Influence of nanoadditives on the physical and mechanical performance of cement concrete

Автор: Loginova S.A., Tanichev M.V., Goglev I.N.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Application of nanomaterials and nanotechnologies in construction

Статья в выпуске: 6 Vol.17, 2025 года.

Бесплатный доступ

Introduction. The influence of nanoadditives on the physical and me-chanical performance of cement concrete remains a relevant issue driven by the need for finding the most promising and cost-effective solutions to enhance performance during in situ concreting. This issue has been thoroughly examined by the authors in earlier publications. Methods and Materials. Two experimental formulations of a composite concrete nanoadditives were developed, based on ammonium hexafluorosilicate ((NH4)2SiF6) and silicon carbide (SiC). Results. In the first part of the study, concrete samples were tested after 28 days of hardening to assess mechanical strength properties. The kinetics of hardening and the influence of each of the specified additives on the concrete were studied. Discussion. The conducted studies allowed for the establishment of the optimal combination of nanoparticles included in the special additive, as well as a detailed investigation of the mechanism of strength gain in cement stone. It was found that the use of the best additive formulation (combination No. 2) significantly improved the strength characteristics of the concrete mix, providing an average strength increase of 38%, as confirmed through both destructive and non-destructive testing. Conclusion. The optimal dosage of nanocomponents for the production of the recommended additive per cubic meter of concrete is approximately 0.0141 of the mass of the main raw material, which confirms the economic feasibility of its application. In addition, low concentration of nanoparticles in the additive ensures environmental compatibility of the finished product, minimizing the impact on the environment. The optimal dosage of nanocomponents ensures the uniform distribution of particles in the concrete structure, contributing to an increase in its durability and resistance to environmental influences.

Cement concrete, curing accelerators, complex nanoadditives, silicon carbide, ammonium hexafluorosilicate, compressive strength enhance-ment

Короткий адрес: https://sciup.org/142246530

IDR: 142246530 | DOI: 10.15828/2075-8545-2025-17-6-750-759

Текст научной статьи Influence of nanoadditives on the physical and mechanical performance of cement concrete

Original article

Логинова С.А., Таничев М.В., Гоглев И.Н. Исследование воздействия нанодобавок на физические и механические свойства цементных бетонов. Нанотехнологии в строительстве. 2025;17(6):750–759. – EDN: QSIZUY.

Cement concretes made with a cement binder are widely used in the construction of cast-in-place concrete structures due to their performance characteristics [1, 2]. Castin-place reinforced concrete is in demand in the construction of various facilities across diverse climatic zones, ranging from the temperate cli-mate of Central Europe to the harsh conditions of cold regions in Norway, Finland, Alaska, and the northern territories of Russia [3, 4].

A characteristic feature of cast-in-place concrete structures in regions with low ambient temperatures is the necessity to maintain favorable conditions for concrete hardening, as the rate of achieving design strength characteristics influences the schedule of subsequent construction operations. One of the most critical requirements is the timely attainment of a minimum strength of 70%, which ensures the feasibility of promptly proceeding to subsequent construction phases.

To date, there is a large number of various concrete additives, and their number continues to increase every year [2–5]. Most of the commercially available additives have both positive and negative effects on concrete. Special chemical additives are used to accelerate cement hydration processes and enhance the stability of the structure in adverse conditions [5–7]. Among them are curing accelerators that reduce the setting period and increase strength at the early stages of concrete hardening. Antifreeze additives prevent the destruction of the crystal-line structures of cement stone at low ambient temperatures, maintaining the strength gain processes at sub-zero temperatures [8–10]. Anti-corrosion additives help protect steel reinforcement from the effects of aggressive environ- ments and moisture [11–13]. Anti-corrosion additives play a key role in ensuring the durability of reinforced concrete structures by protecting steel reinforcement from negative environmental influences, including exposure to moisture and aggressive substances. Such additives create a protective barrier on the metal surface, preventing corrosion processes that occur due to the penetration of water, oxy-gen, and chemically active compounds inside the structure. This is especially important in conditions of high humidity, marine or industrial environment, or when operating structures in harsh climatic conditions. The effectiveness of anti-corrosion additives is manifested in the increased lifespan of construction structures, reduced costs for repair and maintenance of buildings and facilities, as well as enhanced reliability of the entire structures [14, 15]. The use of modern technologies for reinforcement protection significantly improves construction quality and reduces the risks of load-bearing structure destruction due to internal reinforcement corrosion.

