How Nanocarbon Fillers Influence Properties of the Composite Materials

Автор: Vlada N. Ilyina, Stepan V. Ilyin, Victoria A. Gafarova, Iskander R. Kuzeev

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: The study of the properties of nanomaterials

Статья в выпуске: 3 Vol.15, 2023 года.

Бесплатный доступ

Introduction. Currently the most promising type of repair uses composite materials to fill in fractures or fracture-like defects. In order to be effective, the composite material must possess high fluidity in its liquid state to ensure it can fill the cavity of the defect, adhesion to steel to bond the edges of the crack, and plasticity to compensate for any deformation caused by regular and static loading of the structure. Methods and materials. Composite materials with nanocarbon fillers were studied, including fullerenes, nanotubes, and graphene. The solutions to the problems were obtained using both standard and independently developed methods, statistical data processing techniques, and modern software complexes. Results and discussion. The composite material with a fullerene filler demonstrates a sustainable fluidity in comparison to other studied composites. This allows to recommend such a material for fixing cracks with a slight opening. The composite with a carbon nano tube filler maintains the fluidity at the same level within 35 minutes on average. It can be used as a repair material in cases where the location of the defect does not allow for its sealing to be carried out in a short period of time. Conclusion. The conducted research allows to solve the direct and inverse problem: a) studying properties of a composite material and designing its structure allow to determine, if it fit to certain dimensions of the crack; b) a detected crack with a certain configuration of the cavity can be offered the most suitable properties of the composite by adjusting its content.

Fill in fractures, composite materials, fullerenes, carbon nanotubes, graphene

Короткий адрес: https://sciup.org/142238288

IDR: 142238288 | DOI: 10.15828/2075-8545-2023-15-3-228-237

Текст научной статьи How Nanocarbon Fillers Influence Properties of the Composite Materials

Original article

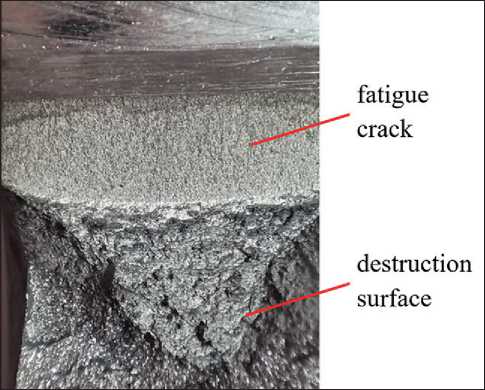

T he experience of studying structures many years shows that many defects such as inclusions of various origins, constellations of disturbances and vacancies, microcracks appear during fabrication. During operation areas around such defects form new cracks and spread existing ones due to high concentration stress. This leads to local or total destruction of the item.

Currently the most promising type of repair uses composite materials to fill in fractures or fracture-like defects. . If a liquid composite material is injected inside such a defect, the material’s structure forms in a restricted way; the composite adheres to the crack edges. It limits further opening of the defect [2]. The computational modelling of a crack fixed with a composite shows that secured edges reduce stress to the apex of the crack. Consequently, possible value singularity is prevented [3–6].

METHODS AND MATERIALS

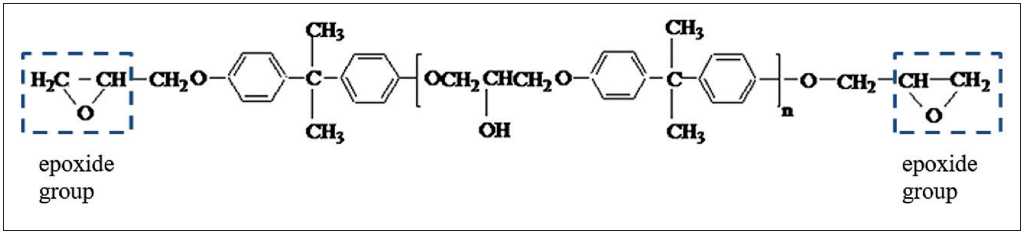

The matrix of composite material should ensure integrity of the material and distribute internal stress. The research uses ED-20 epoxy-diane resin as the polymeric matrix. The structural formula of the resin is given in Fig. 1.

