Influence of a nanostructural modifier from automobile tires on consumer properties of bitumen

Автор: Aleksandr A. Ketov, Marina P. Krasnovskikh, Elena V. Kalinina, Vadim G. Ofrikhter, Daniil A. Tatiannikov

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Application of nanomaterials and nanotechnologies in construction

Статья в выпуске: 3 Vol.15, 2023 года.

Бесплатный доступ

Introduction. Used tire rubber cracking with organic solvents leads to rubber devulcanization and dispersion of the material to nanosized particles. The process can be carried out in a flow reactor. The obtained nanomodifiers are compatible with bitumen and predictably change the bituminous binder technical characteristics. Various practical solutions have been proposed for the use of the resulting modified bituminous binders in the road construction and strengthening soil foundations. Methods and materials. It has been proposed to use a method of joint cracking of rubber with organic solvents to obtain a nanostructured modifier of bitumen. The obtained nanostructural modifier has been studied by the methods of analyzing the sizes of nanoparticles and solubility in toluene. For the bituminous binders obtained with the use of nanomodifiers, standard characteristics for bitumen, such as needle penetration depth, softening temperature, brittleness temperature and extensibility have been determined. Results and discussion. It is established that during the proposed process, a nanostructural modifier compatible with bitumen is formed. It is shown that the addition of a nanomodifier to bitumen makes it possible to purposefully change the properties of the resulting bitumen binder, improve the consumer properties of the bitumen binder and expand its application areas. It is proposed to use the obtained product as a component of waterproofing mastics for waterproofing the underground parts of buildings and structures. Conclusion. Joint cracking of rubber with organic solvents in a flow reactor allows obtaining a nanostructural modifier compatible with bitumen. The resulting product has improved properties compared to the original bitumen, which expands its scope of application. It is proposed to use the resulting product for the manufacture of waterproofing mastics. The proposed technical solutions make it possible to reduce the environmental load of automobile tires wastes.

Nanostructural modifier, bitumen, automobile tires

Короткий адрес: https://sciup.org/142238293

IDR: 142238293 | DOI: 10.15828/2075-8545-2023-15-3-267-273

Текст научной статьи Influence of a nanostructural modifier from automobile tires on consumer properties of bitumen

Review article

O ptimization and selection of suitable materials for specific applications have long been the main goals of material processing and design engineers around the world. Polymer-modified bitumens are no exception. Research has shown that adding polymers to bitumen to produce binary [1] or multi-component blends [2] can improve the final properties of the resulting modified bitumen, producing materials with improved properties for applications where pure bitumen by itself would not work properly.

The issue of using bitumen nanomodifiers for the production of asphalt concrete is ultimately due to economic feasibility [3]. On the one hand, when the cost of the modifier is higher than the cost of bitumen, replacing part of the bitumen with a modifier is economically unreasonable. But, on the other hand, the result of the impact of nanomodifiers is usually an increase in the technical and operational properties of asphalt concrete.

Therefore, the use of crumb rubber obtained from waste tires for the production of bitumen nanomodifiers has not only an economic, but also an environmen-

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION tal effect. Thus, the well-known modifier “Unirem” is obtained in a rotary disperser, where not only grinding of the material, but also partial devulcanization of rubber occurs [4, 5]. In the general case, an increase in the temperature and specific surface area of crumb rubber during the synthesis of modified bitumen leads to partial decomposition of crumb rubber in the asphalt concrete matrix and improvement of consumer characteristics of the product [6].

Directed chemical synthesis of nanomodifiers seems to be more promising due to low specific mechanical costs and the possibility of high productivity. A bitumen fixer of the dicyandiamine class at various ratios gives the modified product elasticity and increased resistance to softening with increasing temperature and has polymerbinding properties that provide high adhesion to the base of the road surface and resistance to aggressive climatic conditions due to the formation of a nanodispersed sol-gel bitumen structure». [7].

The use of thermochemical pressure treatment of the used tires rubber in the presence of oxygen-containing oil makes it possible to obtain a nanostructured product compatible with bitumen for the further use of the resulting modifier in the production of asphalt concrete [8]. The proposed method of recycling the used tires allows us to reduce the environmental burden on the environment as a result of the safe disposal of tires and the absence of hazardous emissions.

