Influence of high-dispersive powder mixture of WC and TiC on the composite materials properties

Автор: Tatyana V. Chayka, Vladimir M. Gavrish, Vyacheslav I. Pavlenko, Natalia I. Cherkashina

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Application of nanomaterials and nanotechnologies in construction

Статья в выпуске: 1 Vol.15, 2023 года.

Бесплатный доступ

Introduction. The purpose of the research is to study the effect of a high-dispersive powder mixture of WC, TiC, obtained from recycling of hard-alloy manufactured articles from TK group (titanium-tungsten alloys), on the change in the structural and physical and mechanical properties of cement materials. Materials and research methods. WC, TiC Powder (particle size 20–150 nm, agglomerates 300 nm – 1.5 μm) was added to the cement mortar by partial replacement of cement in various concentrations of 0%, 1%, 2%, 3%, 4%, 5% by mass. The basic physical and mechanical properties of the cement paste and obtained cement materials were studied in accordance with standard methods, taking into account regulatory documents of Russian and foreign standards. Thermokinetic, X-ray phase analysis, scanning electron microscope investigation with an integrated system of energy-dispersive analysis were also applied. Results and discussion. It has been proved that highly dispersed WC, TiC powder additive to cement materials leads to increase in density, paste fluidity, reduction in setting time, decrease in water absorption, porosity, and increase in strength characteristics both in early and later periods of hardening. A highly dispersed additive promotes earlier hydration. The structure of the cement sample with powder additive is denser throughout the considered periods of hardening compared to the control sample. Conclusion. The obtained results are of great importance for understanding the action mechanism on cement materials of highly-dispersed particles of WC, TiC, which can later be used to improve the properties of composite cement-based materials in various fields of application.

Composites, additive, high-dispersive powder, modification, tungsten carbide, titanium carbide, strength

Короткий адрес: https://sciup.org/142235802

IDR: 142235802 | DOI: 10.15828/2075-8545-2023-15-1-14-26

Текст научной статьи Influence of high-dispersive powder mixture of WC and TiC on the composite materials properties

Original article

The Production cost of composite materials for construction purposes is primary determined by the cost of binders, which have a significant potential in improving the physical and mechanical characteristics [1–6]. It is known from the scientific literature [7–13] that the most in-demand technological method for improvement the quality of cement concretes is the introduction of modifying additives. For this purpose, nano-sized additives are of particular interest, the use of which improves the pore structure and physical and mechanical properties, and also gives cement materials additional or improved properties such as: plasticity, weight reduction, self-compaction, self-cleaning, improved air quality, selfrestorability, as well as longer durability.

Commonly available and well-studied nanoadditives that quite close in composition and type of chemical bonds, and physical and chemical characteristics to the initial binders and hydration product are such as: SiO2 nanoparticles in various forms (pyrogenous nanopowders; nanopowders precipitated from Na2SiO3 solution; SiO2 colloidal sol; nano-SiO2 in combination with other components, etc.) [14–16], aluminum oxide nanopowder Al2O3 [17–20], CaCO3 nanopowder [21], titanium oxide TiO2 [22–24], etc. Carbon nanoparticles (fuller-

АPPLICATION OF NANOTECHNOLOGIES AND NANOMATERIALS IN CONSTRUCTION enes, nanotubes, astralenes, etc.) have found application as nanosized inert additives, chemically inactive to cement systems in cement composites [25–28]. Many scholars [29–36] consider the addition of a combination of nanoparticles is more effective in improving the mechanical properties of concrete than customized usage of additives.

The study [37] examines the role of SiO2, CaCO3 and Ca(OH)2 nanoparticles, which are replaced in cement in various binary and ternary combinations by changing the dosage of 2% and 5% by mass. The results of the experiments showed that the mechanical properties of concrete mixtures were improved by 10–45% due to the additive of nanomaterials in optimal dosage; which in a triple combination is 2% and 5% for increasing corrosion resistance. However, higher durability results (from 5% to 60%) were achieved in the binary combination with 2% replacement.

According to the authors of [38], the combination 0.5% nanosized alumina Al2O3 and 1% nanosized titanium dioxide TiO2 by mass of cement, leads to a compact and dense microstructure with fewer pores, which results in a high optimization of mechanical properties. Compared to the control sample, compressive strength, tensile strength and bending strength have increased by 42%, 34% and 28% respectively. The nanoparticles provide nucleation sections for extra C–S–H gel formation and control the growth of Ca(OH)2 in the cement system.

Currently, there has been much research devoted to the study of nanoparticles mix effect on physical and mechanical properties of cement materials in combination both with industrial [39–46] and agricultural waste [47–49].

The combination of 10% waste textile sludge with 3% nanostructured alumina provides improved strength and durability characteristics of cement concrete. The additive of aluminum oxide nanoparticles has a dual effect, improves hydration properties, as well performs as a filler [41].

In the study [44] authors have developed new types of concrete mixtures with improved adhesion zone and strength characteristics containing 30% rubber crumb (from rubber tire waste) as a substitute, where ordinary Portland cement was replaced by 20% crushed blast-furnace slag and various contents of nanoparticles from glass bottles waste (3, 6, 9 and 12%). Microstructure analysis of the concrete mixtures has showed the formation of dense gels and fewer pores with acceptable technical properties.

The authors [47] have found that the combination of Al2O3 nanoparticles with a content of 3% and 10% rice husk ash, when creating modified cement concretes with increased strength and durability characteristic, turned out to be effective and productive for an environmentally friendly concrete material. When using sugar cane waste ash as a replacement for cement and nanosilica in the range of 1 to 6% by weight of cement, an increase in compressive strength by 80% and flexural strength by 90% was achieved compared to the control sample [49].

Due to the complex manufacturing process, the high production cost of nanomaterials, and the lack of large-scale production technology, the use of nanopowders as additives in cement materials significantly increases the cost of construction, therefore, they are not widely used in practical civil engineering. The exception is technologies where nanodispersed materials are formed as a byproduct or from processing waste in various enterprises, which do not require high production costs, taking into account current trends of resource and energy saving. One such technology is the production of nanopowders from tungsten-containing scrap of solid alloys such as Tungsten-Cobalt alloys (WC+Co), Titanium-TantalumTungsten-Cobalt alloys, Titanium-Tungsten alloys, Tungsten–Nickel–Iron (W+Ni+Fe), etc. [50]. However, as there is a lack of research on the possibility and feasibility of using nanosized tungsten-containing powders as additives in cement composites, it is relevant to determine the effectiveness and feasibility of their use. It requires a comprehensive study, which will expand the range of modifying additives for cement materials.

