Inventions in the area of nanotechnologies and nanomaterials. Part I

Автор: Leonid A. Ivanov, Li D. Xu, Zhanna V. Pisarenko, Svetlana R. Muminova, Nadezda G. Miloradova

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Review of nanotechnological inventions

Статья в выпуске: 1 Vol.15, 2023 года.

Бесплатный доступ

Introduction. Advanced technologies inspire people by demonstrating the latest achievements (materials, methods, systems, technologies, devices etc.) that dramatically change the world. This, first of all, concerns nanotechnological inventions designed by scientists, engineers and specialists from different countries. Main part. The article provides an abstract overview of inventions of scientists, engineers and specialists from different countries: Germany, Russia, China, USA et al. The results of the creative activity of scientists, engineers and specialists, including inventions in the field of nanotechnology and nanomaterials allow, when introduced to industry, achieving a significant effect in construction, housing and communal services, and related sectors of the economy. For example, the invention «The composition and manufacturing method of non-fired zirconium heat-resistant concrete» refers to the construction materials industry and can be used in the manufacture of products from zirconium non-fired heat-resistant concrete obtained without pre-firing. The purpose of the invention is to increase the thermal resistance at 1300оC, improve the water resistance of non-fired zirconium heat-resistant concrete and the exclusion a technologically complex method of converting the above-mentioned components into nanoscale particles and heat-shock treatment requiring high energy costs. The following inventions in the field of nanotechnology can also be interesting for specialists: a method to obtain multi-layered nanocomposite coating: a method for modifying carbon nanomaterials in nitrogen-containing plasma; a method for regeneration of aerosol filters and protective membranes; a method for obtaining a polymer nanocomposite material with reduced flammability; a robotic complex for obtaining nanostructured chromium coatings; a method for producing hydrogen from methane, a method for forming a combined hydrophilic coating; thermochromic nanoencapsulated material, production method and a product containing such material; a method for obtaining a water-soluble paint-and-lacquer material with photobactericidal activity for applying photobactericidal coatings based on water-soluble paint-and-lacquer materials еt al. Conclusion. One of the most challenging tasks the economy of every country face is to increase industrial competitiveness through technological upgrade. From the side of the state and companies the principal object to control in this process are the people and enterprises dealing with introduction of inventions and new technologies.

Nanotechnologies in construction, zirconium non-fired heat-resistant concrete products, method for modifying carbon nanomaterials, method for obtaining a polymeric nanocomposite material, thermochromic nanoencapsulated material

Короткий адрес: https://sciup.org/142235804

IDR: 142235804 | DOI: 10.15828/2075-8545-2023-15-1-37-47

Текст научной статьи Inventions in the area of nanotechnologies and nanomaterials. Part I

Review article

Nanotechnologies and nanomaterials amaze the imagination of people, demonstrating more and more advances (materials, methods, systems, tech- nologies, devices, etc.) that radically change the world around us. This is primarily can be attributed to the inventions of scientists, engineers and specialists from different countries (Germany, Russia, China, USA, etc.) in the nanotechnology field.

REVIEW OF NANOTECHNOLOGICAL INVENTIONS

MAIN PART

Composition and a method of manufacturing non-fired zirconium heat-resistant concrete (RU 2784296 C1)

The invention relates to the construction materials industry and could be used in the manufacture zirconium heat-resistant concretes obtained without prefiring [1].

The purpose of the invention is to increase the thermal resistance at 1300оC, water resistance of non-fired zirconium heat-resistant concrete and the eliminating a technologically complex method converting above mentioned components into nanoscale particles and heatshock treatment requiring high energy costs.

It is achieved by binder inclusion into the composition: for the manufacture of non-fired zirconium heatresistance concrete, with zirconium filler, finely ground additives: zirconium, diatomite, binder – nanosized particles of sodium silicate pieces and nanosized particles of milky white opal and water, the composition contains colloidal polysilicate as a binder sodium with a silicate module of 6.5 and nanodispersed milky white opal – siliceous rock representing natural fine silica, in the following ratio, mass %: zirconium filler 57–81; finely ground zirconium 8-18; finely ground diatomite 6–16; colloidal sodium polysilicate with a silicate modulus of 6.5 obtained according to RF patent 2124475 2-4; natural highly-dispersed silica (the chemical composition and sieve analysis are presented further), – 3–5; water at the rate of W / T 0.12-0.14 by mass of dry components.

The primary components included in the raw material mixture for the manufacture of non-fired zirconium heat-resistant concrete with increased heat and water resistance are:

– colloidal sodium polysilicates with a silicate modulus 6.5, obtained according to Pat. RF 2124475, representing the transition range of compositions from liquid glasses to siliceous and classified as nanomaterials.

