Inventions in the area of nanomaterials and nanotechnologies. Part I

Автор: Ivanov L.A., Xu L.D., Bokova E.S., Ishkov A.D., Borisova O.N.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Review of nanotechnological inventions

Статья в выпуске: 1 Vol.14, 2022 года.

Бесплатный доступ

Introduction. Advanced technologies impress people’s imagination demonstrating the latest achievements (materials, methods, systems, technologies, devices etc.) that dramatically change the world. This, first of all, concerns nanotechnological inventions designed by scientists, engineers and specialists from different countries. Main part. The article provides an abstract overview of inventions of scientists, engineers and specialists from different countries: Germany, Iraq, China, Russia, USA, Ukraine, Sweden, Japan et al. The results of the creative activity of scientists, engineers and specialists, including inventions in the field of nanotechnology and nanomaterials allow, when introduced to industry, achieving a significant effect in construction, housing and communal services, and related sectors of the economy. For example, the invention «Nanomodified building mortar» refers to construction materials and can be used in masonry of ceramic stones, ceramic bricks, hollow bricks in dry and hot climate. The novelty, in respect to the existing construction mortars, is the combination of known components of Portland cement, sand for construction works, amorphous nanomodified silica dioxide, superplasticizer С-3, cure retarders of Portland cement, air-entraining resin. The given qualitative and quantitative composition of nanomodified construction mortar makes it possible to obtain the mentioned mixtures in a simple way: for example, in gravity mixer, with evenly distributed components in volume, which is characterized with specified flowability, water-retaining property, controlled hardening period and can be used in dry and hot climate with air temperature up to 40-50°С. The following inventions in the field of nanotechnology can also be interesting for specialists: a composition of self-compacting construction concrete on the basis of cement matrix, a method of producing polarization-sensitive nanocomposite film on the basis of copper selenide, a method of producing porous moulded article in the form of insulation plaster layer, a method to obtain amorphous nanostructured diamond-like coating, a method of cement surface modification, a system to produce carbon nanotubes, et al. Conclusion. One of the most challenging tasks the economy of every country faces is to increase industrial competitiveness through technological upgrade. From the side of the state and companies the principal object to control in this process are the people and enterprises dealing with introduction of inventions and new technologies.

Nanotechnologies in construction, nanomodified building mortar, nanostructured coating, nanotube, nanocomposite film

Короткий адрес: https://sciup.org/142231177

IDR: 142231177 | DOI: 10.15828/2075-8545-2022-14-1-18-26

Текст научной статьи Inventions in the area of nanomaterials and nanotechnologies. Part I

A dvanced technologies impress people’s imagination demonstrating the latest achievements (materials, methods, systems, technologies, devices etc.) that dramatically change the world. This primarily concerns nanotechnological inventions designed by scientists, engineers and specialists from different countries (Germany, Iraq, China, Russia, USA, Ukraine, Sweden, Japan et al.).

MAIN PART

Nanomodified building mortar (RU 2759479 С1)

The invention refers to construction materials and can be used in masonry of ceramic stones, ceramic bricks, hollow bricks in dry and hot climate [1]. One of the most challenging problems in masonry made of ceramic bricks in dry and hot climate is to provide flowability and water-

REVIEW OF NANOTECHNOLOGICAL INVENTIONS retaining property of the mortar under air temperature more than 20оС and up to 40–50оС. Heated brick intensively absorbs water from the mortar that leads to increase of work labour input due to decrease of mortar flowability.

The task of the technical solution is to obtain building cement and sand mortar which is characterized by specified flowability, water-retaining property, controlled setting time and can be used in dry and hot climate with air temperature up to 40–50оС. The technical result is the increased water-retaining ability, provision of specified flowability and controlled setting time of building mortar. The technical result is achieved due to the following technology: building mortar comprising Portland cement, construction sand with fineness modulus 1.5–2.0, water, additionally contains amorphous nanomodified silica dioxide, superplasticizer С-3, cure retarders of Portland cement, air-entraining resin under the following ratio of components, mass.%: Portland cement – 10.80–16.90; sand for construction works – 69.50–80.70; amorphous nanomodified silica dioxide – 0.01–0.12; cure retarders of Portland cement – 0.002–0.05; superplasticizer С-3 – 0.02–0.15; air-entraining resin – 0.02–0.15; water – 8.5–13.0.