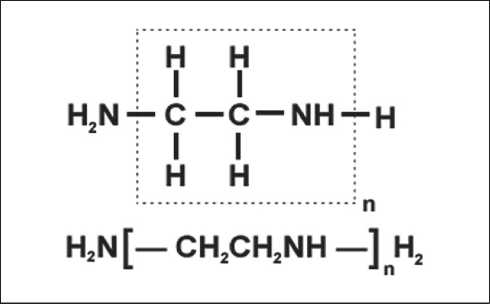

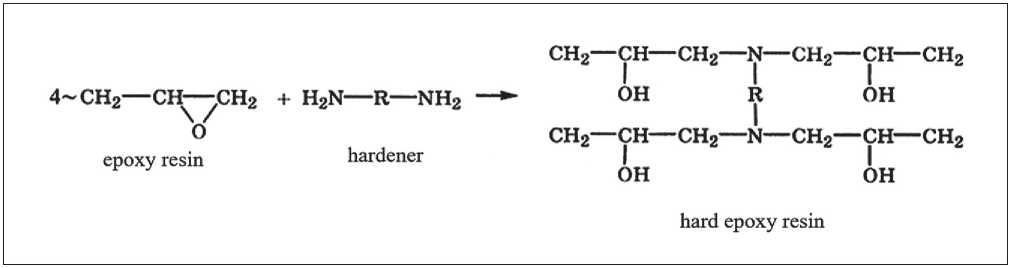

For the epoxy resin to cure, polyethylene polyamine was used. Its structural formula is given in Fig. 2. Poly-

THE STUDY OF THE PROPERTIES OF NANOMATERIALS

Fig. 1. The structural formula of ED-20

Fig. 2. The structural formula of polyethylene polyamine ethylene polyamine allows curing at the ambient air temperature of 20–25оС.

The study researches composite materials with nanocarbon fillers, such as fullerenes, nanotubes and graphene.

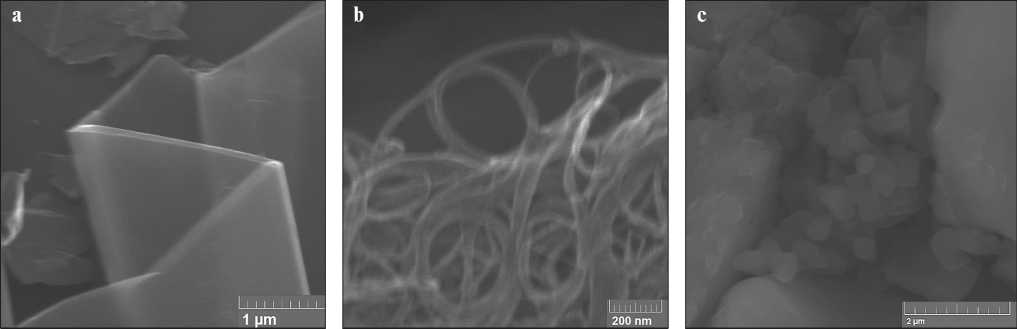

Carbon nanotubes are monodimensional, as their length is several times bigger than their diameter. They are folded sheets of graphene that form hollow cylindrical molecules. Carbon atoms in them are in the state of sp2-hybridization. The specific surface area is around 500–1000 m2/g [16]. The typical structure of carbon nanotubes is shown in Fig. 3b.

Graphene is two-dimensional allotropic carbon. It is a flat aromatic molecule with a developed and bilaterally accessible surface (the free surface area is up to 2630 m2/g), the carbon atoms are in the state of sp2-hybridization [16]. The typical structure of graphene is shown in Fig. 3a.

Fullerenes are three-dimensional fillers. They are enclosed-volume carbon molecules with high curvature. The specific surface area is around 1340 m2/g [40]. They are multi-atom molecules and have the form of pentagons or hexagons with common edges. The carbon atoms are in the state of sp2-hybridization. The typical structure of fullerene is shown in Fig. 3c.

The diluent is gasoline-based magnetic fluid with Fe2O3 magnetic particles of size from 5 to 30 nm. The study’s [1] authors use magnetic fluid to reduce movement resistance in the flow through narrow channels.

When epoxy resins form structures and cure, the mixture is heated up. To explore the pattern of how composite material’s components influence the flow of the exothermic reaction of composite polymerization, the researchers record the thermal effects with a thermographic camera Ti55 IR Flexcam.

The composites’ fluidity is defined by metering the velocity of one drop of the composite material moving down a slope plate to determine the time/distance ratio.

Fig. 3. The typical structure of nanocarbon fillers: a – graphene, b – carbon nanotubes, c – fullerenes

THE STUDY OF THE PROPERTIES OF NANOMATERIALS

The ability to wet metal surfaces with the composite material is researched in the following manner. Drops of the composite were applied one by one to a metal plate. Right after the drops are photographed. Then, the photos are processed with Kompas-3D software to determine the wetting angle.

