How to properly test and apply BETOPRESS® lyophobic sols and sol-based modifiers in cement concrete

Автор: Khovansky V.E.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Application of nanomaterials and nanotechnologies in construction

Статья в выпуске: 1 Vol.16, 2024 года.

Бесплатный доступ

This article provides information in the accessible form about a completely different approach to the testing and application of lyophobic sols and sol modifiers in cement concrete, in contrast to any other chemical additives that are classified as true solutions in liquid form. The criteria outlined in clause 6.11 of GOST 27006-2019 for the selection of compositions produced in laboratory conditions cannot be extended to sols and sol modifiers, which are stabilized colloidal solutions. This specifically pertains to the preparation of concrete mixtures for subsequent testing. GOST 27006-86 was released during a period when all chemical additives used in concrete were solely available in the form of true solutions, comprising fully dissolved molecules and ions resulting from the complete dissolution of all components in water.

Короткий адрес: https://sciup.org/142240527

IDR: 142240527

Текст научной статьи How to properly test and apply BETOPRESS® lyophobic sols and sol-based modifiers in cement concrete

This article provides information in the accessible form about a completely different approach to the testing and application of lyophobic sols and sol modifiers in cement concrete, in contrast to any other chemical additives that are classified as true solutions in liquid form. The criteria outlined in clause 6.11 of GOST 27006-2019 for the selection of compositions produced in laboratory conditions cannot be extended to sols and sol modifiers, which are stabilized colloidal solutions. This specifically pertains to the preparation of concrete mixtures for subsequent testing. GOST 27006-86 was released during a period when all chemical additives used in concrete were solely available in the form of true solutions, comprising fully dissolved molecules and ions resulting from the complete dissolution of all components in water.

M uch later, on January 1, 2020, a new GOST 270062019 was put into effect, which was not much different from the previous one. Everything would have been fine, if it were not for the introduction in the CIS of a whole series of innovative chemical modifiers for concrete in the form of colloidal mortars from April 2012, to which the rules for the selection of concrete compositions according to GOST 27006-2019 clause 6.11. In the laboratory were impossible to apply. A colloidal mortar refers to a mortar in which at least one of its ingredients exists in a colloidal state, as a result of which both the sols and sol-containing modifiers for cement concrete fall under this definition.

Chemical products of the «БЕТОПРЕСС»® series from the Russian company ООО «НПО БЕТОХИМИКС»® (Simferopol) are stabilized lyophobic sols and ash-containing modifiers, the purpose of which is to directly affect forming a special crystalline structure of cement stone in the nanorange in the process of hydration of cement grains for promoting concrete enhanced characteristics that are almost impossible to obtain when using chemical additives in the form of true solutions. For instance, consider the enhanced waterproofing capabilities of cast concrete, water resistance to cast concrete up to W16, which exhibits water absorption of less than 1%. Alternatively, instead of using traditional steaming methods for low-slump concrete products, we can opt for chemical activation of the hydration and hardening processes of cement. This approach accelerates the rate at which the concrete gains compressive strength, reaching

the design level within just 5–7 days, as opposed to the conventional 28-day period. In this latter case, a maximum sol consumption of 0.05% (dry weight) relative to the weight of cement would be sufficient.

This method also imparts the property of hydrophobicity to the manufactured products, which remains effective without expiration.

The author's long-lasting search on the Russian market for comparative tests of similar products in practice form has been unsuccessful, since all of them exist only in the information realm, or rather, in all kinds of scientific papers, articles, reports, dissertations, technical specifications and even patents. For example, one of the dissertations discusses the use of sols and highlights the effectiveness of two sol-containing additives: “Hardness-M” TU 5745-006-51556791-2002 and «ДЭЯ-ЗС» TU 3743-005-46969976-2003. In 2004, these additives demonstrated remarkable performance when incorporated into industrial batches of cement concrete. Additionally, the dissertation states that the findings have led to the publication of 16 research articles and reports in international and industry journals. Furthermore, three technical specifications and three technological regulations have been developed based on the dissertation's materials. Moreover, four patent applications have been filed as a result of the research. Subsequently, the purchase of the above-mentioned products on the construction market is simply not possible due to the complete absence of them. Perhaps this is the reason why there is no de-

АPPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Строительная лаборатория ООО «БЭТТА» СИСТЕМА ДОБРОВОЛЬНОЙ СЕРТИФИКАЦИЯ СДС «СНЛ-МТ» Орган по сертификации ООО «Волгоградский ЦОСМ» Сертификат соответствия выполняемых работ (услуг), по измерениям и испытаниям продукции № 00329 с «13» августа 2021г.

ПРОТОКОЛ ИСПЫТАНИЯ № 32 В

БЕТОНА НА ВОДОНЕПРОНИЦАЕМОСТЬ, ВОДОПОГЛОЩЕНИЕ.

