, which has increased plasticizing and reactive action effects, to produce concrete with increased cracking resistance and increased durability.

It has been experimentally confirmed that the nanodispersions of silica dioxide hydroxide are very well compatible with the surfactants based on polycarboxylate polymers, their joint presence provides a superwater-reducing effect, providing a reduction of W/C ratio of more than 27%, increasing the density of the concrete structure, as evidenced by the decrease in the amount of water absorption from the value of Wm (control composition) 4,3% to the value of Wm (nanomodified composition) 3,2%.

The increase in bending tensile strength is 67% with an increase in compressive strength of 52%, which is probably due mainly to the formation of new hydrate phases with elongated fibrous structure and microreinforcing effect on the hardening concrete mixture. Such hydrosilicates can be classified as low-core, which in its composition contains an increased amount of SiO2, which seems

Table 4

Comparison of complex of physical and mechanical characteristics of concrete

|

No. n/a |

и _

я 5 8 c 2 cy -a Ф £ c oc & Q |

о S C £ |

су о II |

и |

Рн су ОС S |

Strength, МPа |

1 5 s * 94s o’ |

Actual concrete class, В |

а о. ф су |

сУ ОС сУ |

рьГ сУ ОС ф сУ © |

||

|

и и |

5 5.^ с ^ ф |

И |

|||||||||||

|

1 |

II !^ i ll 2 ^ о ^ ^ OS m" О s |

390 |

– |

0.52 |

P3 |

39.0 |

4.6 |

0.117 |

B30 |

B tb 4.6 |

4.3 |

W4 |

F1150 |

|

2 |

390 |

1.0 |

0.38 |

P3 |

59.4 |

7.7 |

0.130 |

B47 |

Btb6.0 |

3.2 |

W10 |

F1400 |

|

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION to be possible in the presence of reactive nanodispersions of silica hydroxide SiO2•nH2O, as components of a complex chemical additive.

Developed nanopolymer concrete, characterized by high strength, reliability and durability, it is advisable to recommend and use for structural elements of OPL.

Список литературы High-performance nano-modified concrete of increased strength and durability

- Svatovskaya L.B., Sycheva A.M., Solovieva V.Ya., Surin D.V., Kozin P.A., Starchukov D.S., Surkov V.N., Yurov O.V., Mandritsa D.P., Ershikov N.V., Solovyov D.V. Modern ideas for controlling the properties of composite materials based on inorganic binders. St. Petersburg: PGUPS; 2015.

- Sakharova A.S. Influence of chemical modification of concrete surface on increase of its durability / Sakharova A.S., Surkov V.N. Bashkir Chemical Journal. 2020; 27(4):59-63. https://doi.org/10.17122/bcj-2020-4-59-63.

- Trofimov B.Yu. Trofimov B.Yu., Kramar L.Yu., Shuldyakov K.V. Methods for assessing the durability of concrete with high performance characteristics. IOP Conference Series: Materials Science and Engineering. 2020; 962(2): 022010. https://doi.org/10.1088/1757-899X/962/2/022010.

- Svatovskaya L.B., Solovieva V.Ya., Stepanova I.V., Sycheva A.M., Korobov N.V., Starchukov D.S. High strength concrete. Patent for invention RU 2332388 C1, 27.08.2008. Application No. 2006143909/03 dated 12/11/2006.

- Erofeev V.T., Emelyanov D.V., Rodin A.I. High-strength concrete based on composite binder. Patent No. 2738151 C1 Russian Federation. Published 12/08/2020.

- Svatovskaya L.B., Solovieva V.Ya., Stepanova I.V., Starchukov D.S. Nanoadditives from silicon- and ironcontaining (III) sol for heavy concrete on ordinary cements. Nanotechnologies in construction: scientific online journal. 2010; 2 (5): 61–68.

- Nikolaev, S.V., Benin, A.V., Popov, A.M. Methodology of the selection of effective dipping and control over the filling depth of open-textured construction materials. Journal of Physics: Conference Series. 2021; 2131(2): 022055. https://doi.org/10.1088/1742-6596/2131/2/022055.

- Kaprielov S.S., Sheinfeld A.V., Dondukov V.G. Cements and additives for the production of high-strength concrete. Building materials. 2017; 11: 4–10.

- Kaprielov S.S., Chilin I.A. Ultra-high-strenght self-compacting fibrous concrete for monolithic structures. Construction and Building Materials. 2013; 28.

