Influence of the preparation characteristics of grape dietary fiber on the technological process of wine

Автор: Soltanov H.

Журнал: Science, Education and Innovations in the Context of Modern Problems @imcra

Статья в выпуске: 4 vol.8, 2025 года.

Бесплатный доступ

The use of recycled raw materials from the winemaking industry, in particular grape pomace, to improve the technology of natural table wines was studied. The study focused on the possibilities of using grape skins as recycled raw materials, whether fresh, dry, powdered or as dietary fiber independently. In this regard, the pomace obtained using modern technological equipment and grape processing technology was studied. Based on the technology we developed, grape dietary fiber prepared by two types of drying - infrared radiation and drying cabinet - was used. The results obtained proved that the type of drying of grape dietary fiber has a greater effect on the chemical composition of the prepared wine materials than the degree of their crushing. Based on scientific research, it can be noted that drying with infrared rays ensures the production of higher-quality grape dietary fiber, and this grape dietary fiber has a more positive effect on the technological process of wine. The extract index of wine is affected by the degree of maturity of the grapes, as well as substances collected during fermentation, including glycerin and other non-volatile polyatomic alcohols, nitrogenous and mineral substances, acids and their salts, and other extractive substances. Based on the mass concentration indicators of the obtained extract, it can be noted that during fermentation, wine is rich in biologically valuable components of dietary fibers. Their transfer to wine depends on the degree of crushing of dietary fibers and the drying method.

Wine, grapes, grape dietary fiber, physicochemical and sensory analysis

Короткий адрес: https://sciup.org/16010624

IDR: 16010624 | DOI: 10.56334/sei/8.4.63

Текст научной статьи Influence of the preparation characteristics of grape dietary fiber on the technological process of wine

PhD student of the Department of "Grape Processing and Wine Technology" of the Scientific Research Institute of Viticulture and Enology of the Ministry of Agriculture of the Republic of Azerbaijan, Azerbaijan, Email: ,

During the production of food products in food industry enterprises, waste remains, which is rich in dietary fiber. Their use in the production of new types of food products and to increase the biological value of food products has always been of particular interest. Food industry waste contains numerous high-value proteins, fats, easily digestible carbohydrates, macro- and microelements, vitamins and other substances. However, grape processing raw materials are not used everywhere and often efficiently. However, there is no doubt that the use of dietary fiber obtained from them in the food industry and winemaking can bring more profit ( Nerantzis et al.: 2006, pp. 659-673; Nogales et al.: 2005, pp. 659673 ).

Dietary fibers of plant origin have beneficial effects on human health ( Radchenko et al.: 2010, pp. 2021; Horn et al.: 2006, pp. 388-394; Otles et al.: 2014, pp. 191-202; Papathanasopoulos et al.: 2010, pp. 65-72 ) has found application in the enrichment of food products with plant fibers . Dietary fibers can also improve their quality by having a positive effect on physicochemical indicators .

It is known that the nutritional value and stability of yogurt can be increased by the use of grape powder ( Deng et al.: 2011, pp. 2712-2720 ). A soft cheese recipe has also been developed by adding grape powder to cow's milk. This has had a positive effect on the organoleptic and consumer properties of the product ( Ibragimova et al.: 2015, pp. 111-114; Renzyaeva et al.: 2014, pp. 43-49 ).

Italian experts have proven the promising use of grape powder in the production of marmalade candies and its great potential for the confectionery industry. Enrichment of marmalade with grape powder increased the amount of anthocyanins, flavonoids and procyanidins, increased antioxidant activity , which ensured stability during preparation. In addition, candies enriched with fibers demonstrated good textural properties and shortened preparation time ( Obolkina et al.: 2013, pp. 772-776 ).

There are studies that have shown that dietary fiber from grapes is an effective inhibitor of lipid oxidation ( Bodyakova et al.: 2013, pp. 14-15 ). They suggest its use as a natural antioxidant in raw chicken meat and sausage products ( Litovka et al.: 2007, p. 99 ). However, there are very few studies in this direction, and experimental data are not systematized. The use of dietary fiber from grapes in winemaking itself, including its use in intensification of the natural wine production process, has not been studied.