METHODS AND MATERIALS

Rubber crumb fraction of 1-3 mm produced by the Bumatika LLC was used as waste tire rubber.

The size of the resulting particles was determined using a Zetasizer Nano analyzer of the Malvern company (Great Britain).

The compatibility of the obtained products with bitumen was determined by the solubility in toluene, according to GOST 20739-75. “Petroleum bitumen. Method for determining solubility».

Сharacteristics of the obtained bituminous binders were determined according to standard methods: softening temperature by the “Ring and Ball” method – accord- ing to GOST 33142-2014; determination of the needle penetration depth – according to GOST 33136-2014; determination of the brittleness temperature according to Fraas – in accordance with GOST 33143-2014 and determination of extensibility in accordance with GOST 33138-2014. The following equipment was used for the analysis: KiSh 20-2200 device (manufacturer: Infra Test Pruftechnic GmbH, Brackenheim, Germany); low-temperature laboratory electric furnace SNOL 58/350 (manufacturer: AB “Amega”, Lithuania); automatic penetrometer (manufacturer: Infra Test Pruftechnic GmbH, Brackenheim, Germany); automatic apparatus for determining the brittleness temperature of oil bitumen (manufacturer: JSC BSKB “NEFTEKHIMAVTOMATIKA”); ductility meter (manufacturer: Infra Test Pruftechnic GmbH, Brackenheim, Germany); and contact digital thermometer TK-5.06.

To implement the process, an installation was made, which is a series-connected horizontally located singlescrew extruder and a tubular reactor operating in a flow mode. The extruder and reactor are equipped with independent electric furnaces. Two types of organic solvents were used. Sunflower unrefined oil of the “Blago” brand was chosen as an oxygen-containing solvent, low-ash fuel oil according to GOST 10585-2013 was chosen as an oxygen-free solvent.

Conditions for the synthesis of modifiers are given in Table 1.

In all the cases, the period of the reaction mass staying in the extruder was 15 minutes, and in the reactor – 45 minutes.

To prepare samples of modified bitumen, we used the bitumen with indicators determined according to GOST 22245-90, see Table 2.

Optimization of the mixture composition and properties can be achieved through an experimental mixture design process. It has been proven [9] that such procedures are useful for establishing relationships between the type of polymer modifiers and the expected modified bitumen properties. The essence of the method is to determine the response functions that characterize the properties of bitumen, on the parameters of the additive synthesis. The standard additive content of 20% by weight is assumed.

Table 1

Conditions for the synthesis of modifiers

|

N |

Organic solvent |

The proportion of solvent in the composition with rubber, wt.% |

Extruder temperature, оС |

Reactor temperature, оС |

|

M1 |

Sunflower oil |

33 |

300 |

400 |

|

М2 |

Sunflower oil |

18 |

300 |

400 |

|

М3 |

Fuel oil |

33 |

300 |

380 |

|

М4 |

Fuel oil |

33 |

300 |

400 |

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Table 2

Characteristics of the original bitumen and requirements according to GOST for BND 60/90 and BND 40/60

|

Indicator |

Explored oil road bitumen BND |

GOST 22245-90 requirements for BND 60/90 |

GOST 22245-90 requirements for BND 40/60 |

|

Needle penetration depth, 0,1 mm, at the temperature of 25оC, mm |

55 |

61–90 not less than 20 |

40–60 not less than 13 |

|

Softening temperature for ring and ball, оС |

50 |

not lower than 47 |

not lower than 51 |

|

Extensibility, min, at 0оC, cm |

3.9 |

not less than 3.5 |

not standardized |

|

Brittleness temperature, оС |

–20 |

not higher than –15 |

not higher than –12 |

Conditions for the synthesis of a nanostructured bitumen product

To prepare a nanostructured bitumen product, a modifier in an amount of 20 wt.% was added with stirring to bitumen at the temperature of 220оC and kept under stirring for 30 minutes. As a result, four samples of a nanostructured bitumen product (NSBP) were obtained, further having the corresponding designations of NSBP-1 – NSBP-4.