Modern construction practices are gradually shifting towards a comprehensive approach to the selection of additives that involves combining several beneficial properties at once [16]. Such combined additives integrate the effects of hardening acceleration, frost resistance, and anti-corrosion protection, increasing the efficiency of the construction process and reducing material costs. How-ever, only a small portion of these additives have minor negative effects on the hardening concrete or reinforcement (for example, they cause the formation and crystallization of side reaction byproducts in the pores of the concrete [17, 18]. Increased crystallization in the pores of concrete (Fig. 1) may indicate that the grinding of the initial reagents in the additive is not fine enough,

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Fig. 1. Crystallization of side reaction byproducts in the pores of concrete. Cracks inside the sample and therefore, it is recommended to use substances and/ or their mixtures for which grinding can be performed at the micro or nano level.

Nanodispersed components increase the contact area between phases, im-prove compositional homogeneity and enhance intermolecular interactions, thus favorably influencing the mechanical properties of concrete and its resistance to external factors [19]. Consequently, it becomes evident that the development of a promising complex additive based on micro- or nano-ground powders is cur-rently a relevant study objective, as it enables a comprehensive understanding of the impact of additive particle size on the nature of hardening and the degree of strength development in concrete.

Furthermore, the incorporation of nanoadditives affects the emergence of a distinctive microcrystalline structure in concrete, contributing to the production of composition materials with enhanced performance properties. Fine particles are uniformly distributed throughout the cement paste volume, ensuring increased structural stability and reducing internal stresses that develop during the hardening process. These factors collectively result in an increase in mechanical strength, resistance to cracking, and an improvement in the durability of the final product. The use of nanotechnology provides new opportunities for improving the characteristics of conventional construction materials, enabling the creation of high-performance compositions with distinctive physical and chemical properties.

The process of strength development and frost resistance enhancement in cement stone is attributable to the reactions of individual components within complex additives with one of the key constituents of hardening concrete: free calcium hydroxide (Ca(OH)2) that was identified by S.V. Fedosov, academician of the Russian Academy of Architecture and Construction Sciences, as the primary factor [20] influencing material strength.

Free calcium hydroxide forms as a product of cement hydration and exists within the concrete structure as calcite crystals. Complex additives contain components capable of chemically interacting with Ca(OH)2, forming new compounds with increased strength and resistance to environmental influences [21, 22].

In addition to chemical bonding, some additives promote accelerated diffusion of free calcium hydroxide from the pore space, ensuring uniform distribution of hydration products and reducing concentration gradients, which also positively affects the structure and properties of hardened concrete [23]. Beyond accelerating the hydration process and stabilizing the concrete structure, specific chemical compounds are capable of forming supplementary protective layers around steel reinforcement, thereby extending the service life of reinforced concrete in aggressive environments [24–26]. Examples of such additives include complexes based on organic acids and phosphate compounds, which form a protective film on the metal surface, restricting the ingress of moisture and oxygen. Another significant aspect is the capability of certain additives to regulate the evaporation rate of free water from concrete, maintaining optimal moisture levels throughout the hardening period [27]. This prevents the occurrence of cracks and deformations caused by rapid drying and creates conditions for the formation of a high-strength and stable matrix. Optimal humidity, in turn, contributes to effective cement hydration and achieving maximum density of the concrete structure.

Frost resistance of complex additives can be ensured by the ability of a component to form crystalline hydrates with water, thereby lowering its crystallization temperature during the mixing and hardening of concrete. For example, this is the mechanism of action of a common antifreeze additive based on calcium formate (Ca(HCOO)2) [28].

Thus, the comprehensive impact of reagents allows for a significant acceleration of the hardening process and improves the quality of the final product, making it possible to use concrete under increased loads and extreme climatic conditions.

The study presented in the article was aimed at achieving specific goals and solving the set tasks based on the available literature data [29–31].

The aim of this study was to evaluate a composite modifier incorporating silicon carbide and ammonium hexafluorosilicate reagents ground to nanoscale dimensions, whose preliminary testing demonstrated a substantial increase in cement stone strength (up to 20%) It was necessary to assess the impact of the additive on strength indicators and identify potential advantages and disadvantages of its use.

