Identification of the stress-strain state and damage of metal structures of building constructions with nanoparticle coatings using the electromagnetic-acoustic method

Автор: Mussa G. Bashirov, Elmira M. Bashirova, Ilvina G. Yusupova, Damir Sh. Akchurin, Rinat T. Yulberdin

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Research results of scientists and specialists

Статья в выпуске: 5 Vol.15, 2023 года.

Бесплатный доступ

Introduction. Approximately 20% of accidents in buildings and structures are associated with the destruction of metal structures. Nanocoatings applied to metal structures significantly improve their operational properties, but at the same time make it difficult to use traditional non-destructive testing methods that require access to the surface of the base metal. The quality of the nanocoating is controlled during its formation. To prevent the destruction of metal structures, it is necessary to identify structural heterogeneities of the base metal in micro- and sub-micron sizes, which arise in areas of increased mechanical stress concentration and transform into macrodefects leading to structural failure. Methods and tools are required to non-destructively identify the stress-strain state and damage of the base metal structure through the layer of nanocoating. Electromagnetic-acoustical (EMA) transformation, is considered promising for solving this problem. Existing EMA tools do not fully utilize the potential of EMA conversion, have insufficient sensitivity and the lack of informativity. Methods and materials. For experimental research, we selected widely used in construction structures steels. Research was conducted on the interrelationship of structural alterations in standard samples of metals and the parameters of the electro-magnetic (EMA) transducer under static and cyclic loads. Results. Load diagrams of metal samples were obtained, with accompanying photographs of microstructure in control points, along with their frequency models derived through spectral analysis of the signal from EMA transducer. Discussion. Changes in the stress-strain state of the metal and accumulation of damage in its structure result in a complex interrelated set of changes in mechanical, acoustic, and electro-physical properties, all of which are reflected in the changes in the parameters of the frequency model. Conclusion. Based on the results of the conducted research, the use of a frequency model has been proposed as an integral parameter for identifying the stress-strain state and damage of metal in the equipment. The use of an artificial neural network for analyzing frequency model parameters simplifies the process of identifying the stress-strain state and damage of metal structures and increases its reliability.

Buildings and structures, metal building structures, nanotechnology, stress-strain state, structural damage, electromagnetic- acoustic transformation, spectral analysis, artificial neural network

Короткий адрес: https://sciup.org/142238328

IDR: 142238328 | DOI: 10.15828/2075-8545-2023-15-5-482-493

Текст научной статьи Identification of the stress-strain state and damage of metal structures of building constructions with nanoparticle coatings using the electromagnetic-acoustic method

Original article

To protect metal structures of buildings and facilities from corrosion, provide an aesthetic appearance, protection against atmospheric effects, and harmful environmental impacts, paint-and-lacquer coatings are applied. In recent global construction practices, the active implementation of nanocoatings is notable. These coatings, manufactured from polymers, metals, composites, and various other materials, have a dried layer thickness ranging from 1 to 100 nanometers, These impart a variety of characteristics to the surfaces of structures, such as hydrophobic and oleophobic properties, resistance to corrosion, wear, and scratches, hardness, transparency, plasticity, among

RESULTS OF SCIENTIFIC AND PROFESSIONAL RESEARCH others. The protective qualities of nanotechnology-based coatings are exponentially superior to those of standard polymer paints [1]. Methods and tools have been developed and continue to be developed for non-destructive testing and diagnosis of nanocoatings of metal structures during application and commissioning to identify nanoinhomogeneities [2]. The primary objective of ensuring the secure operation of metal structures in buildings and facilities, which utilize nanotechnology-based coatings, lies in the prompt identification of critical defects in the principal metal of these structures. This is achieved via advanced non-destructive techniques and diagnostic tools.

Activities focused on ensuring the secure operation of buildings and structures are governed by national technical and regulatory documents, with the primary references being documents [3, 4]. Despite all the measures taken, the Main Inspection of the State Construction Supervision of Russia officially registered an average of about 30 accidents involving buildings and structures per year within the territory of the Russian Federation during the period from 1993 to 2002 [5] and conducted an analysis of materials related to their investigation. As of 2003, official statistics on accidents involving buildings and structures and analysis related to their investigation are not available, and starting from 2004, these functions have been transferred to the Federal Service for Environmental, Technological, and Nuclear Supervision. However, as confirmed by Dmitrieva T.L., Kudrin V.G., and Deordeyev S.V. [6] the results of structure accident records and analysis of their causes are not disclosed.

