Influence of activation methods on the structural and technological characteristics of nanomodified cement compositions

Автор: Natalia O. Kopanitsa, Olga V. Demyanenko, Anzhelika A. Kulikova, Svetlana V. Samchenko, Irina V. Kozlova, Nadezhda A. Lukyanova

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Application of nanomaterials and nanotechnologies in construction

Статья в выпуске: 6 Vol.14, 2022 года.

Бесплатный доступ

Introduction. We studied the effect of nanosized silicon dioxide (SiO2) on the structural and technological characteristics of nanomodified cement compositions introduced together with activated mixing water. Materials and research methods. Activation of mixing water was carried out by means of magnetic field and ultrasonic action. For investigation the capability to maintain their properties for a long time, the stability of silica suspensions in activated water was studied. For finding out the effect of activated silica suspensions on the structure and properties of composite materials based on cement, the physical and mechanical properties of the studied compositions were explored. X-ray and differential thermal analysis of the hardened activated nanomodified cement paste were also carried out. Results and discussion. The positive role of the suspension of silicon dioxide in activated water was associated with a decrease in the microheterogeneity of the hardened cement paste, ensuring the stability of its physical and mechanical characteristics. Based on the above mentioned observations, a mechanism was proposed for more efficient incorporation of nanosized silicon dioxide into cement hydration processes both due to chemisorption with Ca(OH)2 in the hardening cement paste and due to the topological effect of nanoparticle localization in defects and ultramicrovoids of a crystallizing disperse system. Conclusion. The results show that suspensions of silica in activated water can maintain their properties for a long time. Graphical dependencies are shown, indicating the effectiveness of the use of activated silica suspensions in the production of cement composites. This quality makes it possible to obtain repair compounds with the required properties during construction work for various purposes.

Cement compositions, nanomodifiers, magnetic treatment, ultrasonic treatment, mixing water

Короткий адрес: https://sciup.org/142235788

IDR: 142235788 | DOI: 10.15828/2075-8545-2022-14-6-481-492

Текст научной статьи Influence of activation methods on the structural and technological characteristics of nanomodified cement compositions

Original article

Currently, much attention is paid to the development of nanotechnologies in various fields of science and technology. Promising nanodispersed materials include nanocomposites based on silicon compounds [1–3]. The effect of nanomodification on the structure, phase composition, and properties of materials is being actively studied [4–6, 24–28]. The introduction of nanotechnology elements into the system is accompanied by intentional molecular engineering, neoformations, nanostructures, nanosystems and nanoobjects [7, 8].

Most frequently, nanosized silica particles are considered as growth stimulants in biotechnology for the development of the agro-industrial complex [9, 10].

For the construction industry, nanosized silicon compounds are also of interest [11–14]. For example, it was shown in [15] that the introduction of nano-SiO2 and

АPPLICATION OF NANOTECHNOLOGIES AND NANOMATERIALS IN CONSTRUCTION nano-Al2O3 into cement at low relative humidity (60% relative humidity) and low air pressure (50 kPa, 60 kPa, 70 kPa) contributes to compaction of the microstructure, increasing the degree cement hydration and improved flexural and compressive strength, in contrast to samples that do not contain nanocomponents.

The purpose of this research is to establish the influence of activation methods on the structural and technological characteristics of nanomodified cement compositions by activating the mixing water under the influence of a magnetic field and ultrasonic action.

The analysis shows that the processes of hydration and structure formation of cement stone can be “activated” by affecting the mixing water. This leads to intensification of the processes of structure formation, modification of the structure and properties of composite materials. In [16, 17], changes in the structural, optical, kinetic, magnetic, and other physicochemical properties of the studied cement systems are noted. The external influences (chemical, physical) of the field on the components of a disperse system is considered both at the microlevel are considered: from the standpoint of the rearrangement of electron shells, and at the macrolevel, where structural macroscopic formations are modeled, as well as when using various kinds of nanoadditives at the level of formation of nanostructures in composite materials [18, 19]. Despite the promise of using activated water, it has not yet been widely used in constrution technologies [20, 21]. The effect of magnetic activation of mixing water on the properties of composites with a mineral matrix and on the course of their structure formation processes is associated with a change in the properties of the treatment object itself, as well as with the intensity and degree of structure restructuring, as well as with a change in the degree of cement hydration in solid and liquid phases. In the technology of repeated magnetic activation of mixing water, regardless of its type, additional oxygen is introduced into the treatment object and a magnetic field is applied simultaneously, which stimulates the course of processes with a change in the energy saturation of water during treatment and its holding after activation. The treatment of a liquid by a rotating magnetic field enhances its effect on the molecules as a result of the orientational action, which reduces to their combination into complexes. In liquids with polar molecules, the orientational polarization is more pronounced. The electrostatic field is a special case of the electromagnetic field, therefore, the phenomena occurring in the liquid under the influence of this field will be similar, because the magnetic moments of the electrons interact with the external field. The paper presents comparative data on the assessment of the influence of different nano-SiO2 content of the modes of cyclic magnetic activation of water and cement slurry on the strength characteristics of cement stone and the water demand of cement paste.

MATERIALS AND RESEARCH METHODS

Portland cement CEM I 42,5N from the Topkinsky cement plant GOST 31108-2020 was used as a binder.

The chemical and mineralogical compositions of Portland cement clinker are shown in Table 1.

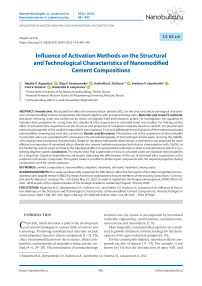

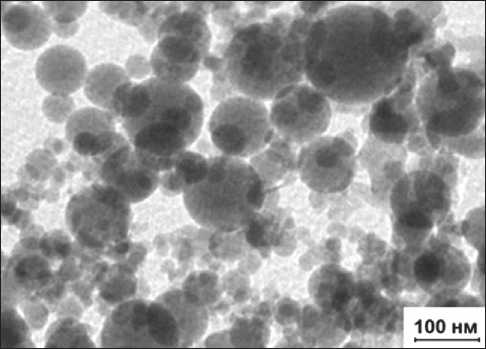

Silicon dioxide obtained by the plasma-arc method was used as a modifying additive [22, 23]. To obtain a nanopowder, diatomite from the Kamyshlovskoe deposit of the Sverdlovsk region in Russia was used as a raw material. Characteristics of nano-modifier silicon dioxide (SiO2) is given in Table 2, micrograph of nano-SiO2 and size distribution curve of SiO2 nanoparticles are shown in Figures 1 and 2, respectively.