The structural element of the polysilicate is a siliconoxygen tetrahedron, which is the main polymer component for polysilicates. The main difference between polysilicates and liquid glasses (highly alkaline silicate systems) is their polymer form, which is silica particles 4 to 5 nm in size. The polymer form is 60% or more of the total siliceous content, which provides high strength properties for the obtained gel structures. The polysilicates efficiency is 4 times higher than the efficiency of liquid glasses – aqueous solutions of sodium silicate pieces, which allows the use of technological solutions with a lower concentration.

Thermochromic nanoencapsulated material, a method for its preparation and product containing such material (RU 2786728 C1)

The group of inventions relates to the field of fire safety, namely to advanced means of controlling and preventing the occurrence of fires at an early stage by constant local, spot monitoring of temperatures or overheating for electrical wiring, contact groups, terminals, equipment and various objects through the use of chemical indicators of a combined operating principle, changing their color and emitting an odor when exposed to temperature. A thermochromic nanoencapsulated material used to generate a signal about local overheating of electrical equipment by simultaneously releasing an odorant and changing the color of the material with increasing temperature includes nanocapsules containing a core inside a polymer shell with an odorant [2].

The material consists of nanocapsules distributed in a polymer binder with a core of a thermochromic substance, based in a multilayer modified polymer shell containing a layer with an odorant and a protective flame retardant layer, with the following ratio of components, mass, %: core of a thermochromic substance 84–88, polymer shell 5–7, plasticizer 3–5, odorant layer 2–3, protective flame retardant layer 2–3. Nanocapsules activation temperature span is 50–250оC. The outer diameter of the nanocapsules is 40–60 microns. The average thickness of the odorant layer is 2–3 microns. The average thickness of the protective flame-retardant layer is 2–3 microns. To obtain a thermochromic nanoencapsulated material, the ther-mochromic substance is crushed, sieved and separated to a homogeneous fine fraction of 30–50 µm.

A mixture of a polymer with a plasticizer is prepared, divided into parts, a mixture with an odorant and a mixture with nanocomposites are prepared, which are then fed into separate tanks of the dosing unit. The polymer solidifying agent is loaded into a separate tank of the dosing unit. The resulting thermochromic substance is electrified with static electricity and loaded into the layer deposition chamber. It is sprayed with dry compressed air and a mixture of polymer and odorant is fed. When finishing the spraying cycle, the raw material coated with the formed layer of uncured shell is deposited in the reaction chamber and the hardener is sprayed and the polymer is being solidified. The resulting raw material is reversed from the reaction chamber to the layer deposition chamber and the mixture of the mentioned above polymer and nanocomposite is sprayed. When finishing the spraying cycle, the raw material coated with the next layer of uncured shell from the layer spraying chamber is deposited into the reaction chamber. The hardener is sprayed and the polymer is cured. At the end of the layers spraying cycles and curing the shells, a finished material is obtained, which is

REVIEW OF NANOTECHNOLOGICAL INVENTIONS unloaded into a technological container, sorted and packed into a shipping container.

The thermochromic nanoencapsulated product is made in the form of a structural item and contains the thermochromic nanoencapsulated material described above. It has been increased: a flowability of the material, long-term storage time while preserving the original properties, increased homogeneity, chemical resistance, and uniformity of mixing in the polymer compositions, resistance to aggressive environments/solvents and stabilization of the activation temperature.

A method for forming a combined hydrophilic coating (RU 2786292 C1)

The invention relates to the energy-saving technology and heat-power engineering, in particular to the methods for improving the wetting and capillary properties of the heat exchange surface to increase heat transfer during evaporation and boiling [3].