tise and non-destructive testing of construction metal structures. They analyzed the main causes of building and structure accidents, determining that 85% of all registered accidents occur in operational buildings and structures. The causes of the accidents were violations of technical operating rules and a lack of proper control over technical condition. Expert organizations were found to have made errors when assessing the condition of objects. These errors could have been attributed not only to the low qualifications of certain specialists, but also to the lack of essential non-destructive testing and diagnostic equipment for construction structures, as well as the lack of appropriate conditions for their operation. They characterized the features of operation and structural specifics of metal structures of buildings and structures that need to be taken into account when selecting methods and means of nondestructive testing and diagnostics. These structures are subject to variable loads (from 40 to 120 cycles/day), have large dimensions, are made from elements of different thicknesses and grades of steel, which differ in their mechanical and physicochemical properties. The organization of non-destructive testing and diagnostics is complicated by the fact that structures are often covered with layers of dirt, industrial dust, have several layers of old paint or are significantly affected by corrosion, and temperature values can fluctuate widely from –60 to +300oC, and heating to +600oC is also possible, with temperature variations occurring both in separate zones of the structures and over time. The lack of direct access to the surface often complicates or makes it impossible to control separate elements or zones of structures. These conditions amplify the need for a higher level of organization in the diagnostic inspection of building structures, and as a result, demand more sophisticated non-destructive testing and diagnostic instruments. It should be noted that under actual circumstances, currently available instruments may not be entirely applicable for monitoring the metal structures of buildings due to their incompatibility with the conditions of their application and their structural features.

Having analyzed the structural peculiarities and operational features of metal structures of buildings and structures, the authors of the paper [9] formulated the main requirements for non-destructive testing and diagnostics tools whose application would contribute to reducing accidents. Taking into account advances in instrument engineering, the authors believe that steady-state systems should be wireless, have long-term steady-state sensors with multi-channel transmission of measurement information to the diagnostic control center. Mobile devices should have dimensions and weight that allow them to operate in cramped conditions and at height, at industrial dustiness and low lighting. The devices ought to facilitate the examination of objects with minimal to no surface preparation, capable of operating under a temperature range from –60oC up to 300–600oC for its contact com-

RESULTS OF SCIENTIFIC AND PROFESSIONAL RESEARCH ponents. They should also possess the ability to either accumulate data or wirelessly transmit it for later processing on a personal computer.

At present, Russia is engaged in mass production of comprehensive non-destructive testing and diagnostic tools. These tools effectively encompass all types and methods of control in compliance with the GOST R 56542-2015 [10] standard. They can detect at a high level all impermissible metal defects during the manufacturing, installation, and operation of steel structures, including welded connections. However, as demonstrated by investigations into accidents related to the destruction of metal building structures and facilities globally, multiple cases have been identified where accidents occurred after planned inspections of structures using nondestructive testing tools that failed to detect impermissible defects [11–13]. It was discovered that the root cause for the breakdown of these structures were specific zones with elevated mechanical stress. In these areas, substantial accumulation of damage takes place within the metal structure, due to constant and fluctuating mechanical loads. This, in turn, develops into microcracks. Microcracks develop into volumetric defects in the homogeneity of a material, which ultimately become the cause of structural failure. Therefore, to prevent accidents associated with building and structure collapses, it is necessary to identify areas of increased mechanical stress concentration in structures and monitor the condition of the metal structure in these areas to detect defects at the earliest stages of their development. However, traditional nondestructive testing methods do not allow for early diagnosis and are focused on detecting developed defects, which may not always be sufficient to ensure the reliability of the diagnosed objects. Thus, it can be concluded that the problem of developing new non-destructive methods and means of controlling the stress-strain state of metal structures, which would ensure guaranteed accuracy in determining the values of mechanical stresses, the ability to determine the distribution of mechanical stress fields in the control area, have high operational quality and sufficient versatility, is highly relevant.

The significance of this matter has catalyzed countless investigations in Russia and other countries, with the objective of developing methods and tools to monitor the stress-strain condition of metal structures and to identify damage at the metal structure level. As an outcome of these research efforts, a wide range of devices leveraging diverse physical principles have been invented. The most relevant devices are those whose principle of operation is based on magnetoelastic (coercitimetric, magnetic anisotropy, and magnetic memory) and acoustoelastic effects. In Russia, GOSTs and other regulatory documents have been developed that regulate the using procedure for such devices [14–19]. Nonetheless, in practice, utilization of these methods presents a myriad of scientific and tech-

nical conundrums owing to the ambiguity and nonlinearity in the relationship between a metal’s mechanical and its magnetic or acoustic properties. Other intricate factors such as the metal’s structure, chemical composition, and the size of the structure being monitored, the coatings’ thickness, its mechanical history, as well as the existence of micro and macro defects, all exert significant influences on the results.

Nanocoatings allow for a significant improvement in many operational characteristics of metal structures, but they create specific requirements for the non-destructive testing and diagnostics methods and tools used. The diversity in nanocoatings, differing in their chemical, mechanical, electrical, magnetic, and acoustic properties, and insulating the surface of primary metal structures, makes it impractical to use many traditional non-destruc-tive testing and diagnostic methods for metal constructions. Based on the analysis of the current state of nondestructive testing and diagnostics of metal structures with nano- and microcoatings, the authors of the article [2] A.B. Rinkevich, Yu.V. Korkh, Ya.G. Smorodinsky conclude that “obtaining information about nano-sized heterogeneities in large objects such as pipelines, boilers, etc., is unnecessary and impractical.” On the other hand, the ability to identify the moment when a nano-discontinuity transforms into a potentially dangerous for many industrial objects micro- discontinuity is necessary and promising for the further development of non-destructive testing methods. The idea of determining the initial stage of defect formation, detecting the predefect state of the material, is increasingly discussed at international and all-Russian conferences and described in many scientific articles. In light of this, our immediate task amplifies the necessity for comprehensive studies focused on exploring and formulating cutting-edge methodologies for the assessment of metallic structures employing nanopaints, identifying new informative control parameters based on the analysis of the effects of electromagnetic and acoustic wave reflection and scattering at the nano and micro levels of the main metal and coating structure, and changes in local acoustic and electro-physical properties of materials. The presence of micro and submicron-sized non-uniformities in the control object leads to changes in acoustic impedance and density of the medium, which causes effects of scattering, diffraction, and refraction of acoustic waves. The result of these effects manifestation is generating of micronehomogeneities in the material structure, spatial and temporal higher harmonic components of the acoustic field, the parameters of which characterize the degree of heterogeneity of the environment. In areas of increased concentration of mechanical stresses in metal structures, non-uniformities of submicron and micron scales merge and form macrodefects, leading to the destruction of structures. Therefore, damage to the structure of the primary metal at the micro- and sub-