Current study presents the research results of the introduction of a highly-dispersed powder, consisting of tungsten and titanium carbides mixture, obtained from production scrap of solid alloys, on the change in the structural and physical and mechanical properties of cement materials. The choice of the additives is due to the variability of properties, as shown by previous studies [51– 52], associated with the specificity of obtaining process, as well as the cost and uniqueness of the powder structure.

MATERIALS AND RESEARCH METHODS

The following materials were used as starting materials in the study of cement composites: Portland cement CEM-II / A-P42.5N (JSC Verkhnebekansky Cement Plant, Russian Federation; see Table 1 for chemical composition; specific surface area 340 m2/kg, specific density 2.26 g/cm3, standard consistency 25%); marine gray building sand, fineness modulus 1.5–2 mm (LLC SK PRIBOY, Russian Federation); high-dispersive powder consisting of a mixture of tungsten and titanium carbides (WC, TiC) (LLC Nanotech VG, Russian Federation).

As a modifying additive, we used a powder of a mixture of tungsten and titanium carbides, that was obtained

Table 1

Chemical composition of Portland cement (mass %)

|

SiO2 |

Al2O3 |

Fe2O3 |

CaO |

MgO |

SO3 |

LOI |

|

24.93 |

4.47 |

4.11 |

58.99 |

0.86 |

2.92 |

2.70 |

АPPLICATION OF NANOTECHNOLOGIES AND NANOMATERIALS IN CONSTRUCTION

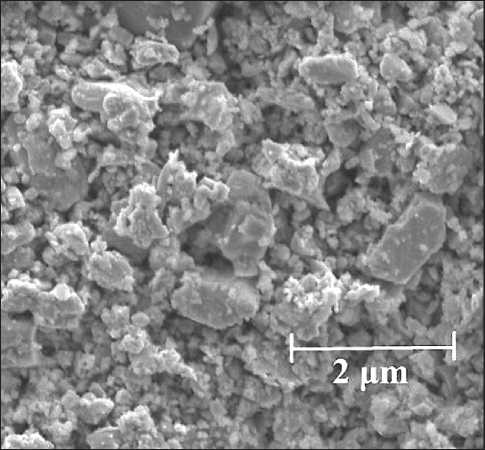

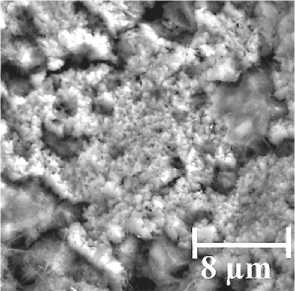

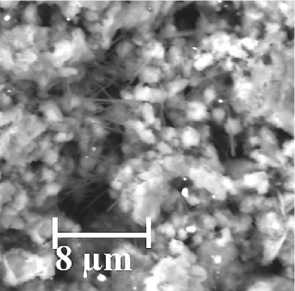

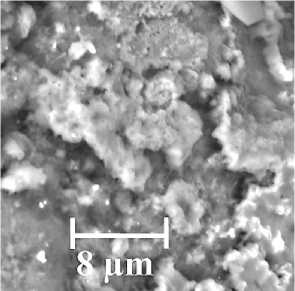

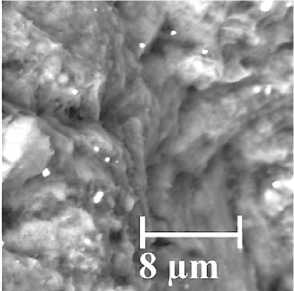

Fig. 1. Micrograph powder mixture of tungsten carbide and titanium carbide as recycling result of solid alloy wastes from production of the Tungsten–Cobalt (WC+Co) type products (tungsten carbide WC, titanium carbide TiC, binder component cobalt Co) [50]. The surface area of the powder is 2.1 m2/g. Specific density is 11.7 g/cm3. The powder consists mainly of two phases – titanium carbide TiC with a cubic crystal structure and tungsten carbide WC with a hexagonal crystal structure. Composition of elements is WC – 93÷95% mass, TiC 7÷5% mass. Powder purity level is 99.5%. The powder is a mixture of particles of various shapes and their agglomerates. The morphology of the particles is inhomogeneous, mostly irregular in shape. Particle size less than 150 nm, agglomerate size from 300 nm to 1.5 µm.

The cement mixture was prepared according to the proportion indicated in Table 2.

To obtain cement stone, we made samples from the cement paste in the form of a cube 20×20×20 mm in size. The first full day the samples have been hardening in the molds in water, and after removal from the mold until the testing (on the 28th day of hardening) in a bath with a hydraulic seal at an ambient temperature of 20±2оC and a relative air humidity of at least 90%.

When making sand-cement mixtures, the following fixed factors were taken: cement-sand ratio C/S = 1:3, water-cement ratio W/C = 0.4. For each experiment, six samples were prepared and poured into beam molds (4×4×16 cm). All specimens were compactly vibrated on a shaking table for better compaction and removed from molds after 24 hours of curing at 100% relative humidity and stored in a bath with a hydraulic seal at an ambient temperature of 20 ± 2оC and a relative air humidity of at least 90% until testing on compression and bending (the 3rd, 7th, 14th and 28th days of hardening).

The cement paste spreadability (studies were carried out using a mini-cone. The cement paste was prepared according to the Table 2. The total ratio of water and binder (where «binder» was defined as Portland cement + additive) was W/C = 0.45. A mini-cone (upper diameter 19 mm, lower diameter 38 mm and height 57 mm) was placed on a glass platform, filled with cement paste; and excess paste was removed from the cone and platform. The we lifted the cone smoothly the vertically to minimize inertial effects. Spreadability was determined by measuring the flow diameter in mutually perpendicular directions and the average was calculated. Each sample paste was tested three times using three separately mixed batches of paste.

It is quite difficult to achieve an even distribution of highly dispersed particles in the mixture, particularly in powder form, therefore, an important operation of the technological process is the method of introducing an additive into cement [53]. There are three methods of the additive input to the cement mixture that have been studied: 1 – blending the powder with mixing water is carried out with an overhead mixer for 5 minutes, then the resulting suspension is introduced into the raw mixture; 2 – cement dry mixing with the powder additive have been carried out in a C 2.0 «TURBULA» mixer (St. Petersburg, VIBROTEKHNIK LLC) for 5 minutes, then mixing water is introduced; 3 – the powder under study is subjected to two-stage ultrasonic dispersion in the water environment for 30 seconds at a frequency of 22 kHz to break large agglomerates, and 30 seconds at a frequency of 44 kHz for more efficient deagglomeration of particles using an ultrasonic disperser UZD-22/44 (Ukraine). The criterion for assessing the method effec-

Table 2

The cement mixture proportions

|

The content of components in the cement mixture, g |

||||||

|

Marking |

М0 |

М1 |

М2 |

М3 |

М4 |

М5 |

|

Cement, g |

400 |

396 |

392 |

388 |

384 |

380 |

|

WC, TiC Powder additive, g |

– |

4 |

8 |

12 |

16 |

20 |

|

Content of WC, TiC in the mixture, % |

0 |

1 |

2 |

3 |

4 |

5 |

АPPLICATION OF NANOTECHNOLOGIES AND NANOMATERIALS IN CONSTRUCTION tiveness when introducing an additive into cement is the compressive strength of the cement stone on the 28th day of hardening, 6 samples for each type of study.