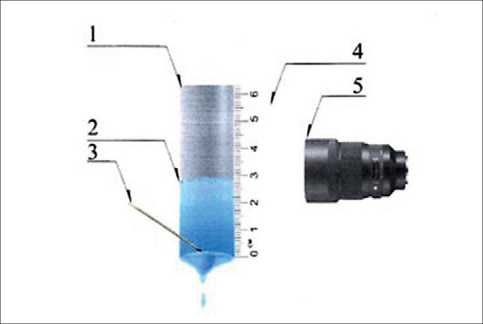

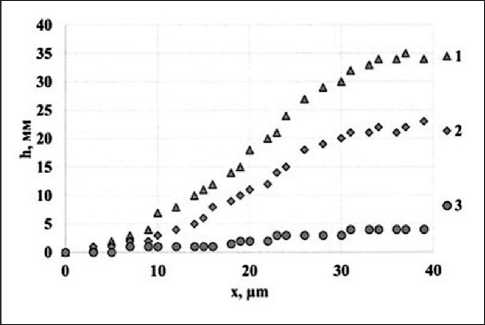

The summary of the method for forming a combined hydrophilic coating is illustrated in the figures, where Fig. 1 shows a photograph of the heat exchange surface with a coating, namely, a layer of aluminum oxide nanoparticles deposited on the microstructure. Fig. 2 shows a diagram of measuring the liquid rosing height over the layer obtained by the claimed method. The scheme measuring the liquid rising height contains the substrate 1, the liquid 2, the needle 3, the ruler 4, the chamber 5. Fig. 3 presents dependence of liquid rising height from the coating thickness.

The method of forming a combined hydrophilic coating is carried out as follows.

With an abrasive with a grain size from10 µm to 100 µm, the grooves are cut on the heat exchange surface, then the surface is heated up to the temperature from 50 to 100оC and a nanofluid is applied. Nanofluid consists of aluminum oxide nanoparticles with a size 50 to 100 nm and isopropanol with nanoparticles concentration from 0.01 to 0.1%. The nanofluid evaporates at the

Fig. 1. Photograph of a coated heat exchange surface, namely, a layer of aluminum oxide nanoparticles deposited on a microstructure

Fig. 2. Scheme for measuring the liquid rising height: 1 – substrate; 2 – liquid; 3 – needle; 4 – ruler;

5 – camera

Fig. 3. Dependence of the liquid rising height on the layer thickness atmospheric pressure in air, which leads to the layer formation of aluminum oxide nanoparticles. The procedure for applying the nanofluid and evaporating the liquid from the nanofluid is repeated 10 to 15 times. The resulting coating (Fig. 1) makes it possible to achieve capillary rising height of the liquid from 30 to 35 mm and a contact angle of 0 degrees.

It has been found experimentally that the coating best characteristics are achieved in the specified parameters ranges. To measure the liquid rising height according to the diagram in fig. 2, liquid 2 is applied to the substrate 1 by feeding through the needle 3, thereafter, with the ruler 4, the rising height is measured in the photograph taken from camera 5. Based on the measured values, the dependence of the liquid rising height on the layer thickness was plotted (Fig. 3), where (1) – combined coating – layer of nanoparticles in grooves, (2) – layer of nanoparticles, (3) – grooves. The combined coating provides significantly better hydrophilic properties than applying a layer of nanoparticles and cutting grooves separately.

REVIEW OF NANOTECHNOLOGICAL INVENTIONS

With an increase in the liquid rising height, the evaporation area also increases, which improves the heat transfer coefficient during evaporation, and the structure based on nanoparticles increases the number of vaporization centers, which leads to an increase in heat transfer during boiling.

The use of the invention makes it possible to exclude technically complex operations of forming a hydrophilic surface by applying particles in the flame of a hydrogenoxygen burner or sintering and applying polymer pastes. The resulting coating allows to increase liquid rising height up to 35 mm compared with the prototype.

A method to produce hydrogen from methane(RU 2784336 C1)

The method to produce hydrogen and ethylene from methane includes supplying a methane stream to the reactor, using a catalyst containing particles of a metal selected from the group: nickel, titanium, molybdenum, iron, cobalt, heating the catalyst through electromagnetic action, followed by the release of hydrogen and ethylene for methane reforming. The nanopowder catalyst is fed into the toroidal reactor simultaneously with the methane flow. The fan inside the reactor mixes and directs the dust-gas mixture to the induction heating zone, where, as a result of heating the catalyst up to 810–850оC, dimerization and dehydrogenation reactions take place with the formation of hydrogen and ethylene, which are stabilized in the subsequent cold zone of the reactor [4].

The technical problem, the solution of which is provided by the present invention implementation, is the high cost and low productivity of hydrogen obtaining process for its further use, specifically, as a promising fuel for the space, aviation, and motor transport industries. Likewise, there is an urgent need for a simple and economically justified method for the direct dimerization of methane into ethylene up to a temperature of 1000оC for industrial enterprises.

The technical result of the claimed invention is a high-performance method for producing two high-margin products: hydrogen and ethylene, suitable for use in small-tonnage production at optimal energy consumption with the possibility of implementing the method both on large-scale stationary industrial installations and in a vehicle-based mobile version.