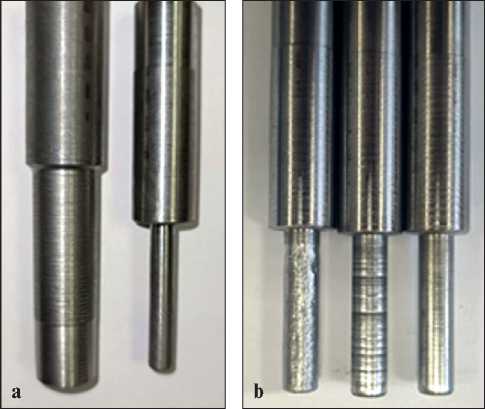

To research how metal surface roughness affects the adhesive strength between the composite material and steel, two substandard specimens are used. They are counter-parts. One them has a cavity to be filled with the composite while the other has a cylindrical stem (Fig. 4). The assumed scope of application of the composite material is filling actual cracks. Therefore, the range of research was selected by measuring the surface roughness formed in the sample crack (Fig. 5). The roughness is assessed with a profilometer TR200. The parts’ adhesion was teste with a tension test machine Instron 8801.

The composite material’s shrinking due to polymerization is tested filling in metal slots with the researched material and measuring the distance between the slot top edge and the hardened composite. The measurements are made with a beam-compass.

RESULTS AND DISCUSSION

When epoxy resin hardens due to interaction of epoxy and aminogen groups, chemical and thermodynamic processes happen and form cross-linked networks (Fig. 6). Liquid oligomer turns hard stage-wise. The first stage is branched macromolecules. They form and then start to interact with one another to form nodes of the network while the mixture becomes thicker. Then, the material completely loses its fluidity [18].

V.A. Gafarova in her study [1] used thermograms to research how composite material components interact. The findings show that this method can be used to study how the dispersion phase is distributed in the composition. Therefore, a series of experiments is arranged to determine the pattern of how composite material’s components influence the flow of the exothermic reaction of composite polymerization.

Fig. 4. The substandard test specimens used to research how metal surface roughness affects the adhesive strength between the composite material and steel: a – specimen appearance; b –specimen with various stem roughness

Fig. 5. Specimen surface with formed crack whose roughness was assessed with a profilometer TR200

Fig. 6. Epoxy resin hardening reaction with polyethylene polyamine hardener

THE STUDY OF THE PROPERTIES OF NANOMATERIALS

There a few hypotheses on how nanosized fillers influence composite materials.

The authors [19] claim, that when a filler is injected in the epoxy base it may alter the stoichiometric ratio at the surface joining the matrix and the filler. Hardening may lead to extra links between the resin and the filler or it may lead to changes in the structure of the formed matrix

resulting in impact on the hardening completeness or the mechanical properties of the resin.

It is displayed [41–47], that the high modifying power of the nano-fillers is determined by the significant specific surface area. Due to that fact that nano-particles have the high surface energy, they tend to adsorb various macromolecules [16]. The authors [15, 20, 9] assume

—•- Mixture 1 (epoxy resin + x hardener)

—o— Mixture 2 (composite with graphene)

5 30 SS 80 105 130 155 180 205

-•— Mixture 7 (epoxy resin + X hardener + Y diluent)

-♦— Mixture 8 (epoxy resin + X hardener + graphene)

Time, minute

b

-♦-Mixture 5 composite with fullerenes)

Time, minute

Mixture 4 (epoxy resin + X' hardener)

Mixture 6 (epoxy resin + Xr hardener + Y' diluent)

—♦— Mixture 9 (epoxy resin + X' hardener + fullerenes)

Time, minute

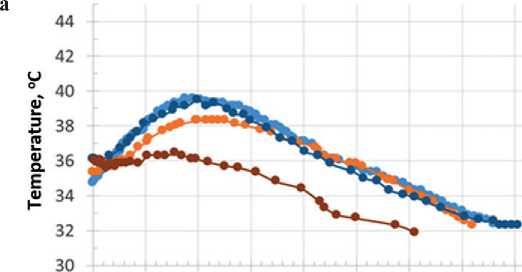

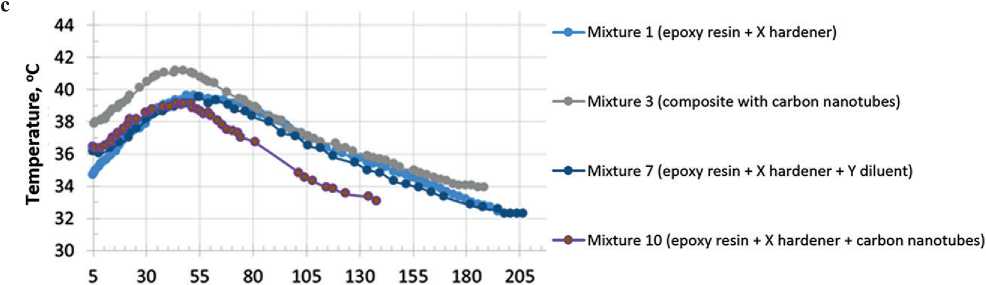

Fig. 7. Temperature curves of composites with carbon fillers: graphene (a), fullerenes (b), carbon nanotubes (c): X, X’ – amount of the hardener in the mixture; Y, Y’ – amount of the diluent in the mixture

THE STUDY OF THE PROPERTIES OF NANOMATERIALS that if the epoxy base and the filler enter an adsorption process, it may reduce the mobility of macromolecules and consequently their reactivity.