As can be seen from Figure 1, SiO2 nanoparticles with a polydisperse size distribution have a characteristic spherical shape and are presented in the form of agglomerates.

Based on the data of micrographs, the size distribution of nanoparticles (for at least 1000 particles) was estimated using the iTEM software (Olympus, Japan). The diagram presented in Figure 2 shows that the nanoparticles of the resulting powder have a size distribution in the range from 10 to 300 nm, but their largest number (82% vol.) is in the range up to 100 nm. The distribution peak falls on particles 11–20 nm in size (13% vol.) [24].

Characteristics of nanomodifiers based on SiO2 used in the work (Тs – nanosized particles; Т – finely dispersed particles) are presented in Table 3.

When conducting experimental studies for mixing cement, water was used that meets GOST 23732-2011. The silicon dioxide nanomodifier was introduced into the water before it was activated in an amount of 0,01–0,05% by weight of the cement.

Table 1

Portland cement clinker and its main components

|

Chemical analysis of Portland cement, % |

Mineralogical composition of clinker (main components of the phase, %) |

||

|

CaO |

61.9 |

C 3 S |

68.9 |

|

SiO2 |

19.8 |

||

|

Al 2 O 3 |

4.6 |

C2S |

12.6 |

|

Fe 2 O 3 |

3.0 |

||

|

MgO |

3.6 |

С3А |

6.0 |

|

SO3 |

2.8 |

C4AF |

11.4 |

|

R2O |

0.9 |

СаО |

1.1 |

АPPLICATION OF NANOTECHNOLOGIES AND NANOMATERIALS IN CONSTRUCTION

Тable 2

Main characteristics of the nanomodifier (SiO2)

|

Indicator name |

Indicator value |

|

Appearance |

Ultrafine powder, gray |

|

Mass fraction of oxides, %, not less than |

|

|

SiO2 |

95.0 |

|

Fe 2 O 3 |

0.11 |

|

Al 2 O 3 |

0.17 |

|

CaO |

0.25 |

|

R 2 O |

1.9 |

|

MgO |

1.0 |

|

P 2 O 5 |

1.0 |

|

SO3 |

0.6 |

|

Mass fraction of water, % no more than |

3.0 |

|

Mass fraction of losses on ignition, % no more than |

1.06 |

|

Specific surface, m2/g |

38 |

|

Average particle size, nm |

40 |

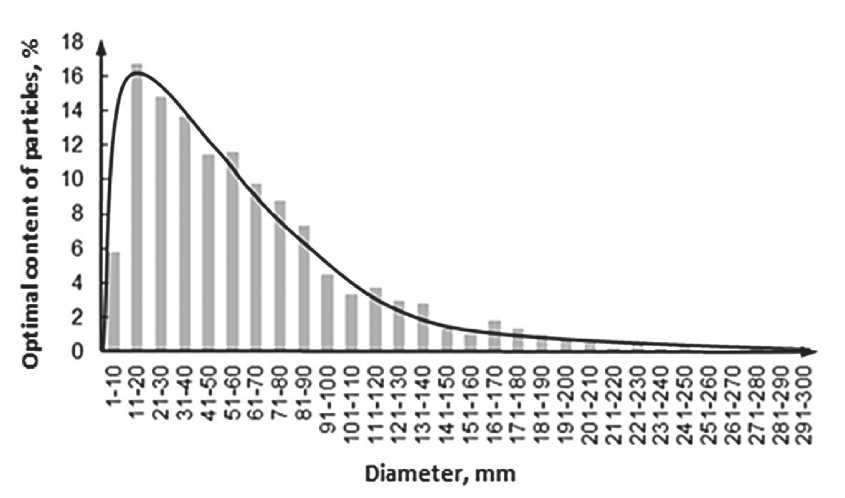

To activate mixing water by means of a magnetic field, an installation was used, which is a rack with magnetic funnels successively attached to it (Figure 3).

Treatment of water mixing cement paste was carried out in a magnetic funnel in the field of a permanent magnet. One cycle of water treatment was considered

Fig. 1. Micrograph of SiO2 nanopowder

Table 3

Characteristics of nanomodifiers

|

Characteristic |

Specific surface, m2/g |

Average particle size, nm |

|

Тs10 |

10 |

45.00 |

|

Тs38 |

38 |

37.12 |

|

Тs59 |

59 |

48.34 |

|

Т84 |

82.9 |

43.71 |

|

Т90 |

92 |

41.50 |

|

Т110 |

111 |

24.50 |

|

Т140 |

140 |

22.61 |

Fig. 2. Size distribution diagram of SiO2 nanoparticles

АPPLICATION OF NANOTECHNOLOGIES AND NANOMATERIALS IN CONSTRUCTION

Fig. 3. Scheme of magnetic activation of mixing water the passage of water through one funnel equipped with a magnetic field.

After reaching the required number of cycles of magnetic water treatment, the cement was mixed with mixing water and a nanomodifier until a cement paste of normal density was obtained.

Mixing water activation by ultrasonic treatment was carried out in an ultrasonic bath YAXUN YX-3560 30W/50W). Specifications: power: 30/50 W; operating frequency: 42 kHz; timer: 1–30 minutes (auto-off). Mixing water was treated for 3 minutes at a power of 50 watts. The suspension of the silica nanomodifier prepared in this way was used to obtain a cement paste of normal density.