The novelty, in respect to the existing construction mortars, is the combination of known components of Portland cement, sand for construction works, amorphous nanomodified silica dioxide, superplasticizer С-3, cure retarders of Portland cement, air-entraining resin. The given qualitative and quantitative composition of nanomodified construction mortar makes it possible to obtain the mentioned mixtures in a simple way: for example, in gravity mixer, with evenly distributed components in volume, which is characterized with specified flowability, water-retaining property, controlled hardening period and can be used in dry and hot climate with air temperature up to 40–50оС.

A new property emerges in the applied set of features: increased water-retaining ability and, at the same time, provision of specified flowability and controlled setting time of building mortar.

A composition of light self-compacting construction concrete on the basis of cement matrix (RU 2758050 С1)

The invention refers to the industry of building materials and can be used in civil and industrial construction as well as in construction of special facilities. The aim of the invention is to obtain light self-compacting construction concrete (LCC) of high strength, high frost-resistance, low product cost and low thermal conductivity.

The suggested composite material is a light concrete with high thermal performance. The result is achieved due to applying light cube-like filler with many closed pores that provide high heat-insulating effect and low density of the final product as well as high adhesion with binding material. When density and thermal conductivity are low, the concrete possesses high strength that is provided by creating high-strength cement matrix in concrete due to rational packing of components and formation of strong chemical bounds. The proposed concrete allows constructing multi-storey buildings with high thermal performance and strength characteristics, which meet modern requirements [2].

A composition for production of self-compacting construction concrete contains mechanically activated Portland cement, foamed glass ceramic granules, rheology active stone dust, water-retaining additive, micro- and nanosilica, polyfunctional modifier on the polycarboxylate basis, water, in the following ratio of components, mass.%: mechanically activated Portland cement 15–25, polyfunctional modifier 1–2.5, rheology active stone dust 10–25, water-retaining additive 0.003–0.02, micro- and nanosilica 1.5–7, foamed glass ceramic granules, 30–50, water – the rest.

The technology of the given composition includes the following stages: mechanical activation of Portland cement jointly with polyfunctional modifier on the polycarboxylate basis and micro- and nanosilica, dosage of dry components, water, mixing till formation of completely streak free, formation of products and curing for 28 days until to the moment when maximum strength is obtained.

A method of producing porous moulded articlein the form of insulation plaster layer (RU 2721612 С1)

The invention refers to porous moulded articles in the form of insulation plaster layer or isolation slab, to the methods of producing such porous moulded articles and to the mortar mixes used in production of these porous moulded articles. It is known that when applying layers of insulation plaster and when producing heat-insulating slabs, highly flammable materials, such as Styrofoam or roamed polyurethane, are often used. The great disadvantage of these materials is their high flammability.

The given invention is aimed at solving the problem concerning development of insulation materials on the basis of mineral light fillers. These materials could be flexible and, at the same time, would possess better fireresistant properties [3].

The features of the method to produce porous moulded article in the form of insulation plaster layer: the layer contains either closed-porous or open-porous or mixed-porous hollow bodies of inorganic materials and the binder is composite particles which contain at least one organic polymer as organic polymer phase and at least one inorganic solid body, which particles are distributed in organic polymer phase, at this, mass fraction of inorganic solid substance is from 15 to 50 mass.% expressed in terms of total mass of organic polymer and inorganic

REVIEW OF NANOTECHNOLOGICAL INVENTIONS solid substance in composite particle, closed-porous or open-porous or mixed-porous hollow bodies of inorganic materials taken in quantity from 10 to 50 mass.%, composite particles taken in quantity from 5 to 20 mass.%, fillers taken in quantity from 40 to 80 mass.%, mineral binders and/or polymer binders taken in quantity from 0 to 20 mass.% and, if necessary, extra additives taken in quantity from 0,1 to 10 mass.%, in each case expressed in terms of total mass of dry mixture without water, at this, in each case summarized values mentioned in mass.% are equal to 100 mass.%, then water is added and obtained solution is applied on the substrate. The invention is developed in depending claims. The technical result is the production of insulation material with flexible and, at the same time, improved fire-resistant properties.

A method of cement surface modification(RU 2715276 С1)

The invention refers to production of building materials, in particularly, to cement production. The task of the invention is to improve quality of cement, to prolong time of its caking, to decrease specific surface by correcting granulometric composition and, as a result, to decrease its water demand [4].