Besides, the authors [9] suggest that the high adsorption capacity allow nano-particles to become centers of chemical linking in polymers.

To check-prove the above hypotheses they studied how nano-sized carbon fillers influence hardening of the composite material.

The component ration in composites is selected based on the earlier complete factorial experiment [17]. The experiments find the best recipes ensuring the best sought adhesion and cohesion strengths of the composite materials.

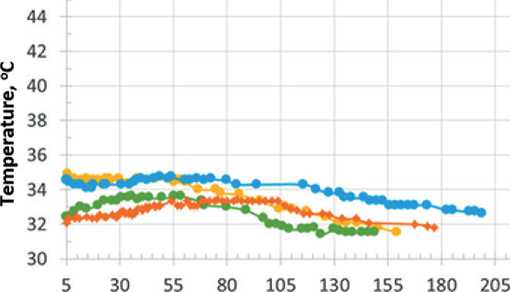

The composite temperature curves during polymerization are presented in Fig. 7. The nature of temperature changes during polymerization can be described with two stages. At the stage one temperature of the mixture increases until it hits the peak. During stage two the mixture is cooling down.

All graphs show that polymerization curves for the developed composite materials (mixtures 2, 5 and 3) are higher than curves of epoxy resin+hardener+filler mixtures (mixtures 8, 9, 10). This can be related to the fact that carbon nano-materials (fullerenes, graphene and carbon nanotubes) have the high surface energy, intense adhesion properties and tend to form agglomerates hundreds of micrometers big. The more the agglomerate is getting, the less adsorbing it becomes due to the decreasing specific surface area. As the result, the number of oligomer macromolecules in the intermediary-phase structures drops. If a diluent is added in to reduce the mixture’s viscosity, it breaks the agglomerates down and makes the particles distribute evenly in the composite material.

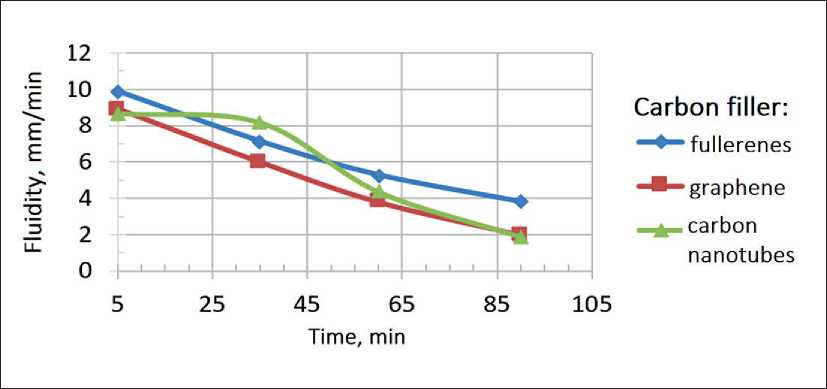

To make the composite material fill in the crack cavity, the composite should be very fluid. They study how the

composite’s fluidity alters in terms of time since polymerization started. The findings are given in Fig. 8.