The study of water absorption was carried out on cubic shape samples 20x20x20 mm in size. All the samples were dried at 80°C for 24 hours to minimize damage to the microstructure from overdrying, then placed in water containers at a constant temperature (20±2оC). The samples were weighed every 24 hours of water saturation with an accuracy of 0.01 g. The samples had been in the water until the weighing results differed by no more than 0.01 g from the previous weighing. According to the degree of water absorption by mass and volume and the values of the solid density and mass specific gravity of the cement stone, the total porosity was calculated.

To study the strength properties, the prepared cementsand samples have been kept for 3, 7, 14, 28 days, and then tested for compressive and bending strength. For each sample, at least six samples were tested for each type and age of the sample, the results were averaged. The study of physical and mechanical characteristics was carried out using a universal testing machine TRM-500 «Tochline» (LLC «Plant of Testing Instruments» (PTI), Ivanovo, Russia, the maximum limit load is 50 kN).

For determining the particular qualities of hydration and the effect of WC, TiC additives on cement properties in terms of heat release dynamics, a ToniCAL Trio (Computer controlled isothermal heat flow calorimeter) was used at a temperature of 20оC (Toni Technik Baus-toffprüfsysteme GmbH, Germany). The measurement duration was 72 hours, the water/binder ratio was 0.5. Sample weight was10 g.

The materials crystal structure was studied with X-ray diffraction (ARL X’TRA, Thermo Techno) with a CuKα source in the angle range 2θ from 4о to 56о in the asymmetric coplanar survey mode with a grazing incidence angle α = 3о (θ-scan). Phase identification and peak indexing were carried out using the ICDD (International Center for Diffraction Data) JCPDF database.

The cleavage microstructure of the studied cement samples on the 3rd, 7th and 28th days of hardening was studied using a PHENOM pro X scanning electron microscope from Phenom–World B.V. (Netherlands) with an integrated energy-dispersive analysis system. Maximum magnification is 150000, resolution – 10 nm, accelerating voltage – 5, 10, 15 kV.

RESULTS AND DISCUSSION

Spreadability of cement paste

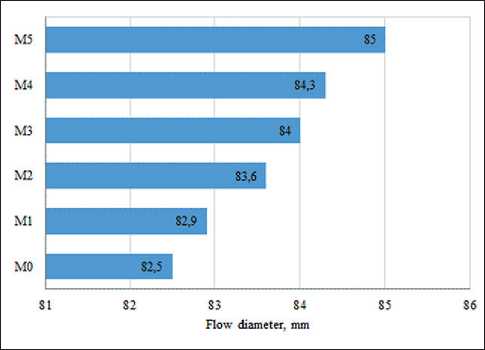

Study results in changing the flow diameter for cement mixtures in the control composition (M0) and with the additives of 1–5 wt. % powder WC, TiC (M1-M5) are presented in Figure 2.

Fig. 2. Cement paste spreadability study results

The results show that with the increasing the additive percentage WC, TiC (1–5 wt.%) in the cement mortar, the flow diameter also increases, compared to the control mixture by 0.4–3%, respectively. Tungsten carbide and titanium carbide powder does not come into chemical interaction with cement components. As studies [32, 54] have shown, the introduction of highly dispersed inert particles (particle agglomerates) that act as a filler increases the lubricity of the cement paste. By occupying the empty space between the larger particles, they release free water, thereby increasing the amount of water available in the system to improve fluidity. That is, the additive acts as a lubricant, increasing the fluidity of the solution.

Setting time and density

Setting time was determined using a Vicat apparatus. The study results for the effect of high-dispersive powder mixture WC and TiC on the setting time of Portland cement are presented in Figure 3.

Fig. 3. Cement paste setting time results

АPPLICATION OF NANOTECHNOLOGIES AND NANOMATERIALS IN CONSTRUCTION

As we can see in Figure 3 with an increase in the content of WC, TiC powder in the additive composition, cement samples density increases. This can be explained by the high specific density of the studied additive compared to the specific density of Portland cement. With a minor amount of additives WC, TiC (up to 1%), a slight increase in density (by 0.3%) is observed, in case of an additive content (4–5%), the density increases by more than 3%.

The setting time for cement samples modified with powder at a modifier concentration of 1–5 mass % is reduced: the initial setting decreases by 7.5%, the final setting – by 12.5%, which may be from both a decrease in the cement proportion due to additives WC, TiC, and with an increase in the degree of Portland cement hydration; as well as the presence of a large number WC, TiC particles in the liquid phase, which act as seeds for the new formation, which in turn also contributes to the acceleration for crystallization process and the setting acceleration.

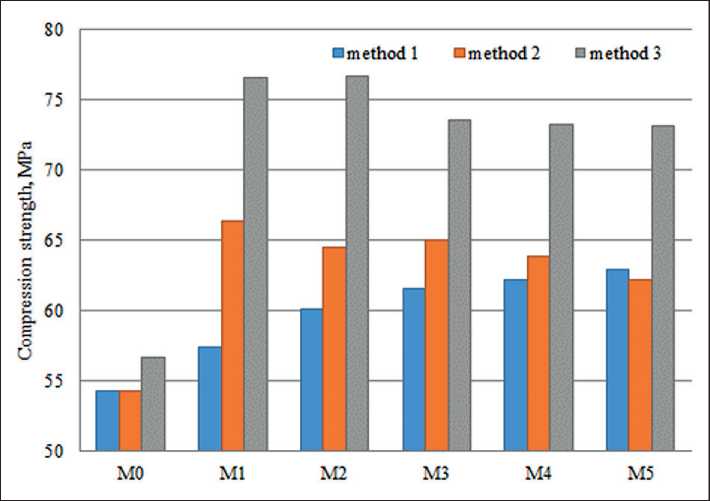

Influence of the introducing additive methodinto the cement mixture

Influence of sequence methods when introducing additive into the cement mixture on the properties of the cement stone is presented in Figure 4.

As we can see from the study results (Fig. 4), to method 1 the influence of the introducing method for the powder into the cement mixture on the change in the strength properties of the samples is not significant, the maximum increase in compressive strength is 13% (at a content of 3 wt.% WC, TiC), which associated with the agglomeration of powder particles in water.