The studies were carried out on cube samples 20×20×20 mm in size, made from cement paste of normal density, hardening under normal conditions (T = 18–20оC, W = 90–100%). The compressive strength of the samples was evaluated at 28 days of curing. For comparative analysis, modified compositions and control Portland cement were investigated. At least 5 samples were prepared for each composition. The strength value was determined as the arithmetic mean value of 5 samples, the coefficient of variation was not more than 5%.

The hydration products of the hardened cement paste were determined by X-ray phase analysis and derivato-graphic analysis.

X-ray phase analysis was performed on an XRD-6000 diffractometer (Shimadzu, Japan) using CuKα radiation. The analysis of the phase composition was carried out using the PCPDFWIN and PDF-4+ databases, as well as the POWDERCELL 2,5 full-profile analysis program.

The features of phase transformations in the cement system and the change in the mass of chemically bound water were determined by derivatographic analysis using an STA 449 F3 Jupiter device.

RESULTS AND DISCUSSION

Obtaining and stabilization of suspensions of silicon dioxide nanomodifier.

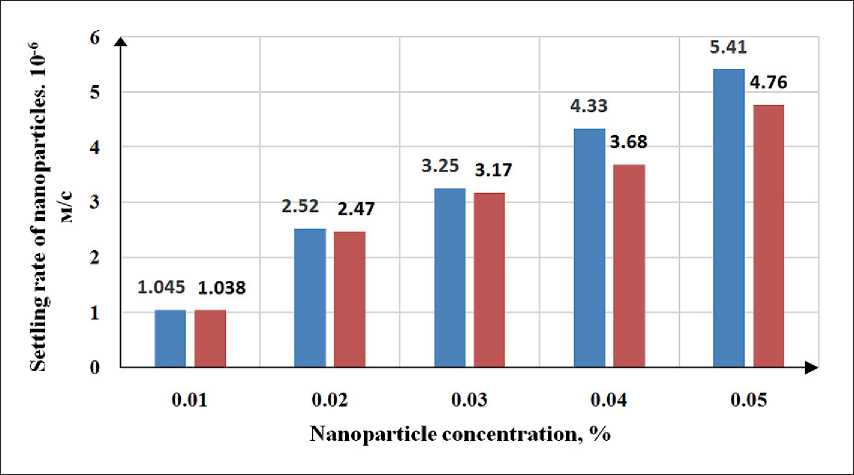

To establish the aggregative stability of the silicon dioxide (SiO2) nanomodifier, the prepared solutions were poured into cylinders with a volume of V = 100 cm3 and the process of their sedimentation was observed. During the experiment, already 50-70 minutes after dispersion, particles with a content of 0,05% of the nanomodifier began to settle, after 90 and 180 minutes, respectively, 0,03% and 0,01% of the particles of the nanomodifier. Consequently, sedimentation proceeds most rapidly in mixing water containing 0,05% nanomodifier silicon dioxide (SiO2), and mixing water containing 0,01 and 0,03% nanomodifier is the most aggregatively stable. The dependence of the deposition rate of the nanomodifier silicon dioxide (SiO2) on their concentration is shown in Figure 4.

As can be seen from the presented data (Figure 4), the stability of systems at low concentrations of the nanomodifier (from 0,01 to 0,03%) is commensurate, and in systems with a concentration of these particles from 0,04 to 0,05%, where mixing water was used activated by magnetic fields are more stable. In systems treated with ultrasonic treatment, they begin to settle after 50 minutes, compared to 70 minutes fixed for systems activated by magnetic field.

Such stability of water-silicon dioxide (SiO2) nanomodifier systems, activated by magnetic field, may be due to the increased effect on both water molecules and

АPPLICATION OF NANOTECHNOLOGIES AND NANOMATERIALS IN CONSTRUCTION

Fig. 4. Dependence of the particle settling rate on the concentration of silicon dioxide nanomodifier: 1 – Activated mixing water by magnetic field (MF); 2 – Activated mixing water by means of ultrasonic influence (USI)

SiO2 nanoparticles as a result of orientational action, which reduces to their combination into aquacomplexes [SiO2•nH2O] .

Ultrasonic action on the system water – nanomodifier silicon dioxide (SiO2) contributes to the dispersion of SiO2 conglomerates, and water dipoles, surrounding individual particles with an active surface, also form aqua complexes that can act as a substrate for the growth and nucleation of crystal hydrates.

Thus, it can be concluded that the activation of systems water – nanomodifier silicon dioxide (SiO2) both by magnetic field and by ultrasonic action are effective methods for obtaining activated mixing water containing nanosized particles.

Study of the effect of activated mixing water with silicon dioxide nanomodifier (SiO2) on the properties of cement paste.

Experimental studies were carried out to assess the influence of structural characteristics of nano-SiO2, methods for obtaining nanosized particles, a rational ratio in the “cement-nanoadditive” system, conditions for the uniform distribution of nanoparticles in the volume of cement paste and the stability of the obtained characteristics.

The studies were carried out on cube samples 20×20×20 mm in size, made from cement paste of normal density with different ratios of additives. The content of the nano-SiO2 additive varied from 0,01 to 0,05% by weight of the cement. For research, silicon dioxide nanomodifiers with different values of specific surface from

-

10 to 140 m2/g were used. To determine the rational way to introduce additives, three options were investigated:

-

• Method 1 – the additive was pre-mixed with mixing water;

-

• Method 2 – the additive was mixed with cement until homogeneous, after which it was closed with water;

-

• Method 3 – the additive was mixed with mixing water, the suspension was subjected to ultrasonication, after which it was added and mixed with cement.

After molding, the samples hardened under normal conditions (T = 18–20оC, W = 90–100%). The compressive strength of the samples was evaluated at 28 days of curing. At least 5 samples were prepared for each composition. The strength value was determined as the arithmetic mean value of 5 samples, the coefficient of variation was not more than 5%. The results of the conducted studies are presented in table 4.