Grape skin contains valuable components such as polyphenols, lignin, aromatic, coloring and mineral substances, amino acids, vitamins. In addition, grape skin contains other components, including a polysaccharide complex formed by hemicellulose, cellulose and phenylpropanalignin, which constitute dietary fibers ( Гусейнов et al.: 2018, pp. 444-447, Гусейнов et al.: 2019, pp. 2-13, Насибов et al.: 2018, pp. 176-179). Based on the analysis of research results in the field of processing and use of recycled raw materials in the food industry, it can be assumed that the production of dietary fibers from grape skins is promising and can be used not only in baking, canning and dairy industries, but also to improve the technological methods of natural table wines. This is also important because only natural components of grapes will be used for their production, which will further increase their naturalness.

Methodology

The objects of the research were four variants of grape pomace processed by destemming. In the first variant, the pomace (sweet pomace) remaining after the juice was separated from the mixture of white grape varieties was included. Since it contains unfermented sugar, it is called sweet pomace. In the second variant, sweet pomace obtained from the Cheh Ray grape variety was taken, in the third variant, pomace obtained from red grape varieties and stored in the press, and in the fourth variant, pomace obtained from red grape varieties and fermented.

In addition, wine materials and dietary fibers obtained from grapes were taken as research objects. Sacharomyces cerevisiae dry yeast was used for fermentation of grape juice. The freshness of the raw materials was checked by examination ( Plotnikova et al.: 2001, p. 302).

The mechanical composition of the grape must was determined by separating it into its components and weighing it on a scale ( Methods of technochemical control in winemaking, Simferopol: "Tavrida", 2002, 258 p.; Salimov et al.: 2018, pp. 47-49; Salimov et al.: 2015, pp. 420-430 ). The amount of dry matter in the raw material was determined by drying the sample at 105 o C until a constant mass was obtained ( -GOST 28038-2013: Standartinform, 2014, 24 p .).

The amount of dry matter in the extracts was determined by the refractometric method ( GOST ISO 2173-2013: Standartinform, 2014, 12 с ), the amount of cellulose was determined by the method of Kyurshen and Ganek. 1 g of the crushed product is placed in a flask with a volume of 120 cm 3 , 40 cm 3 of an acid mixture (3.6 cm 3 of nitric acid with a density of 1.4 and 36.4 cm 3 of an 80% solution of acetic acid ) is added to it, the flask is closed and heated in a sand bath for 1 hour. The contents of the flask are filtered through a glass filter while boiling. After removing the extract, the precipitate is washed 1-2 times in a boiling alcoholic solution of 0.2M sodium hydroxide, and then washed several times with a mixture of distilled water and 10 cm 3 of alcohol-ether. The pure white precipitate was dried at 100...105 o C until a constant mass was obtained, cooled in a desiccator and weighed ( Aliyev et al.: 2008, p. 156 ). To determine the amount of hemicellulose, the raw material sample was extracted into 6% sodium hydroxide at 20...25 o C for 1 hour. The resulting solution was neutralized with hydrochloric acid, filtered through a pre-weighed filter and dried. The amount of hemicellulose was determined by the difference between the masses of the sample and the filter ( Aliyev et al.: 2008, p. 156 ). The determination of lignin was based on the Klason method ( Aliyev et al.: 2008, p. 156 ). The main components of the chemical composition of the must, wine material and grape juice, the mass concentration of the extracted extract, titratable and volatile acids, the volume fraction of ethyl alcohol were determined according to the methods given in the standards ( GOST 13192-1973: Standartinform, 2011, 10 p.; GOST 32114-2013: Standartinform, 2013, 8 p. ), the mass fraction of pectin substances was determined by the volumetric method according to SYRayka ( Podshuvalenko et al.: 2005, pp. 123-124 ). The Nessler method was used to determine the total nitrogen ( Aliyev et al.: 2008, p. 156 ). The Lowry method was used to determine the mass fraction of protein ( Aliyev et al.: 2008, p. 156 ). The amount of reducing agents was determined by the Bertrand method ( Aliyev et al.: 2008, p. 156 ). The determination of vitamin “C” was carried out on the basis of GOST 24556-89 “Processed fruits and vegetables. Methods for determining vitamin “C”. The quantitative determination of anthocyanins was carried out by spectrophotometric method by optical measurement of acid yield at a wavelength of 520 nm. Microbiological control of raw materials and obtained extracts was carried out in accordance with SanPin 2.3.2.1078-01 “Hygienic requirements for the safety and nutritional value of food products”. The organoleptic indicators of the extracts were determined according to the standards ( GOST 32051-2013: Standartinform, 2013, 16 с ). The light stability of the extracts was determined by the change in the solution saturation determined by a photoelectrocalorimeter at different wavelengths, exposed to direct sunlight for three months. The stability to high temperature was determined by the change in product saturation determined by photoelectrocolorimetry at different wavelengths by heating (80 o C) and boiling (100 o C). Qualitative and quantitative analysis of biologically active substances of the extracts was carried out by high-performance liquid chromatography ( Gerzhikova et al.: 2001, p. 624 ).