The main task was to scientifically substantiate the effectiveness of the developed compositions by analyzing the characteristics of modified concrete, calculating the optimal amount of additive per cubic meter of the

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION mixture, as well as comparing the advantages and disadvantages of its introduction into the concrete mixture.

METHODS AND MATERIALS

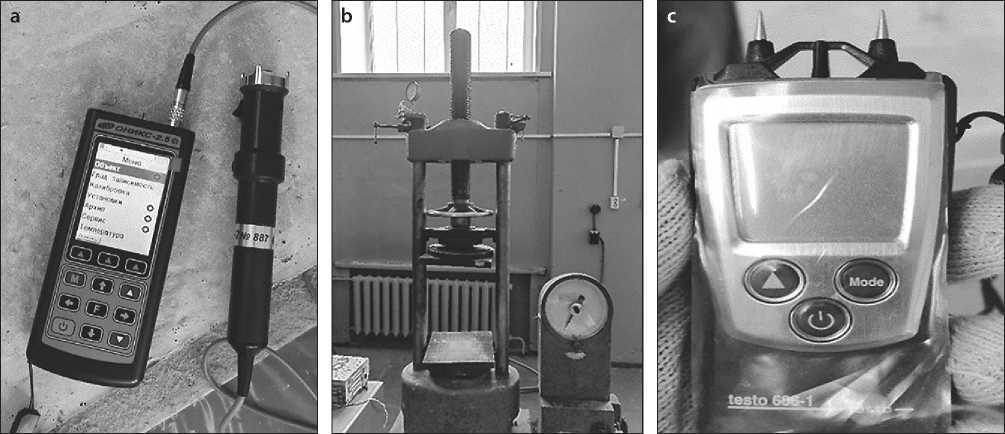

During the experiments, including the preparation of control samples, weighing of materials, and preparation of experimental mixtures, the following devices were used: – ONIKS-2.5 impact-echo tester for non-destructive testing, manufactured by Interpribor (state registration certificate of the Russian Federation No. 30252-10, serial number 887, verification certificate dated January 29, 2025, Fig. 2a);

– PSU-50 testing press (Fig. 2b);

– Testo 606-1 dielectric moisture meter, designed for measuring the moisture content of materials (Fig. 2c);

– Canon 1200D digital SLR camera, providing fast photography;

– Zitrek Z-35-1.5 handheld electric vibrator used for compacting the mixture;

– Mucheng 0.1-500 electronic scales, intended for precise dosing of components (measurement accuracy ranges from 0.1 to 500 grams).

The research procedure was divided into theoretical and practical parts.

As a result of theoretical studies, tables of combinations of various additive components were compiled (Tables 1–2).

To assess the strength of concrete, the shock-pulse method was used ac-cording to the national standard GOST 22690-2015 “Concretes. Determination of strength by mechanical methods of non-destructive testing.” This method is based on the relationship between the strength

Table 1. Combinations No. 1 of individual additive components

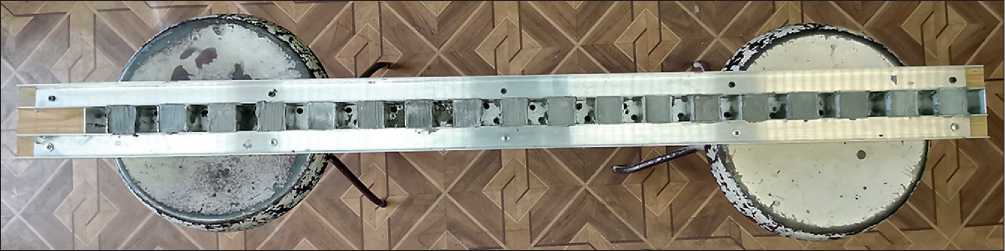

The concrete mixture was compacted during mixing using a handheld electric vibrator. For conducting nondestructive testing, samples measuring 30×30×30 mm (Fig. 3) were made from cement mortar of optimal consistency (approximate water-to-cement ratio = 0.3). The cement mortar was prepared by mixing Portland cement grade M500D0 (Fig. 4a) with an additive solution (or

Fig. 2. a) ONIKS-2.5 Impact-echonon-destructive testing device; b) PSU-50 testing press; c) Testo 606-1 dielectric moisture meter

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Table 2. Combinations No. 2 of individual additive components

A total of 150 control samples (without additives) and samples with dif-ferent combinations of additive compo- sitions were made (50 pieces of each type: X1, X1+X2, X1+X4). After the specified curing periods, testing for compres-sive strength was conducted using the impactecho method and by testing the samples on a press.