With dry mechanical mixing, the increase in the cement strength stone reaches 22% (with the addition of 1 wt.% WC, TiC), with the preliminary ultrasonic treatment of the suspension, the increase in the sample strength is 41% (with the addition of 2 wt.% WC, TiC) compared to the reference sample. This fact is explained by deagglomeration and dispersion of highly dispersed particles in a liquid as a result of ultrasonic exposure, and as a result, an even particles distribution in the volume of the cement material.

With an increase in the content of high-dispersive powder more than 2 mass % the strength of the cement stone is reduced. This may be due to the fact that, firstly, tungsten and titanium carbide do not have cementing properties, therefore, excessive replacement of cement must have led to a decrease in compressive strength, and secondly, as a result of significant agglomeration of powder particles at a dosage of more than 2 mass %. The results obtained are consistent with the data of other researchers [26, 55]. They noted that an excessively high dosage can lead to “poisoning” of the system, a significant slowdown in the processes of hydration and hardening.

Analyzing the results on assessment the influence of the methods introducing additives into the cement paste, as well as the amount of additive content on the properties of the binder, we can to determine the rational ratio of highly-dispersed additives in the cement matrix, equal to 1–2 mass % (an increase in strength is 23–41%).

Water absorption, total porosity

Table 3 shows water absorption and total porosity values of cement stone. The addition of 1–2 mass % highly-dispersed particles reduce the water absorption index by

Fig. 4. Study Results. Influence of the introducing additive method into the cement mixture on the cement stone strength: method 1 – blending the additive with water; method 2 – dry mixing of the additive and cement; method 3 – ultrasonic dispersion of the additive in water environment

АPPLICATION OF NANOTECHNOLOGIES AND NANOMATERIALS IN CONSTRUCTION

Table 3

Water absorption and porosity of cement stone

|

Marking |

M0 |

M1 |

M2 |

|

Water absorption of cement stone by mass, % |

5.09 |

4.31 |

4.13 |

|

Volume of open capillary pores, % |

10.50 |

9.32 |

9.04 |

|

Total pore volume of samples, % |

15.23 |

12.55 |

12.05 |

|

Volume of air nominally-closed pores, % |

4.72 |

3.23 |

3.00 |

15–19%, the total porosity by 31–36%. The decrease in porosity is consistent with the results presented above (Fig. 4), with an improvement in compressive strength due to the formation of a denser structure with the inclusion of a highly dispersed additive WC, TiC.

Cement-sand samples strength kinetics development in compression and bending

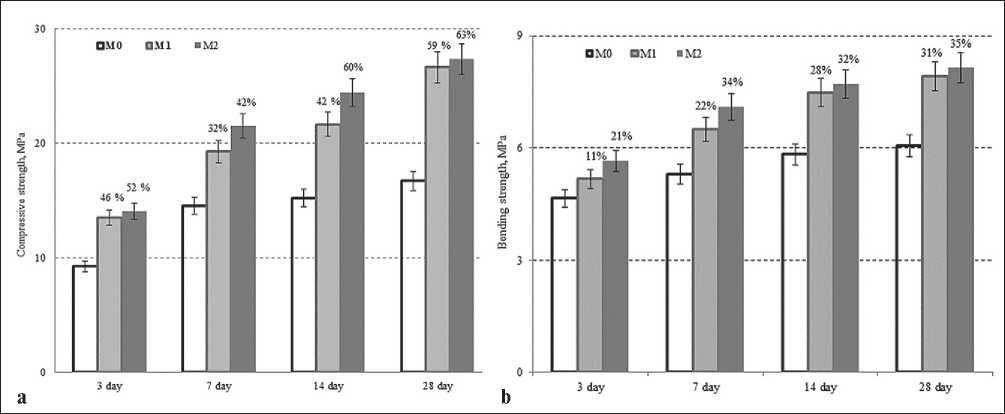

The major indicators for performance properties of cement materials are change of their kinetic characteristics over time. Figure 5 shows graphs characterizing the kinetics of compressive and bending strength of cement-sand samples with 1 wt.%, 2 wt.% highly-dispersed additives WC, TiC.

The results show that the introduction into the cementsand the powder mixture of WC, TiC leads not only to an increase in the final compressive strength (on the 28th day of hardening), but also to an increase in the early rate of strength development of the samples starting from the age samples of 3 days. From the graphs it can be seen that there is an intensive increase in strength in the initial period of hardening for the reference sample, then a gradual decrease occurs in the rate of strength development. Portland cement modified with the additive mixture of WC, TiC has another type of strength growth. Strength development has been increasing for almost 28 days.

In particular, the compressive strength of the cement paste on the 28th day of hardening with the addition of 1–2 mass % WC, TiC, was improved by 59–63%, the bending strength was increased by 30–35%, respectively. As can be seen from the results, the most optimal concentration of the additive is 1 mass %; further studies have been carried out with the optimal concentration additive.

To explain the above obtained results and to detection the regularity of the composition formation, structure and properties of cement stone, thermokinetic studies, X-ray phase and electron microscopic analysis of control and modified samples of cement stone have been carried out.

Thermokinetic studies of the processes of the early stage of hydration of binders

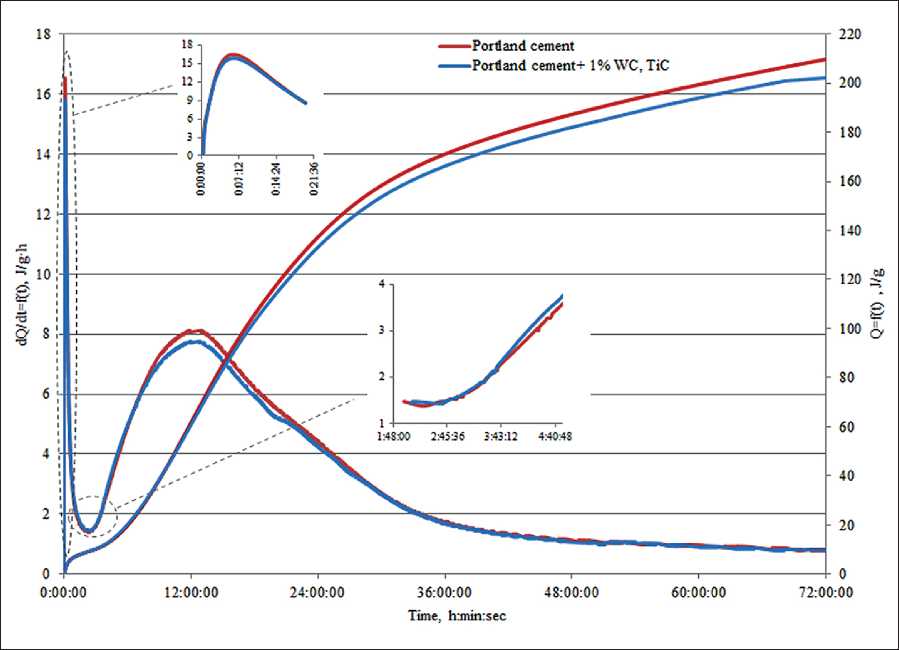

In order to confirm the above obtained results, ther-mokinetic studies have been carried out (Table 4, Fig. 6), aimed at identifying the features of hydration of the binder with the addition of 1 mass % additives WC, TiC powder, determined by the dynamics of heat release indicators, expressed by the dependence dQ / dt = f(t) during the initial period of hardening, and the total amount of heat released, described by the function Q = f(t) for 72 hours, with a differential calorimeter.

