High-strength wall ceramics based on phosphorus slag and bentonite clay

Автор: Suleimenov Zh.T., Sagyndykov A.A., Moldamuratov Zh.N., Bayaliyeva G.M., Alimbayeva Zh.B.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Application of nanomaterials and nanotechnologies in construction

Статья в выпуске: 1 Vol.14, 2022 года.

Бесплатный доступ

Introduction. One of the promising ways to get high-strength ceramics is the method of semi-dry pressing of the "coarsely dispersed component – finely ground binder" formula. This method suggests using crushed industrial waste as the core, and finely ground nanostructured fusible clay as the binder material. Methods and materials. In the research, bentonite clay of the Darbazinsky deposit of the Turkestan region was used as plastic material, and dense crystallized phosphorus slag which is a waste of phosphorus production was used as a non-plastic coarse material. The study of the prescription factors’ influence on the basic physical and mechanical properties of ceramic wall materials was carried out by the simplex method characterized as lattice planning of experiments. The nanostructure of the phosphorus slag and bentonite clay formula was studied by the electron microscopic analysis method. Results. The binder content in the amount of 25% guarantees the density of the packages, while the sintering effect becomes sufficient and the strength of the samples is 27.1 MPa. If the amount of binder increases from 25% to 40%, the sintering effect continues to grow and the strength of the samples reaches 54.3 MPa. Discussion. The results show that the most active sintering effect and the dense structures forming in coarse-grained formulas with high-calcium phosphorus slag occur at 40–60% binder content. The presence of flux around slag grains in an amount of less than 30% contributes to obtaining less dense samples, with a binder content of 40%, a density increase is observed, which corresponds to the mixed ceramic structures modeling. Conclusion. To get high-strength ceramic bricks, the content of coarsely dispersed components in the form of phosphorus slag with a fraction of less than 1.25 mm should amount to 60–70%, finely ground phosphorus slag should be 5–10%, and bentonite clay is to be 20–30%. Optimum technological indicators are: calcination temperature 1050–1100oC, pressing pressure 20–25 MPa, press powder moisture content 7–8%.

Phosphorus slag, bentonite clay, nanostructure, semi-dry pressing, pressing powder

Короткий адрес: https://sciup.org/142231176

IDR: 142231176 | DOI: 10.15828/2075-8545-2022-14-1-11-17

Текст научной статьи High-strength wall ceramics based on phosphorus slag and bentonite clay

Original article

O ne of the promising building materials with a variety of colors, textures, and shapes that can develop the quality of building cladding and improve the architectural appearance of buildings is ceramic brick [1–3].

In Kazakhstan, the demand for high-quality ceramic products, such as clinker, the facade facing bricks is increasing. The limited raw material base of high-quality clay raw materials hampers the production of the abovementioned efficient materials. The main raw materials for the ceramic bricks manufacture are loams, which are low-plastic raw materials with a short sintering interval, which does not allow obtaining high-quality bricks. The maximum strength of products made of loam, fired at a temperature of 1100oС, does not exceed 15 MPa. In this regard, the transition to a semi-dry pressing method using industrial waste is relevant. To obtain high-strength ceramic materials, it is of interest to use “coarse component – finely ground binder” formula. With such a structure, the clay fraction consumption in the formula content will be in the range of 25–30%, and 75–100% in traditional ceramics of plastic molding [4–6].

Nowadays, the attention of ceramic building materials researchers is increasingly attracted by nanosized clay binder usage [7, 8].

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

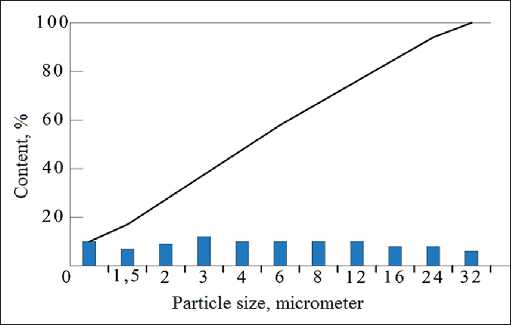

Fig. 1. Micrograph (a, ×100) and size distribution of bentonite clay particles (b): ■ – distribution by fractions; ____ – cumulative distribution

METHODS AND MATERIALS

Bentonite clay of the Darbazinsky deposit of the Turkestan region was used as a plastic material for the studied ceramic masses, and dense crystallized phosphorus slag was used as a coarse material.