- Tarakanov O.V., Kalashnikov V.I. Prospects for the use of complex additives in concrete of a new generation. Proceedings of the Kazan State University of Architecture and Civil Engineering. 2017; 1 (39): 223–229.

- Makridin N.I., Maksimova I.N. Optimization of the structure and prediction of the structural strength of concrete of a new generation. Regional architecture and construction. 2021; 4 (49): 13-24. https://doi.org/10.54734/20722958_2021_4_13.

- Kalashnikov V.I., Erofeev V.T., Tarakanov O.V. Suspension-filled concrete mixtures for powder-activated concrete of a new generation. News of higher educational institutions. Construction. 2016; 4 (688): 30-37.

- Benin A., Bogdanova, E. Influence of storage conditions and corrosive environments on the mechanical properties of GFRP rebars. Civil and Environmental Engineering. 2018;14 (2):86-90. https://doi.org/10.2478/cee-2018-0011.

- Trofimov B.Y., Kramar L.Y., Shuldyakov K.V. Methods of assessing the durability of high performance concrete. IOP Conference Series: Materials Science and Engineering. 2020; 962(2): 022010. https://doi.org/10.1088/1757-899X/962/2/022010.

- Kramar L.Ya., Kydyakov A.I., Shuldyakov K.V. Introducing pozzolanic admixture to improve frost resistance of pavement concrete. IOP Conference Series: Materials Science and Engineering. 2018; 451 (1): 012009. https://doi.org/10.1088/1757-899X/451/1/012009.

- Belash T.A., Mitrofanova M.N. Pile Foundations for Areas with a Joint Manifestation of Permafrost and High Seismic Activity. IOP Conference Series: Materials Science and Engineering. 2018; 463 (2): 022076. https://doi.org/10.1088/1757-899X/463/2/022076.

- Svatovskaya L., Mikhailova K., Kabanov A., Khamenok N. Specificities of soling processes in technologies of geoconstruction. Lecture Notes in Civil Engineering. 2020; 50: 421–429. https://doi.org/10.1007/978-981-15-0454-9_44.

- Svatovskaya L., Urov, O., Mikhailova, K., Supeliuk, T. Information assessment of natural geosystem preservation in geoconstruction by improving the quality of concrete. Lecture Notes in Civil Engineering. 2020; 50: 405–411. https://doi.org/10.1007/978-981-15-0454-9_42.

- Gusev B.V. Concrete with fillers of various dispersion and their nanomodification. Nanotechnologies in construction. 2019; 11(4): 384–393. https://doi.org/10.15828/2075-8545-2019-11-4-384-393.

- Kaprielov S.S., Sheinfeld A.V., Kardumyan G.S., Chilin I.A. On the selection of compositions of high-quality concretes with organo-mineral modifiers. Building materials. 2017; 12: 58-63.

- Zimakova G.A., Solonina V.A., Zelig M.P. High-performance concretes with the use of complex additives and local raw materials. Architecture, construction, transport. 2021; 1: 38-46.

- Zhukova G.G., Saifulina A.I. Study of the application of self-healing concrete. Construction and Geotechnics. 2020; 11(4): 58-68. https://doi.org/10.15593/2224-9826/2020.4.05.

- Babkov V.V., Sakhibgareev R.R., Chuikin A.E., Kabanets V.V. The role of amorphous silica in the processes of structure formation and hardening of concrete. Building materials. 2010; 44-46.

- Kaprielov S.S., Sheinfeld A.V. Some features of the mechanism of action of organo-mineral modifiers on cement systems. Seismic construction. Safety. 2017; 1: 40-46.

- Chernyshov E.M., Artamonova O.V., Slavcheva G.S. Nanomodification of cement composites at the technological stage of the life cycle. Nanotechnologies in construction. 2020; 12(3):130–139. https://doi.org/10.15828/2075-8545-2020-12-3-130-139.

- Korolev E. V., Grishina A. N., Inozemtsev A. S., Aizenshtadt A. M. Study of the kinetics of structure formation of cement dispersed systems. Part I. Nanotechnologies in construction. 2022; 3(14): 176–189. https://doi.org/10.15828/2075-8545-2022-14-3-176-189.

- E. V. Korolev, A. N. Grishina, A. S. Inozemtsev, and A. M. Aizenshtadt, Russ. Study of the kinetics of structure formation of cement dispersed systems. Part II. Nanotechnologies in construction. 2022; 4(14):263–273. https://doi.org/10.15828/2075-8545-2022-14-4-263-273.