The technical result is achieved due to the fact that the method for producing hydrogen from methane, including the supply of a methane stream to the reactor, the use of a catalyst containing particles of a metal selected from the group: nickel, titanium, molybdenum, iron, cobalt, heating the catalyst by means of electromagnetic action, with the subsequent release of hydrogen during methane conversion; according to the invention, the catalyst in the form of a nanopowder is fed into the toroidal reactor simultaneously with the flow of methane, the fan inside the reactor mixes and directs the dust-gas mixture to the induction heating zone, where, as a result of heating the catalyst, dimerization and dehydrogenation reactions occur to form hydrogen and ethylene , which are stabilized in the subsequent cold zone of the reactor.

In the proposed invention, unlike analogues, there is not an optical or microwave, but an induction heating of catalytic particles within the methane medium. The degree efficiency of such a solution is close to 90%, and the number of particles exposed to the electromagnetic radiation of the induction source is much higher than, for example, the carbon dioxide laser beam. The catalytic particles are heated uniformly throughout the induction heating zone of the reactor. The nano-size of catalytic particles allows a larger reactive area in comparison with microparameters.

Robotic complex for the formation of nanostructured chromium coatings (RU 2786270 C1)

The invention relates to equipment for plasma-electrolytic coating and can be used in mechanical engineering, instrumentation and other fields of technology [5].

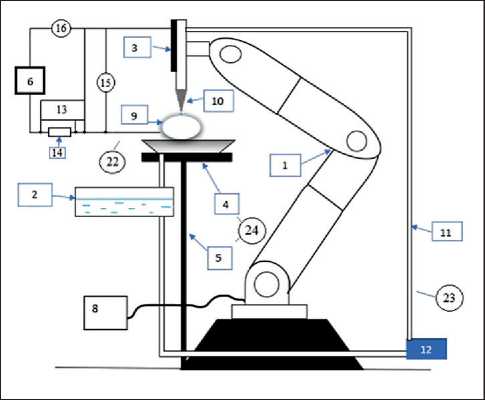

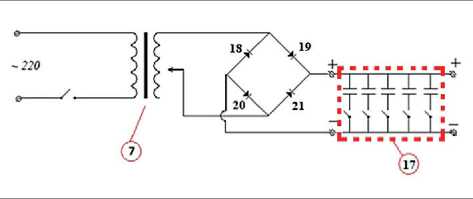

The essence of the claimed technical solution is a robotic complex for the formation of nanostructured chromium coatings, consisting of an industrial robot with a reprogrammable control device, an electrode system, a rotary-horizontal system, an electrolyte supply system; the electrode system includes: cathode – chromium-plated product; anode; an electrical power supply system, which is a high-voltage direct current source for creating and maintaining the burning of an electric discharge with smooth voltage output control in a range with the possibility of supplying an adjustable rectified voltage of various shapes and consisting of a diode bridge and a laboratory autotransformer, while a capacitive induction transformer is connected to the electrical power supply system filter; an oscilloscope with the ability to control the shape of the supplied voltage and electric current; additional resistance; voltmeter with voltage control; ammeter with the ability to monitor the electric discharge current; the rotary-horizontal system consists of: a rotary-horizontal mechanism with the possibility of making circular movements, on which the chrome-plated product is located; base for the horizontal-rotation mechanism, on which the horizontalrotation mechanism is located.

The electrolyte supply system consists of a flow bath with the possibility of adding electrolyte to it, the flow bath is located under the rotary-horizontal mechanism with the possibility of collecting the flowing electrolyte from the surface of the chrome-plated product during the chromium plating process; flexible electrolyte supply tubes connecting all elements of the electrolyte supply system

REVIEW OF NANOTECHNOLOGICAL INVENTIONS with the possibility of electrolyte flowing therethrough while the flexible electrolyte supply tubes are either attached to the body of the industrial robot or located inside the technical channels of the industrial robot, then the flexible electrolyte supply tubes are arranged in the direction the flow bath and further to the base for the rotaryhorizontal mechanism; an electrolyte dispenser connected to the anode and flexible tubes for supplying electrolyte with the possibility of supplying electrolyte to the surface of the chrome-plated product, as well as with the ability to move in space by moving the industrial robot according to the program specified on the reprogrammable control device; a peristaltic pump with the possibility of pumping electrolyte from the flow bath into the electrolyte dispenser, while the peristaltic pump is attached either to the frame of an industrial robot or to the flow bath.

The use of the claimed technical solution makes allows to improve the accuracy and quality of applying nanostructured chromium coatings on products with complex geometry shape and large areas to provide anti-corrosion effects in the field of mechanical engineering, instrumentation and other industries. Schemes of the claimed robotic complex are shown in Fig. 4a and 4b.