Bentonite is a nanostructured material with a high specific surface area, which has the property of self-dispersion, which helps to bind a large amount of non-plastic material. It is well known that the clay mineral montmorillonite consists of three store packages. Crushed particles of the phosphorus slag, located in the interpacket layer of montmorillonite form strong structures [4, 6, 8, 9].

Determination of the granulometric composition of bentonite (Fig. 1) showed that the highly dispersed powder is equally distributed over fractions from 1 to 32 micrometers, with a predominant distribution in the range from 1 to 12 micrometers. Particles form aggregates of irregular shape [10].

Table 1 shows the chemical composition of clay and phosphorus slag.

The slag is characterized by a high content of calcium oxide (47.5%), as well as the phosphorus pentoxide presence and fluorine compounds up to 4.1%, which have a fluxing effect and help to reduce the calcination temperature of ceramic materials. In addition to basic oxides of silicon, aluminium, and iron, clay contains low-melting oxides such as CaO, MgO, Na2O and K2O [11–13].

According to the number of plasticities (38–40), clay belongs to highly plastic, according to the content of clay particles (62.5%) to highly dispersed, according to the index of refractoriness to fusible clays (1250oC).

The phase composition of bentonite clay is characterized by the quartz ( d = 0.335; 0.425 nm), illite ( d = 0.319; 0.256 nm), biotite ( d = 1.000; 0.353 nm), montmorillonite ( d = 0.950; 0.225 nm), kaolinite ( d = 0.709 nm) presence. Carbonate inclusions are represented by calcite ( d = 0,303; 0.228 nm). Potassium feldspar and ferritic phases are also present. The content of montmorillonite is 80–85% [14–16].

Phosphorus slag from the Taraz phosphorus plant is a dense, crystallized mass that melts at a temperature of 1320–1350oC. The phase composition of phosphorus slag is represented mainly by wollastonite and cuspidin [17, 18].

Samples of wall ceramic bricks were made as follows. The slag was subjected to crushing and screening through a 1.25 mm sieve. To obtain a binder, slag and clay were subjected to grinding in a ball mill until they completely passed through a 0.063 mm sieve. Slag granules less than 1.25 mm in size were subjected to moisture until a moisture content of 8% was reached, then a binder was applied

Table 1

Chemical composition of raw materials

|

Raw material |

Composition, mass. % |

|||||||||

|

SiO2 |

Al 2 O 3 |

Fe 2 O 3 |

CaO |

MgO |

Na2O |

K2O |

SO3 |

F + P 2 O 5 |

calcination losses |

|

|

Bentonite Clay |

60.51 |

16.06 |

6.43 |

1.27 |

2.23 |

2.41 |

2.8 |

1.3 |

– |

8.7 |

|

Phosphorus slag |

41.3 |

2.8 |

0.4 |

47.5 |

1.2 |

0.3 |

0.1 |

0.6 |

4.1 |

0.2 |

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION to their surface. The prepared press powder was poured into a mold and subjected to pressing at a pressure of 15–25 MPa. The strength of the molded raw material is 0.35–0.4 MPa, which satisfies the requirements of the automatic stacker. The sintering process of the composition was studied on cubes samples of 50×50×50 mm in size. Samples were dried at a maximum temperature of 105oС for 3 hours; calcination was carried out in an electric muffle furnace at a temperature of 1050–1100oС with an isothermal exposure of 30 min [19–21].

In order to determine the optimal ratio of the core and the shell, the structures were modeled at a ratio of 5, 10, 20. The amount of the shell substance varied from 20 to 50%. The size of the core aggregates was changed from 0.5 to 1.25 mm, the thickness of the shell was changed from 0.05 to 0.3 mm. The strongest structures were obtained at a ratio of their sizes equal to 10–20.

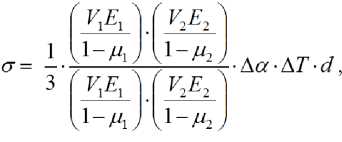

In the technology of semi-dry pressing, it is important to establish the maximum grain sizes of the coarsely dispersed component. To do this, the temperature stresses at the grain boundaries were calculated according to the formula of W.D. Kingery [7]:

where: σ – stress in the contact layer, MPa; E1 and E2 – moduli of elasticity, MPa; µ1, µ2 – Poisson’s ratios; ∆α is the difference in the temperature coefficient of the linear expansion of the phases; ∆T is the temperature interval in which stresses arise; d – grain size; V – are the volume fractions of the contacting phases.