Fig. 5. Kinetics of strength development in compressing (a) and bending (b) for cement-sand mortar of the composition M0 and M1, M2

АPPLICATION OF NANOTECHNOLOGIES AND NANOMATERIALS IN CONSTRUCTION

Table 4

Characteristics of thermokinetic indicators

|

№ Sample |

Sample |

Start of reaction, sec |

Exo-effect |

Heat release, max. for 72 h, J/g |

||

|

The time of reaching h:min:sec |

Maximum value J/g • h |

Heat release, J/g |

||||

|

1 |

Portland cement |

15 |

0:05:31 |

16.53 |

1.08 |

209.9 |

|

13:03:10 |

8.11 |

70.11 |

||||

|

2 |

Portland cement + |

15 |

0:06:01 |

15.82 |

1.15 |

202.2 |

|

1% WC, TiC |

12:51:31 |

7.76 |

67.38 |

|||

Fig. 6. Differential and integral curves of heat release during hydration of the studied samples

The first peak, which falls on a period of 4–7 minutes (Fig. 4), is associated with the process of exothermic wetting, as well as the reactions of the early stage of hydration. After 5 min 30 sec gauging, the studied systems show an intensive increase in heat release (Table 4). Its origination is associated with the dissolution of minerals that form the surface of the clinker particles. Further, the rate of cement interaction with water decreases as the solution is saturated with primary hydration products, the system enters the induction period (no significant effect of WC, TiC powder was observed for that period), after which a repeated increase in the level of heat release of the system under study is observed – the period of active hydration. As the results of our study show, the use of WC, TiC additives accelerates the start of this period (Table 4). This may be due to the accelerated heterogeneous nucleation of hydrates on particles of highly-dispersed powders. However, despite the acceleration of the appearance of the main peak of hydration, there is a decrease in the intensity of heat release for compositions with additives, in relation to the control one, which is due to a decrease in the content of Portland cement in the mixture and a change in the amount of the liquid phase relative to cement.

АPPLICATION OF NANOTECHNOLOGIES AND NANOMATERIALS IN CONSTRUCTION

X-ray phase analysis of cement stone

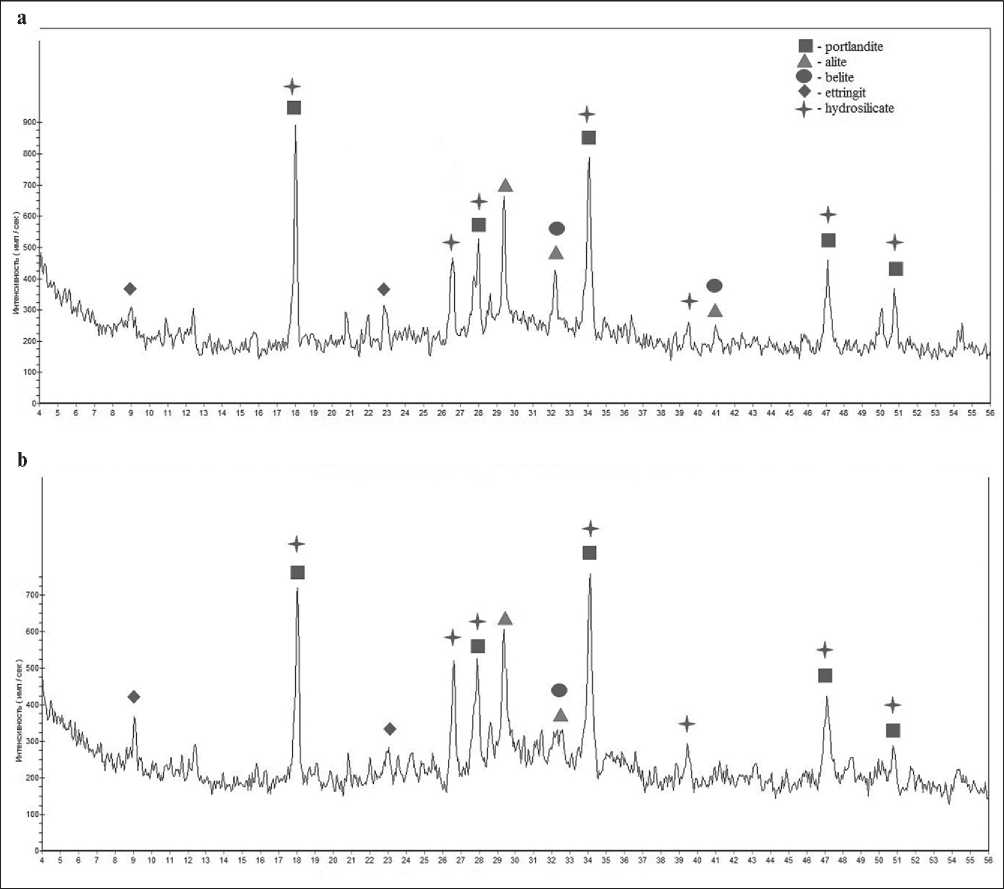

Comparative X-ray phase analysis of the control cement hydration products and cement with 1% WC, TiC additives is presented in Figure 7.

According to X-ray phase analysis, when 1 mass % WC, TiC additive is introduced into the cement mixture, the diffraction pattern shows a tendency to a decrease in the intensity of the peaks of Portlandite Ca(OH)2 and peaks of clinker minerals (C3S and C2S), as well as an increase in the intensity of the peaks belonging to calcium hydrosilicates , in comparison with the control composition, leading to an increase in the physical and mechanical characteristics of the strength of the cement stone, which is additionally confirmed by the results of the microstruc- tural and thermokinetic analysis, as well as mechanical tests of the developed compositions.