Conditions for the synthesis of NSBP mastic

To test the applicability of the proposed direction of using the obtained NSBP, NSBP-mastic was prepared and applied onto the concrete base. The mastic was made on the basis of lime-clay emulsion paste having the composition of NSBP-4 – 50%; clay – 7%; lime – 7%; water – 36%. Clay and lime were mixed dry in the ratio of 1:1, and then the required amount of heated water was gradually added with constant stirring into the dry limeclay mixture (emulsifier), until the mixture reached the consistency of thick sour cream.

The time for preparing the pasta was 2 minutes. The components were mixed with an electric mixer. NSBP mastic was prepared by mixing the finished emulsion paste and heated NSBP. NSBP was gradually added to the mixture of the lime-clay emulsifier with water, until the mixture thickened, then water was added and the operation was repeated until the components of the emulsion paste were fully loaded. The mastic preparation time was 5 minutes.

To test the applicability of the proposed direction of using the obtained NSBP, NSBP-mastic was prepared and applied to the concrete base. The mastic was made on the basis of lime-clay emulsion paste. In order to improve the adhesion of NSBP mastic, before applying the waterproofing composition the concrete base was primed with a primer made from a mixture of NSBP with gasoline. After applying the primer, the surface was completely dried. The readiness of the surface for applying the mastic was checked with a clean white cloth, on which no traces remained after applying it to the primed surface.

RESULTS AND DISCUSSION

To determine the compatibility of modifiers with bitumen, the solubility of modifiers in toluene was studied. The results obtained are presented in Table 3.

Table 3

Solubility of bitumen modifiers in toluene

|

Sample |

Proportion of the substance insoluble in toluene, wt. % |

|

М1 |

45.12 |

|

М2 |

28.21 |

|

М3 |

21.13 |

|

М4 |

33.63 |

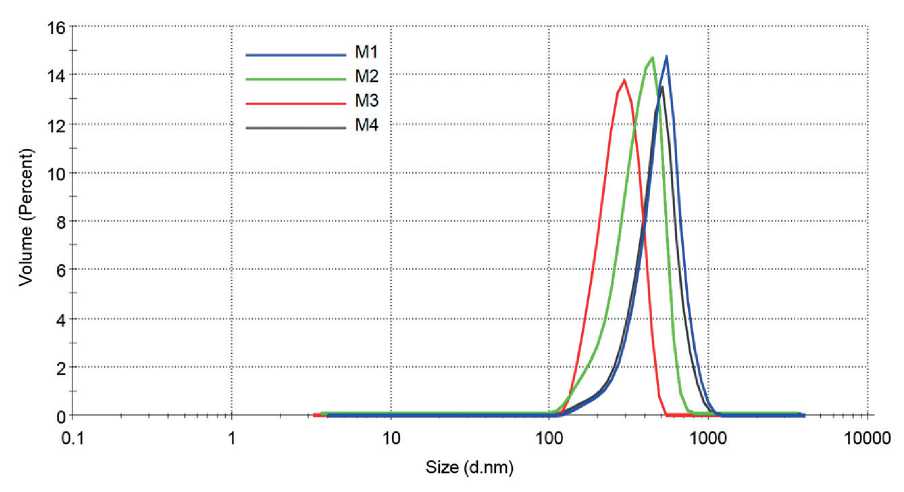

From the above assumptions about the cracking of polymer molecules and the devulcanization of the threedimensional structure of rubber, one can suppose that the continuous three-dimensional structure of rubber is destroyed during thermochemical treatment to the particles of molecular and colloidal sizes. These assumptions were confirmed by determining the size of particles in a toluene solution. Particles size distribution curves in solutions of the modifier samples are shown in Fig. 1.

It is obvious that thermochemical treatment leads to a deep cracking of the rubber polymer composition, and as a result not only the three-dimensional structure of the vulcanized rubber is destroyed, but also the formation of predominantly low molecular weight compounds soluble in toluene takes place. The toluene-insoluble components of the composition are nanosized particles less than 1 µm in size with predominant sizes of 200–800 nm. The toluene-insoluble part of the modifier in its chemical structure can be both inorganic additives in the original composition, such as carbon black, silicon and magnesium oxides, and rubber residues, in which the most stable three-di-

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Fig. 1. Particles size distribution curves in solutions of the modifier samples

mensional structure was formed during vulcanization. With any of these options, particles insoluble in toluene, and hence in bitumen, are heterogeneous inclusions of a colloidal type and cannot prevent mixing the modifier with bitumen and creating a homogeneous composition.