-

1. Наименование продукции, ее характеристика, обозначение:

-

2. Место отбора образцов: завод изготовитель ООО «ВолгКлинСервис».

-

3. Цель испытаний: определение водонепроницаемости, водопоглощения

-

4. Нормативная документация, используемая при испытании:

Кубы -образцы 100*100 мм из смеси бетонной БСТ В40 ПЗ W 16

ГОСТ 12730.5 «Бетоны. Методы определения водонепроницаемости

-

5・ Применяемые СИ и ИО: ВВ-2 № б/н.

РЕЗУЛЬТАТЫ ИСПЫТАНИЙ

|

Маркировка образцов |

Дата изготовления |

Проектная марка бетона на водонепрони цаемость |

Дата испытания |

Возраст образцов, суток |

Диапазон ti. сек |

|

32В/1 |

17.03.2023 |

W 16 |

14.04.2023 |

29 |

580 |

|

32В/2 |

17.03.2023 |

W 16 |

14.04.2023 |

29 |

588 |

|

32 В/3 |

17.03.2023 |

W 16 |

14.04.2023 |

29 |

592 |

|

32В/4 |

17.03.2023 |

W 16 |

14.04.2023 |

29 |

598 |

|

32В/5 |

17.03.2023 |

W 16 |

І 4.04.2023 |

29 |

600 |

|

32В/6 |

17.03.2023 |

W 16 |

14.04.2023 |

29 |

604 |

Испытания проведены на основе экспресс-метода оценки его воздухопроницаемости по ГОСТ127730. Экспресс-метод определения водонепроницаемости бетона основан на наличии установленной статистической зависимости между воздухопроницаемостью поверхностных слоев бетона и его водонепроницаемостью, определенной по методу «мокрое пятно».

В качестве параметра, характеризующего водонепроницаемость, используется значение времени (ti), за которое давление в камере устройства падает на определенную величину.

ЗАКЛЮЧЕНИЕ: 修= (592+5 98):2=5 95 с, что соответствует марке бетона по водонепроницаемости W 16

ЗАКЛЮЧЕНИЕ: Wm = 2295-2275 *100 =0,87 - вод<

испытании на

Начальник строительной лаборатории ООО «Бэтта» 丿衣泓 нтрачкова В.П.

Fig. 1. Concrete waterproof and water absorption test report. The sol additive used was ПК Полипласт (S) 0.85%, and «Флюкс-1ГФ» at 0.025% of the weight of cement

АPPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

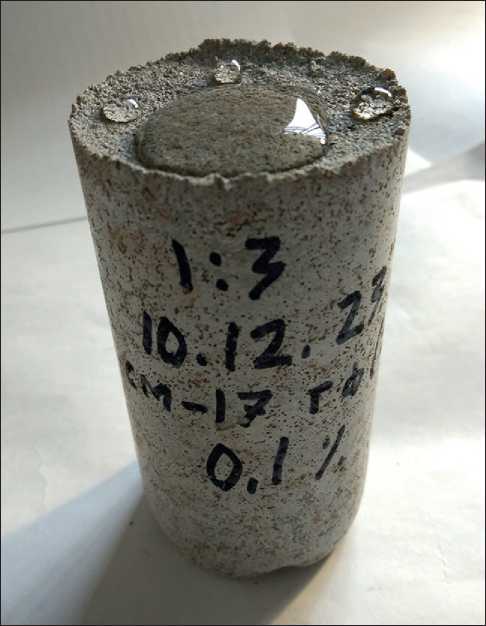

Fig. 2. Vibropressed block made of low-slump concrete on lyophobic sol «ВИБРОФИНИШ СМ-17-ГФ», consumption 0.05% to the weight of cement after 10 days of hardening tailed information about colloidal solutions, their nature, and handling procedures in any of the GOST standards. However, it is worth noting the recently published GOST ISO/TS 80004-1-2017 “Nanotechnology. Basic Terms and Definitions”. While there are established GOSTs and terminology, and the absence of products in this area. Consequently, it could imply a limited presence of potential manufacturers in this particular field!

There is no point in mentioning patents on this topic: the patents are available, but for some reason no industrial nanomaterials in the form of lyophobic sols for cement concrete are still offered on our construction market. Unless, of course, attention is directed towards colloidal solutions from the «БЕТОПРЕСС»® series, which have been without significant attention for the past 12 years! It seems that this fact has gone unnoticed or perhaps deliberately overlooked. However, it is important to acknowledge that these products not only exist but are also manufactured in substantial quantities by the innovetive and unique company, «НПО БЕТОХИМИКС»®, the sole innovator of its kind in Russia.