Fig. 4a. The general scheme of the claimed robotic complex: 1 – 3 degree industrial robot (industrial robot); 2 – flow bath; 3 – anode; 4 – rotary-horizontal mechanism; 5 – base for the rotary-horizontal mechanism; 6 – power supply system; 7 – laboratory autotransformer; 8 – reprogrammable control device; 9 – cathode – chrome-plated product;

10 – electrolyte dispenser, conducting electricity, with a tip; 11 – electrolyte supply tubes, 12 – peristaltic pump; 13 – oscilloscope; 14 – additional resistance;

15 – voltmeter; 16 – ammeter; 17 – capacitive induction filter; 18, 19, 20, 21 – diodes; 22 – electrode system; 23 – electrolyte supply system; 24 – rotaryhorizontal system

Fig. 4b. Electrical power scheme

Method for obtaining a polymer nanocomposite material with reduced flammability (RU 2783446 C1)

The fire hazard of polymeric materials and products made from them is determined in technology, foremost, by combustibility, i.e. the ability of a material to ignite, maintain and propagate the combustion process. However, it is impossible to ensure that the polymer becomes an absolutely non-combustible material that does not burn in intense fire (in case of fire). Therefore, an urgent task is to reduce the flammability of the polymer, slowing down the rate of its combustion and flame propagation, as well as reducing smoke emission. According to the standards (GOST 28157-89), a slow-burning polymeric material is considered to be such a material that can ignite when flame is applied, but when the combustion source is removed, it self-extinguishes after a certain period of time.

The creation and development of advance polymeric materials with reduced flammability includes such main areas as the synthesis of base polymers with reduced flammability; chemical and physical modification of industrial polymers, as well as the introduction of special flame-retardant additives into polymers – flame retardants, which make it difficult to ignite and reduce the speed of flame propagation. To implement the first area, silicon-con-taining polymers and highly heat-resistant heterocyclic polymers (polysulfones, polyphenylene sulfoxides, polyimides, etc.) are synthesized, as well as polymers, during the decomposition of which non-combustible gases (fluorine-, chlorine-, nitrogen-) are formed. The creation of non-combustible polymers based on the chemical and physical modification of carbon chain polymers usually includes chlorination/bromination reactions or treatment of the polymer surface with some kind of energy source. A significant disadvantage of the mentioned consepts is the high production cost of new non-combustible polymers and/or the development of modification technologies and a narrow range of polymers, which significantly limits the areas of practical use of these methods for producing non-combustible polymers.

The present invention [6] relates to the chemistry and technology of polymers and concerns a method for producing nanocomposite polymeric materials with reduced flammability containing nanoparticles of low molecular

REVIEW OF NANOTECHNOLOGICAL INVENTIONS weight inorganic flame retardants based on aluminum or magnesium hydroxides in a highly dispersed state, which can be used in various fields of science and technology as innovative materials with reduced flammability, including materials in the form of films and fibers for household and technical purposes to prevent fires, slow down or stop the development of the initial stage of a fire, ensure its rapid localization, for use in the agricultural sector as non-combustible materials for greenhouses and packaging materials, materials for construction purposes to protect buildings and structures from ignition and fires, textile materials with reduced flammability for technical and household purposes as furniture fabric and stuffing material for use in de civil, public and medical institutions, hotels, vehicles (civil public transport, air and rail transport, etc.), etc.

A method for modifying carbon nanomaterials in nitrogen-containing plasma (RU 2784665 C1)

The invention relates to the technology of carbon nanomaterials, specifically, to the technology for producing carbon nanomaterials that can be used as carriers of electrocatalytically active metal nanoparticles for subsequent use in fuel cells, electrolyzers and other electrochemical devices. In addition, modified carbon nanomaterials can be used as a sorption material for hydrogen storage systems or as a membrane material for hydrogen purification and extraction systems. The method can be used to obtain modified nanomaterials on an industrial scale [7].

The technical issue to be solved by the claimed invention is to increase the activity and stability of the electrocatalyst for the oxygen reduction reaction and, as a result, to improve the performance of low-temperature fuel cells, which is a carbon nanomaterial modified with nitrogen.

The technical result of the claimed invention is to obtain an electrocatalyst carrier for low-temperature hydrogen-air (oxygen) fuel cells. To achieve this technical result, a method is proposed (modifying carbon nanomaterials in a nitrogen-containing plasma). The method consists in processing carbon nanomaterial in the form of a powder, which is carried out in plasma in a vacuum chamber of a magnetron-ion sputtering installation with a current source; upon that the plasma-forming gases are a mixture of nitrogen-argon, a composite graphite target containing sulfur as the second modifying component is used, and the sulfur/graphite ratio lies in the C:S range from 3:1 to 1:3, the substrate with carbon nanomaterial is grounded, the chamber is preliminarily vacuumed to 10–2 Pa and heating the substrate with the material to be processed to a temperature of 120оC to remove water vapor from the pores of the sample, the plasma treatment process is carried out under a mixture pressure of 1–6 Pa.