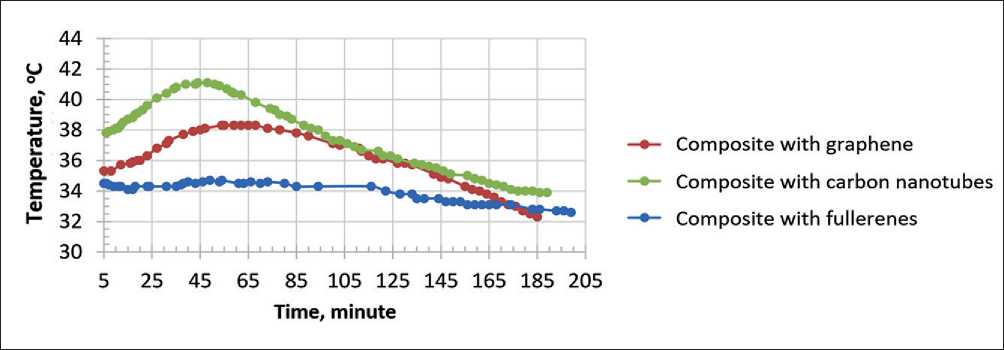

The fluidity of composite material with nanocarbontube-filled composite filler remains at the same level for 35 minutes, after which it sharply decreases (Fig. 8). This can be attributed to the fact that the temperature of the nanocarbon-tube-filled composite material is significantly higher at the beginning of the experiment compared to other investigated composites. Additionally, throughout the 39-minute testing period, there is a self-heating of the mixture which prevents the fluidity from decreasing in this particular composite. (Fig. 9). This property allows to recommend the nanocarbontube-filled composite material for fixing defects that take long to fix because of their complex location. The fullerene-filled composite material demonstrates sustainably high fluidity in comparison to other reviewed composites (Fig. 8), therefore, it is recommended to fix cracks with slightly op en edges.

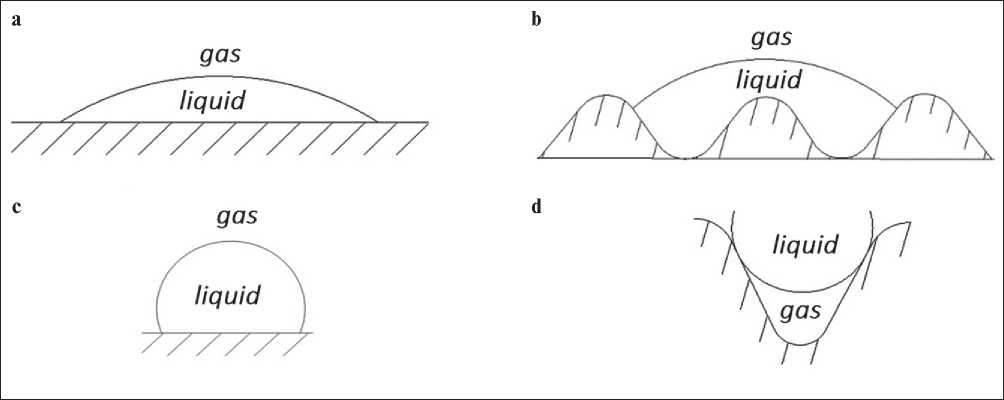

When the composite material flows down the metal surface, it is one of the factors affecting the adhesion strength between the adhesive and the substrate [23]. Fig. 10 displays a few options for wetting differently rough surfaces with a liquid.

If the liquid is good at wetting a highly rough surface, the area of actual contact increases in comparison to the smooth surface, as it is shown in Fig. 10a and 10b.

If the liquid is bad at wetting a highly rough surface, the outcome is opposite. The area of actual contact decreases in comparison to the smooth surface, as it is shown in Fig. 10c and 10d.

Thus, wetting the crack walls with the composite material plays the vital role in its filling degree: the less the wetting angle is, the higher the crack filling degree is [28].

The study considers how the composite wets the metal surface. The findings are given in Table 1.

Fig. 8. Dependence of composite material fluidity on time since polymerization started

Table 1

Angle of wetting metal surface with composite

|

Angle of wetting, о |

Filler |

||

|

Carbon nanotubes |

Graphene |

Fullerenes |

|

|

№ 1 |

55 |

55 |

56 |

|

№ 2 |

53 |

55 |

55 |

|

№ 3 |

50 |

53 |

53 |

|

average |

53 |

54 |

55 |

THE STUDY OF THE PROPERTIES OF NANOMATERIALS

Fig. 9. Patterns of temperature changes in composite materials with three types of nano-sized carbon fillers

Fig. 10. Wetting of surfaces with different roughness by a liquid: smooth surface, good wetting (a); rough surface, good wetting (b); smooth surface, bad wetting (c); rough surface, bad wetting (d) [23]

All the reviewed composite materials effectively wet the metal surface, as the wetting angle lays in the range 0о < θ < 90о.

There is a hypothesis [23, 24] suggesting that the rougher the surface is, the better the adhesion strength is between a liquid and a metal in connection with

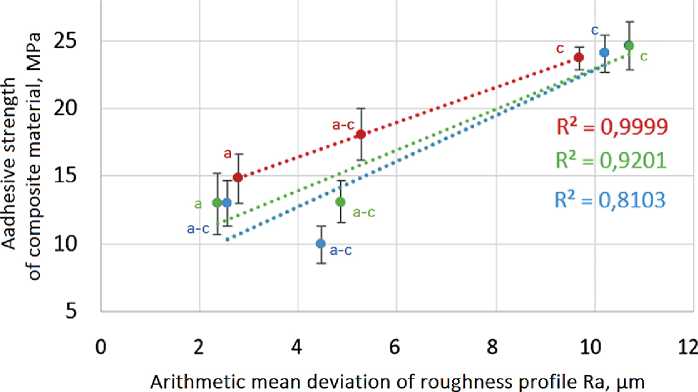

the bigger actual contact area. The check-prove this hypothesis a series of experiments is conducted. The findings allow to display how the adhesive strength between the composite material and metal correlates with the metal surface roughness. The findings are given in Fig. 11.