Analysis of the data presented in Table 4 shows that all types of nano-SiO2 studied in the work provide an increase in the strength of the cement stone in 28 days of hardening from 2 to 38% compared to the control sample. The significance of the effect depends on the modifiable factors. An increase in the specific surface of nano-SiO2 from 10 to 38 m2/g affects the increase in strength by 32% compared to the control sample, but a further increase in the specific surface does not lead to a significant increase in the strength of the cement stone, which is associated with an increase in the water demand of the binder, due to with which further studies were carried out on nano-SiO2 (Ts38). The analysis of the obtained results, depending on the method of introducing the additive, shows the

АPPLICATION OF NANOTECHNOLOGIES AND NANOMATERIALS IN CONSTRUCTION

Table 4

Characteristics of Cement Stone with Nano-SiO2

|

Sample number |

Sample |

Additive content, % by weight of cement |

Water cement ratio |

R28, МРа |

||

|

With mixing water (1 way) |

Dry (2 way) |

Ultrasonic processing (3 way) |

||||

|

1. |

Control |

0.00 |

0.270 |

68.1 |

68.1 |

72.2 |

|

2. |

Cement+Тs-10 |

0.01 |

0.275 |

68.3 |

68.8 |

74.0 |

|

3. |

Cement+Тs-10 |

0.02 |

0.275 |

74.1 |

75.3 |

76.0 |

|

4. |

Cement+Тs-10 |

0.03 |

0.275 |

76.0 |

76.5 |

81.0 |

|

5. |

Cement+Тs-10 |

0.04 |

0.280 |

77.0 |

76.8 |

82.1 |

|

6. |

Cement+Тs-10 |

0.05 |

0.280 |

76.7 |

77.0 |

83.0 |

|

7. |

Cement +Ts38 |

0.01 |

0.270 |

67.0 |

74.0 |

79.0 |

|

8. |

Cement +Ts38 |

0.02 |

0.265 |

74.2 |

81.0 |

79.8 |

|

9. |

Cement +Ts38 |

0.03 |

0.267 |

83.0 |

90.0 |

95.0 |

|

10. |

Cement +Ts38 |

0.04 |

0.270 |

84.0 |

93.7 |

95.3 |

|

11. |

Cement +Ts38 |

0.05 |

0.275 |

85.1 |

94.0 |

96.1 |

|

12. |

Cement +Ts59 |

0.01 |

0.275 |

69.0 |

69.9 |

84.0 |

|

13. |

Cement +Ts59 |

0.02 |

0.280 |

73.0 |

71.0 |

85.0 |

|

14. |

Cement +Ts59 |

0.03 |

0.285 |

71.0 |

71.8 |

86.6 |

|

15. |

Cement +Ts59 |

0.04 |

0.290 |

67.0 |

71.9 |

87.0 |

|

16. |

Cement +Ts59 |

0.05 |

0.290 |

71.0 |

72.6 |

87.1 |

|

17. |

Cement +T84 |

0.01 |

0.275 |

76.0 |

77.0 |

77.0 |

|

18. |

Cement +T84 |

0.02 |

0.280 |

75.0 |

81.0 |

77.1 |

|

19. |

Cement +T84 |

0.03 |

0.280 |

64.9 |

83.0 |

81.0 |

|

20. |

Cement +T84 |

0.04 |

0.285 |

77.0 |

83.9 |

80.1 |

|

21. |

Cement +T84 |

0.05 |

0.290 |

78.0 |

84.0 |

81.9 |

|

22. |

Cement +T90 |

0.01 |

0.280 |

64.6 |

77.0 |

73.0 |

|

23. |

Cement +T90 |

0.02 |

0.285 |

72.3 |

77.2 |

77.0 |

|

24. |

Cement +T90 |

0.03 |

0.285 |

75.2 |

77.3 |

83.8 |

|

25. |

Cement +T90 |

0.04 |

0.285 |

75.0 |

79.0 |

84.1 |

|

26. |

Cement +T90 |

0.05 |

0.290 |

76.0 |

81.0 |

85.0 |

|

27. |

Cement +T110 |

0.01 |

0.265 |

66.0 |

68.0 |

82.0 |

|

28. |

Cement +T110 |

0.02 |

0.265 |

70.0 |

72.0 |

83.0 |

|

29. |

Cement +T110 |

0.03 |

0.265 |

68.0 |

73.0 |

86.0 |

|

30. |

Cement +T110 |

0.04 |

0.275 |

65.0 |

69.0 |

86.6 |

|

31. |

Cement +T110 |

0.05 |

0.275 |

64.9 |

67.0 |

86.8 |

|

32. |

Cement +T140 |

0.01 |

0.270 |

68.0 |

71.0 |

84.0 |

|

33. |

Cement +T140 |

0.02 |

0.270 |

69.0 |

73.0 |

85.4 |

|

34. |

Cement +T140 |

0.03 |

0.270 |

69.9 |

73.3 |

88.0 |

|

35. |

Cement +T140 |

0.04 |

0.280 |

71.1 |

74.5 |

89.0 |

|

36. |

Cement +T140 |

0.05 |

0.285 |

73.0 |

74.9 |

89.1 |

|

37. |

Cement +SiO 2pl |

0.01 |

0.270 |

64.0 |

69.0 |

71.0 |

|

38. |

Cement +SiO 2pl |

0.02 |

0.270 |

67.0 |

64.0 |

69.0 |

|

39. |

Cement +SiO 2pl |

0.03 |

0.270 |

82.0 |

87.0 |

90.0 |

|

40. |

Cement +SiO 2pl |

0.04 |

0.270 |

85.0 |

88.0 |

93.5 |

|

41. |

Cement +SiO 2pl |

0.05 |

0.280 |

86.0 |

89.0 |

94.1 |

АPPLICATION OF NANOTECHNOLOGIES AND NANOMATERIALS IN CONSTRUCTION greatest efficiency when mixing the additive with cement (increase in the strength of the modified cement stone is 38%), as well as with ultrasonic treatment of an aqueous suspension – up to 41% compared with control samples. With the first method of adding the additive, it was noted that nano-SiO2 particles agglomerate, which prevents their uniform distribution throughout the volume of the mixture and does not give a significant effect of increasing strength. It should also be noted that ultrasonic exposure to an aqueous suspension with nanosized silicon dioxide does not significantly increase the strength of the cement stone, but the technology for producing mixtures becomes more complicated.