Conclusion and discussion:

Parallel experiments were conducted to study the effect of the type of drying of the grape skins on the alcoholic fermentation process in the wine technological line. During the experiment, grape dietary fiber prepared using two types of drying - infrared irradiation and drying cabinet - was used based on the technology we developed. Dietary fibers were obtained from white sweet grape skins of a white grape variety blend. Dried dietary fibers were dispersed at different degrees of crushing and grouped with sieves (table 4.5).

Table 1. Characteristics of experimental variants

|

Examples No. |

Drying type |

Fiber crushing rate |

|

1 (control) |

control |

control |

|

2 |

Infrared |

1mm |

|

3 |

Infrared |

3 mm |

|

4 |

Infrared |

5 mm |

|

5 |

Infrared |

uncut |

|

6 |

drying rack |

1mm |

|

7 |

drying rack |

3 mm |

|

8 |

drying rack |

5 mm |

|

9 |

drying rack |

uncut |

The juice of the Bayanshira grape variety was fermented with active dry yeast Saccharomyces cerevisiae Killer Bayanus, race IOS 18-2007, previously immobilized on grape fiber variants. The control sample was fermented in “free” yeast cells (without the use of grape fiber).

Immediately after the yeast immobilized in grape fiber crushed into 1-3 mm particles was applied to the material, some of the grape fiber sank to the bottom of the container, while the larger particles remained floating on top of the liquid.

On the second day, all variants became cloudy. This indicates the beginning of fermentation and the accumulation of yeast biomass. Foam was formed in all variants, except for the sixth variant (1 mm and dried in a drying cabinet) and the second variant (1 mm and dried in an infrared dryer). This characterizes the formation of carbon dioxide and the beginning of sugar fermentation. In the second and sixth variants, this occurred on the third day, which indicates an increase in the lag phase. Here, yeasts multiply, constant movement of particles is observed throughout the volume, and the fermenting juice becomes more turbid.

After fermentation, the wine materials were settled. In the second, third, sixth, and seventh variants (grape dietary fibers were crushed into 1-3 mm particles), the grape dietary fibers formed a dense sediment together with the yeast. This facilitated the subsequent decantation process. In the fourth and eighth variants (grape dietary fibers were crushed to 5 mm), some of the fibers formed a lump (clump) together with the yeast at the bottom of the container, and some remained in the “cap”. In the variants where uncrushed grape dietary fibers were applied, all the fibers remained floating on the surface of the liquid.

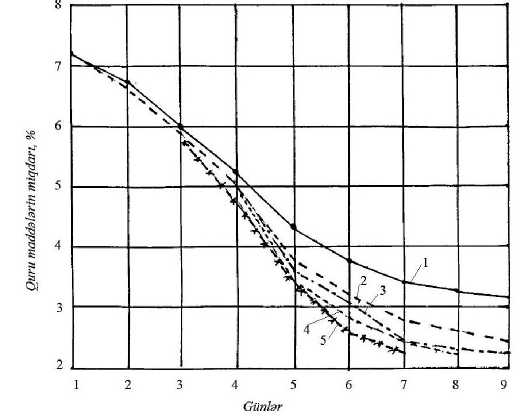

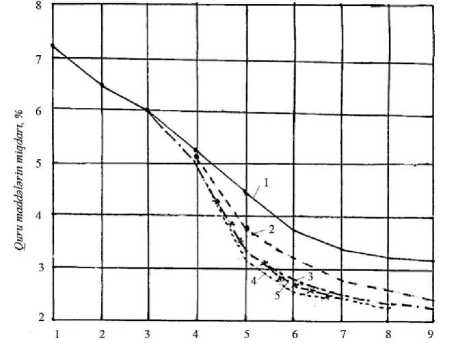

The nature of the change in dry matter during the fermentation of grape juice in the presence of dietary fiber is graphically depicted in Figure 1 and Figure 2.

