Inventions in the area of nanomaterials and nanotechnologies. Part II

Автор: Ivanov L.A., Xu L.D., Muminova S.R., Feoktistova V.M., Romanova E.V.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Review of nanotechnological inventions

Статья в выпуске: 2 Vol.14, 2022 года.

Бесплатный доступ

Introduction. Advanced technologies impress people’s imagination demonstrating the latest achievements (materials, methods, systems, technologies, devices etc.) that dramatically change the world. This, first of all, concerns nanotechnological inventions designed by scientists, engineers and specialists from different countries. Main part. The article provides an abstract overview of inventions of scientists, engineers and specialists from different countries: Germany, Russia, USA, et al. The results of the creative activity of scientists, engineers and specialists, including inventions in the field of nanotechnology and nanomaterials allow, when introduced to industry, achieving a significant effect in construction, housing and communal services, and related sectors of the economy. For example, the task resolved by the invention «A composition on the basis of oxide nanostructures to provide surface with superhydrophobic properties», means to design a new method of obtaining materials with superhydrophobic properties which possess improved performance and functional characteristics which can be applied in various areas: power engineering, electronics, machine-building, construction, ship-building, aviation, aerospace and food industries. The feature of the invention is that the surfaces demonstrate superhydrophobic properties and, as a result of that, their applying allows protecting metal structures, such as power lines, frame structures, roofs, from ice formation and dirtying. The technical result is possible due to the use of composition on the basis of oxide nanostructures to provide surface with superhydrophobic properties. The composition contains tetraethoxysilane and tetraisopropyl titanate as structure-forming agents, hexamethyldisilazane as hydrophobic element, isopropyl alcohol as dissolvent, non-spheric nanocrystal titanium dioxide with particle size from 10 to 50 nm as a grow accelerator of anisotropic structures to provide specified roughness of the surface. The specialist can be also interested in the following inventions in the area of nanotechnologies: a composite heat-conducting material on the basis of nanoliquid, a nanocomposite material on the basis of potassium titanate, a method of obtaining of nanodispersed powders, hybrid supercondenser on the basis of nanosized nickel hydroxide, etc. Conclusion. One of the most challenging tasks the economy of every country faces is to increase industrial competitiveness through technological upgrade. From the side of the state and companies the principal object to control in this process are the people and enterprises dealing with introduction of inventions and new technologies.

Nanotechnologies in construction, nanocrystal titanium dioxide, nanostructure, nanoliquid, nanodispersed powder, nanosized particle

Короткий адрес: https://sciup.org/142231192

IDR: 142231192 | DOI: 10.15828/2075-8545-2022-14-2-105-112

Текст научной статьи Inventions in the area of nanomaterials and nanotechnologies. Part II

A dvanced technologies impress people’s imagination demonstrating the latest achievements (materials, methods, systems, technologies, devices etc.) that dramatically change the world. This primarily concerns nanotechnological inventions designed by scientists, engineers and specialists from different countries (Germany, Russia, USA, et al.).

MAIN PART

A composition on the basis of oxide nanostructures to provide surface with superhydrophobic properties (RU 2763891 С1)

Due to the change of the climate in the last decades the number of the areas and territories with significant change of temperature has increased. That caused fre-

REVIEW OF NANOTECHNOLOGICAL INVENTIONS quent occurrence of icing and pollution of the articles, structures and facilities of different nature (metal, glass, wooden and other types), for example, power lines, frames, roofs and other. If the freeze is not severe, when winter is mild, the rain or fog drops lodge on the surface of the materials. Freezing, they form dense ice «coat». That can lead, for example, to broken wires and to destroyed electricity pylons.

The formation of water layer on material surface is directly depends on the hydrophilic or hydrophobic properties of the surface. To protect the surface and to increase its wear-resistance it is necessary to provide the surface with hydrophobic or super hydrophobic properties, minimizing the contact between the water and surface of the material. Super hydrophobic property is a unique characteristic of the materials, which appears in total liquid non-wettability of the surface. At present, the first steps towards development of the composition on the basis of oxide nanostructures to provide various surfaces with super hydrophobic properties have been made. These coatings possess specific physical and chemical as well as structural and mechanical properties, therefore, development of the materials with super hydrophobic properties and their practical application is of great importance.