RESULTS OF SCIENTIFIC AND PROFESSIONAL RESEARCH micron levels can be used to assess the residual resource and suitability of the structure for further operation.

A promising area for implementing control tools for metal structures with nanoparticle coatings is electromagnetic-acoustical transformation, which allows for noncontact and high-performance defect detection in metals and monitoring of the stress-strain state of structures. The practical application of electromagnetic-acoustical transformation was originally proposed in the USSR in 1933 by B. Ostroumov and L. Plotovskiy for exciting free elastic vibrations in metal rods. In 1935 S.Ya. Sokolov, the founder of ultrasonic non-destructive testing, received a patent for the EMA method of control, patent number 44376 of the USSR, “Method of Stimulation Mechanical Oscillations of Turbine Blades”. R. Randall applied the EMA method to control the structure of metal in 1939. Afterwards, a multitude of works by both Russian and international authors have been published, which presented the results of experimental and theoretical studies on the nature of electromagnetic-acoustic (EMA) transformation and its application for non-de-structive testing [20]. However, existing EMA diagnostic tools significantly lag behind traditional acoustic devices with contact piezoelectric transducers in sensitivity and accuracy due to the low efficiency of double reciprocal transformation of electromagnetic and acoustic waves. Over the past 10–15 years, domestic and foreign scientists have published numerous research works directed towards improving the sensitivity and informativeness of methods and means of control based on the use of EMA transformation. Uglov A.L. and his colleagues developed an EMA device for non-destructive testing of residual stresses using the echo method of control [21].

The authors of this article, in works [29-32], proposed a new approach to improve the EMA monitoring method based on the use of a transfer function – a dynamic mathematical model in the operational form W (p) – as an integral parameter characterizing the stress-strain state and damage of the equipment metal. Changes in all properties of the metal under the influence of static or variable loads affect its integral parameter. Unlike the transfer function, which is used in control theory as a mathematical model of linear and linearized objects, the coefficients and therefore the roots of the numerator and denominator polynomials of the integral parameter W (p) change with changes in the stress-strain state and damage of the metal. Therefore, it can be used for identifying the technical condition of monitored structures. The integral parameter W (p) itself is identified through the signal response of the EMA converter using the method of dynamic identification. The estimation of the stress-strain state and damage of equipment metal in the control zone is carried out by the graphoanalytical method on the complex plane using the coordinates of the roots of the characteristic polynomial of the integral parameter W (p). The grapho-analytical method for evaluating the stress-strain state and damage of metal equipment is visual but has significant computational complexity and does not exclude the influence of human factors on the results of diagnosing the technical condition of objects. These drawbacks have necessitated the continuation of theoretical and experimental research in this direction, as the use of a dynamic mathematical model to identify the stress-strain state and damage of metal equipment is required to overcome these limitations.

The purpose of this work is to experimentally identify new informative parameters of EMA transformation for the formation of new indicators for identifying the stressstrain state and damage of metal of building structures.

METHODS AND MATERIALS

We have chosen for experimental studies steel grades St3sp and 09G2S widely used in building structures. Sixty standard samples (30 samples from each steel grade) were manufactured in accordance with GOST 1497-84 and GOST 25.502-79.

Research utilizing the uniaxial tensile scheme of samples were carried out in the metal laboratory of «Gaz-prom neftekhim Salavat», LLC with a Walter + Bai LF TTM-600 testing machine (Fig. 1).

RESULTS OF SCIENTIFIC AND PROFESSIONAL RESEARCH

Studies under cyclic loads were carried out in the laboratory for diagnostics of oil and gas equipment at the Federal State Budgetary Educational Institution of Higher Education USPTU (Institute of Oil Refining and Petro- chemistry) in Salavat using an installation (Fig. 2) manufactured under the patent No. 2262682.

In the experimental setup, corresponding modules of the EMA thickness gauges EM2210 and EM4000,

Fig. 1. Testing machine Walter + Bai

Fig. 2. Installation for testing cyclic load: a – general view; b – control of a metal sample with the EM2210 device

RESULTS OF SCIENTIFIC AND PROFESSIONAL RESEARCH

Fig. 3. EMA thickness gauge EM4000

which are mass-produced by Octanta, were used as a pulse current generator, an electromagnetic-acoustic transducer, a signal amplifier for the electromagnetic-acoustic transducer, and a matched filter. Using the EMA transducer, acoustic waves are non-contactly excited in the volume of the metal specimen, and the secondary electromagnetic field above its surface is investigated. Metallographic analysis of the test results of steel samples was carried out using a metallurgical microscope. The computer program No. 2018617490 RF developed by the authors of this article was used for the analysis of the dynamic signal of the EMA transformation, its approximation, and identification of the transfer function of the steel sample (Fig. 2, Fig. 3).