The optimal content of nano-SiO2 additive in cement compositions is 0,03% by weight of cement [22, 24]. From the results presented in Table 4, it can be seen that the increase in the strength of cement stone in 28 days of hardening is 28% for composition 4 (additive content 0,03%), 29,2% for composition 5 (additive content 0,04%) and 30,7% for composition 6 (additive content 0,05%).

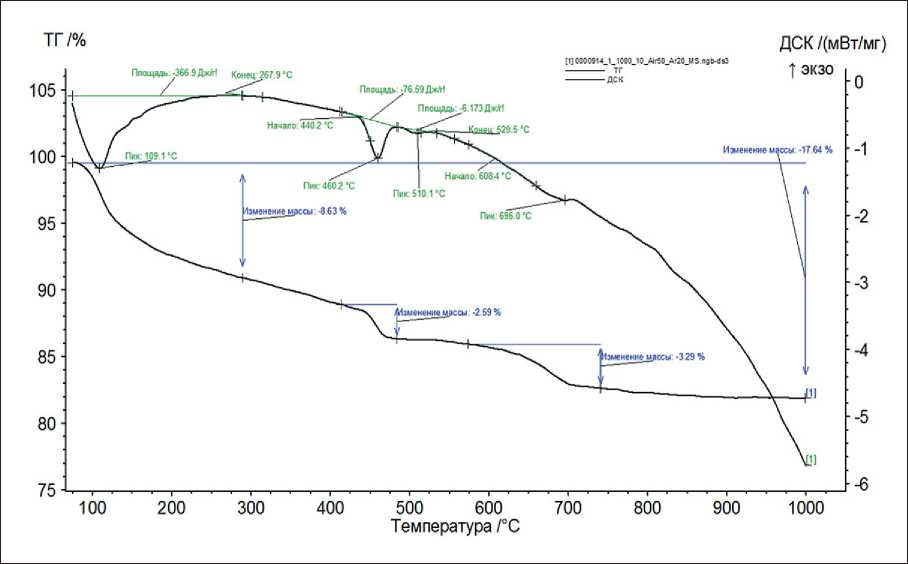

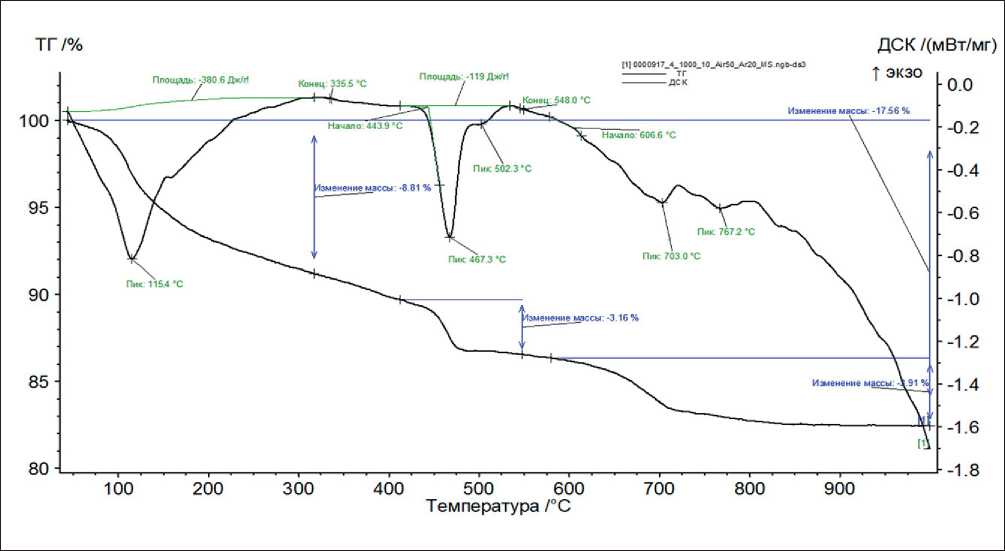

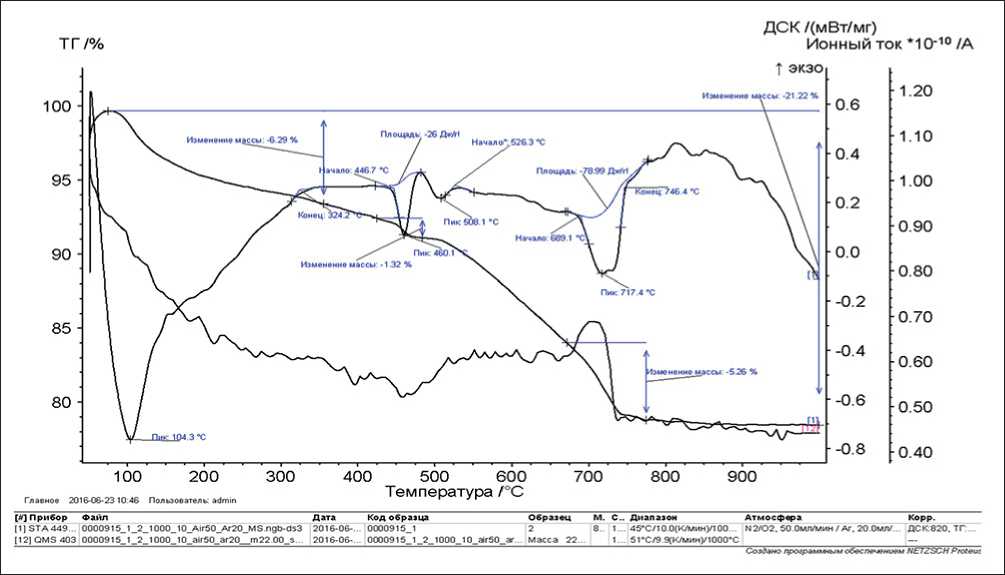

Features of phase transformations in the cement system and the change in the mass of chemically bound water, in the temperature range from 20 to 1000ºС, were determined by derivatographic analysis (DTA). Figures 5–6 show comparative derivatograms of the control and modified samples of cement stone with TG and DSC curves.