Change in the amount of dry matter during fermentation of juice with the application of immobilized yeast in grape dietary fibers dried in an infrared dryer :

1-control; 2-5th option; 3- 2nd option; 4- 4th option; 5-3rd option.

Gunter

Change in the amount of dry matter during fermentation of juice with the application of immobilized yeast on grape dietary fibers dried in a drying cabinet :

1st control; 2nd-9th option; 3rd-6th option; 4th-7th option; 5th-8th option.

It has been established that immobilization of yeast cells on grape fiber helps to intensify the alcoholic fermentation process. The best results are obtained when using fiber crushed into 3-5 mm particles. In this case, the fermentation time is shortened, and complete fermentation of sugar is achieved.

It should be noted that in the third sample (dietary fiber crushed into 3 mm particles and dried with infrared radiation), the fermentation time was shortened by 2 days.

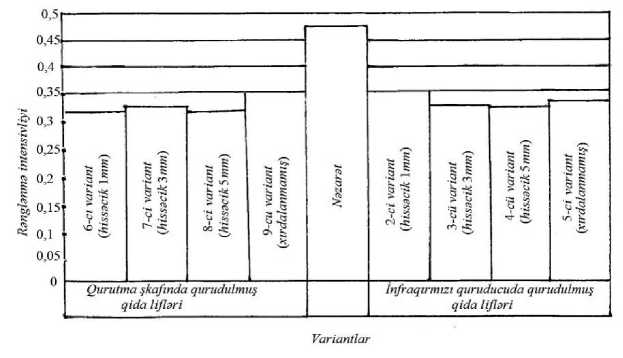

grape dietary fibers affect the color of the finished wine, the total color intensity (sum of optical densities at wavelengths of 420 and 520 nm) was determined (Fig. 3). Low values of color intensity characterize low coloration of the wine without golden and amber shades. Such a situation is considered positive for white natural table wine materials.

Fig. 3. The effect of the drying type and degree of crushing of grape dietary fibers on the color intensity of the resulting wine materials.

In all variants where dietary fiber was applied, the coloring intensity was lower than in the control. Samples 3, 4, 5, 6, 7, 8 had a light straw color . Sample 9 (cupboard-dried, uncrushed dietary fiber) had a more yellow-golden hue, while the control variant had a straw color.

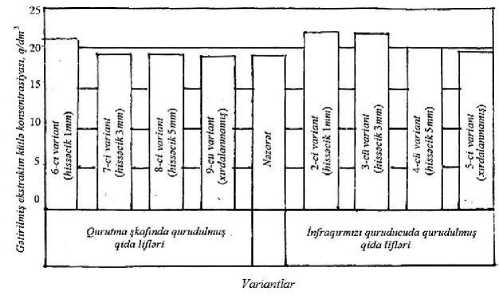

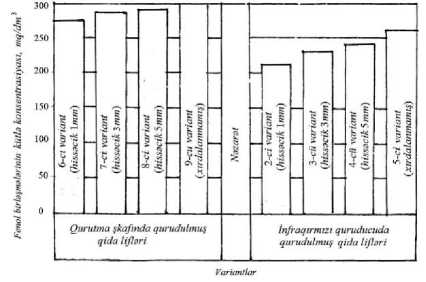

The extract index of wine is influenced by the degree of ripeness of grapes, as well as substances accumulated during fermentation, including glycerin and other non-volatile polyatomic alcohols, nitrogenous and mineral substances, acids and their salts, and other extractive substances. Based on the mass concentration indicators of the extracted extract (Fig. 4), it can be noted that during fermentation, wine is rich in biologically valuable components of dietary fibers. Their transfer to wine depends on the degree of crushing of dietary fibers and the method of drying.

In variants 6-9, when dietary fiber dried in a drying cabinet was used, the amount of extract obtained was between 18.8...20.9 g/dm 3. In variants using dietary fiber dried in an infrared dryer, the amount of extract obtained was 19.4...21.8 g/dm 3 .

Fig. 4. Effect of drying type and dispersion degree of grape dietary fibers on the mass concentration of the extracted extract.

concentration in samples using grape dietary fiber dried in a drying cabinet and crushed to 1 mm particles was 2.1 g/dm 3 higher than in the control variant. When using the same size of crushed dietary fiber dried by infrared radiation, the extract was 3 g/dm 3 higher than in the control. This indicates that the material dried by infrared radiation has a higher quality .