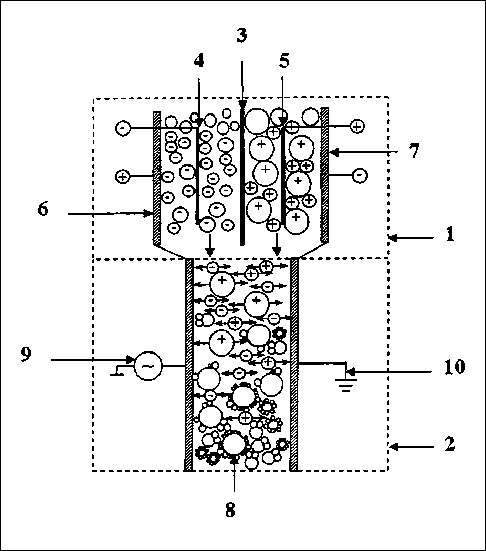

The essence of the invention is that the method of cement surface modification, comprising cement processing, also comprises bipolar charging of cement in electrization chamber under impact of high-voltage electric field of crown discharge, bipolar charging is performed by passing the first half of aerosol flow through positive unit of charging station, and the second half of aerosol flow – through negative unit charging station, then unipolar charged particles get to the agglomerator with varying high-voltage electric field.

The method is performed in the following way (fig. 1). Under impact of electric field, which is generated in the chamber of particle electrization 1 in the first section between crown negative 4 and outer collecting positive 6 electrodes, the initial mineral elements adsorb ions from interelectrode space and get negative charge. The similar process between the electrode with positive charge 5 and negative one 7 runs in the second section, but mineral elements get positive charge. As a result, further bipolar charged mineral dispersed elements get into agglomera-tor 2, in which under the impact of high-voltage varying electric field 9, variations with different amplitude and frequency take place. Coarse particles are oscillated with higher amplitude and frequency than fine particles, gradient of frequency and amplitude of variations provides increase of particle interference frequency, that leads to formation of spheroidal cement 8. Ground bed is made by means of electrode 10.

The technical result is the prolonged time of cement caking, decreased amount of «free» high-dispersed par-

Fig. 1. A plant for surface modification of mineral dispersed elements:

1 – particle electrization chamber; 2 – agglomerator;

3 – separation of dielectric material; 4 – crown electrode; 5 – electrode with positive potential; 6 – outer collecting electrode; 7 – negative electrode; 8 – spheroid cement; 9 – high-voltage varying electric field;

10 – electrode by which ground bed is performed.

ticles (diameter is less than 3 µm), decreased coarseness of «spheroids» surface and specific surface due to correction of granulometric composition, as well as slower hydration of cement at the early stages, that improves flowability of concrete mixtures, prepared on the basis of such «spheroid» cement, and, as a result, its water demand falls (water-cement ratio is decreased by 6–8%). When superplasticizers are implemented in concrete mixtures, their adsorption per unit of cement surface also decreases (up to 20%).

Multilayer wear-resistant coating on the steel substrate (RU 2759163 С1)

The modern machinery industry is widely using the tools and the details of mechanical systems, on the working surface of which protective wear-resistant nanostructured coatings are applied. Application of protective coatings on processing tools and equipment parts significantly prolongs their service life. Moreover, metals and alloys can be destroyed also by corrosion, for example, after chemical, electrochemical, radiation and other types of environment impacts. When equipment is operating, the

REVIEW OF NANOTECHNOLOGICAL INVENTIONS processes of corrosion and mechanical wear can run simultaneously, for example, that happens with pumps, mixers, male screws, etc. Therefore, wear- and corrosionresistant coating are badly needed.

Diamond-like carbon coatings (DCC) are well-known due to their capability to provide, low friction, high wear-resistance and high thermal conductivity. Owing to low friction coefficient and high hardness, they are used in tribology as a protection from abrasive and frictional wear. Nevertheless, their high hardness and high inner stresses often lead to weak adhesion with steel substrates, that is a problem for many high technological industries. Hard, dense DCC are also used to protect metal substrates from corrosion in different chemically aggressive media. However, residual nanopores and defects in coating are the initial sources of corrosion, which causes emergence of defect network in DCC that is a channel of corrosion impact on the substrate under the coating from environment.