On the derivatogram (Figure 5) of the control sample of cement stone, by the 28th day of hardening, the first peak of the endoeffect is identified at 109°C with a weight loss of 8,63% due to the removal of free, and then, weakly bound water, the peak area is 366 J/g; the peak of the endo effect at a temperature of 100–120оC corresponds to the dehydration of C2SH2 C2S3H2; endoeffect (peak 460оC) with a weight loss of 2,59% refers to the dehydration of CaOH2, calcium hydrosilicates of the C2SH(B), C2SH2 type peak area 76,59 J/g; the endoeffect (peak 696оC) with a weight loss of 3,29% is associated with the dehydration of highly basic calcium hydrosilicates: tobermorite-like phases, C2SH(C), C2SH2 and CaCO3 decarbonization.

In the modified cement stone sample, the derivato-gram (Figure 6) shows a shift of endoeffects towards higher temperatures; the first peak of the endoeffect, at 115оC, can presumably be explained by the transition of weakly bound water into chemically bound water. An increase in the peak area to 380.6 J/g, compared with the control sample, indicates the formation of a larger amount of nanostructured hydrated compounds. Endoeffects in the range of 440–490оC with a mass loss of 3.16% are responsible for the removal of water associated with partial surface hydration of the original mineral, and endoeffects at a temperature of 700–800оC with a mass loss of 3.91% are associated with complete dehydration calcium hydrosilicate type CSH(I). An increase in the intensity and area of the peaks indicates an increase in the number of hydrate neoplasms.

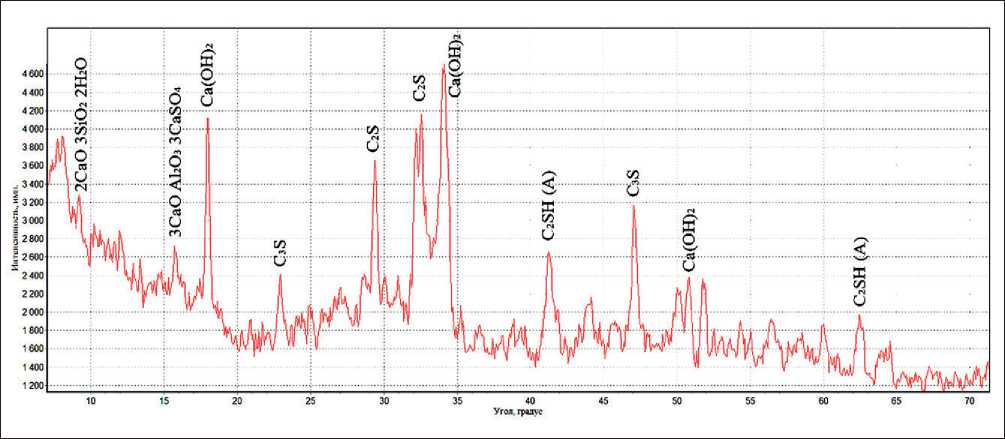

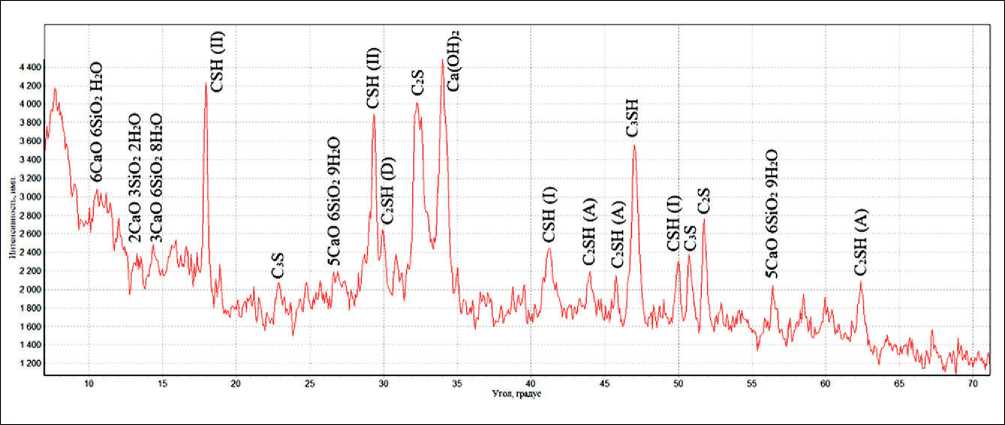

Comparative X-ray phase analysis of the hydration products of the control cement and cement with Ts38

Fig. 5. Derivatogram of the control sample of cement stone in 28 days of hardening

АPPLICATION OF NANOTECHNOLOGIES AND NANOMATERIALS IN CONSTRUCTION

Fig. 6. Derivatogram of a sample of cement stone with the addition of nano-SiO2 in 28 days of hardening

(Figure 7, 8) confirms the formation of new crystalline phases in the modified cement stone. According to the data of X-ray phase analysis, the introduction of nano-SiO2 additive activates the binding of calcium hydroxide, contributing to an increase in the content of low-basic calcium hydrosilicates С–S–Н (d/n = 4.94; 2.92; 2.18; 2.06; 1.98; 1.82•10–10m), which leads to an increase in the strength of the cement stone. A significant decrease in the proportion of free calcium hydroxide is confirmed on the diffraction patterns by an increased background in the region of small angles and a decrease in the intensity of the peaks of the Ca(OH)2 crystalline phases (d/n = 4.9; 2.63; 1.79; 1.48•10–10 m), which is associated with hydration reactions of cement clinker minerals.