Besides that, a negative bias voltage of 100–800 V with a frequency of 10 kHz is applied to the substrate with the nanomaterial being processed using a pulsed current source.

The combination of the above essential features leads to the fact that the electrocatalyst carrier obtained by the claimed method has a high surface activity, which will make it possible to obtain an active and stably operating electrocatalyst with a long service life, and thereby improve the performance of low-temperature fuel cells.

Frost-resistant and wear-resistant rubber basedon epichlorohydrin rubber (RU 2784185 C1)

The invention relates to the field of elastomeric nanocomposites used in the rubber industry and can be used in the manufacture of rubber wear-resistant products for sealing and structural purposes, operated under intense wear and tear, low temperatures and aggressive environments [8].

The objective of this invention is to develop a technology for “dry” ultrasonic treatment of carbon nanotubes (CNTs) to reduce the degree of agglomeration and the introduction of treated CNTs into a rubber compound based on Hydrin T-6000 epichlorohydrin rubber to obtain strong, frost-resistant and wear-resistant elastomeric materials.

The technical effect obtained is expressed in the rubber production based on epichlorohydrin rubber, which shows increased frost resistance and wear resistance. In addition, the technology is characterized by a reduction in the number of preliminary stages for ultrasonic treatment of CNTs, the possibility of introducing nanofillers into the rubber mixture at the stage of mixing the components of the rubber mixture in a standard rubber mixer, improving the performance properties of vulcanizates, namely, the conditional tensile strength, relative elongation at break, increased wear resistance while maintaining elastomer frost resistance.

This task is achieved due to the fact that the rubber compound based on epichlorohydrin rubber Hydrin T-6000, including sulfur, captax, thiuram disulfide, zinc oxide, magnesium oxide, stearic acid, carbon black P-803, antiaging agent 4010 NA, additionally contains multi-walled carbon nanotubes, processed in an ultrasonic bath, with the following ratio of initial components, wt. hours: Hydrin T-6000 rubber – 100.0; sulfur – 1.0; carbon black P-803 – 50.0; zinc oxide – 3.0; magnesium oxide – 3.0; stearic acid – 1.0; captax – 0.5; thiuram disulfide – 1.0; antiaging agent 4010 NA – 1.0; multi-walled carbon nanotubes – 0.5–10.0.

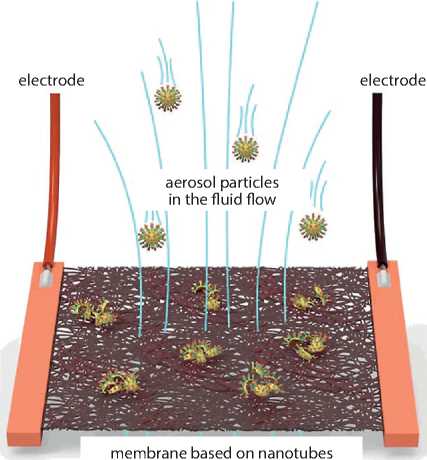

A method for regeneration aerosol filters and protective membranes (RU 2786874 C1)

The invention relates to the creation of new devices based on carbon materials and their composites, in particular, of regenerated membranes for trapping aerosol

REVIEW OF NANOTECHNOLOGICAL INVENTIONS particles. The proposed invention can be used for capturing practically any aerosol particles and for partially or completely removing organic and inorganic substances. In particular, the invention can be used as structural elements of ultraviolet lithography (EUV lithography) and air purifiers for removing organic aerosol particles [9].

The invention makes it possible to solve existing problems by using free-standing membranes/aerogels of carbon nanotubes and based composites which can be heated without significant irreversible structural changes to extreme temperatures: 1800оC in vacuum or inert atmosphere and 700оC in air, by heating. Heating can be provided both by the material itself (resistive due to the supply of electric current to the membrane, microwave/ induction due to the supply of an external field), and due to external heating sources. In this treatment, the aerosol particles filtered by the membrane are partially or completely removed from the surface of the filter element, regenerating the surface.