From the analysis of changes in the thermal stresses developing at the grain boundaries, the maximum sizes of slag grains (1.25 mm) were selected.

Studies of the microstructure of ceramic samples were carried out on a JEOL JSM7500 scanning electron microscope with an X-ray spectral analysis attachment [20].

RESULTS

The influence study of recipe factors on the basic physical and mechanical properties of ceramic wall materials was carried out by the simplex-lattice planning of experiments using the properties of an incomplete cubic form model as a mathematical model [21]:

Y = A 1 + A 2 + A 3 + A 4 xy + A 5 xz + A 6 yz +

+ A 7 xyz + A 8 xy ( x–y ) + A 9 xz ( x–z ) + A 10 yz ( y–z ). (2)

The ultimate compressive (R com ) and bending strength (R bend ), shrinkage (U, %), and water absorption (W, %) were studied as Y response functions.

The followings were used as raw materials for the ceramic bricks production:

-

Х 1 – the content of phosphorus slag fraction less than 1.25 mm, 55–70%;

Х 2 – the content of finely ground bentonite clay, 25–40%;

Х 3 – the content of finely ground phosphorus slag, 5–20%.

The experiment planning matrix is given in the Table 2.

Table 2

Experiment Design Matrix

|

Composition number |

Content of components,% |

Properties |

|||||

|

Phosphorus slag fraction less than 1.25 mm, % |

Bentonite clay, % |

Finely ground phosphorus slag, % |

U, % |

Rcom, МPа |

Rbend, МPа |

W, % |

|

|

Х 1 |

Х 2 |

Х 3 |

|||||

|

1 |

70 |

25 |

5 |

0.9 |

26.1 |

2.8 |

13.8 |

|

2 |

55 |

40 |

5 |

1.9 |

54.3 |

4.7 |

5.2 |

|

3 |

55 |

25 |

20 |

1.6 |

36.7 |

3.6 |

8.2 |

|

4 |

65 |

30 |

5 |

1.2 |

32.3 |

3.4 |

11.8 |

|

5 |

60 |

35 |

5 |

1.6 |

51.5 |

3.7 |

10.4 |

|

6 |

65 |

25 |

10 |

1.4 |

30.8 |

3.2 |

11.8 |

|

7 |

60 |

25 |

15 |

1.5 |

34.7 |

3.7 |

11.2 |

|

8 |

55 |

35 |

10 |

1.1 |

45.3 |

3.6 |

7.4 |

|

9 |

55 |

30 |

15 |

1.2 |

38.6 |

3.7 |

8.6 |

|

10 |

60 |

30 |

10 |

1.4 |

43.4 |

3.9 |

10.9 |

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

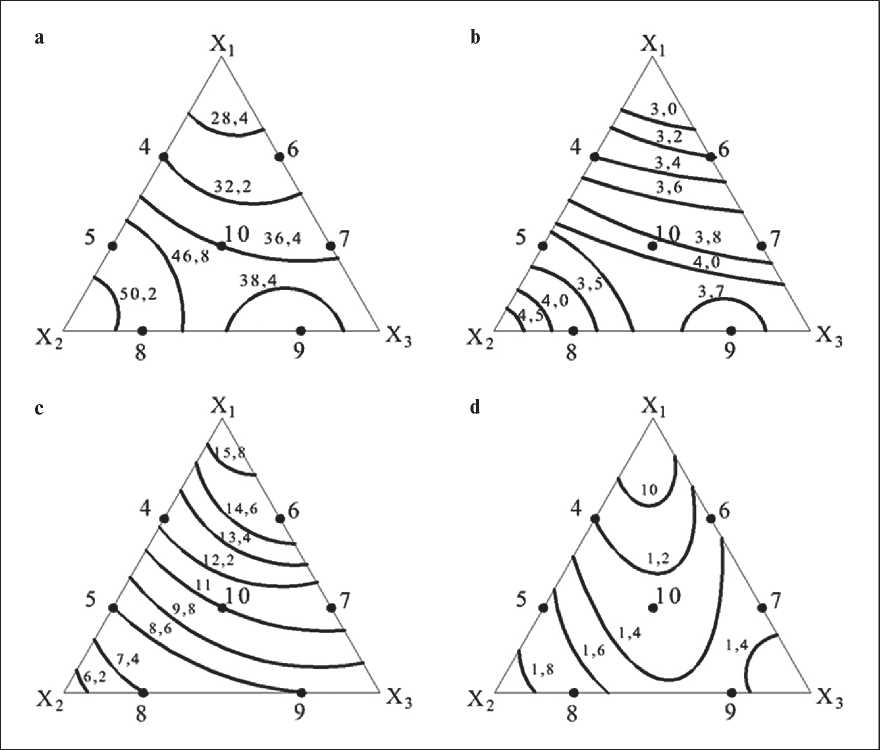

Fig. 2. Equal values lines of high-strength ceramics properties changes:

a – compressive strength; b – bending strength; c – water absorption; d – shrinkage