To test this assumption, modified bitumens were made and their main consumer characteristics were determined. The results are presented in Table 4 in comparison with the changes in properties in relation to the original bitumen.

To compare the properties of modifiers with untreated rubber crumb, a sample was additionally prepared with 20 wt. % rubber crumb in the original bitumen according to the standard method for modifiers. However, it turned out to be impossible to determine the main characteristics of the resulting bitumen modified with rubber crumb according to GOST 22245-90: when the binder sample was heated to 160оC, a homogeneous liquid state was not achieved, and it was also not possible to filter the sample through a 0.7 mm sieve. Thus, it is obvious that rubber crumb in its original form cannot be considered as a bitumen modifier.

In terms of the level of thermochemical impact, the described method surpasses the well-known method of high-temperature shear grinding [10, 11], in which the diffusion of aromatic hydrocarbons from the bitumen component into the modifier particles, and sulfur compounds from the modifier particles into bitumen, has been proven. Therefore, the proposed method of thermochemical cracking leads to the enhancement of such types of mutual diffusion and creation of a more homogeneous composition. It should be noted that it is the poor solubility of polymer modifiers in the bitumen

Table 4

Characteristics of the modified bitumen according to GOST in comparison with the corresponding characteristics of the original bitumen

|

Indicator |

MB1 (in relation to the original bitumen) |

МB2 (in relation to the original bitumen) |

МB3 (in relation to the original bitumen) |

МB4 (in relation to the original bitumen) |

|

Needle penetration depth, 0.1 mm, at the temperature of 25оC, mm |

41 (–14) |

191 (+136) |

139 (+84) |

152 (+97) |

|

Softening temperature for ring and ball, оС |

36 (–14) |

43 (–7) |

47 (–3) |

44 (–6) |

|

Extensibility, min, at 0оC, cm |

11.6 (+7.7) |

10.5 (+6.6) |

9.8 (+5.9) |

10.1 (+6.2) |

|

Brittleness temperature, оС |

–31 (–11) |

–26 (–6) |

–26 (–6) |

–29 (–9) |

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION matrix that is considered to be the main disadvantage of most polymer additives [12]. Therefore, the removal of this limitation can be unambiguously characterized as an important advantage of the proposed method.

For the studied bitumen modifiers, the most obvious conclusion is the fact that all the obtained modifiers improve the consumer properties of bitumen. In fact, in terms of the needle penetration depth, bitumen used for the research formally does not meet the requirements of either BND 60/90 or BND 40/60. At the same time, three of the four modifiers dramatically improve the viscous properties of bitumen, increasing the value of the needle penetration depth by two or more times.

Similarly, there is an improvement in extensibility and brittleness temperature. Thus, in accordance with the requirements of GOST 22245-90, the lower limit for extensibility at 0оC is set at 3.9 cm, and the use of modifiers increases this indicator for all the samples by about two times. The brittleness temperature for all the samples also decreases. The only indicator by which the properties of the modified bitumens deteriorate slightly is the softening temperature. This is probably due to the cracking of organic molecules and decrease in the average molecular weight of the bitumen composition. It is possible, however, to use the bitumens with a lower softening point in areas other than road construction. In addition, the possibility of creating complex modifiers using polymer molecules that will increase the softening temperature is known [13].

Thus, the joint pyrolysis of rubber crumb of used tires and vegetable oil under pressure results in the production of a nanostructured product compatible with bitumen. One of the possible directions of using the obtained nanostructured bitumen product (hereinafter referred to as NSBP) is its use for waterproofing underground parts of buildings, structures and communications, as well as for sealing expansion joints in underground parts. Recommendations for the prospective use of NSBP were formulated taking into account [14].

It seems promising to use NSBP in asphalt mastic compositions (NSBP-mastic), which can be applied in one or several layers in the form of mechanized or manual basting on concrete (reinforced concrete) or brick bases, forming a plastic plaster coating.