The task resolved by the invention «A composition on the basis of oxide nanostructures to provide surface with super hydrophobic properties», means to design a new method of obtaining materials with super hydrophobic properties which possess improved performance and functional characteristics which can be applied in various areas: power engineering, electronics, machinebuilding, construction, ship-building, aviation, aerospace and food industries. The feature of the invention is that the surfaces demonstrate super hydrophobic properties and, as a result of that, applying of the, allows protecting metal structures, such as power lines, frame structures, roofs, from ice formation and pollution [1].

The technical result is achieved due to the use of composition on the basis of oxide nanostructures to provide surface with super hydrophobic properties. The composition contains tetraethoxysilane and tetraisopropyl titanate as structure-forming agents, hexamethyldisilazane as hydrophobic element, isopropyl alcohol as dissolvent, non-spheric nanocrystal titanium dioxide with particle size from 10 to 50 nm as a grow accelerator of anisotropic structures to provide specified roughness of the surface. The ratio of the components is as follows, in % (mass.): tetraethoxysilane – 1–10, tetraisopropyl titanate – 1–15, hexamethyldisilazane – 2–10, nanocrystalline titanium dioxide – 0,01–1, isopropyl alcohol – the rest.

A composition on the basis of oxide nanostructures used to provide the surface with super hydrophobic properties is different as follows. Nanocrystalline titanium dioxide is introduced into reaction mass to intensify growing process of anisotropic structures to form specified rough- ness of the coating, which provides super hydrophobic properties. This composition is a homogenous transparent liquid with a specific, not strong, smell and aggregative stability in storage process.

A composite heat-conducting material on the basisof nanoliquid (RU 2764219 С1)

Development of energy-packed electronic technologies caused the necessity to create efficient cooling systems and to control large heat flows. One of the ways to intensify heat transfer is to improve thermophysical characteristics of heat carrier. That can be achieved by increasing thermal conductivity by means of introduction of solid particles with high thermal conductivity. At this, along with thermal conductivity other characteristics are changed too. Viscosity of cooling substance is an important characteristic of cooling flow system.

In the process of designing such systems, nanoliquids are of great interest. Nanoliquid is a biphasic medium which consists of liquid and evenly distributed in it nanosize particles of solid phase. A particular feature of nanoliquids is a significant change of thermophysical properties of basic liquid even under small concentration of nanoparticles. At present, the use of nanoliquids as an efficient heat carrier is considered to be a promising method of obtaining new combined heat and power plants, heat energy transferring plants, various microelectromechanical systems, thermal interphase materials (TIM).

The given invention relates to heat-conducting pastes which contain a mixture of synthetic oil, silicone oil and a mixture of heat-conducting fillers. The composite heatconducting material on the basis of nanoliquid can be used as heat carrier to create new combined heat and power plants and thermal interphase materials (TIM). The invention is a multicomponent heterogenic system filled with fine dispersed agglomerates of particles possessing various structure, heat-conducting characteristics, dielectric and mechanic properties under specified quantitative ratio between components as well as technological features of their combination [2].

The task of the invention is to widen the range of operation temperature and to increase thermal conductivity, that means to create heat conducting compound on the basis of nanoliquid. This compound is used for technical products and systems, which operation process requires efficient withdrawal of excessive thermal energy. The compound is to combine the following characteristics: – optimum range of performance temperature for broader application in different electronic devices from 50 to 200 Celsius degrees;

-

– thermal conductivity 9 Watt/(m•К);

– density 3,5 g/cm3;

-

– dynamic viscosity 900 Pa;

-

– service life time 5 years.

REVIEW OF NANOTECHNOLOGICAL INVENTIONS

The study determined the necessary quantity of nanopowder of heat conducting carrier (almost 20%±0,07). At this, the paste possesses geoline-like consistence under normal conditions. If the content of nanopowder of heat conducting carrier in the mixture is more than 20% ±0,07, the paste loses its geoline-like state and acquires crispy structure and becomes unsuitable for applying. The technical result is improved thermal conductivity and dynamic viscosity of obtained material.