To assess the effect of cyclic magnetic activation of mixing water and cement paste with the addition of a nanomodifier, cube samples of 20×20×20 mm in size

Fig. 7. Diffractogram of the control cement stone in 28 days of hardening

АPPLICATION OF NANOTECHNOLOGIES AND NANOMATERIALS IN CONSTRUCTION

Fig. 8. Diffraction pattern of cement stone on the 28th day of hardening: cement + nano-SiO2

were prepared. The number of cycles of magnetic treatment of mixing water was 5, 10, 15, 20, 25.

Data on the effect of cyclic magnetic treatment of water for mixing cement paste with the addition of a nanomodifier on the strength of cement stone are presented in Table 5.

Analysis of the data presented in Table 5 shows that with 10 cycles of water treatment for mixing cement paste, it leads to a change in the main physical and mechanical characteristics of the resulting composites. The strength of the nanomodified cement stone is increased by 38% (composition 3) compared to the control composition, without activation. At the same time, for each composition, the coefficient of variation was calculated, which for composition 3 is 4.75%, which proves the effectiveness of the developed method for activating mixing water on the uniform distribution of nanoparticles in the volume of cement paste. The water demand of cement stone is reduced from 0.27 to 0.255.

Features of phase transformations in the cement system and the change in the mass of chemically bound water, in the temperature range from 20 to 1000оС, were determined by derivatographic analysis (DTA). Figure 9 shows the derivatogram of a nanomodified cement stone sample with activated mixing water.

On the derivatogram (Figure 9) of the modified cement stone, by the 28th day of hardening, the first peak of the endoeffect at 104оC is identified and is associated with the removal of water adsorbed by finely dispersed neoplasms; endoeffect (peak 460оC) with a weight loss of 1.32% and peak (508.1оC) refers to the dehydration of CaOH2, calcium hydrosilicates of the C2SH(B) type, C2SH2 peak area 26 J/g; the endoeffect (peak 717оC) is associated with the dehydration of highly basic cal-

Table 5

Characteristics of nano-SiO2 cement stone with magnetic treatment

|

Sample number |

Sample |

Additive content, % by weight of cement |

Number of processing cycles |

Water cement ratio |

R28, МРа |

The coefficient of variation, % |

|

К |

C+W |

0 |

0 |

0.27 |

68.1 |

6.25 |

|

1 |

(C+nano-SiO2)+W |

0.03 |

0 |

0.27 |

87.0 |

6.9 |

|

2 |

(C+nano-SiO2)+W |

0.03 |

5 |

0.267 |

89.1 |

6.1 |

|

3 |

(C+nano-SiO2)+W |

0.03 |

10 |

0.255 |

94.2 |

4.75 |

|

4 |

(C+nano-SiO2)+W |

0.03 |

15 |

0.26 |

91.4 |

5.1 |

|

5 |

(C+nano-SiO2)+W |

0.03 |

20 |

0.265 |

93.6 |

5.36 |

|

6 |

(C+nano-SiO2)+W |

0.03 |

25 |

0.26 |

93.7 |

4.99 |

АPPLICATION OF NANOTECHNOLOGIES AND NANOMATERIALS IN CONSTRUCTION

Fig. 9. Derivatogram of a sample of cement stone with the addition of nano-SiO2 with activated mixing water

cium hydrosilicates: tobermorite-like phases, C2SH(C), C2SH2.

CONCLUSION

The obtained results of experimental studies on the role of magnetic treatment of mixing water together with the use of nano-SiO2 in composite materials based on Portland cement prove the effective possibility of con-

trolling the structural state and phase composition of the hardening cement stone with a significant increase in its strength. The magnetic activation of mixing water together with the additive improves the quality of the cement stone, ensuring the stability of the obtained characteristics. The established patterns of changes in the physical and mechanical parameters of the studied compositions indicate the effectiveness of the use of water activated by a magnetic field in the production of building materials.

Список литературы Influence of activation methods on the structural and technological characteristics of nanomodified cement compositions

- Pustovgar A.P., Vedenin A.D. Teploizolyacionnye nanokompozity na osnove aerogelya kremnezema. Nauchnotekhnicheskij vestnik Povolzh’ya. 2013; 1: 252-254. (In Russ)

- Skoczylas K., Rucinska T. The effects of low curing temperature on the properties of cement mortars containing nanosilica. Nanotechnologies in Construction: A Scientific Internet-Journal. 2019; 11 (5): 536-544.

- Kim L.V., Potapov V.V., Kashutin A.N., Gorbach V.A., Shalaev K.S., Gorev D.S. Increasing of concrete strength ising nanosilica extracted from the hydrothermal solutions. Proceedings of the Twenty-third (2013). International Offshore and Polar Engineering Conference. Anchorage, Alaska, USA, June 30-July 5, ISOPE. 2013: 148-152.

- Zhang A., Yang W., Ge Y., Wang Y., Liu P. Effect of nanomaterials on the mechanical properties and microstructure of cement mortar under low air pressure curing. Construction and Building Materials. 2020; 249: 118787. https://doi.org/10.1016/j.conbuildmat.2020.118787.

- Sorvacheva YU.A. Vliyanie nano-kremnezema na kinetiku protekaniya shchelochnoj korrozii betona. Izvestiya Peterburgskogo universiteta putej soobshcheniya. 2014; 2 (39): 118-123. (In Russ)

- Feng H., Zhao X., Chen G., Miao C., Zhao X., Gao D., Sun G. The effect of nano-particles and water glass on the water stability of magnesium phosphate cement-based mortar. Materials. 2019; 12(22): 3755. https://doi.org/10.3390/ma12223755.

- Shabanova T.A., Prihod’ko N.G., Auelhankyzy M. and Mansurov Z.A. Fullerity i “struktury rosta” nanoob”ektov. Inzhenerno-fizicheskij zhurnal. 2016; 89(4): 1034-1040.

- Kwan A.K.H., Li L.G. Combined effect of water film thickness and paste film thickness on rheology of mortar. Materials and Structures. 2012; 45 (1): 1359-1374.