THE STUDY OF THE PROPERTIES OF NANOMATERIALS

• Composite with graphene

Composite with carbon nanotubes

• Composite with fullerenes

Fig. 11. How the adhesive strength between the composite material and metal correlates with the metal surface roughness

As it is shown in Fig. 11, all reviewed recipes of composites demonstrate better adhesive strength between the composite and the metal, if the surfaces are rougher. It is confirmed by the fact that having roughness around Ra = 12 µm, composites with all types of filler tend to cohesive destruction.

While composite materials are hardening, certain amounts of volatile components are produced, which leads to shrinking. Under the shrinkage stress the layer of polymer materials forms irreversible deformations leading to residual stress. They substantially affect the composite’s properties leading to a worse strength, cracks and defects [25, 9, 15]. The findings of measuring the composite shrinkage during polymerization are given in Table 2.

All reviewed materials demonstrate little-to-none shrinkage, which speaks for minor residual stress caused by composite polymerization.

CONCLUSION

The conducted research allows to solve the direct and inverse problem: a) studying properties of a composite material and designing its structure allow to determine, if it fit to certain dimensions of the crack; b) a detected crack with a certain configuration of the cavity can be offered the most suitable properties of the composite by adjusting its content.

The analysis shows that the composite material with a fullerene filler demonstrates a sustainable fluidity in comparison to other studied composites. This allows to recommend such a material for fixing cracks with a slight opening.

The composite with a carbon nano tube filler maintains the fluidity at the same level within 35 minutes on average. It can be used as a repair consumable, if the defect does not allow fixing within a short period of time.

Table 2

Measurements of composite shrinkage during polymerization

|

Carbon filler |

Shrinkage, mm |

|||

|

Experiment No. 1 |

Experiment No. 2 |

Experiment No. 3 |

Average |

|

|

Graphene |

0.05 |

0 |

0.05 |

0.03 |

|

Carbon nanotubes |

0.02 |

0.01 |

0.02 |

0.02 |

|

Fullerenes |

0.01 |

0 |

0 |

0 |

THE STUDY OF THE PROPERTIES OF NANOMATERIALS

Список литературы How Nanocarbon Fillers Influence Properties of the Composite Materials

- Gafarova V.A. Materials and method of sealing cracks in oil and gas equipment during the maintenance period of operation: diss. … cand. tech. sciences: 05.16.09. Ufa. 2019. 132 p. (In Russ.).

- Gafarova V.A., Krioni N.K., Mingazhev A.D. Restoration repair of the main pipeline during its operation. Prom-Engineering: III International Scientific and Technical Conference. 2017;121-125. (In Russ.).

- Gafarova V.A., Babin A.Yu., Bazarova Yu.V., Kuzeev A.M. Influence of composite material on stress distribution in the crack region Modern technologies of composite materials. 2019;295-296. (In Russ.).

- Gafarova, V.A., Babin A.Yu., Gareeva E.R., Abdrakhmanova K.N., Lomakina L.N. Influence of a filler on strength characteristics of the properties of a composite material based on epoxy resin. Materials Today: Proceedings. 2019;11:252-257.

- Abdrakhmanova K. N., Babin A.Yu., Gareeva E.R., Gafarova, V.A. Modeling of crack filling with composite material in the Abaqus software package. Industrial safety expertise and diagnostics of hazardous production facilities. 2018;135-140. (In Russ.).

- Gafarova V. A., Nevzorov V.N. Modeling of the process of penetration of composite material into the crack cavity. Welding and control – 2016. Ufa. 2016;85-86. (In Russ.).

- Kondrashov S.V., Shashkeev K.A., Petrova G.N., Mekalina I.V. Polymer composite materials of structural purpose with functional properties. Aviation materials and technologies. 2017; 405-419. https://doi.org/10.18577/2071-9140-2017-0-S-405-419. (In Russ.).

- Zagora A.G., Kondrashov S.V., Antyufeeva N.V., Pykhtin A.A. Investigation of the influence of technological modes of manufacturing epoxinanocomposites with carbon nanotubes on their heat resistance. Proceedings of VIAM. 2019;1(73):64-73. https://doi.org/10.18577/2307-6046-2019-0-1-64-73. (In Russ.).

- Pykhtin A.A. High - tech epoxy nanodispersions and nanocomposites with a controlled structure and a set of properties: diss. ... cand. tech. sciences: 05.17.06. Moscow: 2017. (In Russ.).