A nanocomposite material on the basis of potassium titanate (RU 2766089 С1)

The task of the invention is to obtain a new type of potassium titanate powder which consists of squamous particles of submicron size decorated with nanosize particles of three-component layered double hydroxide. The technical result, obtained when the task is resolved, is the improved complex of trybological properties of potassium titanate powder, that is expressed in decreasing friction coefficient, rising wear-resistance of wearing surfaces and increasing critical load and welding load when using lubricant compositions containing this type of powder as an admixture [3]. The technical result is achieved as follows: in the modified powder of potassium titanate which consists of layered squamous particles of submicron size, the particles of potassium titanate are decorated with nanosized particles of carbonate shape of layered hydroxide containing Cu, Zn and Al, in which mole ratio of the mentioned metals is 1:1:1 with possible deviation in content of each element is not more than by 10%. It is efficiently also to use particles of nanocomposite material that are processed with surface-active substance, for example, non-ionic surface-active substance.

High tribological properties of the particles of nanocomposite material (modified potassium titanate), obtained by means of this method, introduced into wetting agent can be explained by their tribochemical interaction with metal wear surface, that results in formation of modified surface layers preventing from cooling due to their lower thermal conductivity compared to the one of the metal (steel).

Formation of modified layer on the wearing surface of the details in the presence of added particles potassium polythanate / layered double hydroxide, as well as filling surface roughness with them prevent from direct contact of tribointerface of details. All that results in increasing not only antifriction, but also antiwear and antiwelding properties of wetting agents. At this, antiwear properties of synthesized powders of modified potassium polythanate are also determined by their layered structure and low value of friction coefficient. At the same time, tribochemical interaction of potassium polythanate particles with steel surface leads to introduction of titanium into the surface layer of the metal and that increases its microhardness and wear-resistance, similarly to action of the additives of the pure potassium polythanate powder. Alumina in modified powder of potassium polytitanate causes formation of special areas on wearing surfaces. These areas are covered with a film of aluminum oxide, and this film not only increase microhardness (wear-resistance) of steel surface, but also prevents from welding under the load (welding load rises). At the same time, introduction of copper into modified potassium polythanate allows significant improving anti-wear properties of the additives, that directly affects the properties of the copper-containing layers formed on the steel surface in the friction process between the layers. Copper-containing compounds are cladding additives which can form layers with high plasticity and low resistance to shear on the metal surface, all that additionally prevents from welding under high loads. As a result of this, additives of powder of modified potassium polytitanate provide higher anti-wear properties and higher load of welding lubricants on the basis of them.

The invention relates to chemical, automobile, machine engineering and textile industries and can be used in production of antifriction additives to wetting agents for rolling and sliding friction units.

A biocide composition and a method to obtain it(RU 2763930 С1)

The technical result of the invention is to obtain biocide composition for applying it as antimicrobial additive to paints and polymer materials to strengthen antimicrobial effect due to the presence of nanoparticles of zinc oxide in it, that causes damage of bacteria’s protein structure and their destruction [4]. The imposed task is resolved in the following way: the biocide composition consists of nanoparticles of zinc oxide which are homogeneously distributed in the dissolvent and the particular feature is that the size of nanoparticles of zinc oxide is 80±10 nm and the specific surface is 10±2 m2/g, with additional content of nanoparticle stabilizer chosen from the group that comprises polycarboxylate, polyvinyl pyrrolidone, 2-amino-2-methyl-1-propanol, 8-oxyquinoline, phen-anthrolin, dipyridyl or their combination, and the ratio of mass% is as follows:

-

• nanoparticles of ZnO 30–50;

-

• nanoparticle stabilizer 2,0–4,0;

-

• dissolvent 46–68.

To combine biocide composition with a thermoplastic polymer (polymethyl methacrylate and copolymers, polylactide, polyethene of low density, polypropylene, polystyrene and others) a dried composition is used. For that, processed nanoparticles are separated from the dissolvent and are dried in the chamber under the temperature 90–100оC for 5 hours.