The figurative points of the binder compositions based on slag and clay are in the CaO–Al 2 O 3 –SiO 2 state diagram and are located in the anorthite-wollastonite-quartz triangle with eutectic at a temperature of 1165oC.

The regression equation of the compressive strength dependence of ceramic bricks on the composition of the charge has the form:

Rc = 27,1 x 1 + 54,3 x 2 + 49,7 x 3 – 17,1 x 1 x 2 +

+ 18,225 x 1 x 3 – 61,875 x 2 x 3 + 315 x 1 x 2 ( x 1 – x 2 ) +

+ 400,275 x 1 x 3 ( x 1 – x 3 ) + 282,375 x 2 x 3 ( x 2 – x 3 ) +

+ 228,15 x 1 x 2 x 3 . (3)

The clay content in the amount of 25% guarantees the packing density, the sintering effect becomes sufficient, and the samples strength is 27.1 MPa (Fig. 1, b). If the clay amount increases from 25% to 40%, the sintering effect continues to grow and the samples strength reaches 54.3 MPa.

According to the obtained “composition-property” diagrams (Fig. 2, a, b, c, d), ceramic bricks have low shrinkage (0.9–1.6%), water absorption (7.4–12.1%), high bending strength index (2.8–4.7 MPa).

DISCUSSION

The obtained results show that the most active sintering and dense structures formation in coarse-grained formulas with high-calcium slag occur at a binder content of 35–45% and core-to-shell ratios of 10–20 in accordance with the mixed ceramic structures modeling [17–19].

According to thermodynamic calculations, the most likely anortite (CaO Al 2 O 3 2SiO 2 ), quartz, and wollastonite formation is in the calcination process at temperatures of 400, 800, and 1000oC; such phases with the largest negative values of the Gibss free energy (∆Z), with densities that do not change during the synthesis process and contribute to the increase in the brick strength.

The frame structure creation was ensured through the use of a polyfractional composition (phosphorus slag) and finely ground bentonite and phosphorus slag binder.

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

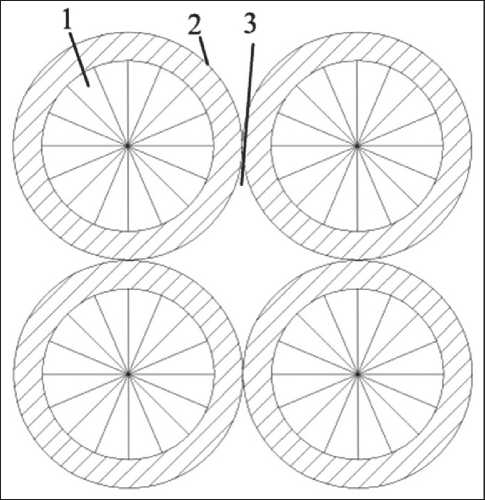

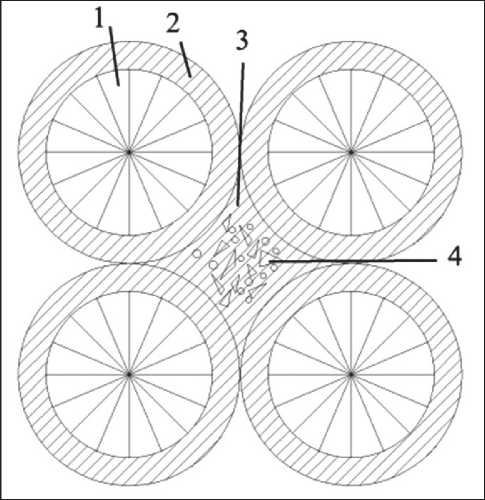

Fig. 3. Frame structure model of ceramic materials according to the “core – shell” type:

1 – slag granule; 2 – binder; 3 – pores; 4 – binder and wollastonite and anorthite crystals

Figure 3 shows frame structure models of the material constituent elements (crystal frame and binder).