Thе above mentioned colloidal solutions are produced with an advanced method of chemical dispergasion, using rather complex aggregate of various high-molecular peptizers as stabilizing substances, also developed by the company. All of our lyophobic hydrosols and sol-containing modifiers, along with their corresponding technologies, were not patented as it was unnecessary. However, these products were introduced to the Ukrainian market for unrestricted sale by the developer in early 2012, and they have been available in Russia since 2014, fully authorized with permits, including the Trademarks of Ukraine and Russia. It turns out that there is a patent, but there is no product, and, conversely, there is no patent, but the product exists, and quite abundant in our case!

Now back to the topic. GOST 27006-2019 clause 6.11 provides recommendations for preparing a concrete mixture for the composition selection in a standard laboratory mixer of gravity or forced action or in manual mode with a volume of no more than 15 liters output of the ready mixture in a container pre-moistened with water and with mixing time for at least 5 minutes. The recommendations provided are not appropriate for the hydrosols or solcontaining additives offered by «НПО БЕТОХИМИКС». These products are specifically designed for industrial applications and are considered professional-grade. Consequently, the conditions for concrete preparation prior to testing should adhere strictly to the production requirements rather than the artisanal guidelines outlined in the above-mentioned GOST.

The fact is that the sols for cast concrete of the «БЕТОПРЕСС»® series are dosed no more than 0.005% (dry weight) relative to the weight of cement and therefore require only intensive mechanical mixing for quick and uniform distribution of all colloidal nanoparticles over the volume of the concrete mixture, and the larger the volume of the mixer and its power, the better the process. The minimum output of the ready-mixed concrete mixture is preferably at least 0.5 m3, which fully corresponds to the manufacturing environment. This applies to both sol modifiers and sol-containing additives. Hence, we highly advise conducting the concrete preparation process for testing our chemical products directly under industrial conditions, using the existing compositions. Otherwise, the effectiveness of our chemical additives may not be evident, as if they are not present at all.

The only alternative to determine the sols effectiveness in comparison with a similar control sample is to directly prepare one or two liters of the mixture in a 5-liter planetary laboratory mixer at a fairly high speed (at least 3rd speed) while stirring for three minutes. Both cement dough and cement-sand mortar can be used here, with sand pre-screened from coarse particles and with the determination of mobility, for comparison, using a laboratory cone of spreadability (KR-1). Then the cement dough should be immediately placed in metal molds with cells of 20×20×20 mm, 12×25×75 mm, and in the case of cementsand mortar – in molds 70×70×70 mm. After the complete completion of the hardening process, these samples should be tested according to GOST 30459-2008. However, the testing option is suitable only for determining the effectiveness of the colloidal mortar in comparison with the control sample, and it is not the case for selection of the composition for heavy concrete with crushed stone. Yet at the same time it is possible to check the sols for their compatibility with cements from different manufacturers.

АPPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

The fact is that colloidal particles, being in the mixing water, with a sharp increase in pH in the process of cement hydration are transforming from the sol state into a gel, and for their rapid distribution throughout the entire volume of the concrete mixture in the form of vast amount scattered nanoparticles until the reaction itself (called the sol-gel method in colloidal chemistry) a sufficiently powerful and fast concrete mixer is needed. We have established a successful collaboration with manufacturers who test our products under industrial conditions right on their factory premises. In these controlled environments, where the concrete mixture is thoroughly blended within seconds, we supply them with sol and sol modifiers without encountering any issues. Remarkably, even our long-standing partners, with whom we have maintained a fruitful relationship for 12 years, have not only refrained from reverting to their previous additives in the form of true solutions but also expressed no intention to do so. This can be attributed to the fact that no one wishes to incur additional expenses on cement, let alone compromise the improved quality of their products!

In addition to the developed sol-containing modifiers in the form of superplasticizers of the SP group, we manufacture five sols for high-slump concrete (cast) and two low-slump concrete (semi-dry) used in tamping, hyper- and vibrocompression technologies. The difference between high-slump and low-slump concrete is that sols for cast concrete are mainly recommended to be applied as nanoadditives to domestic liquefiers based on PC, NFS and LST1, while sols for low-slump concrete are fully finished products for industrial applications. What unites these products is their crystal-forming nature, although each possesses unique properties, levels of effectiveness, and specific applications. For more detailed information about our products, including comprehensive test reports, we encourage you to visit our company's official website, where you can find informative articles providing in-depth insights.