The mentioned technical problems can be solved by designing technical solution as follows. The wear-resistant multilayer coating on steel substrate which contains a nanocomposite layer, comprising carbon, and a layer of diamond-like carbon, with interchange of the given two layers, according to the invention, in this coating, a diamond-like carbon layer is hydrogenized, precipitated by PACVD method, and a nanocomposite layer obtained with combined method of physical precipitation from vapor (PVD method) and plasma-chemical precipitation from gas phase (PACVD method) includes chrome, aluminum and their compound with carbon [5]. At this, the total content of chrome in nanocomposite layer is 30–35 аt. %, aluminum – 50–52 at. %, carbon – 13–18 at. % and the rest is oxygen. The coating is performed with thickness 800–2500 nm with amount of the mentioned layers from 20 to 50 and the thickness of each layer is from 40 to 50 nm.

The invention can be used in metal processing, mechanical engineering, oil and gas industry, chemical industry, etc. to improve performance characteristics of the units exposed to various performance conditions.

A method of producing polarization-sensitive nanocomposite film on the basis of copper selenide (2758150 С1)

The task of the invention is to develop a method of producing polarization-sensitive nanocomposite film on the basis of copper selenide with better efficiency of conversion of laser light power into photoelectric current [6].

The essence of the invention is that, compared to the known method of producing polarization-sensitive nanocomposite film on the basis of copper selenide in which sequential application of layers of selenium and copper on dielectric substrate, oriented perpendicular to current of sprayed particles, is performed with vacuum-thermal spraying method under room temperature, the obtained nanocomposite film is annealed in vacuum under the temperature in the range 120–217оС

The technical result is the increased efficiency of conversion of laser light power into photoelectric current in polarization-sensitive nanofilm on the basis of copper selenide.

The method of producing polarization-sensitive nanocomposite film on the basis of copper selenide is performed as follows. Under the room temperature the layers of selenium and copper are sequentially applied on the dielectric substrate by the method of vacuumthermal spraying in a single vacuum cycle. At this, the substrate is oriented perpendicular to the current of spraying particles. Hot vapors and clusters of copper, reaching low-melting layer of selenide, react with it, that resulted in emergence of semitransparent electrical conductive polarization-sensitive nanocomposite film on the surface of substrate. This nanofilm consists of polycrystalline copper selenide and amorphous selenium. The obtained nanocomposite film is annealed in vacuum, that causes crystallization of amorphous selenium and coarsening of crystallites of copper selenide, that results in increase of efficiency of conversion of laser light power into photoelectric current.

In the experiments, formation of polarization-sensitive nanocomposite film on the basis of copper selenide was performed by the method of vacuum-thermal spraying on rectangular quartz substrate which size is 17.5×34.5 mm. Along short sides of the substrate two parallel thin-film measuring electrodes which wideness is 5 mm were preliminary applied. In the course of spraying, the substrate was under room temperature and was at the distance of 0.12 m from evaporator plant perpendicular to motion direction of sprayed particles. The ratio of selenium and copper preforms in the evaporator was 19:5. The thickness of the final film was 130 nm and resistance to the direct current between measuring electrodes was 37.2 O.

The annealing of the experimental sample is performed under the temperature 150оС for 30 minutes. The resistance to the direct current current between measuring electrodes in the annealed film was 25.7 О.

A method of obtaining ethenyl wallpaperswith bactericidal coating (RU 2758770 С1)

The invention refers to the methods of obtaining ethenyl wallpapers with bactericidal coating, protecting from emergence of bacteria and fungus on the surfaces of paper-overlaid articles and it also makes possible to eliminate pathogenic microorganisms from room air and to repress their birth process. The invention can be used to disinfect surfaces and air rooms, especially, in public places and medical centers [7].

REVIEW OF NANOTECHNOLOGICAL INVENTIONS

It is known that one of the option to solve disinfection problem for surfaces and room air, in particularly, in public places and medical centers, can become application of wallpapers with bactericidal coating on the basis of aqueous paints with nanosize particles of silver, copper or gold with increased biocide activity. These wallpapers can protect from emergence of bacteria and fungus on the surfaces of paper-overlaid articles and it also makes possible to eliminate pathogenic microorganisms from room air and to repress their birth process.