The metrological support of experimental research has been developed in compliance with the current regulatory documents and passports of measuring equipment.

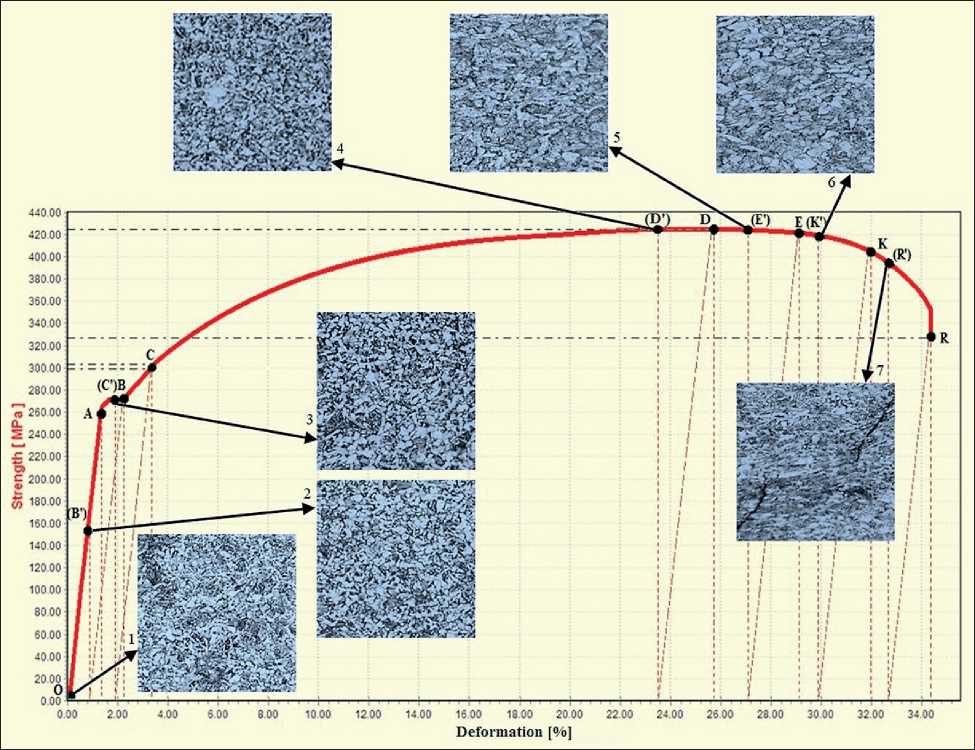

When studying metal samples under static load, a tension diagram was taken, on which control points O, A, B, D, R were marked where significant changes occur in the mechanical and hence, electrophysical and acoustic properties of the metal. These points include the initial unladen state of the metal σ0, proportional limit σpl, elastic limit σel, yield strength σs, ultimate tensile strength (UTS) σuts, and stress directly prior to the sample’s failure σfs (Fig. 4).

Fig. 4. Tension diagram and change in the microstructure of a sample made of St3sp steel at control points (DMIL M LED microscope, magnification x100)

RESULTS OF SCIENTIFIC AND PROFESSIONAL RESEARCH

A more detailed examination of changes in the metal structure of samples was conducted at the checkpoints with a high-resolution microscope and corresponding changes in electromagnetic acoustic transformation parameters. In order to obtain residual values of stress state and deformation of metal samples corresponding to their values at the control points, the samples were loaded to stress and deformation values exceeding those at the control point, taking into account the reversible deformation of the sample – points C, E, K.

During the cyclic load testing of samples (Fig. 2), the samples were loaded at a frequency that did not allow the sample to heat above 80oC (for 200 load cycles). The sample deformation was measured using the clock indicator ICH-10 indicator. After a specified number of cycles, the counter disabled the setup for conducting EMA measurements using a device at points marked on the surface of the sample. The tests were conducted until the samples were completely destroyed.

RESULTS

The tension diagram and corresponding microstructure changes of samples made of steel St3sp at control points O, A, B, D, and R are shown in Figure 4. The tension diagram also indicates the points at which the samples were loaded with consideration of reversible deformation of the samples – C, E, K.