Microstructure of samples

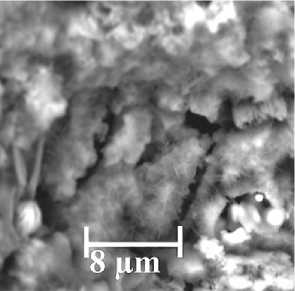

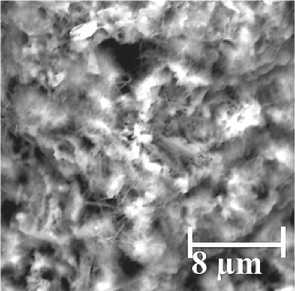

In order to study the microstructure and to explain the origin for the increase in the strength characteristics of the cement material with the addition of a highly-dispersed powder, an electron microscopic study of the cleavage surface microstructure of cement samples was carried out with magnification of x 10,000 times on the 3rd, 14th, 28th day of hardening (Fig. 8).

As can be seen from the presented micrographs (Fig. 8, a), there is a heterogeneity of the structure, a large volume of open pores and voids in the control sample,

Fig. 7. X-ray of the control composition cement stone (a) and modified with 1 mass. % WC, TiC powder (b) at the age of 28 days

АPPLICATION OF NANOTECHNOLOGIES AND NANOMATERIALS IN CONSTRUCTION

a

3 days

b

14 days

28 days

Fig. 8. Microstructure of cement samples from the control composition (a) and modified with a mixture of WC, TiC powders (b) at the age of 3, 14, 28 days despite the cement paste achievement of hydration on the 28th day of hardening. The structure of the cement sample with the powder additive (Fig. 8, b) is denser in all the considered periods of hardening compared to the control sample.

CONCLUSION

The article is focused on the study of the effect from the content of highly-dispersed WC, TiC powder on the properties of cement pastes and cement stone: changing the setting time, spreadability, compressive strength and bending. We also analyzed the effect of WC, TiC additive on thermokinetic parameters, hydration products and the microstructure of cement hardening pastes. From the above research process, the following conclusions can be drawn:

– With an increase in the percentage of additives of 1–5 mass % WC, TiC in the cement mortar, the spreading diameter increases by 0.4–3% compared to the control mixture, the density of cement samples increases by 0.3–3%, respectively. The initial and final setting time of the modified samples decreased with an increase in the content of the additive by 7.5%, the end of setting – by 12.5%.

The article considers the issues related to the ways of introducing a highly-dispersed powder into the cement mixture and hence the strength change in properties of the samples. With dry mechanical mixing, the increase in the strength of the cement stone reaches 22%, when using ultrasonic treatment of an aqueous suspension, more than 41% compared to the control sample.

– The addition of 1–2 mass % highly-dispersed particles reduce the water absorption index by 15–19%, the total porosity by 31–36%, respectively. The decrease in porosity is consistent with the improvement in compressive strength due to the formation of a denser structure with the WC, TiC additive.

– A categorical tendency to increase the strength characteristics was revealed when the powder of the WC, TiC mixture was introduced into the cement-sand mixture, both in the early and later periods of hardening (on the 28th day of hardening). In particular, the compressive strength of the cement paste on the 28th day of hardening with the addition of 1–2 mass % WC, TiC, was improved by 59–63%, the bending strength was increased by 30–35%, respectively.

– The addition of a highly dispersed additive contributed to earlier hydration. Those could be due to the accelerated heterogeneous nucleation of hydrates on powder particles. There was a decrease in the intensity of heat release of compositions with additives, in relation to the control one, which was due to a decrease in the content

АPPLICATION OF NANOTECHNOLOGIES AND NANOMATERIALS IN CONSTRUCTION of Portland cement in the mixture and a change in the amount of the liquid phase relative to cement.

– X-ray phase analysis of the hydration products of the control cement and cement with 1% additive WC, TiC showed a decrease in the intensity of the peaks of portlandite and clinker minerals, as well as an increase in the intensity of the peaks belonging to calcium hydrosilicates, compared with the control composition, leading to an increase in the physical and mechanical characteristics of cement stone strength.

– According to data from scanning electron microscope (SEM), the studied powder effectively reduced voids and defects in cement-based materials, making the structure denser, while the composition of hydrated phases in cement pastes was not violated by the addition of highly-dispersed additives, which in turn not only interferes with the normal passage of the system through each stage of hydration, but also accelerates hydration.

A mixture of highly-dispersed WC and TiC powders, obtained from hard-alloy waste, can be used as a modifying additive for cement materials in the production of both structural and special-purpose concretes (hydraulic, radiation-resistant, etc.).

Список литературы Influence of high-dispersive powder mixture of WC and TiC on the composite materials properties

- Pârvan M.G., Voicu G., Bădănoiu A.I. Study of hydration and hardening processes of self-sensing cement-based materials with carbon black content. J Therm Anal Calorim. 2020; 139: 807–815. https://doi.org/10.1007/s10973-019-08535-8

- Alnahhal W., Taha R., Al-Nasseri H. et al. Effect of Using Cement Kiln Dust as a Nano-Material on the Strength of Cement Mortars. KSCE J Civ Eng. 2018; 22: 1361–1368. https://doi.org/10.1007/s12205-017-0010-6

- Sopin M.D., Lesovik R.V., Mitrokhin A.A. Coarse-poured concrete on composite binders for low-rise construction. Bulletin of the Belgorod State Technological University named after V.G. Shukhov. 2016; 10:45-50. https://doi.org/10.12737/22024

- Askari Dolatabad Y., Kamgar R., Gouhari Nezad I. Rheological and Mechanical Properties, Acid Resistance and Water Penetrability of Lightweight Self-Compacting Concrete Containing Nano-SiO2, Nano-TiO2 and Nano-Al2O3. Iran J Sci Technol Trans Civ Eng. 2020; 44: 603–618. https://doi.org/10.1007/s40996-019-00328-1

- Yifan Wang, Hongbo Tan, Xianyue Gu, Xingyang He, Junjie Zhang. Preparation of nano-kaolin by wet-grinding process and its application as accelerator in Portland cement. Journal of Building Engineering. 2021; 44: 103401. https://doi.org/10.1016/j.jobe.2021.103401

- Ariyagounder J., Veerasamy S. Experimental Investigation on the Strength, Durability and Corrosion Properties of Concrete by Partial Replacement of Cement with Nano-SiO2, Nano-CaCO3 and Nano-Ca(OH)2. Iran J Sci Technol Trans Civ Eng. 2022; 46: 201-222. https://doi.org/10.1007/s40996-021-00584-0

- Monteiro H., Moura B., Soares N. Advancements in nano-enabled cement and concrete: Innovative properties and environmental implications. Journal of Building Engineering. 2022; 56: 104736. https://doi.org/10.1016/j.jobe.2022.104736

- Snehal K., Das B.B., Sudhi A. et al. Pozzolanic Reactivity, Hydration and Microstructure Characteristics of Blended Cementitious Composites Comprising of Ultrafine Particles. Iran J Sci Technol Trans Civ Eng. 2022. https://doi.org/10.1007/s40996-022-00859-0