- Ivanov V.A. Methods of restoration of technological and auxiliary equipment with wear-resistant composite materials: diss. ... cand. tech. sciences: 05.02.13. Moscow; 2015. (In Russ.).

- Brusentseva T.A., Filippov A.A., Fomin V.M. Composite materials based on epoxy resin and nanoparticles. Proceedings of the Altai State University. 2014;1-1(81):25-27. https://doi.org/10.14258/izvasu(2014)1.1-04. (In Russ.).

- Chebotareva E.G. Nanomodified composites for construction purposes using epoxy resin: abstract of the dissertation of the candidate of technical sciences: 05.23.05. Belgorod; 2010. (In Russ.).

- Novoselova S.N. Development and research of properties of low-viscosity polymer composites of functional purpose: abstract of the dissertation of the candidate of technical sciences: 05.17.06. Biysk; 2012. (In Russ.).

- Gorbunov F.K., Shevtsov Yu.N., Berdnikova L.K. Thermodynamic characteristics of materials used for the repair of road and airfield coatings. Roads and bridges. 2017;2(38):21. (In Russ.).

- Gorbacheva S.N., Gorbunova I.Y., Kerber M.L., Antonov S.V. Properties of composite polymer materials

- based on epoxy resin modified with boron nitride. Advances in chemistry and chemical technology. 2017;11(192):35-36. (In Russ.).

- Irzhak V.I. Structure and properties of polymer materials: textbook. Saint Petersburg: Lan; 2019. URL: https://e.lanbook.com/book/123663 (accessed: 11.22.2022). (In Russ.).

- Ilyina V.N., Gafarova V.A., Bugai D.E., Ilyin S.V., Kuzeev I.R. Adhesive and cohesive strength of composite material with carbon fillers for sealing cracks. Petroleum engineering. 2021;19(6):124-133. https://doi.org/10.17122/ngdelo-2021-6-124-133. (In Russ.).

- Chen Ya., Marakhovsky P.S., Malysheva G.V. Determination of thermophysical properties of epoxy materials during their curing. Works of VIAM. 2018;9(69):119-123. https://doi.org/10.18577/2307-6046-2018-0-9-119-123. (In Russ.).

- Brusentseva T., Zobov K., Filippov A. Introduction of nanopowders and mechanical properties of materials based on epoxy resins. Nanoindustry. 2013;3(41):24-31. (In Russ.).

- Mostovoy A.S. Development of compositions, technologies and determination of properties of micro- and nanofilled epoxy composites of functional purpose: abstract of the dissertation of the candidate of technical sciences. 05.17.06. Saratov; 2014. (In Russ.).

- Samoilova D.O. Investigation of the conditions for the introduction of carbon nanotubes into a polymer-carbon composite in order to increase strength. Chelyabinsk: SUSU. ET. 2018;443:138 p. (In Russ.).

- Marakhovsky P.S., Kondrashov S.V., Akatenkov R.V. About modification of heat-resistant epoxy binders by carbon nanotubes. Bulletin of the Bauman Moscow State Technical University. Mechanical Engineering series. 2015;2(101):118-127. (In Russ.).

- Topolyansky P.A. Investigation of adhesive properties and the mechanism of formation of a coating applied by the method of finishing plasma hardening. Part 2. Mater. 7th international. practical conference-exhibitions “Technologies of repair, restoration and hardening of machine parts, mechanisms, equipment, tools and technological equipment”. 12–15th April 2005. St. Petersburg. 2005:316-333. (In Russ.).

- Zimon A.D. Adhesion of films and coatings. Moscow: Chemistry; 1977 (In Russ.).

- The use of intelligent materials in the production, diagnosis and repair of machines. Second edition, revised and expanded. Moscow: Limited Liability Company “Scientific and Publishing Center INFRA-M”; 2015 (In Russ.).

- Ognev A.Yu., Teplykh A.M., Bataev V.A. Polymer composite material based on epoxy resin, reinforced with multilayer carbon nanotubes. Scientific Bulletin of the Novosibirsk State Technical University. 2009;4(37):115-122. (In Russ.).

- Khvostov S.A. Principles of modification of epoxy binders by carbon nanoparticles and technology for obtaining composites based on them: specialty 05.02.01: abstract of the dissertation for the degree of candidate of technical sciences. Barnaul; 2007. (In Russ.).

- Ghanem A, Lang Y. Introduction to polymer adhesion. ResearchGate: Network Journal. 2017. URL: https://www.researchgate.net/publication/319098070_Introduction_to_polymer_adhesion (accessed: 03.24.2023).