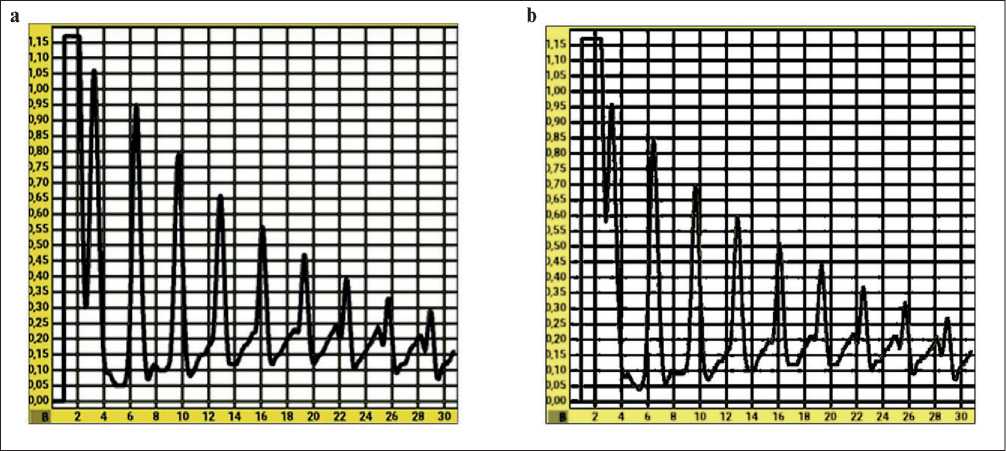

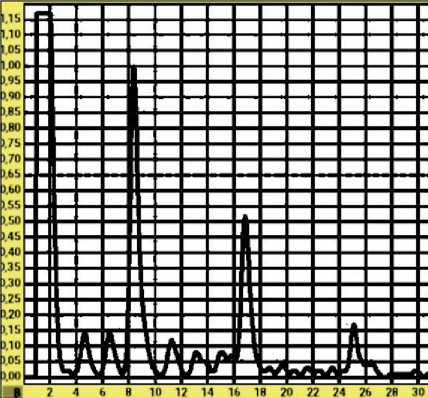

Figures 5 and 6 show the probing and multiple reflected (bottom) signals of the EMA transformation interacting with the sample of steel St3sp under static and cyclic loads, respectively.

DISCUSSION

When metal undergoes changes in its stress-strain state and accumulates damage in its structure, a whole complex of interrelated changes in mechanical, acoustic, magnetic, and electrical properties occurs. Bashirov M.G., Bashirova E.M., and Khusnutdinova I.G. experimentally investigated changes in the magnetic, electrical, and acoustic properties of steel samples up to failure under static and cyclic loads, and proposed criteria for evaluating the limit state of metals [30].

In their theoretical study on the conditions for the propagation of acoustic waves stimulated by an Electromagnetic-acoustical (EMA) transformation in media with local micron-sized inhomogeneities, Bashirov M.G., Minlibaev M.R., and Safin E.M. demonstrated that these local inhomogeneities can effectively serve as sources of harmonic components within the acoustic field. Furthermore, they proved that the parameters of these harmonic components are dictated by the specifications of the inhomogeneities themselves [33].

The ideas and assumptions put forward in the aforementioned articles [29–33] were confirmed by the results of experimental studies obtained in this research, which vividly demonstrate that the change in the stress-strain state and structural damage of the metal specimens leads to a change in the shape, amplitude, and temporal parameters of the EMA signal, i.e., a change in the parameters of the spectrum of the harmonic components of the EMA signal (see Fig. 5 and Fig. 6). It should be noted that the EMA signal also contains harmonic components due to secondary temporal and spatial harmonics of the

Fig. 5. Probing and multiple reflected signals of an EMA transformation at tension of a St3sp steel sample:

a – without load; b – at tensile stress 300 MPa (units of signal amplitude along the ordinate axis – volts, units of measurement of signal duration on the abscissa axis – microseconds)

RESULTS OF SCIENTIFIC AND PROFESSIONAL RESEARCH

а

Fig. 6. Probing and multiple reflected signals of the EMA transformation during fatigue testing of a St3sp steel sample: a – EMA signal at the initial state of the sample 0; b – EMA signal after 2200 sample loading cycles (units of signal amplitude along the ordinate axis – volts, units of measurement of signal duration on the abscissa axis – microseconds)

electromagnetic field above the surface of the test object, which are not related to the acoustic field and depend on the thickness, electrical and magnetic properties, and structural damage of the material coating.

As previously noted, direct use of the transfer function to identify the stress-strain state and damage of metal structures is associated with certain difficulties. Therefore, it is proposed to use a frequency model obtained from the dynamic model of the control object by formally replacing the operator p with ϳ ω:

= ^^ _K bo+bi^>^ +Ь»^У _KBU^

ДХ/ш) а0+а^<о>^.--+ап-Ц(оТ Л^шУ where Y(jω) and X(jω) are the response and input signals of the EMA (electromechanical actuator) in frequency domain;

B(jω) and A(jω) are the numerator and denominator polynomials, and K – is the transfer coefficient;

ai and bi are the coefficients of the numerator and denominator polynomials.

The advantage of utilizing a frequency model is the possibility of using an efficient method of spectral analysis, simplifying the process of identification, and increasing its reliability with the help of an artificial neural network.