- Faez A., Sayari A., Manie S. Mechanical and Rheological Properties of Self-Compacting Concrete Containing Al2O3 Nanoparticles and Silica Fume. Iran J Sci Technol Trans Civ Eng. 2020; 44: 217–227. https://doi.org/10.1007/s40996-019-00339-y

- Mahmood R.A., Kockal N.U. Nanoparticles used as an ingredient in different types of concrete. SN Appl. Sci. 2021; 3(5): 1-17. https://doi.org/10.1007/s42452-021-04461-3

- Shirzadi Javid A.A., Ghoddousi P., Zareechian M. et al. Effects of Spraying Various Nanoparticles at Early Ages on Improving Surface Characteristics of Concrete Pavements. Int J Civ Eng. 2019; 17: 1455–1468. https://doi.org/10.1007/s40999-019-00407-4

- Bharath Melugiri-Shankaramurthy, Sargam Y. et al. Evaluation of cement paste containing recycled stainless steel powder for sustainable additive manufacturing Construction and Building Materials. 2019; 227: 116696. https://doi.org/10.1016/j.conbuildmat.2019.116696

- Bharath Melugiri-Shankaramurthy, Sargam Y. et al. Evaluation of cement paste containing recycled stainless steel powder for sustainable additive manufacturing. Construction and Building Materials. 2019; 227: 116696. https://doi.org/10.1016/j.conbuildmat.2019.116696

- Potapov V., Efimenko Yu., Fediuk R., Gorev D. Effect of hydrothermal nanosilica on the performances of cement concrete. Construction and Building Materials. 2021; 269 (10): 121307. https://doi.org/10.1016/j.conbuildmat.2020.121307

- Chernishov E.M., Artamonova O.V., Slavcheva G.S. Nanomodification of cement-based composites in the technological life cycle. Nanotechnologies in construction. 2020; 2(3): 130–139. https://doi.org/10.15828/2075-8545-2020-12-3-130-139

- Nayak C.B., Taware P.P., Jagadale U.T. et al. Effect of SiO2 and ZnO Nano-Composites on Mechanical and Chemical Properties of Modified Concrete. Iran J Sci Technol Trans Civ Eng. 2022; 46: 1237–1247. https://doi.org/10.1007/s40996-021-00694-9

- 17 Gayathiri K., Praveenkumar S. Influence of Nano Silica on Fresh and Hardened Properties of Cement-based Materials – A Review. Silicon. 2022; 14: 8327-8357. https://doi.org/10.1007/s12633-021-01598-z

- Szymanowski J, Sadowski L. The Development of Nanoalumina-Based Cement Mortars for Overlay Applications in Concrete Floors. Materials. 2019; 12 (21): 3465. https://doi.org/10.3390/ma12213465

- Yaoyu Wang, Jiye Li, Lihan Jiang, Lihua Zhao Enhanced. Mechanical and Microstructural Properties of Portland Cement Composites Modified with Submicron Metakaolin. Advances in Civil Engineering. 2020; 2020: 1-13. https://doi.org/10.1155/2020/8882385

- 20 Mohan K., Pankaj M., Trivedi M.K. Strength of Cement Mortar Using Nano Oxides: An Experimental Study. International Journal of Engineering and Advanced Technology. 2019; 8 (3): 294-299.

- Liu Changjiang, He Xin, Deng Xiaowei, Zheng Zhoulian et al. Application of nanomaterials in ultra-high performance concrete: A review. Nanotechnology Reviews. 2020; 9(1): 1427-1444. https://doi.org/10.1515/ntrev-2020-0107

- Pietrzak A., Adamus J., Langier B. Application of Titanium Dioxide in Cement and Concrete Technology. Key Engineering Materials. 2016; 687: 243-249. https://doi.org/10.4028/www.scientific.net/КЕМ.687.243

- Szymanowski J., Sadowski L. The influence of the addition of tetragonal crystalline titanium oxide nanoparticles on the adhesive and functional properties of layered cementitious composites. Composite Structures. 2019; 233: 111636. https://doi.org/10.1016/j.compstruct.2019.111636

- Krushel’nickaya E. Evaluation of the photocatalytic activity of concrete. Bulletin of Belgorod State Technological University named after. V. G. Shukhov. 2021; 6: 13-20. https://doi.org/10.34031/2071-7318-2021-6-4-13-20

- Dong Lu, Xianming Shi, Jing Zhong. Understanding the role of unzipped carbon nanotubes in cement pastes, Cement and Concrete Composites. 2022; 126: 104366. https://doi.org/10.1016/j.cemconcomp.2021.104366

- Muhammad Azeem, Muhammad Azhar Saleem. Role of electrostatic potential energy in carbon nanotube augmented cement paste matrix. Construction and Building Materials. 2020; 239: 117875. https://doi.org/10.1016/j.conbuildmat.2019.117875

- Chernishov E, Artamonova O.V., Slavcheva G. Nano-Modification of Building Composite Structures. Strength of Materials. 2020. https://doi.org/10.5772/intechopen.86388

- Kumar Ajay, Namboodiri Vishnu, Joshi Gaurang, Mehta Kush. Fabrication and applications of fullerenebased metal nanocomposites: A review. Journal of Materials Research. 2021; 36: 114–128. https://doi.org/10.1557/s43578-020-00094-1

- Jan A., Pu Z., Khan K.A. et al. A Review on the Effect of Silica to Alumina Ratio, Alkaline Solution to Binder Ratio, Calcium Oxide + Ferric Oxide, Molar Concentration of Sodium Hydroxide and Sodium Silicate to Sodium Hydroxide Ratio on the Compressive Strength of Geopolymer Concrete. Silicon. 2022; 14: 3147–3162. https://doi.org/10.1007/s12633-021-01130-3

- Stefanidou Maria, Tsardaka Eirini-Chrysanthi, Karozou Aspasia. Nanoparticles controlling self-healing properties in cement pastes. Materials Today: Proceedings. 2021. https://doi.org/10.1016/j.matpr.2021.07.028

- Nikbin Iman, Shad Mojtaba, Jafarzadeh Gholam, Dezhampanah Soudabeh. An experimental investigation on combined effects of nano-WO3 and nano-Bi2O3 on the radiation shielding properties of magnetite concretes. ProgressinNuclearEnergy, 2019, 117, 103103. https://doi.org/10.1016/j.pnucene.2019.103103

- Kong D., He G., Pan H., Weng Y.., Du N., Sheng J. Influences and Mechanisms of Nano-C-S-H Gel Addition on Fresh Properties of the Cement-Based Materials with Sucrose as Retarder. Materials. 2020; 13(10): 2345. https://doi.org/10.3390/ma13102345