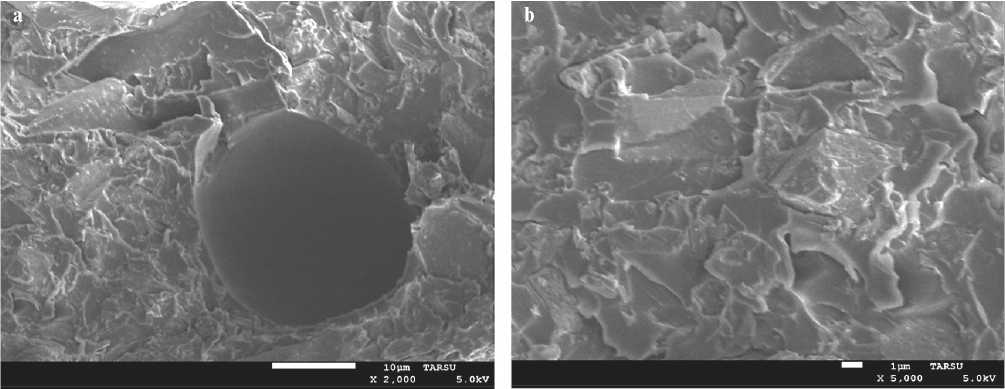

The samples structure from the granular slag with binders formula is the most pronounced variant of “core – shell” type structures (Fig. 4, a, b). And the nature of slag with binders structures most clearly reflects the process of their formation. It can be seen from the structure of the samples that the binder forms shells not only around large grains but also around medium and small slag grains located between them. It may be viewed that the shells interact with the surface of the grains to form the crystalline phases of wollastonite and anorthite. The shell and grain interaction proceeds very actively. As a result of this interaction, a fairly noticeable transition zone is formed from the slag grain surface to the shell. The transition zone formation determines the slag grain and the shell consistency. Therefore, the samples strength is high and amounts to 49–54.3 MPa in compression and 4.3–4.7 MPa in bending [15].

From the structure of the densely sintered samples, achieved by using the maximum (40%) amount of clay in the binder and after calcination at a high temperature

Fig. 4. Ceramics microstructure from the phosphorus slag and bentonite clay composition: a – calcination temperature 1050oC; b – calcination temperature 1100oC

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

(1050–1100oC), it is seen that the smallest slag grains are involved in the liquid phase formation. The amount and reactivity of the glass phase increases due to the influence of fluorine-containing components of the slag. As a result, the thickness of the zone between the large slag grains surface and the shells grows and the crystallization of the new phases in the form of wollastonite and anorthite became active in the shell. Furthermore, glass phase viscosity decrease due to calcium ions, a growth in its penetrating ability and the glass phase affinity for slag grains contribute to its spreading over the samples’ surface and the vitreous coating formation, which crystallizes upon cooling [14].

Interaction products are observed along the slag grains edges and between them, as well as on their surface.

CONCLUSION

To get high-strength ceramic bricks, the content of coarsely dispersed component in the form of phosphorus slag with a fraction of less than 1.25 mm should amount to 55–65%, finely ground phosphorus slag should be 5–10%, and bentonite clay is to be 30–40%. The most favorable technological parameters are: calcination temperature 1050–1100oС, pressing pressure 20–25 MPa, press powder moisture content 7–8%.

Список литературы High-strength wall ceramics based on phosphorus slag and bentonite clay

- Suvorova O.V., Selivanova E.A., Mikhailova J.A., Masloboev V.A., Makarov D.V. Ceramic products from mining and metallurgical waste. Applied Sciences (Switzerland). 2020; 10 (10): 3515.

- Poznyak A.I., Levitskii I.A., Barantseva S.E. Production of interior facing tiles using local raw materials. Glass and Ceramics. 2012; 69: 77–80.

- de Figueirêdo J.M.R., Sousa Silva J.R., de Araújo Neves G., Ferreira H.C., de Lima Santana L.N. Influence of processing variables on clay-based ceramic formulations. Materials Research. 2019; 22 (3): e20180548.

- Kadyrova Z.R., Purkhanatdinov A.P., Niyazova S.M. Research of benonite clays of Karakalpakstan for producing ceramic heat-insulating materials. New Refractories. 2020; (9): 3–5.