At least one substance which acts as the stabilizer in this invention is chosen from the following list:

REVIEW OF NANOTECHNOLOGICAL INVENTIONS polycarboxylate, polyvinyl pyrrolidone, 2-amino-2-methyl-1-propanol, 8-oxyquinoline, phenanthrolin, dipyridyl or their combination. These organic compounds meet the requirement specified for ligands for surface treatment of zinc oxide nanoparticles. They contain atoms of nitrogen and oxygen, the orientation of atoms of nitrogen and oxygen respect to each other is fixed, that determines strong interaction between organic molecule and cation of metal.

The biocide composition which contains from 30 to 50 mass.% zinc oxide nanoparticles keeps sedimentation stability for a long time that is necessary for transportation and use of concentrate. If the content of zinc oxide nanoparticles in the concentrate is less than 30 mass.%, it must be loaded into paint in large quantities, that leads to undesirable dilution of paints or polymer material. If the content of zinc oxide nanoparticles in the concentrate is more than 50 mass.%, ultra sound treatment is not efficient for dispergation of nanoparticles, the average size of particles (nanoparticle aggregations) in concentrate is more than 100 nm. That causes loss of sedimentation stability and decrease od antimicrobial activity of the concentrate.

A method of obtaining nanodispersed powders(RU 2763814 С1)

The invention relates to powder metallurgy, in particular, to obtaining nanodispersed wolframcontaining powders used in production of hard alloys on the basis of wolfram. The technical result is the production of nanodispersed powders containing wolfram or tungsten carbide from articles or wastes made of hard alloys, such as titanotantalovolframocobalt hard alloys, titaniumtungsten-cobalt hard alloys, tungsten-cobalt hard alloys or similar ones, with high technologies or productivity, low energy consumption and possibility to dispose hard alloy wastes. To obtain nanodispersed powder, a universal equipment of simple design, safe and with long operational life is used. Synthesis of nanodispersed powders can be performed under room temperature. The outcome of this process can be high quality nanodispersed powders of wolfram, wolfram carbide, mixture of wolfram and titanium carbides, carbides of wolframe, titanium and tantalum, as well as other compounds that are the basic components of disposed metal wastes [5].

The technical result of the invention is achieved as follows: to obtain wolfram-containing nanodispersed powders, articles and/or wastes of hard alloys are loaded into sealed reactor which angle of slope to spinning axis is from 0 to 90 degree, and dispersing fluid which pH is 1–4 is poured. The dispersing fluid consists of aqueous solution Fe2(SO4)3 with concentration 5–30 g/l, sulphuric acid and microorganisms Thiobacilhts ferwoxidans. Synthesis of nanodispersed powders is carried out with ratio

1:(1–7) between solid and liquid phases, respectively. Reactor continuously rotates with the rate 2–60 rotations per minute under the temperature 16–35оС for 480–600 hours. After that, sludge is allowed to settle, the solution is decanted, the obtained precipitation is washed, dried and sieved.

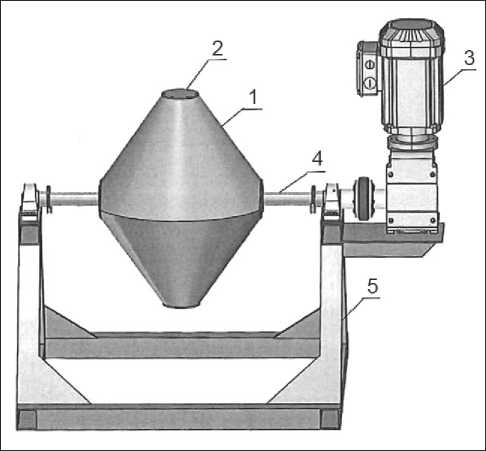

Rotating sealed reactor can be made in the form of drum with round or polyhedral cross-section, in the bicubic, biconic or V-shape form. The figure shows the device for obtaining nanodispersed powders, with working tool in the biconic form (fig. 1). Such alloys as titanotantalovol-framocobalt hard alloys, titanium-tungsten-cobalt hard alloys, tungsten-cobalt hard alloys are used as hard alloys. When the body frame rotates, dispersing fluid, hard alloy articles and and/or wastes are displaced.