In this article, in more detail we present two of our branded products based on a stabilized iron hydroxide solution for intensive molding of low-slump (granular) concrete – «ВИБРО СМ-16» and «ВИБРОФИНИШ СМ-17-ГФ» (ТУ 2601-001-00823210-2015). The latter product underwent its most recent modification in November-December 2023, resulting in its ability to impart genuine hydrophobicity to the products. Both of these products distinguish themselves from other lyophobic sols, which are typically used in microdoses as additives to chemical admixtures. This distinction arises from the fact that our sols, designed specifically for low-slump concrete mixtures in a particulate state, do not necessitate the use of diluents. This characteristic aligns with their classification as “semi-dry”. Not only do these sols refrain

Fig. 3. The cylinder made of cement-sand mixture produced with semi-dry tamping method on lyophobic sol «ВИБРОФИНИШ СМ-17-ГФ», consumption 0.1% from liquefying mixtures, but they also enable an increase water consumption while maintaining the particulate state of the mixture. This, in turn, enhances the compaction of the products during pressing and eliminates the risk of mixture adhesion to metal equipment.

As a result, it is the increase in water consumption that leads to increased compaction of products with an intensive physical and mechanical impact on the mixture. When making direct comparison with the composition on any other modifier: by 2–4% or even 6%, but to the control one, in which there is no “chemistry” at all. Due to the increase in the compaction coefficient, in the first variant we get an increase in the compressive strength of products by +20–40%, and in the second by almost +60 (record set +67%) with equal consumption of the binder, since the strength of low-slump concrete does not depend at all on the ratio Water/Cement and the amount of cement, but on its density (volume-weight). In addition, sols allow us to stamp products of the same quality with an ideal surface without sticking to inert materials of different wetness, without the need to constantly “catch” the amount of water in each batch, while reducing the vibration time itself by almost half.

АPPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

(ХЮ-ИНСТИТ1Т -КРЫМГІІИНТНІ*

2*»W. (чвлймю «Э«. r^»«frcp0fta»K〉》Jkuk”. 6机 ici.:*~(WS2>55-O('W. frint: *7fMJ2)W-;*-J9 E-ouil ;л(Ь^кг$ііпь/.п ам« »ri・K5

ОГРК H$9ltt»5*M3 МИН КПП 91g№№ -410М1Ю1

HAlJOlSr.

■мешЛ

NKC2. ҒК. г.Са»4«і»мшц уж. Гдитсм, 鱷. #нт. Ср«ц>ет«лъ<Ж о «сгиіпііи

— __ ____ат25> »ті 2<І2Э 乜 —

一: 7^ ?? 存預_ «тейымМія l«20r

.6дЗ 而;。庇 Тбкилиікс —

ИифОрМАЯМЯ <іб 』 M ・ rr ММІЫГЗННЯ

Гр9Т ) чрнп Мит ООО «ФЛИНСТОҮК»

Бетмміі впг^аа mxm ІООкЗСКХбО i _ I Ла6«р*тсрны> УЬД4І-МЗ

&<^ҚТ?^!±е _2^^g£. _lJjEiy^J^£g fr* ・ .ті^ р я^ 二二 … L__

"*■*、 І1рр4млму«<«ш 0ОІ«Зу Е &*А6ИйО J 8 стбврт птрвигпортчрл» Ир^СтрО""МЬМ1 ・ I .ибсраторнк ) часпи һс прннимш. Отпептн«ш№п ш лрцзнаиахтъ5&>р* ңреД [ji gw^ i^KWM. I«^y»y g_ . tp» y 吧 ртт^с^»^ F 5 T *^*^*ГЕ :

|l4 MMf«CT<|HHg

i?hh* <^4h3* Қ)n•

Тсшачки 。 условті N нгтозакв асаиіянвк

IT6OI-2QI7 іГІмш Дев— к гтотуіранг. Га.аҒСм 产《 cee.J'OCT 2* , №Х

♦Клмы. Млям опргалгимя іц^мнхіг іюобріпшн. счрбрініми н>

(■рммамае й|Ш«*хи* н> сіраивім 2 )

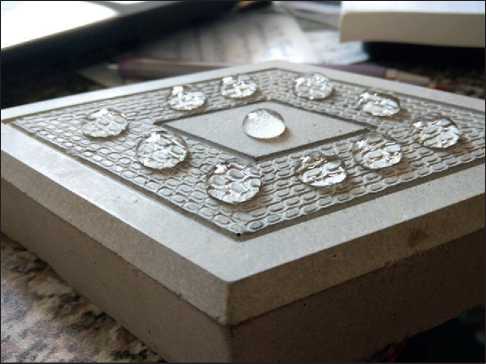

Fig. 4. Report of comparative tests of the chemical additive «Мурасан БВА19» (manufacturer «Эм Си Баухеми») with the lyophobic sol «ВИБРОФИНИШ СМ-17» (manufacturer ООО «НПО БЕТОХИМИКС») in core-samples drilled from paving slabs produced by vibrocompression method of low-slump concrete with the same composition and consumption of cement

That's easily screenable tangible cost savings in the form of an “excessive” amount of cement, which appeared as a result of equalizing compressive strength between all samples, both with and without other additives, up to the requirement of GOST 17608-2017. In order to increase the compressive strength of concrete, we advise not to use extra cement, but use effective sol modifiers, which gives not only benefits due to their little to nothing consumption, but also the highest quality of the ready-for-sale condition for vibropressed products, the durability and frost resistance of which does not depend on the strength itself, but depends on the density of the crystal structure of the cement stone, including the total capillary porosity of the concrete. The latter always increases in direct proportion to the increase in the consumption of the binder.