- Chetverikova A.G., Kanygina O.N., Alpysbaeva G.Z., Yudin A.A., Sokabayeva S.S. Infrared spectroscopy as the method for determining structural responses of natural clays to microwave exposure. Condensed Matter and Interphases. 2019; 21 (3): 446–454.

- Asal S., Erenturk S.A., Haciyakupoglu S. Bentonite based ceramic materials from a perspective of gamma-ray shielding: Preparation, characterization and performance evaluation. Nuclear Engineering and Technology. 2021; 53 (5): 1634–1641.

- Montayev S., Shakeshev B., Zharylgapov S. Development of a technology for producing ceramic refractory material in a composition of montmorillonite clays (bentonite-like) and ferrochrome production wastes. MATEC Web of Conferences. 2020; 315, 07007.

- Kadyrova Z.R., Purkhanatdinov A.P., Niyazova Sh.M. Karakalpakstan Bentonite Clays – Perspective Raw Materials for Obtaining Ceramic Heat-Insulating Materials. International Journal of Innovative Technology and Exploring Engineering. 2020; 9 (8): 417–420.

- Erdogan Y., Kok O.E. Production and characterization of nanobentonite from Sodifm bentonite with mechanical grinding. Fresenius Environmental Bulletin. 2019; 28 (11): 8141–8150.

- Kadyrova Z.R., Purkhanatdinov A.P., Niyazova S.M. Study of Karakalpakstan Bentonite Clay for ProducingCeramic Heat-Insulating Materials. Refractories and Industrial Ceramics. 2021; 61 (5): 478–480.

- Ngoc Lam N. Eco – Concrete made with phosphogypsum-based super sulfated cement. IOP Conference Series: Materials Science and Engineering. 2020; 869 (3), 032031.

- Nguyen V.H., Nguyen V.C., Nguyen T.C., Tran D.M.T., Nguyen T.T.T., Vu Q.T., Nguyen D.T., Thai H. Treatment of Yellow Phosphorus Slag and Reuse of It as an Absorbent of Chromium (VI) Ions and Methylene Blue. Journal of Chemistry. 2020; (1): 1–16.

- Garbaya H., Jraba A., Khadimallah M.A., Elaloui E. The Development of a New Phosphogypsum-Based Construction Material: A Study of the Physicochemical, Mechanical and Thermal Characteristics. Materials (Basel). 2021; 14 (23): 7369.

- Djobo J.N.Y., Stephan D. Control of the setting reaction and strength development of slag-blended volcanic ash-based phosphate geopolymer with the addition of boric acid. Journal of the Australian Ceramic Society. 2021; 57 (4).

- Najimi M., Ghafoori N., Sharbaf M. Alkali-activated natural pozzolan/slag binders: Limitations and remediation. Magazine of Concrete Research. 2020; 72 (18): 919–935.

- Sarsenbayev N.B., Kurbaniyazov S.K., Saktaganova N.A., Karshygayev R.O. The influence of additives of dehydrated clay on the properties of unburned binders and concrete on their basis. IOP Conference Series: Materials Science and Engineering. 2020; 945 (1), 012048.

- Kenzhaliyev B.K., Surkova T.Y., Abdikerim B.E., Berkinbayeva A.N., Abikak Y.B., Yessimova D.M. Research on sorption properties of phosphoric production slag-waste. Metalurgija. 2022; 61 (1): 209–212.

- Tian X., Zhang Y., Zhao F. Mechanism of steel slag-phosphoric acid system regulating the setting performance of phosphogypsum based building gypsum. Huagong Jinzhan/Chemical Industry and Engineering Progress. 2021; 40 (8): 4438–4444.

- Werner V.F., Khudyakova T.M., Sarsenbayev B.K., Kashey A.M., Sauganova G.R. Production of synthetic wollastonite based on phosphoric slag and amorphous silica produced by “solar” silicon. Materials of the International scientific and Practical online conference dedicated to the 60th anniversary of the Doctor of Technical Sciences, Professor Sayd-Alvi Yusupovich Murtazaev. 2021; 135–138.

- Gao P., Lu X., Yang C., Li X., Shi N., Jin S. Microstructure and pore structure of concrete mixed with superfine phosphorous slag and superplasticizer. Construction and Building Materials. 2008; 22(5): 837–840.

- Suleimenov Z.T., Sagyndykov A.A., Kirgizbaev A.T. Ceramic Face Tiles Using Phosphoric Slags. Glass and Ceramics. 2016; 73: 62–65.