Fig. 1. A device for obtaining nanodispersed powders, with working bicone tool: 1 – welded shell of stainless steel in the shape of bicone; 2 – loading system;

3 – engine; 4 – shaft; 5 – foundation slab

A polymer material (RU 2765293 C2)

The invention relates to polymer material used in production of fiber, film or absorbing article; it also concerns fiber, non-woven fabric and absorbing article which comprise mentioned polymer material as well as to the methods of formation of polymer material and fiber. The polymer material contains thermoplastic composition. The composition contains continuous phase which includes matrix polymer and siloxane component. The siloxane component contains super high molecular siloxane polymer which is dispergated in the continuous phase in the form of descrete domains. There is a pore network with numerous nanopores in the thermoplastic composition. The siloxane component is characterized by

REVIEW OF NANOTECHNOLOGICAL INVENTIONS weight-average molecular weight which is approximately 100 000 g/mole or more. Matrix polymer includes a complex polyester or polyolefine. The technical result is the improved porous polymer material [6].

According to one of the options of the present invention, a polymer material (for example, fiber, fiber, molded product) with thermoplastic composition is described. The composition contains continuous phase which comprises matrix polymer and siloxane component. The siloxane component contains super high molecular siloxane polymer which is dispergated in the continuous phase in the form of discrete domains. There is a pore network with numerous nanopores in the thermoplastic composition.

In general, the present invention is aimed at polymer material (for example, fiber, fiber, molded product, etc.) which is formed by drawing-out thermoplastic composition (for example, drawing-out in solid state) that contains continuous phase which included matrix polymer and siloxane component. Siloxane component contains, at least, one super high molecular siloxane polymer which is due to its molecular weight and viscosity can be dispergated in continuous phase in the form of discrete nanosize phase domains. Moreover, despite of its high molecular weight and viscosity, the chain of siloxane polymer can remain flexible and possess free volume, that means, it can be in relatively soft state, like liquid one. Siloxane polymer is also hydrophobic, that can minimize friction on the interface of matrix polymer. Moreover, due to its chemical structure and free volume, siloxane polymer can be characterized by relatively low bond strength and can easily form voids under mechanical impacts and deformation.

Hybrid supercondenser on the basis of nanosize nickel hydroxide (RU 2763028 С1)

The technical solution is related to electric engineering and electrochemistry. It can be applied in portable electronics, as starter of automobile, in uninterruptible power supplies, flash-lights, medicine equipment. Nickel hydroxide, among metal hydroxides, is a widely used material for accumulator and super condensers due to its multi-layer structure with large interlayer distance and relative safety for environment, high theoretical capacity, perfect electrochemical properties, stability, low cost and availability. To increase specific capacity, various methods of synthesis are used. Highly porous structure and high specific area of the surface improve electrochemical properties due to faster and easier diffusion of electrolyte on the active segments and more frequent use of the mass. There are methods to control the properties of obtained hydroxide, such as change of its structure in synthesis, as well as dopping it with various additives (cobalt, aluminum, zinc, etc.). That makes it possible to significantly improve properties of obtained hydroxide and its electrochemical capacity.

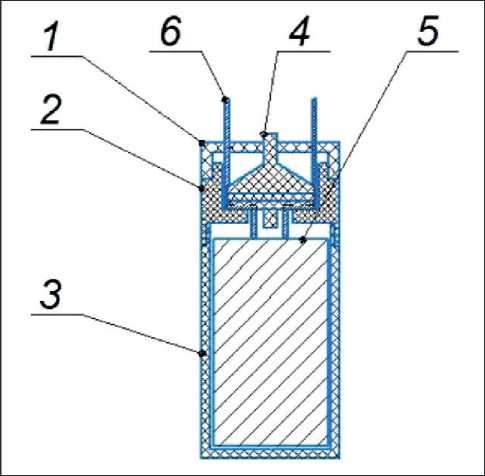

The technical result of the invention is achieved as follows: hybrid supercondenser on the basis of nanosize nickel hydroxide consists of plastic frame (fig. 2) which includes a cap, a holder of valve and a glass in which two electrodes are placed, at this, one electrode is made of nanocarbon material, another electrode is made of nickel hydroxide, rolled and divided by separator; two foam nickel substrates, to each substrate a nickel conductor is welded; a valve for discharging excessive pressure of emitted gases is in the frame; at this, 30% solution of potassium hydroxide, dissolved in water, is poured into frame [7].