But even here, some craftsmen try to hand-to-hand prepare a semi-dry mixture with our hydrosols in artisanal laboratory conditions according to GOST 270062019, which allows you to mix up mixtures manually in small volumes, which they do, and then form samples for strength tests by vibrating in metal molds with a nozzle underweight. Such cases occur more often at large enterprises, where technologists, considering themselves high-class professionals (and who will check this!?), for some reason, are very afraid to use our nanosols immediately in production. Another rather important mistake of technologists is the incorrect granulometric selection of inert materials, if the composition itself is intermittent, then in this case nothing will help the manufacturer at all: neither our nanosols, nor the power of the vibropress, nor the increase in cement consumption, the latter will simply get lost in the resulting voids and without any benefit.

At the same time, our air-entrained colloidal mortars for intensive molding of low-slump concrete mixtures, in addition to a significant increase in compressive strength due to an increase in the compaction coefficient (Cc), also have a rather unique property of nanostructuring cement stone, in which, firstly, our air-entrained colloidal mortars show the ability to interrupt capillary porosity with microbubbles of air with an internal hydrophobic surface and reaching the design level within just 7 days, as opposed to the conventional 28-day period, four times reduce. The latter property gives the manufacturer possibility to ship the products directly from the workshop on the second day, bypassing the warehouse, as it has fully reached the required 70% of the design strength. Along with this, forced heating is not required, it is replaced by the sols themselves.

АPPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

ГОСУДАРСТВЕННЫЙ КОМИТЕТ РЕСПУБЛИКИ БАШКОРТОСТАН ПО СТРОИТЕЛЬСТВУ И АРХИТЕКТУРЕ ГУП «Научно-исследовательский, проектно-конструкторский и производственный институт строительного и градостроительного комплекса Республики Башкортостан» (ГУП институт «БашНИИстрой») Испытательный центр «Башстройиспытания». Аттестат аккредитации № РОСС RU.0001.22CJ137, действителен до 14.07.2019г.

450027, г. Уфа, ул. Уфимское шоссе, 3. Тел./факс (347) 243-35-35

УТВЕРЖДАЮ Главный I ГУП инет

Протокол № 2017/893-01 испытаний образцов брусчатки вибрбпрессованной

Заказчик: ООО «Производственная компания АВЕГА»

Основание для проведения работ: письмо нсх. № 6/н от 01.06.2017r.. вх. № 893 от 06.07,2017r.

Наименование НД на материал: ГОСТ 17608-81

Наименование НД на методы испытаний: ГОСТ 12730.3-7& ГОСТ 10180-2012, 「 ОСТ 18105-2010 (схема Г)

Наименование оборудования:

08.11,2017г.) 、 пине 访 ка стальная

Гилпавлический пресс П-50 (зав № 1592. поверка до 12.07.2017г.). штангенциркуль ШЦ-11 (зав. № Р177244, поверка до

(зав № 231 поверка до 08 ] 1 2017rl весы электоонные MK-I5.2-A2I (зав. № 123961, поверка до 09.11.2017г.\

Зав. лабораторией ИСМИ

Испытатель

И .Я. Тевс

Г.Ф. Ишбулдина

Наименование объекта, место изготовления образцов: ООО «ГЬонзводственная компании АВЕГА» (г. Стерлитамак). Образца брусчатки внбропрессованно 正《 Старик город» 120х|20“60_мм нзготовлень 】 с применением добавок .ООО «НПО 6ЕТОХНМНКС», доставлены Заказником.