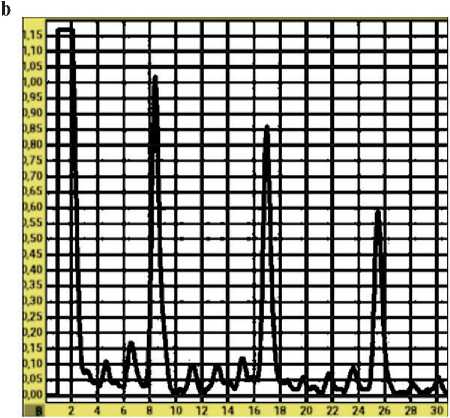

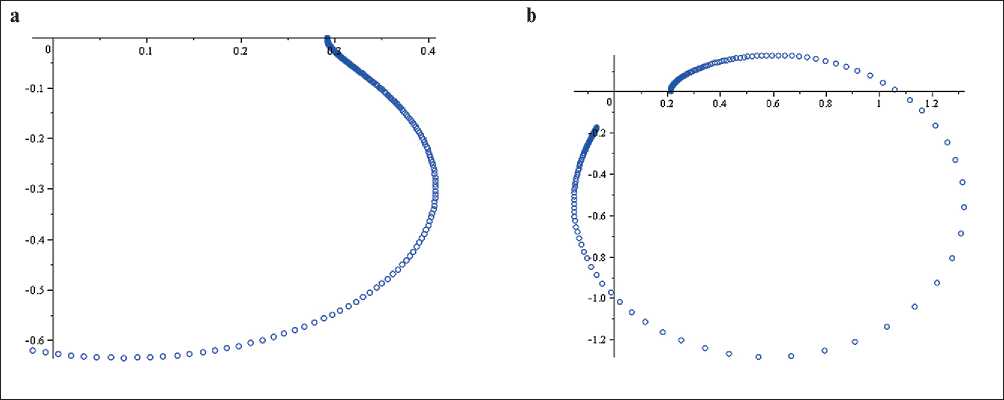

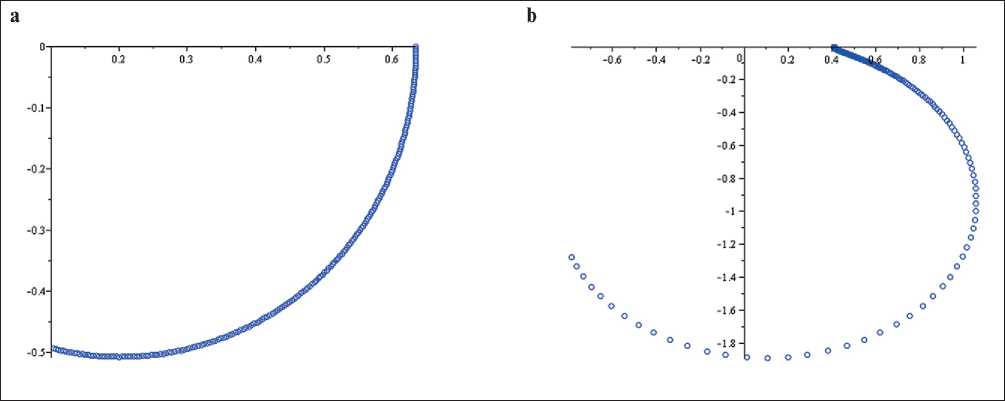

The frequency model’s graphical representation on the complex plane is the amplitude-phase-frequency characteristic. If we consider the diagram of metal stretching, each point on this curve will correspond to its frequency model (frequency pattern), formed by the combination of harmonic components of the EMA transformation signal. Therefore, based on the values of the parameters for the harmonic components of the signal, it is possible to solve the inverse problem – to identify the current stress-strain state of the metal sample. Figure 7 shows the amplitude-phase frequency characteristics of the St3sp steel sample in its initial, unloaded state, and under tensile stress of 318 MPa.

Figure 8 shows amplitude-phase-frequency characteristics of the sample of steel 09G2S without load and after 1400 load cycles.

The obtained results clearly demonstrate the changes in the parameters of the frequency models of samples with the variation of static and cyclic loads, and the possibility of applying frequency models for unambiguous identification of the level of stress-strain state and damage of tested steel samples.

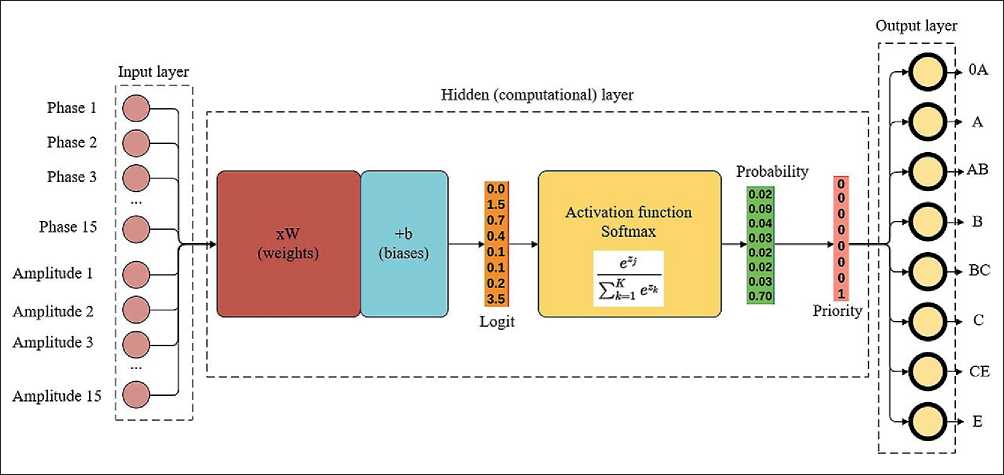

Identification of the stress-strain state and damage of metal structures is carried out by analyzing the parameters of the harmonic components of the frequency model of the research object with an artificial neural network (Fig. 9).