- Zelenkov V.N., Potapov V.V. Gidrotermal’nyj nanokremnezem v sel’skohozyajstvennom rastenievodstve I biotekhnologii. Nanoindustriya. 2020; 13. (1 (94)): 22-33. (In Russ)

- Bekuzarova S.A., Datieva I.A., Dzampaeva M.V. Gidrotermal’nyj nanokremnezem kak stimulyator rosta I razvitiya rastenij odnoletnih vidov klevera i amaranta. Nauchnaya zhizn’. 2021; 16 (2 (114)): 162-171. (In Russ)

- Gorev D.S., Potapov V.V., Goreva T.S. Nanokremnezem na osnove gidrotermal’nyh rastvorov: harakteristiki, rezul’taty povysheniya prochnosti melkozernistogo betona. Sovremennye naukoemkie tekhnologii. 2018; 8: 54-58. (In Russ)

- Maagi M.T, Lupyana S.D., Gu J. Effect of Nano-SiO2, Nano-TiO2 and Nano-Al2O3 Addition on Fluid Loss in Oil-Well Cement Slurry. International Journal of Concrete Structures and Materials. 2019; 13(1); 62. https://doi.org/10.1186/s40069-019-0371-y.

- Potapov V., Kashutin A., Serdan A., SHalaev K., Gorev D. Nanokremnezem: povyshenie prochnosti betonov. Nanoindustriya. 2013; 3 (41): 40-49. (In Russ)

- Potapov V.V., Tumanov A.V., Gorbach V.A., Kashutin A.N., SHalaev K.S. Poluchenie kompleksnoj dobavki na osnove nanodispersnogo dioksida kremniya dlya povysheniya prochnosti betona. Himicheskaya tekhnologiya. 2013; 14 (7): 394-401. (In Russ)

- Zhang A., Yang W., Ge Y., Wang Y., Liu P. Effect of nanomaterials on the mechanical properties and microstructure of cement mortar under low air pressure curing. Construction and Building Materials. 249 (2020) 118787. https://doi.org/10.1016/j.conbuildmat.2020.118787.

- Stark J. Recent advances in the field of cement hydration andmicrostructure analysis. Cement and Concrete Research. 2011; 41: 666-678.

- Thomas J. J. A new approach to modeling the nucleation and growth kinetics of tricalcium silicate hydration. Journal of American Ceramic Societies. 2007; 90(10): 3282-3288.

- Juilland P., Galussi E., Flatt R., Scrivener K. Dissolution theory applied to the induction period in alite hydration. Cementand Concrete Research. 2010; 40: 831-844.

- Sobolev K., Flores I., Hermosillo R. Nanomaterials and Nanotechnology for Highperformance cement composites. Proceedings of ACI Session on, 132 Nanotechnology of Concrete: Recent Developments and Future Perspectives. Denver. 2006; 91-118. (In Russ)

- Erofeev V.T., Mitina E.A. [i dr.] Kompozicionnye stroitel’nye materialy na aktivirovannoj vode zatvoreniya. Stroitel’nye materialy. 2007; 11: 56-57. (In Russ)

- V. N. Safronov, G. G. Petrov, S. A. Kugaevskaya [i dr.] Svojstva tverdeyushchih kompozicij na omagnichennoj vode. Vestnik TGASU. 2005; 1: 134-142. (In Russ)

- Kosmachev P.V., Vlasov V.A., Skripnikova N.K. Issledovanie struktury i svojstv nanoporoshka SiO2 poluchennogo plazmennym metodom iz prirodnyh syr’evyh materialov. Izv. vuzov. Fizika. 2017; 60 (2): 46-50. (In Russ)

- Il’ves V.G., Zuev M.G., Sokovin S.YU., Murzakaev A.M. Svojstva amorfnogo nanoporoshka dioksida kremniya, poluchennogo impul’snym elektronnym ispareniem. Fizika tverdogo tela. 2015; 57(12): 2439-2445 (In Russ)

- Kosmachev P.V., Dem’yanenko O. V., Vlasov V.A, Kopanica N.O., Skripnikova N.K. Kompozicionnye materialy na osnove cementa s nanodispersnym dioksidom kremniya. Vestnik TGASU. 2017; 4: 139-146. (In Russ)

- Kopanitsa N.O., Demyanenko O.V., Kulikova A.A. (2022) Effective Polyfunctional Additive for Composite Materials Based on Cement. In: Klyuev S.V. (eds) Digital Technologies in Construction Engineering. Lecture Notes in Civil Engineering, vol 173. Springer, Cham. https://doi.org/10.1007/978-3-030-81289-8_17.

- Kulikova A.A. Kompleksnye modificiruyushchie dobavki dlya stroitel’nyh smesej na cementnoj osnove. A.A. Kulikova, O.V. Dem’yanenko, E.A. Sorokina, N.O. Kopanica. Vestnik Tomskogo gosudarstvennogo arhitekturnostroitel’nogo universiteta. 2019; 21 (6): 140-148. https://doi.org/10.31675/1607-1859-2019-21-6-140-148 (In Russ)

- Dem’yanenko O.V. Ocenka vliyaniya kompleksnoj polifunkcional’noj dobavki na ekspluatacionnye harakteristiki cementnogo kamnya i betona. O. V. Dem’yanenko, A.A. Kulikova, N.O. Kopanica. Vestnik Tomskogo gosudarstvennogo arhitekturno-stroitel’nogo universiteta. 2020; 22 (5): 139-152. https://doi.org/10.31675/1607-1859-2020-22-5-139-152 (In Russ)

- Dem’yanenko O.V. Vliyanie kompleksnyh modificiruyushchih dobavok na ekspluatacionnye svojstva tyazhelogo betona. O. V. Dem’yanenko, A.A. Kulikova, N.O. Kopanica, A.G. Petrov. Izvestiya vuzov. Stroitel’stvo. Novosibirsk. 2021; 5: 23-32. https://doi.org/10.32683/0536-1052-2021-749-5-23-32 (In Russ)