Дата изготовления образцов: 30.05.2Q17r. _________________________________________________ . . ,

|

Результаты испытаний на 2 сут. норм, твердения. Дата испытания образцов: 01.06.2017г. |

Результать на 7 сут. нор Дата испытания об |

испытаний м. твердения, разное: 06.06.2017г, |

Результаты испытаний на 28 сут. норм, твердения. Дата испытания образцов: 27.06.2017г. |

|||||||

|

Плотность изделий, кг/м3 |

Водопогло-щение, % по массе |

Прочность на сжатие, кгс/см" |

Фактический класс бетона по прочности на сжатие |

Плотность изделий, кг/м5 |

Водопогло-щение, % по массе |

Прочность на сжатие, кгс/см- |

Фактический класс бетона по прочности на сжатие |

Плотность изделий, кг/м? |

Прочность на сжатие, кгс/см2 |

Фактический класс бетона по прочности на сжатие |

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

п> |

и |

|

2251 2285 2236 2216 ср. 2247 |

2,8 2J 3,3 ср. 2,7 |

397 388 ср. 393 |

взо |

2221 2251 2244 2230 ср. 2237 |

3,7 2,9 4,3 ср. 3,6 |

522 478 ср. 500 |

В35 |

2220 2252 2240 2220 2225 2215 ср. 2229 |

478 466 466 ср. 472 |

В35 |

Прнмечанне. Требуемуй прочность бетона для проектного класса рассчитывают по формуле 9 ГОСТ ipfp5-2010:

Rt һ Кт Вң^. где В” - проектный класс прочнемяи бетона, МПа; Кт коэффициент требуемой прочисти (при зтом Кт ° 1.28 - все виды бетона, кроме плотного силикатного и ячеистого).

Результаты испытаний относятся только к испытанным образцам. Вез разрешения руководителя ИЦ «Башстройиспытания» перепечатка протокола запрещена

Fig. 5. Test report of vibropressed paving slabs made of low-slump concrete with lyophobic sol «ВИБРОФИНИШ СМ-17» by the rate of compressive strength gaining no heating up to 80% on the second day and up to 100% on the seventh. Further, the strength does not increase.

In 2024, all “concrete pavement slabs” produced in Russia are subject to mandatory certification according to GOST 17608-2017. This will lead to an increased demand for chemical modifiers, particularly stabilized sols, which can be used in both vibropressed and vibrocast paving slabs. The frost resistance and durability of paving slabs do not depend on their compressive strength. The quality of the crystal structure of the cement stone, first of all, on the correctly located the capillary system within the stone, as well as the diameter and shape of the pores play a significant role. Ideally, the pores should have hydrophobic properties.

All of the above qualities of cement stone are directly affected by chemical modifiers for cement concrete and nothing else. In comparative tests for chemical additives in the form of true solutions with colloidal ones, in the form of lyophobic sols, the latter will always take advantage under industrial conditions, since they have the unique property of forming future crystallization centers in cement stone from artificially introduced nanoscale colloidal particles for the growth of a three-dimensional spatial grid in the form of a matrix that directly affects its entire structure in the nanorange. Due to the specifics of the product, «БЕТОПРЕСС»® sols for low-slump concrete mixtures, in contrast to sols for cast concrete, have a higher dry matter consumption in the range from 15 to 50 grams per 100 kg of cement, which corresponds to a minimum of 0.05%, and a maximum of 0.2% of the ready-to sell product in liquid form to the weight of the binder.

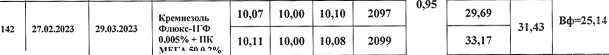

«НПО БЕТОХИМИКС»® company will not ignore manufacturers of vibrocasting products, such as concrete paving slabs, curbs, flashings, park architecture, etc. We can offer the lyophobic silica sol «Флюкс-1ГФ», which is allowed to be added in the amount of 0.025% of the commercial product to the mass of cement directly into the cast concrete mixture in the very process of its preparation with the mixing water and without other chemical additives. Within 28 days of hardening, the finished vibratory cast products acquire a pronounced property of

АPPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

ООО «ИНСТИТУТ «КРЫМГИИНТИЗ»

295022, Республика Крым. г.Симферополь, ул. Глинки, 68.

тел.:+7(3652)55-04-00. факс: +7(3652)69-24-39 E-mail:

ОГРН 1159102054253 ИНН/КПП 9102169394 / 910201001 、

Член СРО Ассоциация «ОГПО» регистрационный № 116 от 27.09.2018 г.

Стр. 2 из 2

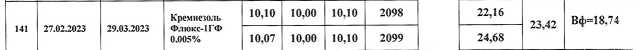

Протокол испытаний № СТ 0140-0143 от 29 марта 2023 г. (продолжение) Результаты лабораторных испытаний

Дата начала испытаний: 29.03.2023 г. Дата окончания испытаний: 29.03.2023 г.

Значения влияющих факторов:

I Температура^Сг 24,0 | Влажность, %: | 8* 丨 Давление, кПа: | 97.9

.+7(3652)55-

изделий.