The proposed method comprises some existing technical methods as stages but the new result is achieved, namely, wallpapers with bactericidal coating possessing high and long bactericidal activity in respect to stocks of different microorganisms. The task of the given invention is to develop a method of obtaining ethenyl wallpapers with bactericidal coating, possessing high and long bactericidal activity in respect to stocks of different microorganisms which are pathogenic for mammals and human, and these wallpapers should be applicable in production and utility rooms, kindergartens and medical centers, public places, etc.

The set task is solved as follows. The considered method of obtaining ethenyl wallpapers with bactericidal coating consists of these stages:

-

1. Obtaining of antibacterial agent, which is silver nanoparticles on carbon matrix, by spraying composite electrode in plasma of electric arc charge of direct current in inert gas under pressure 1–500 torr, discharge current 100–300 A and voltage on discharge 15–35 V of composite electrode which is a graphite core. The mixture of silver and graphite dusts, in which silver content is from 1 to 100 mass.% is pressed into drilled hole of the graphite core.

-

2. Obtaining of biocide suspension by performing the following steps:

– introduction of silver nanoparticles on carbon matrix into basic liquid in such a way to provide concentration of silver nanoparticles on carbon matrix in basic liquid would be from 1 to 5 mass.%. Basic liquid is an aqueous paint diluted with water up to specific viscosity which is no more than 35 Pa•sec;

– processing of obtained composition in ultrasound bath with power 60–1200 Watt and frequency 15–40 kHz for 10–600 minutes under continuous mixing with rotation frequency 1–20 Hz;

– deposition for at least 4 hours;

– draining off without precipitation;

– dilution with basic liquid in such a way to provide concentration of silver nanoparticles on carbon matrix in the final product would be equal from 0.1 to 0.01 mass. %.

-

3. Application of obtained biocide suspension on face surface of wallpapers and heat processing of applied layer.

A method of obtaining amorphous nanostructured diamond-like coating (RU 2760018 С1)

The invention refers to the method of applying corrosion-resistant hard wear-resistant nanostructured coatings made of amorphous nanostructured diamond-like carbon and can be used metal processing, machinery, medicine, electronics, solar energy, electrooptics, photonics, in production of liquid-crystal displays and other areas to increase performace characteristics of surfaces of articles of different purposes [8].

The technical result of the given invention is creation of even dense structure, which does not pass moisture, on the surface of diamond-like coating. The imposed task is resolved as follows. The main stages of the given method: preliminary plasma treatment of article surface in vacuum chamber by means of accelerated ions, applying an adhesive layer, and applying at least one layer of carbon diamond-like film by means of graphite cathode spraying; after the coating layer has been applied, it is taken from the chamber and is polished, then it is again placed in the chamber, it is exposed to the second coating, after that it is secondly polished.

At the first stage, as usual, the article is thoroughly cleaned from dirty and grease is removed. Then the article is put into the vacuum chamber and PVD- coating is applied on its surface. The surface of the article is preliminary exposed to plasma stripping with accelerated ions, an adhesion layer is applied on its surface, and after that a layer of carbon diamond-like film is applied with graphite cathode spraying in the form of vapor phase and it is gradually precipitated on the surface of the article. This causes formation of amorphous nanostructured diamond-like coating which thickness is 1–3 µm. The diamond-like coating of the bigger thickness becomes fragile and it is not usable.

Having being obtained, the coating possesses a rough layer слой and uneven structure in the form of graphite nanoparticles and other substances, also in the form of micro- and nanopores. These defects on the surface act as capillaries through which moisture penetrates inside the coating and causes corrosion of article surface. To remove initial rough layer and, along with it defects of the structure, the surface of diamond-like coating is polished until seediness is Ra 0.04 µm or lower. Only this value of seediness makes it possible to cure micro- and nanopores.

After polishing the surface of the coating is cleaned thoroughly and deoiled again, ant it is put into vacuum chamber for the second time. The second layer of the carbon diamond-like film with thickness 1–2 µm fills nano- and micropores. Further polishing of the surface up to Ra 0.04 µm and lower removes rough defect layer forming the surface of even dense structure which does not pass moisture. Low seediness of the surface also protects from moisture retaining on the surface and increases its wear-resistance.