The use of grape dietary fiber during fermentation leads to a decrease in the mass concentration of phenolic compounds that play a role in the color of the wine. Phenolic compounds are correlated with the above-mentioned color intensity indicators. The addition of dietary fiber dried by infrared radiation has a lower extractive content, including phenolic substances (Fig. 5). This is very important in the preparation of natural white wine. Because when preparing this type of wine, it is necessary to activate the oxidation process with the participation of phenolic compounds. In this case, the degree of crushing of dietary fibers also affects the amount of phenolic compounds. The higher the degree of crushing, the lower the phenolic compounds in the experimental variants.

Fig. 5. Effect of drying type and dispersibility degree of grape dietary fiber on the mass concentration of phenolic compounds.

The experimental values obtained (table 2, table 3) show that grape dietary fiber significantly affects the chemical composition of the wine material, especially glycerol and organic acids. It should be noted that there is a high correlation between the mass concentration of the extracted extract and glycerol. This indicates that the introduction of dietary fiber helps the fermentation process to proceed via the glyceropyruvate pathway and a large amount of glycerol is formed.

In the experimental variants, especially in variants 6, 7, 3, and 5, a significant decrease in malic acid concentration was observed, which may be related to the activation of the enzyme system in the tricarboxylic acid cycle.

Table 2. Effect of drying type and dispersibility degree of grape dietary fiber on physicochemical parameters of wine material

|

Options |

Volume fraction of ethyl alcohol, % |

Mass concentration of acids, g/dm 3 |

pH |

Glycerin, g/dm 3 |

|

|

trembling |

Volatile |

||||

|

1st (control) |

9.25 |

8.4 |

0.56 |

3.09 |

4.12 |

|

2nd (infrared, 1 mm) |

8.56 |

6.2 |

0.28 |

3.08 |

6.70 |

|

3rd (infrared, 3 mm) |

8.56 |

6.0 |

0.33 |

3.11 |

6.55 |

|

4th (infrared, 5 mm) |

8.48 |

5.9 |

0.32 |

3.11 |

6.60 |

|

5th (infraq. all) |

8.16 |

5.7 |

0.34 |

3.10 |

6.82 |

|

6th (cabinet, 1 mm) |

9.78 |

6.9 |

0.43 |

2.91 |

6.08 |

|

7th (cabinet, 3 mm) |

9.52 |

7.2 |

0.31 |

2.88 |

5.78 |

|

8th (cabinet, 5 mm) |

9.85 |

7.4 |

0.33 |

2.87 |

5.25 |

|

9th (wardrobe, all) |

9.25 |

7.2 |

0.36 |

2.76 |

4.88 |

Table 3. Effect of drying type and dispersibility degree of grape dietary fiber on the mass concentration of organic acids

|

Options |

Surface water, g/dm 3 |

||||

|

wine |

Apple |

light |

amber |

Milk |

|

|

1st (control) |

4.77 |

1.98 |

0.47 |

0.87 |

1.80 |

|

2nd (infrared, 1 mm) |

2.43 |

1.13 |

0.36 |

0.74 |

1.54 |

|

3rd (infrared, 3 mm) |

2.28 |

1.23 |

0.36 |

0.68 |

1.54 |

|

4th (infrared, 5 mm) |

1.82 |

1.28 |

0.38 |

0.58 |

1.37 |

|

5th (infraq. all) |

1.96 |

1.47 |

0.30 |

0.56 |

1.28 |

|

6th (cabinet, 1 mm) |

4.32 |

1.61 |

0.27 |

0.79 |

2.21 |

|

7th (cabinet, 3 mm) |

4.50 |

1.66 |

0.28 |

0.76 |

2.18 |

|

8th (cabinet, 5 mm) |

4.66 |

1.91 |

0.29 |

0.73 |

2.09 |

|

9th (wardrobe, all) |

4.56 |

1.96 |

0.34 |

0.70 |

1.92 |

Statistical analysis of experimental values for the amount of glycerin was performed. It was proved that the type of drying of the fiber affects the accumulation of glycerin more than the degree of crushing of the dietary fiber. The obtained values proved that the type of drying of grape dietary fiber has a greater effect on the chemical composition of the prepared wine materials than their degree of crushing. Based on the results of the study, it can be noted that infrared drying provides higher quality grape dietary fiber.