As a data processing algorithm, a subtype of logistic regression – polynomial logistic regression – was chosen for an artificial neural network. This algorithm is a classification method that generalizes logistic regression to multiclass classification problems. This method is used to predict probabilities of different possible outcomes of a categorically distributed dependent variable given a set of independent variables. The principle of training the artificial neural network is supervised learning. The input data for the neural network consists of complex coordinates of characteristic harmonic frequencies –

RESULTS OF SCIENTIFIC AND PROFESSIONAL RESEARCH

Fig. 7. Amplitude-phase frequency response of a St3sp steel sample under static load: a – tensile stress 0 MPa; b – tensile stress 318 MPa

Fig. 8. Amplitude-phase-frequency response of the 09G2S steel sample under cyclic load: a – number of cycles – 0; b – 1400 load cycles

amplitudes and phases of the first 15 signal harmonics of an electromagnetic-acoustic transformation. The data sample is formatted in MS Excel for further uploading into the neural network for training. One row corresponds to one measurement, consisting of 30 values and a class label. The output of the neural network is the probability of belonging to one of 8 classes (states of stress and strain of metal according to the loading diagram), which are then converted into priority (the highest probability of belonging to a specific class).

CONCLUSIONS

RESULTS OF SCIENTIFIC AND PROFESSIONAL RESEARCH

Fig. 9. Block diagram of an artificial neural network for identifying the stress-strain state and damage according to the frequency model of the studying object

structures, methodologies and tools are needed that permit contactless recognition of the stress-strain condition and deterioration of the essential metal structure through a nano-coating layer.

One of the promising directions for implementing methods and tools of non-destructive testing and diagnostics is the use of electromagnetic-acoustic transformation, whose informative potential is currently not fully explored.

As a result of the research, the use of a frequency model obtained based on spectral analysis of the electromagnetic-acoustic (EMA) transformation signal is proposed as an integral parameter for identifying the stress-strain state and damage of the metal equipment.

The use of an artificial neural network for analyzing frequency model parameters simplifies the process of identifying the stress-strain state and damage of metal structures and increases its reliability.

Список литературы Identification of the stress-strain state and damage of metal structures of building constructions with nanoparticle coatings using the electromagnetic-acoustic method

- Falikman V.R. Nanocoatings in modern construction. Nanotechnologies in construction: scientific online journal. 2021;13(1):5-11. https://doi.10.15828/2075-8545-2021-13-1-5-11

- Rinkevich A.B., Korkh Y.V., Smorodinsky Y.G. Prospects for the use of non-destructive testing for the diagnosis of nano- and microstructured materials. Defectoscopy. 2010;(1):14-20.

- Technical regulations on the safety of buildings and structures: Federal Law No. 384-FZ. Electronic fund of legal and regulatory technical documents. Available from: https://docs.cntd.ru/document/902192610.

- GOST 31937-2011. Buildings and constructions. Rules of inspection and monitoring of the technical condition: interstate standard. Approved and put into effect by Order of the Federal Agency for Technical Regulation and Metrology dated December 27, 2012 N 1984-st: implementation date 2014-01-01. Moscow: Standartinform; 2014.

- Accidents of buildings and structures on the territory of the Russian Federation in 1993-2002. Bulletins of the Main Inspectorate of the State Architecture and Construction Supervision of Russia.

- Dmitrieva T.L., Kudrin V.G., Deordiev S.V. Ways to increase the efficiency of research into accidents of steel structures. News of universities. Investments. Construction. Real Estate. 2022;12(1):28–39. https://doi.10.21285/2227-2917-2022-1-28-39

- Bayburin A.Kh., Stoyakin I.V. Accidents of buildings and structures (lessons from construction accidents). Chelyabinsk: Cicero; 2019.

- Eremin K.I. Systematization of scientific research in the field of integrated safety of construction sites. Materials of the round table “Integrated safety in construction.” Available from: https://profi.erzrf.ru/upload/iblock/97d/Eremin-K.I._-Sistematizatsiya-nauchnykh-issledovanii_-v-oblasti-kompleksnoi_-bezopasnosti-v-stroitelstve.pdf.

- Eremin K.I., Matveyushkin S.A. Features of examination and non-destructive testing of building metal structures. Prevention of accidents in buildings and structures. Available from: https://prevdis.ru/osobennosti-ekspertizyi-nerazrushayushhego-kontrolya-stroitelnyh-metallicheskih-konstruktsij/.

- GOST R 56542-2015. Non-destructive testing. Classification of types and methods. Electronic fund of legal and regulatory documents. Available from: https://docs.cntd.ru/document/1200123257.

- Dubov A.A. Fundamental distinctive features of the method of magnetic memory of metals and testing devices in comparison with known magnetic methods of non-destructive testing. Control. Diagnostics. 2003;(12):27-29.