Additionally, the moisture content of the samples was measured using a portable moisture meter. The average moisture content of the concrete samples during the testing period was 1.6%. After mixing, it was found that combination No. 2 caused the concrete mixture to heat from 23 to 42 °C, which theoretically allows the use of this component for winter concreting. The mixture gradually cooled over the period from 45 minutes to 1 hour.

The obtained data were averaged and entered into results tables, on the ba-sis of which graphs of the kinetics of cement stone hardening were constructed.

RESULTS

The principle of action of the individual components of the proposed additive is based on the ability to bind free calcium hydroxide present in concrete (Ca(OH)2) [32, 33] with hexafluorosilicate ions to form slightly soluble calcium hexafluorosilicate (CaSiF6) through direct reaction (1):

Са(ОН)2 + (NН4)2[SiF6] → 2NH4OH +

+ СаSiF6↓ + Q. (1)

2NH4OH → 2NH3↑ + 2H2O. (2)

It should be noted that since hexafluorosilicates are essentially complex compounds in which 2 molecules of hydrofluoric acid (HF) are attached via hydrogen bonding to a molecule of silicon tetrafluoride (SiF4), the reaction is exothermic, as calcium oxide and hydroxide always react with hydrofluoric acid solution with heat release.

It is known that individual components of the additive increase the solubility of cement particles in the water-salt solution, increasing the content of hydration products in it. Calcium hexafluorosilicate, formed as a result of this process, is in a nanodispersed state [22, 32]. This ensures rapid bonding of cement grains with each other, which

Fig. 3. General view of the test samples for non-destructive testing

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Fig. 4. a) Weighing Portland cement on electronic scales; b) Example of one of the additive components (silicon carbide (SiC) nanopowder)

accelerates the hardening of the material and increases the rate of strength gain.

SiC + Са(ОН)2 →.(3)

SiC + 2H2O (superheated steam +1300°C) →

→ SiO2↓ + CH4↑.(4)

Са[SiF]6↓ (370 °С) → СаF2 (800 °С) +

+ SiF4↑ (+ steam) → СаO + 2HF↑.(5)

SiO2+ 4HF → SiF4↑.(6)

3SiF4↑ + 2H2O → SiO2↓ + 2H2[SiF]6.(7)

2Н2[SiF]6 + Са(ОН)2 (residual) → Са[SiF]6↓.(8)

The ammonia (NH3) generated within the system evaporates upon the addition and mixing of water with Portland cement. Consequently, when this nanoadditive is introduced into concrete, a strong smell of ammonia is noticeable in the first minutes of mixing with water.

Unlike ammonium hexafluorosilicate, silicon carbide does not participate directly in the reaction (2) with the hydration products of Portland cement (which would require elevated temperature, strong alkaline conditions, and the presence of oxygen in the system); rather, it functions as micro- and nano-dispersed particles capable of occupying the pores within the hardening cement stone. Theoretically, the incorporation of silicon carbide may enhance the hard-ness of cement stone, however, this issue has not yet been fully studied in the industry. Additionally, potential effects of introducing micro- or nanoparticles of silicon carbide into concrete may include enhanced fire resistance (silicon car-bide undergoes decomposition by superheated steam at temperatures exceeding +1300 °C), as well as acting as a “trap” for inorganic fluorides (i.e., other possi-ble additive components in the system) during concrete exposure to high-temperature environments, thereby binding fluoride components within the sys-tem (see reactions 4–8). An extensive review of Russian and international litera-ture was conducted on the subject of this study [5–21].

Data processing following non-destructive testing was performed using the Microsoft Excel software package. Measurement precision was ensured through systematic averaging of actual compressive strength values for each sample series.