295022, РК, г.Симферополь, ул. Глинки, 68, лит. Аттестат акк по 21 января

Физико-механические характеристики бетонных образцов

Протокол испытаний № СТ 0140-0143

|

Договор |

№5.78-23 от 27 марта 2023 г. |

|

Наименование заказчика |

ООО «НПО БЕТОХИМИКС» |

|

Адрес заказчика |

295017, РФ, Республика Крым, г. Симферополь, ул. Бетховена, д. 16/2. |

Информация об объекте испытания

|

Наименование объекта |

Кубики литые. |

|

Наименование проб |

Бетонные кубы размером 100x100x100мм. Лабораторный № 140-143 |

|

Дата изготовления пробы |

27.02.2023 J Дата поступления пробы в лабораторию | 27.03.2023 г. |

|

Информация об отборе пробы |

Пробы получены по акту от 27.03.2023 г. Образцы отобраны на стройплощадке. В отборе и транспортировке проб Строительная лаборатория участия не принимала. Ответственность за правильность отбора проб, консервации, хранения и транспортирования несет заказчик. |

Цель испытаний

|

Определение физико-механических характеристик бетонных образцов. |

|||

|

Средства измерений, используемые при проведении испытаний |

|||

|

№ |

Наименование и тип СИ |

Зав. № |

Сведения о поверке |

|

1 |

Пресс гидравлический ПММ-125 |

385 |

Свидетельство о поверке №С-КК/06-12-2022/208982695 действительно до 05.12.2023 г. |

|

2 |

Штангенциркуль ШЦ-І-125-0.1-2 |

F36892 |

Свидетельство о поверке №С-КК/17-01-2023/216365704 действительно до 16.01.2024 г. |

|

3 |

Весы лабораторные ВМ-5101, per. №36468-07, |

642615 |

Свидетельство о поверке №С-КК/02-06-2022/161992917 действительно до 01.06.2023 г. |

Испьітательное оборудование, используемое прн проведении нспьітанній

|

№ |

Наименование и тип ИО |

Зав. № |

Сведения об аттестации |

|

1 |

Камера нормального твердения и влажного хранения образцов КНТ-72 |

150909 |

Аттестат 01.00004.23 от 13.01.2023 г. действительно до 12.01.2024 г. |

Технические условия н методики нспьгганнй

|

Методики испытаний: (шифры НД, наименование методик) |

ГОСТ 10180-2012 «Бетоны. Методы определения прочности по контрольным образцам», ГОСТ 12730.0-2020 «Бетоны. Методы определения плотности, влажности, водопоглощения, пористости и водонепроницаемости», ГОСТ 26633-2015 «Бетоны тяжёлые и мелкозернистые. Технические условия» ГОСТ 18105-201 8 «Правила контроля и оценки прочности» |

(продолжение протокола на странице 2)

言 С2ІЛ0НЯЛ0ЮЯС-

(Nox=heexeg RO§m=§«HOUS0 KHH3uq0I0J2一 енеп

K=z№H2E0= «НЯИ-

-^аяюон- 9IqN3KHds=du

(0z07,0.0§ J°o」)

「6/J 6IOOHJ.0UU KKH48do

ІНЗІзІ- ө -фео 工 C3XOWH3O«S

ЯС2 -е--знпнефсох OJOHge-Lmosv NOJLahx 0 3 Hlе*。ен qJ-OOHhodu

Wes 6HIB*。ен EOHhodu Rsxvpnzn SHUad。

(」ZBXO)o5e,so-8-(-00」OU --.6ОНҺОІ-0= JSHOJ.89 арил «-sowysb-яө

19,00

--------18,76 Вф=15,01

18,52

МЕГА 50 02%

Лиофобный

27.02.2023 29.03.2023

Экструзия 0.005%+ ПК

МЕГА 50 02%

10,08 10,00 10,08

10,07 10,00 10,07

28,85

30,01

29,43 ВФ=23,54

Конец протокола

Результаты испытаний относятся только к данным пробам, прошедшим испытания.

Протокол испытаний не может быть частично воспроизведён без письменного разрешения Строительной лаборатории ООО "Институт "КРЫМГИИНТИЗ". за исключением воспроизведения в полном объеме.

Ответственные исполнители:

Инженер лаборатории

Лаборант

Fig. 6. Test report of hydrophobic concrete with silica sol «Флюкс-1ГФ» at its dry matter consumption of 0.005% to cement (5 g per 100 kg) to the control sample without adding chemicals. The test result is an increase in strength by +25% with equal W/C reatio, the same amount of binder and density of the cast concrete. Only nanomodifiers can function this way a hydrophobic surface due to the joint reaction of the sol based on organosilicon with cement hydration products, primarily lime with the direct influent of carbon dioxide from the air. The compressive strength of the concrete itself, in turn, increases by +25% compared to the control sample without adding chemicals.