- Yakubovsky R.Y., Bulanov I.A., Oliper I.A., Salakhov R.G., Kazakov A.A. Methods for examining metal, reinforced concrete and stone structures. Young scientist. 2015; 23 (103): 283-287. Available from: https://moluch.ru/archive/103/23680.

- Arefiev Y.V., Bezlyudko G.Ya., Shalygo A.A. New in diagnostics of the technical condition of metal building structures. Stroymetall. 2014;(42):2-6.

- GOST R 52330–2005. Non-destructive testing. Monitoring the stress-strain state of industrial and transport facilities. General requirements. Available from: https://docs.cntd.ru/document/1200039616.

- GOST R 53966–2010. Non-destructive testing. Monitoring the stress-strain state of structural materials. General requirements for the procedure for selecting methods. Available from: https://docs.cntd.ru/document/1200082717.

- MDS 53-2.2004. Diagnostics of steel structures. Available from: https://docs.cntd. ru/document/1200030802.

- GOST R 52731-2007. Non-destructive testing. Acoustic method for monitoring mechanical stress. General requirements. Available from: https://docs.cntd.ru/document/1200051032.

- GOST R ISO 24497-2-2009. Non-destructive testing. Metal magnetic memory method. Part 2. General requirements. Available from: https://docs.cntd. ru/document/ 1200075955.

- GOSTR 58599-2019. Technical diagnostics. Diagnostics of steel structures. Magnetic coercimetric method. General requirements. Available from: https://docs.cntd.ru/document/1200168809/titles.

- Bashirov M.G., Bashirova E.M., Yusupova I.G., Dratsky V.O., Murtazina A.I., Kvachinsky S.A. Modeling and experimental study of the influence of mechanical stresses and metal damage of oil and gas equipment on the parameters of electromagnetic-acoustic conversion. Oil Gas Bus. 2023;21(1):183-194.

- Uglov A.L., Khlybov A.A., Bychkov A.L., Kuvshinov M.O. On non-destructive testing of residual stresses in axisymmetrically shaped parts made of steel 03N17K10V10MT. Bull IzhSTU Named After MT Kalashnikov. 2019;22(4):3-1.

- Muravyov V.V., Budrin A.Y., Sintsov M.A. Structoscopy of heat-treated steel rods based on the speed of propagation of Rayleigh waves. Intelligent Syst Prod. 2020;18(2):37-20.

- Volkova L.V., Muravyova O.V., Muravyov V.V. Unevenness of acoustic anisotropy of rolled steel plates. Steel. 2021;(5):36-41.

- Muravyova O.V., Volkova L.V., Muravyov V.V., Sintsov M.A., Myshkin Y.V., Basharova A.F. Sensitivity of the electromagnetic-acoustic multiple shadow method using Rayleigh waves when inspecting oil pipes. Defectoscopy. 2020;(12):48-57.

- Ducousso M., Reverdy F. Real-time imaging of microcracks on metallic surface using total focusing method and plane wave imaging with Rayleigh waves. NDT E Int. 2020;116:102311. https://doi.org/10.1016/j.ndteint.2020.102311

- Trushkevych O., Edwards R.S. Characterisation of small defects using miniaturised EMAT system. NDT E Int. 2019;107:102140. https://doi.org/10.1016/j.ndteint.2019.102140

- Zhai G, Li Y, Qin Y, Liu Y. Design Method of Multiwavelength EMATs Based on Spatial Domain Harmonic Control. IEEE Trans Ultrason Ferroelectr Freq Control. 2021;68(6):2259-2270. https://doi.org/10.1109/TUFFC.2021.3055871

- Guo W., Yu Z., Chui H.C., Chen X. Development of DMPS-EMAT for Long-Distance Monitoring of Broken Rail. Sensors (Basel). 2023;23(12):5583. https://doi.org/10.3390/s23125583

- Bashirov M.G., Khusnutdinova I.G. The use of electromagnetic-acoustic method for estimating the stressstrain state of the metallic elements of power equipment. Key Eng Mater. 2017; 743:463–467. https://doi.org/10.4028/www.scientific.net/KEM.743.463

- Bashirov M.G., Bashirova E.M., Khusnutdinova I.G. The dynamic identification of the technical condition of pipelines on the basis of the analysis of the temporal characteristics of electromagnetic-acoustic signal. IOP Conf Ser Mater Sci Eng. 2019; 12042. http://doi.org/10.1088/1757-899X/511/1/012042

- Khusnutdinova I.G., Bashirov M.G., Bashirova E.M., Prakhov I.V. Device for non-contact monitoring of the stress-strain state and level of damage of metal structures. Russian Federation Patent N 2016150488. 2017.

- Bashirov M.G., Bashirova E.M., Bashirov R.A., Khusnutdinova I.G. Assessment of the stress-strain state and damage of metal structures using the electromagnetic-acoustic method. Certificate of state registration of computer programs No. 2018617490.

- Bashirov M.G., Minlibaev M.R., Safin E.M. Theoretical Analysis of Wave Electromagnetic-Acoustic Processes in a Medium During the Operation of an Electromagnetic-Acoustic Transducer. In: Proc of International Multi-Conference on Industrial Engineering and Modern Technologies (FarEastCon). 2020; 1-4. http://doi.org/10.1109/FarEastCon50210.2020.9271089