The creation of membranes/aerogels based on carbon nanotubes or nanotube/graphene composites can be achieved both by filtering suspensions, aerosol precipitation, or supercritical drying. Composites can be produced by chemical deposition from the gas phase of the boron nitride layer, as well as pyrolysis of hydrocarbons on the membrane surface, deposition of graphene flakes on the membrane surface, or its replacement with graphene materials.

(heating while filtering or while regeneration)

fluid flow

Fig. 5. Schematic device operating concept

Figure 5 shows a schematic device operating concept.

The technical results achieved in the present invention are: the possibility of controlled partial regeneration of the membrane to maintain one of the specified parameters in the required range of values: transparency, pressure difference, filtering efficiency, filter membrane quality, etc.; the possibility of removing and/or destroying the structure of fixed aerosols by high-temperature treatment; simplification of filter heating by eliminating the substrate (carrier) and using a free-standing membrane; increase heating energy efficiency by removing the membrane substrate from the device, heating rate, cooling, direct heating of the membrane, not the environment.

In the proposed method for demonstrating the possibility of an approach, the problem of completely removing tin particles from the surface of nanotubes by resistive heating in a vacuum is implemented.

A method for producing a water-soluble paint material with photobactericidal activity for applying photobactericidal coatings based on water-soluble paints and lacquers and hybrid associates of silver sulfide nanocrystals with methylene blue molecules (RU 2782567 C1)

Recently, there has been an increasing need to develop new generations of antimicrobial compositions and coatings based on them, due to the growing number of diseases with bacterial and viral nature. Patent and scientific literature analysis shows that one of the ways to solve this problem is to develop methods for obtaining antimicrobial agents based on semiconductor nanoparticles (TiO2, ZnS, ZnO, CdS, etc.) with photocatalytic activity, metal nanoparticles (Ag, Au, Cu, Zn, etc.), hybrid associates of nanoparticles with organic dye molecules that are sensitizers of reactive oxygen species [10].

A special place is occupied by the development of methods for introducing the above mentioned agents into the composition of paints and lacquers, including watersoluble ones, while ensuring antimicrobial and photomi-crobicidal effects of the compositions and thus expanding the functionality of paints and lacquers.

The present invention relates to the field of obtaining photobactericidal coatings, more precisely, to methods for modifying water-soluble paints and lacquers and their usage for the developing of self-sterilizing surfaces. A method for producing a water-soluble paint and lacquers material with photobactericidal activity for applying photobactericidal coatings based on water-soluble paints and lacquers and hybrid associates of silver sulfide nanocrystals with methylene blue molecules includes: coacervating solutions of thioglycolic acid and silver nitrate with constant stirring at a speed of 300–600 rpm, with subsequent dropwise titration with an aqueous solution of NaOH up to pH 9, adding an aqueous solution of sodium

REVIEW OF NANOTECHNOLOGICAL INVENTIONS sulfide with further stirring to form silver sulfide nanocrystals (NC Ag2S), precipitation, centrifugation at a speed of 5000 rpm for 30 min, purification of the obtained Ag2S NCs, addition of 50% water-ethanol solution and adding a solution of methylene blue in 96% ethanol to obtain a water-ethanol solution of an antimicrobial composition based on associates of silver sulfide nanoparticles with methylene blue molecules. An aqueous ethanol solution of an antimicrobial composition is then added to the commercial water-soluble paints and lacquers materials on an acrylic or siloxane basis: an antimicrobial solution of an antimicrobial composition in the ratio: a coating material 1:10 by mass. The coatings produced with the developed material exhibit photomicrobicidal properties under exposure to light, wherein the photobactericidal action is also retained on artificially aged samples simulating the operation of coatings for 1 year.

The specialists can also be interested in the following inventions related to nanotechnologies:

-

• A polymer composite heat-conducting paste with nanofiber modifier [11].

-

• A method for producing cobalt ferrite nanoparticles [12].

-

• A method for forming a periodic pattern on the surface of amorphous thin films of phase-operable chalcogenide materials [13].

-

• A method for determining superresonance on high-order modes E for spherical dielectric particle [14].

-

• A method for obtaining nanoparticles of cobalt ferrite [12].

-

• Innovative technology of municipal wastewater treatment for rapid sludge sedimentation and enhancing pollutants removal with nano-material [15].

-

• Terahertz crystalline ceramics of the system [16].

-

• Laser radiation converter based on a quantum molecule in an external electric field [17].

-

• A method of quantum dots hydrophilization [18].

-

• A method to produce metal-polymer nanocomposite materials with metal nanoparticles [19].

-

• A method for producing a slow release retarder for a well cementing [20].

-

• A method for laser-induced nanoparticles production of type core-shell in polymer matrices [21].