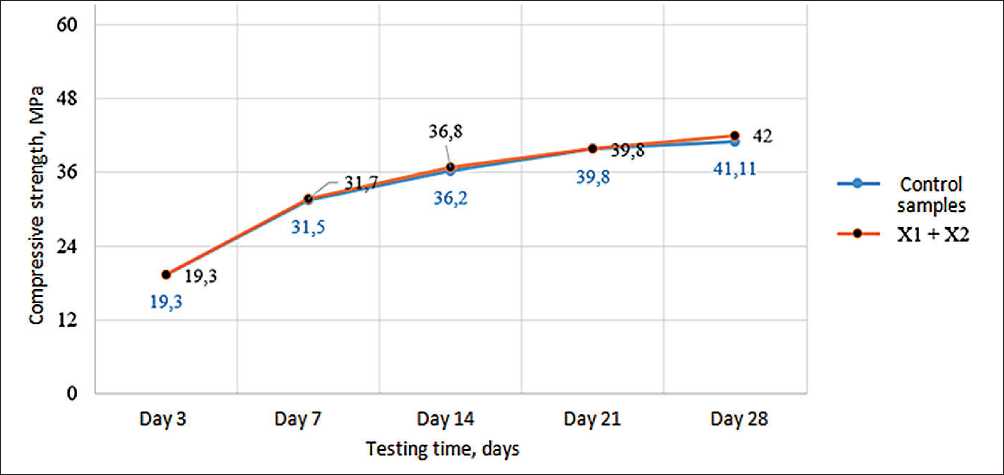

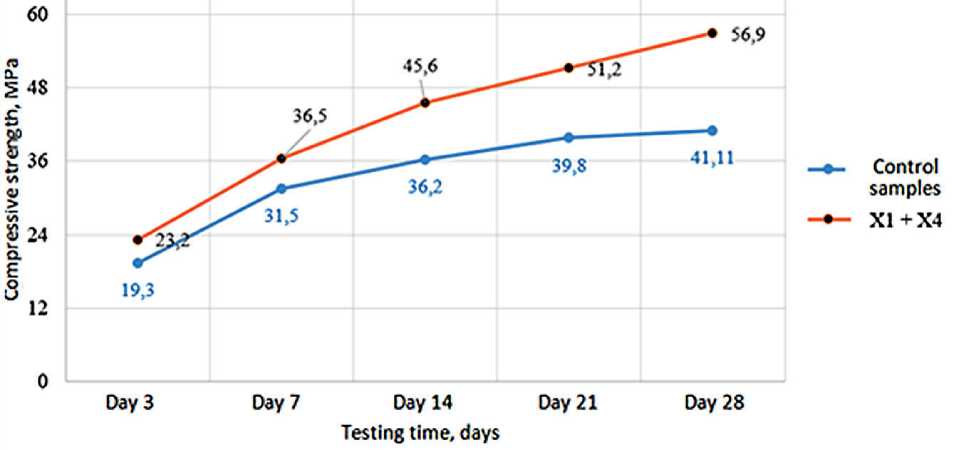

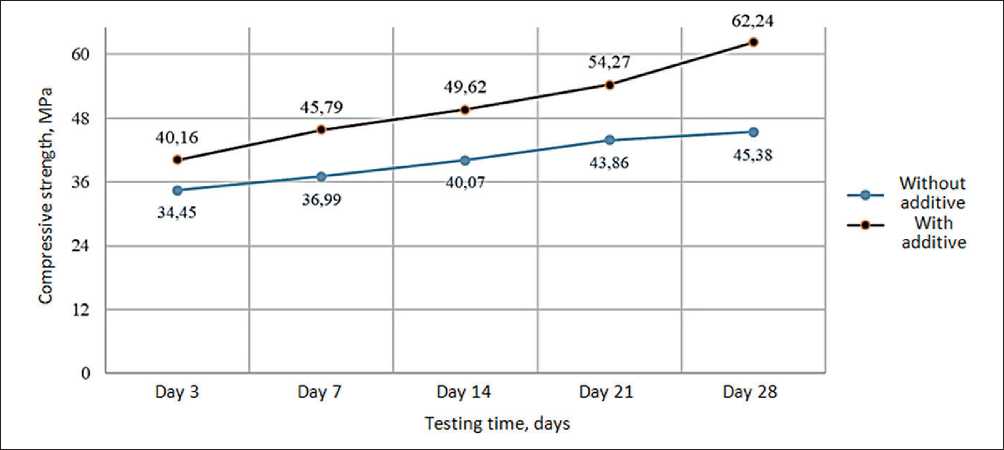

Based on the obtained average results and strength values determined by the impact-echo method, comparative hardening kinetics graphs were construct-ed for concrete samples containing the proposed additive components (combina-tions No. 1 and No. 2) and unmodified concrete (control) samples over the peri-od from 3 to 28 days (Figures 5–6).