NSBP mastic is made from a mixture of NSBP emulsion paste with a powdered mineral filler. Various materials can be used as an emulsifier for the preparation of NSBP emulsion paste, for example, mineral powder, talc, chalk, clay, phosphogypsum, soot, cement, lime [15]. It should be noted that lime or lime-clay compositions will be most preferable as emulsifiers. Tripoli and diatomite are low-quality emulsifiers. To prepare NSBP-emulsions, only easily crushable low-cemented varieties of tripoli and diatomite can be suitable. In any case of using tripoli or diatomite, only unstable coarse pastes can be prepared, therefore these emulsifiers are not recommended for the preparation of NSBP emulsion pastes. To prepare NSBP mastic, limestone or brick powders and fly ash from thermal power plants can be used as fillers. The use of up to 10% of Portland cement is allowed. It must be borne in mind that the use of fly ash is unacceptable in case of sulfate aggression of groundwater. Accordingly, cement in case of sulfate aggression must be sulfate-resistant. Water for the preparation of NSBP-emulsion pastes and NSBP-mastics must be suitable for the preparation of concrete (GOST 23732-2011).

The adhesion of NSBP-mastic applied to the concrete surface was tested by a peel test in accordance with [14]. The pull test was performed by applying a pull-off load to a 30×30 mm steel plate. The plate was glued to the surface of the applied mastic coating with thermoplastic adhesive. During the pull-off test, a breaking force of 60 N (6.7 N/cm2) was applied to the steel plate, which was held for 180 seconds, then the force was increased to 100 N (11.1 N/cm2), and after that the separation of the plate with mastic occurred after 40 seconds. Thus, the adhesion of NSBP mastic to a concrete base meets the requirements for asphalt mastic to waterproof underground parts of buildings and structures [14].

The obtained characteristics of NSBP-mastic make it possible to assume high performance characteristics typical for mastics with dispersed aggregates [16] and for an asphalt concrete binder [17]. An increase in the resistance of mastics to deformation, high rigidity and impact strength usually observed are associated with the appearance of a stable nanostructure of bituminous mastic [18, 19].

The results on the applicability of the obtained nanomodified bitumen are consistent with the results of other researchers proving the comparability of bitumens modified with rubber crumb processing products with a compound made from rubber waste [20].

CONCLUSION

The use of thermochemical pressure treatment of waste tire rubber allows producing a nanostructured modifier compatible with bitumen in a flow reactor.

The resulting nanostructured bitumen-containing product can be used as a binder in waterproofing mastics for insulating underground parts of buildings and structures. NSBP mixes well with an emulsifier, and the prepared mastic is easily applied to the surface to be insulated. Components for the manufacture of waterproofing mastic (clay, lime) are available and inexpensive. Waterproofing NSBP-mastics are quickly prepared directly at the construction site in the quantities required for application, which makes it possible to practically eliminate construction waste from waterproofing and does not have an additional burden on the environment.

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Список литературы Influence of a nanostructural modifier from automobile tires on consumer properties of bitumen

- Socal da Silva L., de Camargo Forte M.M., de Alencastro Vignol L., Cardozo N.S.M. Study of rheological properties of pure and polymer-modified Brazilian asphalt binders. Journal of Materials Science. 2004; 39(2): 539–546. https://doi:10.1023/b:jmsc.0000011509. 84156.3b

- Polacco G., Berlincioni S., Biondi D., Stastna J., Zanzotto L. Asphalt modification with different polyethylenebased polymers. European Polymer Journal. 2005; 41(12): 2831–2844. https://doi:10.1016/j.eurpolymj.2005.05.034

- Gotovtsev V.M., Shatunov A.G., Rumyantsev A.N., Sukhov V.D. Nanotechnology in the production of asphalt concrete. Fundamental’nye issledovaniya. 2013; 1 (1): 191–195. https://fundamental-research.ru/ru/article/view?id=30925 (In Russian)

- Klyuev S.V., Klyuev A.V. Man-made raw materials – effective filler for fibrobetons. Uspekhi sovremennoi nauki. 2015; 1: 33-35. (In Russian)

- Romanov P.S., Pantelova Kh.M Application of nanotechnology in road construction in Russia. Territoriya nauki. 2016; 4: 63-67. (In Russian)

- Tang N., Huang W., Xiao F. Chemical and rheological investigation of high-cured crumb rubber-modified asphalt. Construct. Build. Mater. 2016; 123: 847-854. https://doi.org/10.1016/j.conbuildmat.2016.07.131