REVIEW OF NANOTECHNOLOGICAL INVENTIONS

A method of organized precipitation of nanostructured carbon thin films in constant electric field (RU 2761200 С1)

The technical result of the invention is the improved quality of precipitated layer and possibility to control/ organize precipitation modifying the structure of precipitated layer due to possibility to control the obtained high energy plasma by means of induced constant electric field of high voltage in the area of its spread (between conductive metal grid and substrate). This approach allows focusing and scattering plasma beam, thus varying strength of electric field and polarity of electrodes [9].

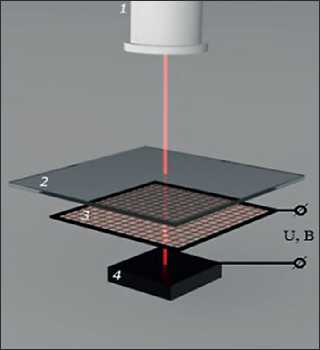

Description of the method (fig. 2): a metal grid (3) with cell size 100 µm is placed between transparent substrate (2) (polished quartz glass and glass К8, seediness of the surface Ra = 2.06 nm) and carbon target (4) (spectroscopically pure graphite of grade СЭУ, glass carbon of grade СУ-2000, pyrographite ПГИ). Total distance from the target to the substrate can be changed from 1 mm to 5 mm. The distance from metal grid to the target varies in the range 0.5–2.5 mm. Conductive contacts are fixed to the surface of the target and the metal grid. The negative potential is delivered to the surface of the target, and the positive one – to the grid, that creates braking difference of potentials U for the flow of ionized atoms. Additionally, the use of the grid allows dividing single flow of ablated particles into a set of separate sources.

The performed measures allow us to show that morphological properties of the precipitated layer strongly depend on the distance between the substrate and the target and accelerating voltage of the grid between them. In all cases the usage of the grid leads to precipitation with clear periodic structure, the step of which depends on the distance between the substrate and the grid. The structure of the precipitated layer varies in dependence on the distance between the substrate and the grid and the

Fig. 2. A method of organized precipitation of nanostructured carbon thin films in constant electric field difference of potentials between the grid and the target. In the course of precipitation, when voltage is up to 800 V and the distance between the substrate and the grid is varied in the range 1.5–2 mm (and the distance between the grid and the target is 1 mm) the carbon nanofibers are formed. Increased voltage between the grid and target up to U = 1000 V causes formation or precipitations from carbon nanotube mass.

To explain the mechanism of control of laser-induced plasma cloud, a mathematical modeling of precipitation experiment was performed. Accordance of model and experiment results is objective. Performed modeling demonstrates change of morphology of precipitated layer in dependence on test conditions. The application of methods of kinetics and molecule dynamics will make it possible to model the process of formation of carbon nanotubes in the future.

A system producing carbon nanotubes(RU 2760734 С1)

The given invention proposes a system producing carbon nanotubes. The system comprises [10]:

– preliminary grown tube for initial preliminary reaction of starting materials before obtaining carbon nanotubes;

– atomizer for atomizing starting materials of carbon nanotubes and further spraying atomized starting materials in preliminary grown tube; the atomizer is in the front end of the preliminary grown tube and it possesses spraying exhaust pipe which is travel into preliminary grown tube;

– the grown tube for production of carbon nanotubes and continuous growing carbon nanotubes; at this, the front end of the preliminary grown tube is hermetically connected to the back end of the preliminary grown tube;

– a generator of air curtain which provides air curtain that surrounds atomizing air flow around discharge of the spraying exhaust pipe, at this, air curtain is parallel to direction of the preliminary grown tube extension; and the generator of air curtain is inside of the preliminary grown tube.

In the given system for production of carbon nanotubes air curtain is formed around spraying exhaust pipe. On one side, in the preliminary grown tube laminar flow is formed by air curtain to stabilize air flow and, on the other side, sticking of carbon nanotubes or admixtures is eliminated, all that provides continuous growth of carbon nanotubes.