- Panin S.V., Kornienko L.A., Aleksenko V.O. Influence of carbon nanofibers/nanotubes on the formation of physico-mechanical and tribotechnical characteristics of polymer composites based on thermoplastic UHMWPE and PEEK matrices. News of higher educational institutions. Series: Chemistry and Chemical Technology. 2017;60(9):45-51. https://doi.org/10.6060/tcct.2017609.7y. (In Russ.).

- Krutikov I.Y. Restoration of operability of parts of technical devices with crack-like defects by composite materials: diss. ... cand. tech. sciences: 05.02.13. Ufa; 2010. (In Russ.).

- Gvozdev A.A. Ways to improve the technology of repair of parts and joints with HMS compounds – cold molecular welding. Vladimirsky husbandman. 2014;4(70):39-40. (In Russ.).

- Patent No. 2157306 C1 Russian Federation, IPC B23P 6/04. Method of repair of defects in protective coatings: No. 99116373/02. application. 28.07.1999, publ. 10.10.2000. V.V. Kravtsov, I.R. Kuzeev, O.V. Shingarkina. The applicant is Ufa State Petroleum Technical University. (In Russ.).

- Sungatullin I.R. Increasing the security of hazardous production facilities during the operation of critical elements with cracks: dissertation ... cand. tech. sciences. 05.26.03. Ufa; 2022. (In Russ.).

- Gafarova V.A. Application of composite materials for containment of crack growth in oil and gas equipment. Petroleum engineering. 2018;16(5):99-107. https://doi.org/10.17122/ngdelo-2018-5-99-107. (In Russ.).

- Gafarova V.A. Carbon in condensed hydrocarbon phases, steels and cast irons. Nanotechnologies in construction. 2017;9(6):111-128. https://doi.org/10.15828/2075-8545-2017-9-6-111-128. (In Russ.).

- Patent for invention No. 2601782 Method of pipeline restoration repair and device for its implementation. Kuzeev I.R., Gafarova V.A., Mingazhev A.D. (RF). Application no. 2015122333. Announced on 10.11.2015. Zareg. 14.10.2016 Publ. 10.11.2016, Byul. No. 31. (In Russ.).

- Tlyasheva R.R., Gafarova V.A., Vagazova K.R., Kuzeev A.M. Composite material for filling the cavity of cracks and crack-like defects. Bashkir Chemical Journal. 2016;23(3):56-62. (In Russ.).

- Gafarova V.A., Vaganova K.R. The nature of the interaction of composite material with the surface of steel with different levels of roughness. Industrial safety expertise and diagnostics of hazardous production facilities. 2015; 56-59. (In Russ.).

- Gafarova V.A., Kravtsov V.V., Kuzeev I.R. Analysis of methods and review of composite materials for sealing cracks in structures. Actual problems of science and technology: materials of the VII International Scientific and Practical Conference of Young Scientists, Ufa, November 18–20, 2014. Ufa. 2014;2:104-106. (In Russ.).

- Berezkin V.I., Viktorovsky I.V., Vul A.Ya. Fullerene microcrystals as adsorbents of organic compounds. Physics and Technology of semiconductors. 2003;37(7):802-810. (In Russ.).

- Smirnov I.V. Modeling of physical and mechanical properties and climatic resistance of epoxy composites: diss. ... cand. tech. sciences: 05.23.05. Saransk; 2017. (In Russ.).

- Kondrashov S.V., Shashkeev K.A., Popkov O.V., Solovyanchik L.V. Promising technologies for obtaining functional materials for structural purposes based on nanocomposites with CNT (review). Proceedings of VIAM. 2016;3(39):7. https://doi.org/10.18577/2307-6046-2016-0-3-7-7. (In Russ.).

- Yeletsky A.V. Sorption properties of carbon nanostructures. Successes of physical sciences. 2004;174(11):1191-1231. (In Russ.).

- Bondaletova L.I., Bondaletov V.G. Polymer composite materials: textbook. Tomsk: Publishing House of Tomsk Polytechnic University; 2013. (In Russ.).

- Korneev A.D., Burkov P.V., Klyshnikov A.A., Papin I.V. Structuring of protective polymer coatings. Bulletin of the Volgograd State University of Architecture and Civil Engineering. Series: Construction and Architecture. 2011;22(41):69-72. (In Russ.).

- Danchenko Yu., Andronov V., Teslenko M., Permiakov V., Rybka E., Meleshchenko R., Kosse A. Study of the free surface energy of epoxy composites using an automated measurement system. Eastern-European Journal of Enterprise Technologies. 2018;12:9-17.

- Lizunov D.A. Development of high-strength carbon fiber plastics based on epoxy-containing oligomers: diss. ... cand. tech. sciences: 05.17.06. Moscow; 2014. (In Russ.).