A cap 1, a holder of valve 2 and a glass 3 are printed in 3D printer from acryl-butadiene-styrene plastic, which is resistant to alkali. These details being assembled is a frame of hybrid super condenser. a valve for discharging excessive pressure 4 is a mass-produces valve, model 7HH1103383-3. It is used in super condenser to aggregate excessive pressure of the gases emitted in the process of degrading of aqueous electrolyte if current or resistant exceed limit values, as well as in case of excessive overcharge. Rolled block of electrodes 5 is a system of two electrodes, for each of them electrochemically activated foam nickel is used as a substrate. The first electrode is made of carbon nanomaterial, for example, from “Taunit-M”. The second electrode is made of nickel hydroxide with high specific surface and stable particles. The nickel conductor 6 is welded to foam nickel substrate. The technical result of the proposed invention is the increased capacity characteristics of the hybrid super condenser.

Fig. 2. Hybrid supercondenser on the basis of nanosize nickel hydroxide: 1 – cap; 2 – holder of valve; 3 – glass;

4 – a valve for discharge of excessive pressure;

5 – rolled block of electrodes; 6 – nickel conductor

REVIEW OF NANOTECHNOLOGICAL INVENTIONS

A method of obtaining tungstenless hard-alloy powder materials in distilled water (RU 2763431 С1)

The invention relates to powder metallurgy, in particular to compositions and methods of obtaining tungstenless hard-alloy powder, and can be used to produce sintered bodies, to apply wear-resistant coatings to restore and strengthen details of the equipment employed in mining and metallurgical industry and details of vehicles [8].

A method of obtaining tungstenless hard-alloy powder of micro- and nanosize spherical powders from the wastes of tungstenless hard-alloys comprises electroerosive dis-pergating of the wastes of hard-alloys. Electroerosive dis-pergating is performed in distilled water of the wastes of tungstenless hard-alloy of grade КНТ-16 under impulse sequence frequency 100–105 Hz, voltage on electrodes 200–205 V and capacity of the condensers 65,5 µF. After that, the obtained solution which contains micro-, nano- and coarse size powder is centrifuged to separate coarse powder from it. Then the solution which contains micro- and nanosize powder is evaporated and obtained micro- and nanosize powder is dried. That provides ecologically friendly process of obtaining tungstenless hard-alloy powder.

The first stage consists of sorting wastes of tungstenless hard-alloys, their washing, drying, oil removing and weighing. The reactor was filled with processing medium – distilled water – wastes were loaded into reactor. Electrodes were assembled. Installed electrodes were connected to the generator. The required parameters of the process were set: impulse sequence frequency, voltage on electrodes, capacity of condensers.

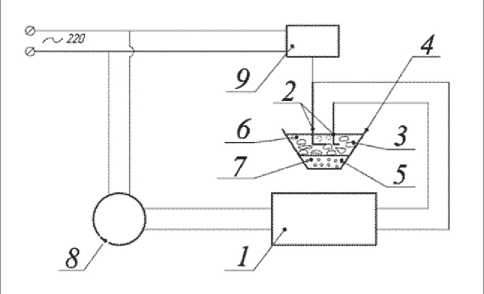

At the second stage – the stage of electroerosive dis-pergating (EED) – the installation was launched (fig. 3). Impulse voltage of the generator 1 is applied to electrodes 2 and then to the wastes 3 (the wastes of tungstenless hard-alloy of grade КНТ-16 were also used as electrodes) in the reactor 4. When the voltage reaches the specified value, electric breakdown emerges in processing medium 5, it is in interelectrode space, the channel of discharge is formed. Due to high concentration of thermal energy, material melts and evaporates at the point of discharge, processing medium evaporates and extends around the channel of discharge with gas products of degradation (gas bubble 6). Due to dynamic forces, increasing in the discharge channel and gas bubble, the drops of melted metal are ejected out of discharge zone into processing medium, surrounding electrodes, and set solid in it, forming droplet particles of the powder 7. The voltage regulator 8 is used to set required voltage values and the rapper 9 shift one electrode, that provides continuous running of EED process.

At the third stage processing liquid with powder material is extracted from the reactor, fine dispersed particles are separated from the coarse dispersed ones in centrifuge.

At this, coarse particles are sedimented under the impact of centrifugal forces, and fine dispersed particles remain the solution.

At the fourth stage the solution is evaporated, dried, weighed, prepacked, packed with further examination of obtained powder material.

The achieved technical result is as follows: obtaining powder materials from wastes of tungstenless hard-alloy with regular spherical particles by means of electroerosive dispergating (EED) which process is characterized by low power consumption and ecological cleanness.

Fig.3. Process of electroerosive dispergating:

1 – generator; 2 – electrodes; 3 – wastes; 4 – reactor;

5 – processing medium; 6 – channel of discharge;

7 – droplet particles of the powder; 8 – voltage regulator; 9 – rapper

The specialists can also be interested in the following inventions related to nanotechnologies:

-

• Nanomodified building mortar [9].

-

• An undercoat composition for creation of light conductive coating of the detail prior to electrostatic painting, a method of preparing undercoat composition and undercoat [10].

-

• A method of processing the surface of non-ferrous metal by forming microrelief [11].

-

• A method to obtain amorphous nanostructures diamond-like coating [12].

-

• A method of electrochemical obtaining nanosize graphite plates. [13].

-

• A method of combined treatment of channels of complex shape and a device to perform it [14].

-

• A method to modify concrete with complex additive which includes hydrothermal nanoparticles SiO2 and multilayer carbon nanotubes [15].

-

• A sol with the content of titanium dioxide, a method to obtain it and the products made of it [16].

-

• Optically transparent luminous nanostructured ceramic material [17].

REVIEW OF NANOTECHNOLOGICAL INVENTIONS

-

• Ferroelectric nanocomposite on the basis of porous glass and monopotassium phosphate materials [18].

-

• A field-emission emitter with nanocrystal diamond film [19].

-

• Multifunctional nanostructured additive for coatings [20].

-

• A porous material on the basis of polyester [21].

-

• A method of precipitation of composite coating [22].

-

• Low-temperature ecology-friendly viscous lubrication and a method to produce it [23].

CONCLUSION

One of the most challenging tasks the economy of every country face is to increase industrial competitiveness through technological upgrade. From the side of the state and companies the principal object to control in this process are the people and enterprises dealing with introduction of inventions and new technologies. Therefore, we hope that the information published in this section will be in demand and useful for specialists.

To be continued.

Список литературы Inventions in the area of nanomaterials and nanotechnologies. Part II

- Snezhkova Yu.Yu., Blinov А.V., Golik А.B. et al. A composition on the basis of oxide nanostructures to provide surface with superhydrophobic properties. RF Patent 2763891. 2022-01-11.

- Vinogradova P.V., Manzhula I.S. A composite heat-conducting material on the basis of nanoliquid. RF Patent 2764219. 2022-01-14.

- Tsyganov А.R., Gorokhovsky А.V. A nanocomposite material on the basis of potassium titanate. RF Patent 2766089. 2022-02-07.

- Mikheev V.E., Vorozhtsov А.B., Lerner M.I. et al. A biocide composition and a method to obtain it. RF Patent 2763930. 2022-01-11.

- Vishnyakov S.R., Gavrish V.M., Vinogradsky S.S., Khikmatulloev R.I. A method of obtaining nanodispersed powders. RF Patent 2763814. 2022-01-11.

- Makinini R.D., Galabura Yu., Carriglio О., Antonio Kh. at al. Polymer material. RF Patent 2765293. 2022-01-28.

- Sykchin А.S., Vepreva А.I., Spirov I.V. et al. Hybrid supercondenser on the basis of nanosize nickel hydroxide. RF Patent 2763028. 2021-12-27.

- Ageev Е.V., Ageeva Е.V., Sabelnikov B.N. A method of obtaining tungstenless hard-alloy powder materials in distilled water. RF Patent 2763431. 2022-12-29.

- Ivanov L.A., Xu L.D., Bokova E.S., Ishkov A.D., Borisova O.N. Inventions in the area of nanomaterials and nanotechnologies. Part I. Nanotechnologies in Construction. 2022; 14(1): 18-26. https://doi.org/10.15828/2075-8545-2022-14-1-18-26.10.

- Predtechensky M.R., Chebochakov D.S., Shilyaev G.Е. An undercoat composition for creation of light conductive coating of the detail prior to electrostatic painting, a method of preparing undercoat composition and undercoat. RF Patent 2765132. 2022-01-25.

- Zheleznov V.Yu., Malinsky T.V., Mikolutsky S.I. et al. A method of processing the surface of non-ferrous metal by forming microrelief. RF Patent 2764777. 2022-01-21.

- Ivanov L.A., Xu L.D., Razumeev K.E., Pisarenko Zh.V., Demenev A.V. Inventions of scientists, engineers and specialists from different countries in the area of nanotechnologies. Part VI. Nanotechnologies in Construction. 2021; 13(6): 370–378. https://doi.org/10.15828/2075-8545-2021-13-6-370-378.13.

- Rukhov А.V., Bakunin Е.S., Obraztsova Е.Yu. et al. A method of electrochemical obtaining nanosize graphite plates. RF Patent 2763535. 2021-12-30.

- Trifanov I.V., Melkozerov M.G., Trifanov V.I. A method of combined treatment of channels of complex shape and a device to perform it. RF Patent 2764538. 2022-01-18.

- Ivanov L.A., Xu L.D., Pisarenko Zh.V., Nguyen C.T., Muminova S.R. Inventions of scientists, engineers and specialists from different countries in the area of nanotechnologies. Part IV. Nanotechnologies in Construction. 2021; 13(4): 242–251. Available from: https://doi.org/10.15828/2075-8545-2021-13-4-242-251.

- Bekker R., Tide Т., Galbarchik N., Bohnen Z. A sol with the content of titanium dioxide, a method to obtain it and the products made of it. RF Patent 2763729. 2021-12-30.

- Kiryakov А.N., Zatsepin А.F., Dyachkova Т.V., Tyutyunnik А.P. Optically transparent luminous nanostructured ceramic material. RF Patent 2763148. 2021-07-05.

- Ivanov L.A., Xu L.D., Bokova E.S., Ishkov A.D., Muminova S.R. Inventions of scientists, engineers and specialists from different countries in the area of nanotechnologies. Part I. Nanotechnologies in Construction. 2021; 13(1): 23–31. Available from: https://doi.org/10.15828/2075-8545-2020-13-1-23-31.

- Vikharev А.L., Ivanov О.А., Yashanin I.B. A field-emission emitter with nanocrystal diamond film. RF Patent 2763046. 2021-12-27.

- Ivanov L.A., Xu L.D., Bokova E.S., Ishkov A.D., Muminova S.R. Nanotechnologies: are view of inventions and utility models. Part V. Nanotechnologies in Construction. 2020; 12(6): 331–338. Available from: https://doi.org/10.15828/2075-8545-2020-12-6-331-338.

- Makinini R.G., Xue Yu. A porous material on the basis of polyester. RF Patent 2761619. 2021-12-13.

- Mamontova Yu.Е., Stekolnikov Yu.А. A method of precipitation of composite coating. RF Patent 2761573.2021-03-01.

- Tonkonogov B.P., Kilyakova А.Yu., Safieva R.Z. et al. Low-temperature ecology-friendly viscous lubrication and a method to produce it. RF Patent 2713451. 2020-02-05.