- Long Z., Chen Y., Yin W., Wu X., Wang Y. The Effects of Graphene Oxide-Silica Nano-Hybrid Materials on the Rheological Properties, Mechanical Properties, and Microstructure of Cement-Based Materials. Materials. 2022; 15: 4207. https://doi.org/10.3390/ma15124207

- Tkach E., Semenov V., Shumilina Yu. Optimization of the composition and technological processes of dispersed cement systems with high performance properties. IOP Conference Series: Materials Science and Engineering. 2021; 1030: 012024. https://doi.org/10.1088/1757-899X/1030/1/012024

- Li H., Zuo J., Dong B. et al. Effect of Lamellar Inorganic Fillers on the Properties of Epoxy Emulsion Cement Mortar. Int J Concr Struct Mater. 2020; 14. https://doi.org/10.1186/s40069-020-0395-3

- Danna Wang, Wei Zhang, Yanfeng Ruan, Xun Yu, Baoguo Han,Enhancements and mechanisms of nanoparticles on wear resistance and chloride penetration resistance of reactive powder concrete. Construction and Building Materials. 2018; 189: 487-497. https://doi.org/10.1016/j.conbuildmat.2018.09.041

- Ariyagounder J., Veerasamy S. Experimental Investigation on the Strength, Durability and Corrosion Properties of Concrete by Partial Replacement of Cement with Nano-SiO3, Nano-CaCO2. Iran J Sci Technol Trans Civ Eng. 2022; 46: 201-222. https://doi.org/10.1007/s40996-021-00584-0

- Orakzai Muhammad. Hybrid Effect of Nano-Alumina and Nano-Titanium Dioxide on Mechanical Properties of Concrete. Case Studies in Construction Materials. 2021; 14(4): e00483. https://doi.org/10.1016/j.cscm.2020.e00483

- Singh G., Saini B. Nanomaterial in cement industry: a brief review. Innov. Infrastruct. Solut. 2022; 7: 45. https://doi.org/10.1007/s41062-021-00649-z

- Lim N.H.A.S., Mohammadhosseini H., Tahir M.M. et al. Microstructure and Strength Properties of Mortar Containing Waste Ceramic Nanoparticles. Arab J Sci Eng. 2018; 43: 5305-5313. https://doi.org/10.1007/s13369-018-3154-x

- Praveenkumar T.R., Manigandan S., Gemede H.F. et al. Effective utilization of waste textile sludge composite with Al2O3 nanoparticles as a value-added application. Appl Nanosci. 2021. https://doi.org/10.1007/s13204-021-02001-4.

- Winder Raj, Chaturvedi Vaibhav, Kumar Ankit, Patel Mahesh. Utilization of Industrial Waste in Concrete Mixes – A Review. 3rd International Conference on Innovative Technologies for Clean and Sustainable Development. 2020; 29. https://doi.org/10.1007/978-3-030-51485-3_7

- Huseien Ghasan, Faridmehr Iman, Nehdi Moncef et al. Structure, morphology and compressive strength of Alkali-activated mortars containing waste bottle glass nanoparticles. Construction and Building Materials. 2022; 342: 128005. https://doi.org/10.1016/j.conbuildmat.2022.128005

- Akram M. Mhaya, Shahrizan Baharom, Ghasan Fahim Huseien. Improved strength performance of rubberized Concrete: Role of ground blast furnace slag and waste glass bottle nanoparticles amalgamation. Construction and Building Materials. 2022; 342: 128073. https://doi.org/10.1016/j.conbuildmat.2022.128073

- Naglaa G. Fahmy, Reham M. Hussien, L.M. Abd el-Hafez et al. Comparative study on fresh, mechanical, microstructures properties and corrosion resistance of self compacted concrete incorporating nanoparticles extracted from industrial wastes under various curing conditions. Journal of Building Engineering. 2022; 57: 104874. https://doi.org/10.1016/j.jobe.2022.104874

- Tyukavkina V.V., Shchelokova E.A., Tsyryatyeva A.V., Kasikov A.G. TiO2–SiO2 nanocomposites from technological wastes for self-cleaning cement composition. Journal of Building Engineering. 2021; 44: 102648. https://doi.org/10.1016/j.jobe.2021.102648

- Meddah M.S., Praveenkumar T.R., Vijayalakshmi M.M., Manigandan S., Arunachalam R. Mechanical and microstructural characterization of rice husk ash and Al2O3 nanoparticles modified cement concrete. Construction and Building Materials. 2020; 255: 119358. https://doi.org/10.1016/j.conbuildmat.2020.119358

- Praveenkumar T.R., Vijayalakshmi M.M., Meddah M.S. Strengths and durability performances of blended cement concrete with TiO2 nanoparticles and rice husk ash. Construction and Building Materials. 2019; 217: 343-351. https://doi.org/10.1016/j.conbuildmat.2019.05.045

- Rao M.S.C., Vijayalakshmi M.M., Praveenkumar T.R. Behaviour of green concrete (blended concrete) using agro-industrial waste as partial replacement of cement along with nanoparticles. Appl Nanosci. 2021. https://doi.org/10.1007/s13204-021-01917-1

- Galuga A., Baranov G., Gavrish V., Smirnov S., Losenkov A., Vostrognutov S. Patent ЕР 3 138 932 А1, 08.30.2017.

- Chayka T., Gavrish V., Baranov G., Oleynik A., Shagova Y. Investigation of the influence of tungsten carbide nanopowder WC and the mixture of tungsten carbides and titanium carbides (WC, TiC) on the change of concrete performance properties. Journal of Physics: Conference Series. 2021; 1866 (1): 012008. https://doi.org/10.1088/1742-6596/1866/1/012008

- Gavrish V., Chayka T., Oleynik A., Derbasova N. Influence of Tungsten Nanopowders on the Kinetics of Cement Stone Strength Gain. Key Engineering Materials. 2022; 910 KEM: 697-702. https://doi.org/10.4028/p-1682bh

- Kopanitsa N.O., Demyanenko О.V., Kulikova А.А., Samchenko S.V., Kozlova I.V., Lukyanova N.A. Influence of Activation Methods on the Structural and Technological Characteristics of Nanomodified Cement Compositions. Nanotechnologies in Construction. 2022; 14(6): 481–492. https://doi.org/10.15828/2075-8545-2022-14-6-481-492

- Choi M., Park K., Oh T. Viscoelastic Properties of Fresh Cement Paste to Study the Flow Behavior. Int J Concr Struct Mater. 2016; 10 (3): 65–74. https://doi.org/10.1007/s40069-016-0158-3

- Chernishov E.M., Artamonova O.V., Slavcheva G.S. Nanomodification of cement-based composites in the technological life cycle. Nanotechnologies in construction. 2020; 12 (3): 130–139. https://doi.org/10.15828/2075-8545-2020-12-3-130-139