- Boev E.V., Islamutdinova A.A., Aminova E.K. Obtaining the retainer for waterproofing road bitumens. Nanotehnologii v stroitel’stve = Nanotechnologies in Construction. 2021; 13(5): 319–327. https://doi.org/10.15828/2075-8545-2021-13-5-319-327 (In Russian)

- Krasnovskikh M.P., Chudinov S.Yu., Slyusar’ N.N., Pugin K.G., Vaisman Ya.I. Production of a nanostructured bitumen modifier in the processing of automotive tires. Nanotehnologii v stroitel’stve = Nanotechnologies in Construction. 2022; 14 (6): 501–509. https://doi.org/10.15828/2075-8545-2022-14-6-501-509 (In Russian)

- Munera J.C., Ossa E.A. Polymer modified bitumen: Optimization and selection. Materials & Design. 2014; 62: 91–97. https://doi.org/doi:10.1016/j.matdes.2014.05.009

- Gordeeva I.V., Mel’nikov D.A., Gorbatova V.N., Reznichenko D.S., Naumova Yu.A. Study of the Effect of the Modification Process on the Group Composition of Bitumen and Modifiers by Fourier-IR Spectroscopy. Tonkie khimicheskie tekhnologii. 2020; 15 (2): 56–66. https://doi.org/10.32362/2410-6593-2020-15-2-56-66 (In Russian)

- Nikol’skii V.G., Dudareva T.V., Krasotkina I.A., Zvereva U.G., Bekeshev V.G., Rochev V.Ya., Kaplan A.M., Chekunaev N.I., Vnukova L.V., Styrikovich N.M., Gordeeva I.V. Development and properties of new nanomodifiers for pavement. Khimicheskaya fizika. 2014; 33 (7): 87–93. (In Russian)

- Behnood A., Modiri Gharehveran M. Morphology, Rheology and Physical Properties of Polymer-Modified Asphalt Binders. European Polymer Journal. 2019; 112: 766-791. https://doi.org/10.1016/j.eurpolymj.2018.10.049

- Bosnik V., Vaisman Y., Ketov A., Krasnovskikh M., Rudakova L. Promising Areas for Producing Bitumenlike Materials Based on Synthetic Polymers Waste. Ecology and Industry of Russia. 2020; 24(5): 34-39. https://doi.org/10.18412/1816-0395-2020-5-34-39 (In Russian)

- P 13-73 VNIIG Rukovodstvo po ustroistvu kholodnoi asfal’tovoi gidroizolyatsii i bezrulonnykh krovel’. Energiya; 1973. (In Russian)

- Tyrtyshov Yu.P., Pechenyi B.G., Kurbatov V.L., Eshchenko A.I. Optimization of compositions, technologies for preparing bitumen pastes and mastics. Stroitel’nye materialy. 2013; 1: 70-72. (In Russian)

- Chen M., Javilla B., Hong W., Pan C., Riara M., Mo L., Guo M. Rheological and Interaction Analysis of Asphalt Binder, Mastic and Mortar. Materials. 2019; 12: 128. https://doi.org/10.3390/ma12010128

- Malyanova L.I Modified asphalt concrete with limestone crushing waste in road garments. Stroitel’nye materialy. 2018; 7: 24-27. https://doi.org/10.31659/0585-430Х-2018-761-7-24-27 (In Russian)

- Liu Z., Wang H., Gong X., Cui P., Wei H. Stiffening and Toughening of Asphalt Mastic Induced by Bitumen–Mineral Selective Molecular Adsorption and Nanostructural Reconstruction. Sustainability. 2023; 15: 4398. https://doi.org/10.3390/su15054398

- Dong Z., Liu Z., Wang P., Gong X. (2017). Nanostructure characterization of asphalt-aggregate interface through molecular dynamics simulation and atomic force microscopy. Fuel; 189: 155–163. https://doi:10.1016/j.fuel.2016.10.077

- Carpani C., Bocci E., Prosperi E., Bocci M. Evaluation of the rheological and performance behaviour of bitumen modified with compounds including crumb rubber from waste tires. Construction and Building Materials. – 2022; 361: 129679. https://doi.org/10.1016/j.conbuildmat.2022.129679