Lyophobic silica sol also is nanostructuring the cement stone, and therefore, increasing its water and frost resistance and in parallel is accelerating the hardening of the products themselves, starting from the first day. This will subsequently allow products to continue gaining their strength in a temperature regime, starting from -8 degrees below zero and above. Please do not confuse hydropho-bization with waterproofing. Hydrophobic paving slabs, both vibropressed and vibrocast, have almost the same water absorption when they are immersed in water for several days as non-hydrophobic ones. The difference is that on the road, precipitation water will roll down from the hydrophobic surface directly into the underlying layer. As for the unprotected slabs, they will absorb water with all surface, which can subsequently lead to the appearance of rather unsightly fades on the products in the form of lime outcrops, and to peeling due to frost.

In case both manufacturer and consumer are interested in cast concrete products with water resistance of W16 and even more with water absorption of less than 1%, lets compare water absorption with natural granite, which is within the range of 0.2% to 0.5%. In this case we will have to use the same lyophobic silica sol «Флюкс-1ГФ», but as a hydroinsulating and crystallizing nano-additive to any available polycarboxylate hyperplasticizers in the amount of 25 grams of sol per 100 kg of cement or to polycarboxylate ether as a raw material purchased directly from its manufacturer. In the latter case, an anti-foaming agent should be added. «Флюкс-1ГФ» could be recommended for the construction of basements, underground parking lots, pools and foundations of heavy waterproof concrete by the so-called «white bath» water proofing technology. When utilizing such technology, concrete should not only be of quality, but also with a W/C not higher than 0.38!

We offer lyophobic silica sol «Флюкс-2ГФ» for the production of roads and airfield slabs, which have more stringent requirements for counteracting salt aggression than conventional concrete pavement slabs. This sol is entered into the heavy concrete in the polycarboxylate hyperplasticizer and with the same dosage. The silica sol in-

АPPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION creases the tensile strength of concrete in bending, which is crucial for heavy dynamic and static loads, especially on the road surfaces and on take-off runways. Mind that «Флюкс-2ГФ» is not to be frozen, unlike «Флюкс-1ГФ». «Флюкс-2ГФ» does not work as a low-temperature accelerator: its lower limit is +5оC. At the same time, it will be indispensable in the construction of pavements and runways, because it clearly increases the resistance of salt corrosion and dusting of the concrete surface with almost zero water absorption.

The lyophobic sols of the «БЕТОПРЕСС»® series stabilized in the manufacturing process by special chemicals and high-molecular Surface-active agents with every domestic chemical additive with «БЕТОПРЕСС»® are or will be custom-designed colloidal solutions with unique formula. Further such products can be stored for years and without loss of newly acquired properties, the most important of which is crystallization inside the cement stone structure, in pores and capillaries, or in the surface, depending on the nature of the sol, in accordance with recommendations and conditions. Now we can clearly divide all existing concrete chemical additives in the CIS market in two main groups, where the first group includes more than two dozen complex colloidal solutions in the form of lyophobic sols under the Trademark «БЕТОПРЕСС», and the second group is to all others. It makes little difference whether the manufacturer, but only as true solutions, which in Russia today are about five hundred, and all of them in comparison at almost the same level in their properties and efficiency.

All developments by «НПО БЕТОХИМИКС»® are of significant strategic value for Russia, presenting a unique opportunity to transition the entire construction industry of the country from conventional concrete production to nanostructured concrete within a short span of time. For companies manufacturing chemical additives for concrete, this marks a chance to manufacture their products directly as innovative sol-containing modifiers falling under the industrial nanomaterials category, for

Fig. 7. Paving slabs made of vibrocast concrete with the only silica sol «Флюкс-1ГФ» – only 25 grams of end product per 100 kg of cement both domestic and international markets. This shift will empower all regions to produce heavy weight сoncrete and products with special properties for residential and industrial structures, bridges, canals, concrete roads and airfields, tunnels and subways, ports and docks, nuclear power facilities, waste storage, and more. Our team not only envisions Russia's swift to technological sovereignty in the esteemed industry of nanotechnology, but also remains committed to advancing this goal tirelessly. The outcome of our efforts is a range of innovative nanoproducts derived from domestic resources that have no analogues even in the Western markets, along with the cutting-edge technologies employed in their production.

P.S. Due to the fact that the colloidal solutions of the «БЕТОПРЕСС» are not eligible to any existing GOSTs, please apply to the company «НПО БЕТОХИМИКС»® as the only company in Russia that has more than a decade of experience in cement concrete and mortar sol-modification technologies.

General Director

ООО «НПО БЕТОХИМИКС» and ООО «БЕТОХИМИКС ГРУПП»

+7 978-917-27-97, + 7 978-284-74-55

R

This article continues the article “Lyophobic sols «БЕТОПРЕСС»® as additives to chemical admixtures into concrete”, published in the e-edition of “Nanotechnologies in Construction: Scientific Internet Journal.” 2023; 6:538 – 542. Nanobuild-6-2023/