The specialists can also be interested in the following inventions related to nanotechnologies:

-

• A method to produce metal-polymer nanocomposite materials with metal nanoparticle [11];

REVIEW OF NANOTECHNOLOGICAL INVENTIONS

A method of producing textile material containing nano- and microcapsuled bio-effecting agents with sustained release [12];

Chemical compounds for covering nanostructures [13]; A device to obtain nanocrystalline titanium dioxide with anatase structure [14];

A method to produce porous graphene membranes and the membranes produced with this method [15]; A method of obtaining golden nanocores with specified position of plasmon resonance [16];

A method of electrolytic obtaining silica from melted salts [17];

A method of obtaining nanotubes InSb by electropulse method [18];

Innovative technology of municipal wastewater treatment for rapid sludge sedimentation and enhancing pollutants removal with nano-material [19];

A method of producing thermal conductive composite material from powders of aluminum or its alloy with graphene coating [20];

A method of obtaining thin films of zinc oxide or tin oxide, combined zinc oxide and tin oxide [21];

A method of obtaining cobalt ferrite [22];

Mesoporous carbon and a method of producing it as well as fuel cell with polymer electrolyte [23];

High RAP in WMA surface mixture containing nanoglass fibers [24]

-

• Modifiers for polymer-bituminous binder on the basis of media II Vacuum cut and Extract selective purification residual [25];

-

• A method of obtaining nanopowder yttrium-alumin-ium garnet [26].

-

• A method of precipitation of composite coating [27];

-

• Porous material on the basis of complex poliester [28];

-

• A method of obtaining nanopowder vanadium trioxide [29];

-

• A method to obtain polymer-composite material and a composite reinforcement [30].

-

• CVD – reactor of rolled type [31]

-

• Hybrid supercondenser on the basis of nanosize nickel hydroxide [32];

-

• Innovation complex of textile technologies used in production of nanofibrous nonwoven fabric [33].

CONCLUSION

One of the most challenging tasks the economy of every country face is to increase industrial competitiveness through technological upgrade. From the side of the state and companies the principal object to control in this process are the people and enterprises dealing with introduction of inventions and new technologies. Therefore, we hope that the information published in this section will be in demand and useful for specialists.

To be continued.

Список литературы Inventions in the area of nanomaterials and nanotechnologies. Part I

- Svintsov А.P., Abbas А.А.N., Galishnikova V.V. Nanomodified building mortar. RF Patent 2759479. 2021-11-15.

- Ananiev M.S., Lyubin P.А., Zakrevskaya L.V. A composition of light self-compacting construction concrete on the basis of cement matrix. RF Patent 2758050. 2021-10-26.

- Khashemadze А., Ze Kh., Asbek P. A method of producing porous moulded article in the form of insulation plaster layer. RF Patent 2721612. 2020-05-21.

- Zaichenko N.М., Khalyushev А.К., Stelmach S.А. et al. A method of cement surface modification. RF Patent 2715276. 2020-02-26.

- Rubstein А.P., Vladimirov А.B., Plotnikov S.А., Rinkevich А.B. Multilayer wear-resistant coating on the steel substrate. RF Patent 2759163. 2021-11-09.

- Mikheev G.M., Kogai V.Y.-S., Styapshin B.М., Mogileva T.N. A method of producing polarization-sensitive nanocomposite film on the basis of copper selenide. RF Patent 2758150-10-26. 2021.

- Novopashin S.А., Maltsev V.А., Moiseenko V.V. A method of obtaining ethenyl wallpapers with bactericidal coating. RF Patent 2758770. 2021-11-01.

- Okhlupin D.N., Korolev А.V., Sinev I.V. etc. A method of obtaining amorphous nanostructured diamond-like coating. RF Patent 2760018. 2021-11-22.

- Osipov А.V., Kucherik А.О., Samyshkin V.D. A method of ordered precipitation of nanostructured carbon thin films in constant electric field. RF Patent 2761200. 2021-12-06.

- Yun Ch., Li C., Jin H. A system producing carbon nanotubes. RF Patent 2760734. 2021-11-30.

- Ivanov LA., Kapustin I.A., Borisova O.N., Pisarenko Zh.V. Nanotechnologies: a review of inventions and utility models. Part II. Nanotechnologies in Construction. 2020, Vol. 12, no. 2, pp. 71–76. DOI: 10.15828/2075-8545-2020-12-2-71-76.

- Kozlova O.V., Smirnova S.V., Odintsova O.I. et al. A method of producing textile material containing nanoand microcapsuled bio-effecting agents with sustained release. RF Patent 2758647. 2021-11-01.

- Akeselsson О., Sansone А. Chemical compounds for covering nanostructures. RF Patent 2757904. 2021-10-22.