Based on the results of the conducted studies, it was established that the average rate of strength gain of samples using additive combination No. 1 is comparable to the indicators of control samples. The experimental data obtained convincingly demonstrate that combination No. 2 among the proposed complex additives most effectively accelerates the process of strength gain of cement stone both at

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Fig. 5. Diagram of the maximum indicators of the kinetics of cement stone hardening according to non-destructive impact-echo control data for combination No. 1 (X1+X2)

Fig. 6. Diagram of the maximum indicators of the kinetics of cement stone hardening according to non-destructive impact-echo control data for combination No. 3 (X1+X4)

the early stages of hardening (up to 14 days) and at the later stages (up to 28 days). In this regard, samples made with the use of additive combina-tion No. 2 were tested for compressive strength by destructive testing (Fig. 7).

The analysis of the processed data allowed for the determination of pat-terns in the change of cement stone strength during various stages of hardening. The graphical representation of the results provided a clear understanding of the dynamics of strength growth and identified criti- cal periods when the intensity of strength gain was greatest or least. This allowed for the optimization of storage and maintenance regimes for the samples.

DISCUSSION

The hardening kinetics diagrams provided a foundation for subsequent optimization of concrete mixture formulations. These diagrams corroborated the hypothesis

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Fig. 7. Kinetics of cement stone hardening with the addition of combination No. 2 according to destructive control data

regarding the beneficial influence of the investigated additives on ac-celerating the hydration process and enhancing cement stone quality. Such in-vestigations are essential for advancing innovative approaches in the construc-tion industry and for strengthening the competitiveness of Russian products in the international market.

The experimental data confirm an increase in cement stone compressive strength exceeding 30%, irrespective of the assessment method employed: both non-destructive testing and direct (destructive) testing demonstrated this en-hancement with the addition of combination No. 2. Analysis of the strength de-velopment dynamics of the cement stone over the interval from 3 to 28 days yielded average strength gains with the proposed additive: nondestructive test-ing data indicated a strength increase of 38.57%, and destructive testing indicat-ed a corresponding value of 37.15%.

Through testing, it was also established that the optimal dosage rate of the additive per 1 m³ of concrete is approximately 0.01–0.011 of the total concrete mass. A calculation of economic indicators (technical and economic efficiency) for the produced additive is not required due to the insignificance of the associ-ated costs.

Theoretical and experimental analysis demonstrates the principal charac-teristics of the proposed additive, which is a mixture of fluoroborate and fluoro-silicate nanopowders. Its high efficacy combined with the minimal required dos-age renders this innovation promising for further investigation and implementa-tion in industrial production. An additional advantage of the proposed additive is its versatility. It is compatible with most cement types and can be adapted to var-ious climatic conditions, which expands its application scope. The capability to adjust dosage according to specific requirements will allow achieving superior performance even in complex production situations.

CONCLUSION

The conducted research successfully achieved all established objectives and accomplished the corresponding tasks, thereby enabling the identification of the optimal ratio of nanoscale additive components and the investigation of cement stone hardening kinetics.

Based on the obtained results, the application of the optimal composition (combination No. 2) yielded an average increase in concrete strength of approx-imately 38% as determined through both non-destructive and destructive testing methods. The quantity of nanocomponents required for the recommended addi-tive formulation corresponds to approximately 0.0141% of the total weight of the initial concrete.

The accumulated theoretical and experimental evidence demonstrating the effectiveness of the developed complex additive, comprising a mixture of na-nopowders of silicon carbide and ammonium hexafluorosilicate, supports a pre-liminary conclusion regarding the considerable advantages of this formulation.

The adoption of novel composite materials incorporating nanopowders will enable Russian construction enterprises to advance to an enhanced technological level, thereby achieving competitiveness with international counterparts. This development demonstrates substantial potential in both civil construction appli-cations and infrastructure projects, including the construction of bridges, road-ways, and industrial facilities.

No.

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION