Inventions in the area of nanomaterials and nanotechnologies. Part III

Автор: Leonid A. Ivanov, Li D. Xu, Svetlana R. Muminova, Aleksandr D. Ishkov, Aleksey V. Demenev

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Review of nanotechnological inventions

Статья в выпуске: 6 Vol.14, 2022 года.

Бесплатный доступ

Introduction. Advanced technologies inspire people by demonstrating the latest achievements (materials, methods, systems, technologies, devices etc.) that dramatically change the world. This, first of all, concerns nanotechnological inventions designed by scientists, engineers and specialists from different countries. Main part. The article provides an abstract overview of inventions of scientists, engineers and specialists from different countries: Russia, USA, Turkmenistan, Japan et al. The results of the creative activity of scientists, engineers and specialists, including inventions in the field of nanotechnology and nanomaterials allow, when introduced to industry, achieving a significant effect in construction, housing and communal services, and related sectors of the economy. For example, the invention «Modifying additive» is related to the road construction and can be applied in production of asphalt-concrete, including that with utilizing of nanotechnologies. To improve performance characteristics of bitumen and asphalt concrete one can use modifying additive which comprises a mix of carbon nanomaterials. The aim of the invention is to solve the task of creating new technology which could provide obtaining of asphalt concrete with enhanced performance characteristics. The following inventions in the field of nanotechnology can also be interesting for specialists: a method to obtain multi-layered nanocomposite coating; a method of laser surface treatment for steel products; a device to obtain graphene-containing suspension; a method to obtain nanocrystal silicon powder; a self-cleaning material with chemical and biological protection properties; a method of obtaining nanostructured composite material on the basis of aluminum; a device control system with the shape memory effect to manipulate micro- and nanoobjects; a method to form plasmon nanostructures on the object surfaces to provide non-destructive analysis of low concentrations of chemical compounds by Raman spectroscopy et al. Conclusion. One of the most challenging tasks the economy of every country face is to increase industrial competitiveness through technological upgrade. From the side of the state and companies the principal object to control in this process are the people and enterprises dealing with introduction of inventions and new technologies.

Nanotechnologies in construction, nanocomposite coating, nanocrystal powder, nanostructured composite material, nanoobject

Короткий адрес: https://sciup.org/142235786

IDR: 142235786 | DOI: 10.15828/2075-8545-2022-14-6-466-474

Текст научной статьи Inventions in the area of nanomaterials and nanotechnologies. Part III

Review article

Advanced technologies impress people’s imagination demonstrating the latest achievements (materials, methods, systems, technologies, devices etc.) that dramatically change the world. This primarily concerns nanotechnological inventions designed by scientists, engineers and specialists from different countries (Russia, USA, Ukraine, Turkmenistan, Japan et al.).

REVIEW OF NANOTECHNOLOGICAL INVENTIONS

MAIN PART

A modifying additive (RU 2781192 С1)

Road carpet is considered to be a cost-consuming and complex engineering project in both construction and maintenance processes. The most relevant problem is still a task to design an optimum asphalt binder along with granulometric crushed agent composition from a perspective of performance characteristics of final road carpet.

Asphalt binders, even those designed according to existing state standards, are not always capable to provide required inter-repair period of bitumen-concrete mixture. It is the lack of proper quality of bitumen-concrete mixtures that is the main cause of low durability of asphaltconcrete (fragility in the temperature range lower –20oC in combination with strong softening in the range above 50oC).

To meet real requirements of climate conditions of environment and car traffic it is necessary to use various additives and modifiers in composition of asphalt binders. The additives on the basis of styrene-butadiene-styrene (SBS) are often employed as such modifiers.

To improve performance characteristics of bitumen and asphalt concrete it is proposed to use modifying additive which comprises a mix of carbon nanomaterials. The scope of the invention is to solve the task of creating new technology which could provide obtaining of asphalt concrete with enhanced performance characteristics [1].

The imposed task is resolved in the following way: a modifying additive comprises a mix of carbon nanomaterials which are distributed in the matrix of oil extract of grade А and include single-layer carbon nanotubes, multi-layered carbon nanotubes, graphene and carbon nanofibers at the following component ratio, mass.%:

– single-layer carbon nanotubes – 0.01 – 7.5%,

– multi-layered carbon nanotubes – 0.01 – 7.5%,

– graphene – 0.01 – 7.5%,

– carbon nanofibers – 0.01 – 7.5%,

– oil extract – the rest.

Single-layer carbon nanotubes, multi-layered carbon nanotubes, graphene and carbon nanofibers can be of any grade and any manufacturer. The additive is obtained when carbon nanomaterial is introduced into oil extract of grade A on three-roller grinding mill with heat transfer by heat-carrier. The obtained product is a plastic mass.

The technical result is the additive which enhances performance characteristics of road asphalt and asphalt concrete. The invention is related to road construction and can be applied in production of asphalt-concrete, including that with employment of nanotechnologies.

A device to obtain graphene-containing suspension (RU 2777632 С1)

The invention is related to the technology of obtaining graphene-containing suspensions by shear graphite exfoliation in liquid and can be used in various industries in the processes of modification of plastic lubricants, epoxy resins and concretes with graphite. The technical task of the given invention is to increase efficiency of graphite exfoliation and to rise the degree of conversion from graphite into graphene [2].

The imposed task is resolved in the following way: the device contains a stator in the form of cylindrical shell with holes for supplying and drawing suspension and a rotor with blades. The length of the rotor is divided into N sections and the blades at each further section on the circle are shifted in respect to the blades at a certain angle, at this, along the length of the rotor between the blades of neighbor sections there is a gap, which size is 5-10 mm.

The efficiency of the proposed method and the device for its implementation has been tested by comparing with the prototype. The prototype was a device built according the patent RF №2737925 with inner diameter of the stator 42 mm and the length 180 mm. The rotor possesses four radial slots in which feathering blades are located. The dimension of the proposed device is the same, but the rotor along the length is divided into three sections, the length of each section is 54 mm. The distance between the sections is 5 mm, and the distance between end blades and end walls is 4 mm. At each section the blades are rotated respect to the blades at previous section at the angle ϕ = 30o, calculated by formula. For each test series the initial suspension with graphite concentration from 10 to 20% in volume 10 liters was prepared. The suspension was supplied into the device with the pump which performance was from 2 to 4 liters per minute. After every 5 treatment cycles a concentration of graphene plates in suspension was measured. It was found out that the intensity of exfoliation process when using the proposed method and the device is about by 10% higher than that of the prototype. Moreover, by 10–15% more particles of graphite were converted into graphene plates.

A method of laser surface treatment for steel products (RU 2777793 С1)

The invention is related to hardening and enhancing of mechanical properties and increasing resistance to various types of wearing of steel articles and it can be applied in many machinery industries. The technical result is performance of the process of hardening steel articles without additional treatment and additional equipment, with possibility to control the extent of hardening [3].

The technical result is achieved due to the fact that the method of laser treatment of surface of steel articles

REVIEW OF NANOTECHNOLOGICAL INVENTIONS comprises laser impact on the surface of steel articles. This laser impact is performed with technological laser complex equipped with ytterbium impulse fiber laser with power density 108–109 W/cm2, pulse duration from 50 to 200 nanoseconds with pulse repetition time 20 kHz, at this, stacking of laser spots is more 97%. This method of treatment of steel articles provides narrow deep (50–70 µm, up to 600 µm) zones of remelted material with hardness 720 HV (for steel 45) and 1150 HV (for steel 40Х).

The advantage of the proposed method is localization of its impact, possibility to apply treatment in hard-to-reach places at significant distance. All that results in deep “knife” fusion penetration of metal, without necessity to expose the article to mechanical treatment later. Thus, the laser systems, equipped with fiber lasers which impulse duration is tens-hundreds of nanoseconds, make it possible not only to perform engraving and labeling of article surface but also to impact on near-surface zone of material, changing the properties of the whole article.

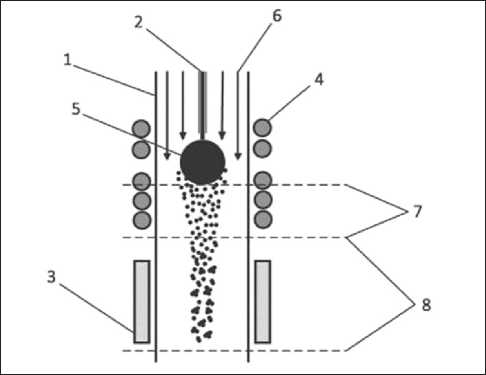

The imposed task is resolved in the following way: the method to obtain nanocrystal silicon powder is designed to be implemented in the reactor with vertical orientation in which counterflow inductor is located. There is an ohmic heater under the counterflow inductor. A monocrystal silicon bar with the spherical seed at its end is immersed from the top in the heater and silicon is preheated to rise its electric conductivity. After that, preliminary heated seed is placed in high-frequency field of counterflow inductor and silicon is heated in high-frequency field up to melting temperature. Melted drop is suspended in the levitation condition between waps of the inductor and is vapored in continuous laminar flow of gas-carrier. The transfer of atomic vapor to the condensation zone, and then to the cooling zone with further accumulation in the filter is provided by the same flow of gas-carrier. Compensation of the vapored drop is performed due to continuous supply of monocrystal silicon bar.

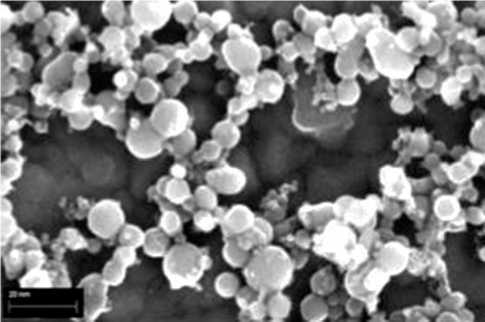

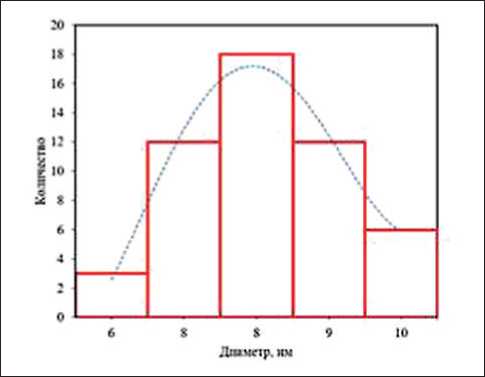

The implementation of the proposed method to obtain nanocrystal silicon powder is shown on the figures 1–3.

A method to obtain nanocrystal silicon powder (RU 2777468 С1)

The invention is related to the area of nanotechnology and nanomaterials, in particularly, to obtaining nanosized silicon powders by means of gas-phase method and it can be used in production of lithium-ion batteries, solar panels and lacquer coatings [4].

The technical problem of the given invention is to obtain nanocrystal silicon powder which average size of particles is less than 20 nm in continuous mode by means of ecology-friendly method with high performance and possibility to control the average size of particles.

Fig. 2. The image made by scanning electric microscopy of obtained nanocrystal silicon particles

Fig. 3. Distribution of nanocrystal silicon particles by size

Fig. 1. Structure diagram for the proposed method to obtain nanocrystal silicon powder: 1 – reactor; 2 – monocrystal silicon bar; 3 – ohmic heater; 4 – counterflow inductor; 5 – a drop of melted silicon; 6 – laminar flow of gas-carrier; 7 – condensation zone; 8 – cooling zone

REVIEW OF NANOTECHNOLOGICAL INVENTIONS

A self-cleaning material with chemical and biological protection properties (RU 2780376 С2)

The invention is related to self-cleaning materials with chemical and biological protection properties, the efficiency of which is based on combined action of hydrolytic properties of ferment nanoparticles that are stabilized by bacitracin and possess antimicrobial effect, and tantalum oxide nanoparticles with biocide properties which are used as modifiers of tissue and non-tissue materials [5]. Self-cleaning material is aimed at protecting against mycotoxins and toxic organophosphorus compounds (OPC) as well as against the cells of different microorganisms (bacteria, false yeasts and spores of filamentous fungi) and can be used in production of environment protection means, high-efficiency wear of personal and collective protection including those available for massive protection in emergency situations (disasters and terroristic attacks), in production of protection apparels, masks and other options of articles to be applied in manufacturing (industrial and agricultural) conditions.

Self-cleaning material with chemical and biological protection properties are aimed at preventing human body from contact damages caused by chemical and biological contaminants. If these contaminants get into the material, detoxification and self-cleaning processes run due to initiation of functional activity of the components which the basic material (tissue or non-tissue basis) was modified by.

The efficiency of activity of self-cleaning material with chemical and biological protection properties is determined by the range of their functioning respect to toxins and cells of microorganisms, efficiency of detoxification under minimum number of elements that are introduced in tissue or non-tissue material to modify it and its properties in the proper way.

The proposed invention is characterized by:

– simplified composition of the self-cleaning material, since there is no specially introduced stabilizing component for the ferment as the applied antibiotic acts as stabilizer.

– significant widening of substances which can be exposed to detoxification;

– unified composition of the material, which can be used to protect against many types of microorganism cells and self-cleaning from them for the time which is less than that of prototype (the prototype’s time is 24 hour) etc.

A method of cohesive hardening of bitumen(RU 2781584 С2)

The invention is related to road construction materials on the basis of bitumen – road concrete mixes, in particularly, to the method of cohesive hardening of bi- tumen. The method is performed by introducing carbon scaffold structures into bitumen under the temperature of its processing, at this, intercalated graphite taken in quantity at least 2.5% of bitumen weight acts as scaffold structure. The technical result of the proposed invention is cohesive hardening of bitumen by means of intercalated graphite. That simplifies manufacturing technology of road concrete miх (for example, there is no need to prepare modified bitumen by ultrasound mixers) and provides evident reliable binding bitumen molecules into polymer product [6].

Widely applied technique to enhance strength-cohesive parameters of bitumen is to add high-molecular polymer: comparatively short length of bitumen molecules (500–6000 Daltons), keeping its basic properties – water resistance and lability which determines adsorbing capacity to the fillers – are reinforced by embedded long molecules of high-molecular polymers, thus making the system relaxing, i.e. withstanding tensile and compressive loads. As a rule, the quantity of introduced polymers is about 10 mass.% of bitumen.

Another way to increase the strength of bitumen compositions (that doesn’t exclude the first one) is to use, mainly, anisometric fillers. At this, the fillers are added in comparatively large amount – up to 40% of composition volume.

The proposed invention involves using intercalated graphite (IG) for cohesive hardening of bitumen. IG is added by simple mixing in dissolver or in mixing device of any design. When preparing the mix, it is heated up to the temperature about 180–200oС being mixing. IG starts blowing up, decomposing in layers, that strongly affects mixing process. The layers by their surface electrons bind proton-donor ingredients of common bitumen composition, for example, carboxylic groups which are contained in asphaltene fraction. Besides of this, unconditional presence of even small amount of water makes it possible to join electron-donor molecules which are contained in bitumen tar fraction and which contain atoms of oxygen, nitrogen, sulfur. Some authors consider (and explain!) the activity of carbon nanobodies as well as IG by the presence of labile electrons on the surfaces of these substances (that is true), regarding these additives to be the catalysts of red-ox transitions.

A method of obtaining multi-layered nanocomposite coating (RU 2780078 С1)

The invention is related to the methods of applying multilayered coatings with synergetic effect of the layers with physical and mechanical properties and nanocomposite anti-corrosion top layer and can be used in machinery, mining- and oil industries, in tool-making and repairs manufacturing for strengthening substrate in the form of machine parts, friction pairs and cutting tool, it

REVIEW OF NANOTECHNOLOGICAL INVENTIONS also can be used to increase their thermodynamic stability when processing materials with low thermal conductivity and high friction coefficient [7].

The advantage of the proposed method is that it reliably allows obtaining specified composition, structure and complex of properties of the coating for each layer. The method makes it possible to control structure formation, phase and element composition of formed layers by changing basic technological precipitation parameters.

The claimed technological modes allow obtaining multifunctional coating with synergetic effect of sublayer TiN, layers TiAlN and TiAlSiN with physical and mechanical properties and anticorrosion characteristic of nanocomposite top layer, as well as high adhesive strength of coating with substrate material.

The test results demonstrate that the proposed coating obtained with this method possesses high physicom-echanical, trybological, anticorrosion properties and high adhesive strength of coating with substrate material.

Spintronic detector of terahertz oscillations on the basis of nanoheterostructure antiferromagnetic – high-density metal (RU 2781081 С1)

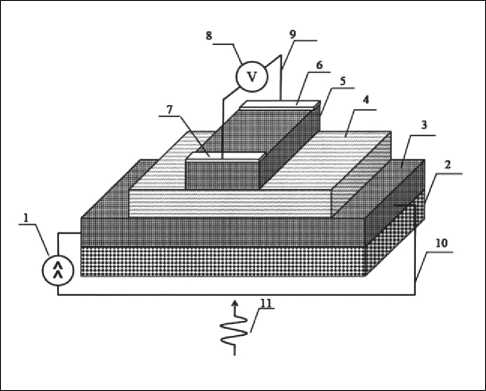

The invention is related to measurement technique and concerns detector of terahertz oscillations. The detector contains a substrate which is transparent for radiation, one surface of it is open for radiation detection and another one comprises heterostructure based on a layer of ferromagnetic material, the first layer of non-magnetic metal and receiving electrodes [8]. Additionally, the second layer of non-magnetic metal was introduced, this layer is between the substrate and the layer of antiferromagnetic material. Antiferromagnetic material is a mono-axial conductive metal antiferromagnetic with light axis of anisotropy and it contains current leads to pass static current in the layer surface to change detector frequency. The receiving electrodes are located on the surface of the first layer of non-magnetic metal and are oriented perpendicular to current flow on the layer of anti-ferromagnetic material. The technical result is the possibility to change detector frequency.

The fig. 4 demonstrates the scheme of the device detecting terahertz oscillations that contains multilayer heterostructure comprising sequentially located on the substrate 2 the first layer of platinum 3, the layer of antiferromagnetic 4, the second layer of platinum 5 and the electrodes 6 and 7. The current lead 9 connects the second layer of platinum 5 and the electrodes 6 and 7 with voltage meter 8. The first layer of platinum 3 is connected to the source of static current 1 by means of the current lead 10. The layer of antiferromagnetic 4 is to be made of mono-axial conductive metal antiferromagnetic with light axis of anisotropy, for example, IrMn. The invention can be

Fig. 4. The scheme of the device detecting terahertz oscillations realized on the basis of existing materials and technologies of nano- and microelectronics.

A method of obtaining nanostructured composite material on the basis of aluminum

(RU 2780728 С1)

The drawback of existing method used to produce aluminum composite is that carbon nanotubes are insufficiently evenly distributed in the volume of aluminum matrix, at the same time, nanotubes partially destroy and become amorphous when obtaining aluminum composite.

The supposed invention refers to the method of obtaining nanostructured composite material on the basis of aluminum, modified with carbon nanotubes, with enhanced physical and mechanical properties that can be used as construction material for machinery and aerospace industries [9].

The technical result is the enhanced properties: microhardness, tensile strength, compressive strength and bending resistance. All that expands opportunities to use the material in machinery and aerospace industries.

The proposed method of obtaining nanostructured composite material on the basis of aluminum is performed in the following way. At the first stage the components of the initial charged material are batched up: quantity of aluminum powder and cetyl acetic acid is 0.6 weight% and quantity of carbon nanotubes is 1.5–1.9 weight.%. After that, the obtained mix is processed for 190 minutes in attritor, rotation rate is 390 cycles per minute. At the next stage the metal block is pressed under the temperature 20oС and pressure 430 MPa. At the conclusive stage hot pressing is performed under the temperature 545oС and pressure 610 MPa.

REVIEW OF NANOTECHNOLOGICAL INVENTIONS

A method to form plasmon nanostructures on the object surfaces to provide non-destructive analysis of low concentrations of chemical compounds by Raman spectroscopy (RU 2780404 С1)

The result which is the aim of the given invention achieves high sensitivity of the method of surface-enhanced combinational scattering and the simultaneous provision of the opportunity to remove plasmon nanostructures from the object surface without its damage. All that makes the proposed analysis method nondestructive.

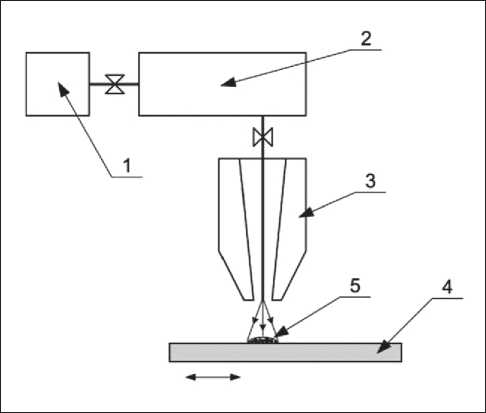

The essence of the invention is as follows. Formation of plasmon structures on the object surfaces for nondestructive analysis of small concentrations of chemical compounds in objects by means of Raman spectroscopy consists of the following stages: obtaining flow of aerosol with nanoparticles in the transport gas flow, heating of aerosol with nanoparticles in the transport gas flow to obtain spherical nanoparticles of specified size from metals, transportation of the obtained flow of aerosol with nanoparticles to the head with the nozzle, focusing of the flow of nanoparticle aerosol with the nozzle, precipitation of nanoparticles from focused flow of aerosol on the surface of analyzed object. The feature of the given method is that it employs non-sintered dry particles, free of solvents, binders and other admixtures, obtained from plasmon-active metals with unit sizes that provide local strengthening of electromagnetic field of the probing laser radiation of Raman spectrometer, at this precipitation of nanoparticles on the surface of the analyzed object is per-

Fig. 5. The principal scheme of formation of plasmon nanostructures on object surfaces: 1 – source of flow of aerosol nanoparticles; 2 – unit of nanoparticle optimization; 3 – focusing head of the nozzle; 4 – analyzed object; 5 – plasmon nanostructure formed with low rate to provide sufficiently weak fixation of nanoparticles to the object surface in order to remove them later without damaging the object (for example, by blowing by inert gas flow) and provide partial coverage of micro zone to be measured on the object surface with a monolayer of particles to maximize the range of surface-strengthened combinational scattering. The technical result: obtained possibility to form plasmon nanostructures on the object surface that allow performimg the method of surface-strengthened combinational scattering with high sensitivity and simultaneously to provide possibility for further removing plasmon nanostructures from the object surface without its damaging, all that makes the given method non-destructive [10]. The principal scheme of formation of plasmon nanostructures on object surfaces is shown on fig. 5.

A device control system with the shape memory effect to manipulate micro- and nanoobjects

(RU 2778525 С1)

The invention is related to a device control system with the shape memory effect (SME) to manipulate micro- and nanoobjects. The scope of the proposed invention is to enhance quality and nanomanipulation process technology by minimizing heat drift of manipulation device (nanonippers) under its thermal activation, that results in decreased inaccuracy of manipulation process as well as in reduced consumption of current and increased its fast operation speed and its performance in general [11].

The imposed tasks are achieved in the following way. The device control system with SME to manipulate micro- and nanoobjects includes microwire, at the conical end of which (cutting grinding of it is done by electrochemical corrosion) there is a device with SME to manipulate micro- and nanoobjects and an operating field with manipulated object and a heating source. The base of the wire is fixed on the nanopositioner, and the heating source is a small-sized resistive heating element which has thermal contact with microwire near its end, and electronic system of power supply and control over the current running through resistive element, there are also leading wires connecting resistive element with electronic system of power supply and current control. The shape of the microwire end is variable, it is a combination of geometrical shapes – blanted cone, cylinder with diameter less than that of wire bottom and a cone, at the top of which there is the device with SME to manipulate micro- and nanoobjects and the heating element is on the surface of the cylinder with smaller diameter very close to the cone (diameter of cylindric part of the microwire end is mainly 5–10 times less than that of microwire bottom).

REVIEW OF NANOTECHNOLOGICAL INVENTIONS

The specialists can also be interested in the following inventions related to nanotechnologies:

-

• A method to obtain biocide suspension applied on wallpaper and wall finishings [12].

-

• A method to produce conductive nanocell with quantum dots [13].

-

• A surface-modified nanodiamond, dispersed composition of nanodiamond and a method of obtaining surface-modified nanodiamond [14].

-

• Nanomodified building mortar [15].

-

• A method of obtaining active in visible spectrum photocatalysts with nanosize titanium dioxide with anatase structure and a mixture of anatase and rutile, dopped with transition metals (ni, v, ag, cu, mn) [16].

-

• A device fоr producing graphene-containing suspensions by means of graphite cascade exfoliation [17].

-

• A method of obtaining nanosize films of titanium nitride [18].

-

• A method to produce dry construction mixtures [19].

-

• A method of obtaining conductive coating on the basis of carbon nanotubes [20].

-

• A protective nanomarker with spectrum identification code for marking valuable articles and a method of marking valuable articles with protective nanomarker [21].

-

• Innovative technology of municipal wastewater treatment for rapid sludge sedimentation and enhancing pollutants removal with nano-material [22].

-

• A nanosize quartz and a method of obtaining it [23].

-

• A method of obtaining monolayer silicen [24].

-

• A fluorescent multi-purpose nanosize mark and conjugates on the basis of it [25].

-

• Copoly(urethan-imide) polymer structure with shape memory effect [26].

-

• Dry sliding wear behavior of Fe–Cr–C–B hardfacing alloy modified with nano-CeO2 and its mechanisms of modification [27].

-

• A method of designing productive stratum of low-permeability [28].

-

• Technologies of obtaining flexible and transparent electronic components on the basis of graphene-like structures in polymer for electronics and microelectronics [29].

-

• A method of obtaining layered composite carbonmolybdenum disulphide [30].

-

• A composition on the basis of oxide nanostructures to provide surface with superhydrophobic properties [31].

-

• A method to excite standing spin waves in nanostructured epitaxial films of iron garnet by means of femtosecond laser impulses [32].

-

• Functional element of quantum emitter [33].

CONCLUSION

One of the most challenging tasks the economy of every country face is to increase industrial competitiveness through technological upgrade. From the side of the state and companies the principal object to control in this process are the people and enterprises dealing with introduction of inventions and new technologies. Therefore, we hope that the information published in this section will be in demand and useful for specialists.

Список литературы Inventions in the area of nanomaterials and nanotechnologies. Part III

- Schwarzman D. I., Napartovich М.А., Gershevich M.I. A modifying additive. Patent RF 2781192. 2022-10-07.

- Pershin V.F., Al-Mashkhadani А.М.R., Osipov А.А, Tkachev А.G. A device to obtain graphene-containing suspension. Patent RF 2777632. 2022-08-08.

- Nozdrina О.V., Melnikov А.G., Tarasov S.Yu. et al. A method of laser surface treatment for steel products. Patent RF 2777793. 2022-08-10.

- Markov А.N., Kapinos А.А., Vorotyntsev А.V. et al. A method to obtain nanocrystal silicon powder. Patent RF 2777468. 2022-08-04.

- Еfremenko Е.N., Zavialova N.V., Lyagin I.V. et al. A self-cleaning material with chemical and biological protection properties. Patent RF 2780376. 2022-09-22.

- Bukhalyonkov А.V., Shubin V.I., Mnatsakanov S.S. A method of cohesive hardening of bitum. Patent RF 2781584. 2022-10-14.

- Kameneva А.L. A method of obtaining multi-layered nanocomposite coating. Patent RF 2780078. 2022-09-19.

- Kozlova Е.Е., Safin А.R., Kalyabin D.V. et al. Spintronic detector of terahertz oscillations on the basis of nanoheterostructure antiferromagnetic – high-density metal. Patent RF 2781081. 2022-10-05.

- Sapunov V.V., Varlamov S.А. A method of obtaining nanostructured composite material on the basis of aluminum. Patent RF 2780728. 2022-09-29.

- Ivanov V.V., Efimov А.А., Kornyushin D. et al. A method to form plasmon nanostructures on the object surfaces to provide non-destructive analysis of low concentrations of chemical compounds by Raman spectroscopy. Patent RF 2780404. 2022-09-22.

- Koledov V.V., Prokunin А.V., Shavrov V.G. et al. A device control system with the shape memory effect to manipulate micro- and nanoobjects. Patent RF 2778525. 2022-08-22.

- Ivanov L.A., Xu L.D., Razumeev K.E., Pisarenko Zh.V., Demenev A.V. Inventions of scientists, engineers and specialists from different countries in the area of nanotechnologies. Part VI. Nanotechnologies in Construction. 2021; 13(6): 370–378. https://doi.org/10.15828/2075-8545-2021-13-6-370-378.

- Gavrikov M.V., Glukhovskoy Е.G., Zhukov N.D. et al. A method to produce conductive nanocell with quantum dots. Patent RF 2777199. 2022-08-01.

- Shiro Daisuke, Kume Atsousi. A surface-modified nanodiamond, dispersed composition of nanodiamond and a method of obtaining surface-modified nanodiamond. Patent RF 2780325. 2022-09-21.

- Ivanov L.A., Xu L.D., Bokova E.S., Ishkov A.D., Borisova O.N. Inventions in the area of nanomaterials and nanotechnologies. Part I. Nanotechnologies in Construction. 2022; 14(1): 18–26. https://doi.org/10.15828/2075-8545-2022-14-1-18-26.

- Gainanova А.А., Kuzmicheva G.М. A method of obtaining active in visible spectrum photocatalysts with nanosize titanium dioxide with anatase structure and a mixture of anatase and rutile, dopped with transition metals (Ni, V, Ag, Cu, Mn). Patent RF 2776582. 2022-07-22.

- Pershin V.F., Al-Jarakh R.А.S., Al-Mashkhadani А.М.R. et al. A device fоr producing graphene-containing suspensions by means of graphite cascade exfoliation. Patent RF 2776502. 2022-07-21.

- Аkashev L.А., Popov N.А., Shevchenko V.G. A method of obtaining nanosize films of titanium nitride. Patent RF 2777062. 2022-08-01.

- Ivanov L.A., Xu L.D., Bokova E.S., Ishkov A.D., Muminova S.R. Nanotechnologies: are view of inventions and utility models. Part V. Nanotechnologies in Construction. 2020; 12(6): 331–338. https://doi.org/10.15828/2075-8545-2020-12-6-331-338.

- Romashkin А.V., Levin D.D., Polikarpov Yu.А. A method of obtaining conductive coating on the basis of carbon nanotubes. Patent RF 2779608. 2022-09-12.

- Mikhailov M.D., Manshina А.А., Mamonova D.V. et al. A protective nanomarker with spectrum identification code for marking valuable articles and a method of marking valuable articles with protective nanomarker. Patent RF 2779619. 2022-09-12.

- Ivanov L.A., Xu L.D., Bokova E.S., Ishkov A.D., Muminova S.R. Inventions of scientists, engineers and specialists from different countries in the area of nanotechnologies. Part I. Nanotechnologies in Construction. 2021; 13(1): 23–31. https://doi.org/10.15828/2075-8545-2020-13-1-23-31.

- Rozhkova N.N., Rigaeva Yu.L., Rozhkov S.S. et al. A nanosize quartz and a method of obtaining it. Patent RF 2778691. 2022-08-23.

- Zhizhin Е.V., Pudikov D.А., Komolov А.S. A method of obtaining monolayer silicen. Patent RF 2777453. 2022-08-04.

- Kuznetsov D.B., Dezhurov S.V. A fluorescent multi-purpose nanosize mark and conjugates on the basis of it. Patent RF 2777648. 2022-08-08.

- Didenko А.L., Smirnova V.Е., Vaganov G.V. et al. Copoly(urethan-imide) polymer structure with shape memory effect. Patent RF 2777175. 2022-08-01.

- Ivanov L.A., Xu L.D., Bokova E.S., Demenev A.V., Ivanov V.A. Inventions of scientists, engineers and specialists from different countries in the area of nanotechnologies. Part III. Nanotechnologies in Construction. 2021; 13(3): 158–165. https://doi.org/10.15828/2075-8545-2021-13-3-158-165.

- Nazimov N.А., Vakhin А.V., Nurgaliev D.К. A method of designing productive stratum of low-permeability. Patent RF 2776516. 2022-07-21.

- Shiversky А.V., Abaimov S.G., Akhatov I.Sh. Technologies of obtaining flexible and transparent electronic components on the basis of graphene-like structures in polymer for electronics and microelectronics. Patent RF 2778215. 2022.

- Zheleznov V.V., Saenko N.S., Maiorov V.Yu. et al. A method of obtaining layered composite carbon-molybdenum disulphide. Patent RF 2777083. 2022-08-01.

- Ivanov L.A., Xu L.D., Muminova S.R., Feoktistova V.M., Romanova E.V. Inventions in the area of nanomaterials and nanotechnologies. Part II. Nanotechnologies in Construction. 2022; 14(2): 105–112. https://doi.org/10.15828/2075-8545-2022-14-2-105-112.

- Belotelov V.I., Berzhansky V.N., Ignatieva D.О. A method to excite standing spin waves in nanostructured epitaxial films of iron garnet by means of femtosecond laser impulses. Patent RF 2777497. 2022-08-04.

- Kotlyar К.P., Reznik R.R., Soshnikov I.P. et al. Functional element of quantum emitter. Patent RF 2781531. 2022-10-13.