- Sivkov А.А., Vympina Yu.N., Nikitin D.S. et al. A device to obtain nanocrystalline titanium dioxide with anatase structure. RF Patent 2759314. 2021-11-11.

- Ivanov L.A., Xu L.D., Bokova E.S., Demenev A.V., Ivanov V.A. Inventions of scientists, engineers and specialists from different countries in the area of nanotechnologies. Part III. Nanotechnologies in Construction. 2021; 13(3): 158–165. Available from: doi: 10.15828/2075-8545-2021-13-3-158-165.

- Khanadeev V.А., Khlebtsov B.N., Khlebtsov N.G. A method of obtaining golden nanocores with specified position of plasmon resonance. RF Patent 2759484. 2021-11-15.

- Gevel Т.А., Zhuk S.I., Vakhromeeva А.Е. et al. A method of electrolytic obtaining silica from melted salts. RF Patent 2760027. 2021-11-22.

- Zhukalin D.А., Dolgikh I.I., Bityutskaya L.А. A method of obtaining nanotubes InSb by electropulse method. RF Patent 2760392. 2021-11-24.

- Ivanov L.A., Xu L.D., Bokova E.S., Ishkov A.D., Muminova S.R. Inventions of scientists, engineers and specialists from different countries in the area of nanotechnologies. Part I. Nanotechnologies in Construction. 2021; 13(1): 23–31. Available from: doi: 10.15828/2075-8545-2021-13-1-23-31.

- Zhuravlev V.V., Gerasimov V.F., Chernyaeva S.О., Eremin S.А. A method of producing thermal conductive composite material from powders of aluminum or its alloy with graphene coating. RF Patent 2760896. 2021-12-01.

- Petrov V.V., Bayan Е.М. A method of obtaining thin films of zinc oxide or tin oxide, combined zinc oxide and tin oxide. RF Patent 2761193. 2021-12-06.

- Denisova К.О., Ilyin А.А., Ilyin А.P. et al. A method of obtaining cobalt ferrite. RF Patent 2761198. 2021-12-06.

- Khasegava N., Yano К., Takesita Т. Mesoporous carbon and a method of producing it as well as fuel cell with polymer electrolyte. RF Patent 2761216. 2021-12-06.

- Ivanov L.A., Xu L.D., Bokova E.S., Ishkov A.D., Muminova S.R. Nanotechnologies: are view of inventions and utility models. Part V. Nanotechnologies in Construction. 2020; 12(6): 331–338. Available from: doi: 10.15828/2075-8545-2020-12-6-331-338.

- Korolev Е.VВ., Shekhovtsova S.Yu. Modifiers for polymer-bituminous binder on the basis of media II Vacuum cut and Extract selective purification residual. RF Patent 2761220. 2021-12-06.

- Abiev R.Sh., Zdravkov А.V., Kudryashov Yu.S. A method of obtaining nanopowder yttrium-aluminium garnet. RF Patent 2761324. 2021-12-07.

- Mamontova Yu.E., Stekolnikov Yu.А. A method of precipitation of composite coating. RF Patent 2761573. 2021-12-10.

- Makinini R.D., Xue Yu. Porous material on the basis of complex polyester. RF Patent 2761619. 2021-12-13.

- Krasilnikov V.N., Gyrdasova О.I. A method of obtaining nanopowder vanadium trioxide. RF Patent 2761849.2021-12-13.

- Ivanov L.A., Xu L.D., Razumeev K.E., Pisarenko Zh.V., Demenev A.V. Inventions of scientists, engineers and specialists from different countries in the area of nanotechnologies. Part VI. Nanotechnologies in Construction. 2021; 13(6): 370–378. https://doi.org/10.15828/2075-8545-2021-13-6-370-378.

- Smovzh D.V., Matochkin P.Е., Bezrukov I.А., Krivenko А.S. CVD – reactor of rolled type. RF Patent 2762700. 2021-12-22.

- Sykchin А.S., Vepreva А.I., Spirov I.V. et al. Hybrid supercondenser on the basis of nanosize nickel hydroxide. RF Patent 2763028. 2021-12-27.

- Budyka А.К., Ekidin А.А., Vasyanovich М.Е. et al. Innovation complex of textile technologies used in production of nanofibrous nonwoven fabric. In: Modern Engineering Problems of Key Industries. International Scientific and Technical Symposium and the III International Kosygin Forum. Moscow; 2021. p. 95–102.