-

• A method for reprocessing waste polyethylene terephthalate into a porous carbon material (versions) [22].

-

• A method of manufacturing a semiconductor device [23].

-

• A modifying additive [24].

-

• Humidity sensor and gas analytic multisensor chip based on two-dimensional molybdenum carbide (maxen) and method of their production [25].

-

• A method for the obtaining of tungsten carbide films on a tungsten-silicon heterostructure by pyrolysis of

a polyamide film obtained by molecular layer deposition [26].

-

• A method for producing a thermally activated organometallic coordination polymer and a method for producing a composite nanoporous adsorbent based on it [27].

-

• A method for manufacturing a matrix of chemoresis-tive sensors [28].

-

• A method for obtaining liposomal nanocontainers with immobilized enzyme [29].

-

• A method for obtaining ultrafine diamonds and installation for its implementation [30].

-

• A method for obtaining nanoscale oxides of rare earth elements using acetamide [31].

-

• A composition of light self-compacting construction concrete on the basis of cement matrix [32].

-

• A method for obtaining a luminescent medium with laser control [33].

-

• A method for producing hydrogen (variants) [34].

-

• A device for obtaining graphene-containing suspensions by graphite exfoliation [35].

-

• Block composite material for gas accumulation and method for its production [36].

-

• Composite nanopowder based on titanium carbonitride and method for its preparation [37].

-

• Thermally conductive organosilicon paste [38].

-

• A protective nanomarker with a spectral identification code for marking valuable products and a method for marking valuable products with a protective nanomarker [39].

-

• A method for obtaining a conductive coating based on carbon nanotubes [40].

-

• Nanosized quartz and method for its preparation [41].

-

• A method of the surface laser treatment for steel products [42].

-

• A method for obtaining monolayer silicene [43].

-

• A method for excitation of standing spin waves in nanostructured epitaxial ferrite garnet films using femtosecond laser pulses [44].

-

• A method for obtaining a layered carbon-molybdenum disulfide composite [45].

-

• A method for developing a productive low-permeability reservoir [46].

CONCLUSION

One of the most challenging tasks the economy of every country face is to increase industrial competitiveness through technological upgrade. From the side of the state and companies the principal object to control in this process are the people and enterprises dealing with introduction of inventions and new technologies. Therefore, we hope that the information published in this section will be in demand and useful for specialists.

REVIEW OF NANOTECHNOLOGICAL INVENTIONS

Список литературы Inventions in the area of nanotechnologies and nanomaterials. Part I

- Toturbiev B.D., Mamaev S.A. Composition and method of manufacturing non-firing zirconium heat-resistance concrete. Patent 2784296 RF MPK C1. Bull. 2022; 33.

- Skirnevsky D.A., Pigalitsyn V.A. Thermochromic nanoencapsulated material, method for its production and a product containing such material. Patent 2786728 RF MPK C1. Bull. 2022; 36.

- Kuzma-Kichta Yu.A., Ivanov N.S., Lavrikov A.V. Method for forming a combined hydrophilic coating. Patent 2786292 RF MPK C1. Bull. 2022; 35.

- Vesnin M.A. Method for producing hydrogen from methane. Patent 2784336 RF IPC C1. Bull. 2022; 33.

- Kashapov N.F., Kashapov R.N., Kashapov L.N. et al. Robotized complex for the formation of nanostructured chromium coatings. Patent 2786270 RF MPK C1. Bull. 2022; 35.

- Arzhakova O.V., Kopnov A.Yu., Nazarov A.I., Dolgova A.A. Method for obtaining a polymeric nanocomposite material with reduced flammability. Patent 2783446 RF MPK C1. Bull. 2022; 32.

- Pushkarev A.S., Pushkareva I.V., Akelkina S.V. et al. Method for modifying carbon nanomaterials in nitrogencontaining plasma. Patent 2784665 RF MPK C1. Bull. 2022; 34.

- Timofeeva E.N., Petrova N.N., Mukhin V.V., Dyakonov A.A. Frost-resistant and wear-resistant rubber based on epichlorohydrin rubber. Patent 2784185 RF MPK C1. Bull. 2022; 33.

- Krasnikov D.V., Ramirez Benavidez H.A., Kondrashov V.A. et al. Method of regeneration of aerosol filters and protective membranes. Patent 2786874 RF MPK C1. Bull. 2022; 36.

- Perepelitsa A.S., Ovchinnikov O.V., Smirnov M.S. Method of obtaining a water-soluble paint and lacquers material with photobactericidal activity for applying photobactericidal coatings based on water-soluble paint and lacquers materials and hybrid associates of silver sulfide nanocrystals with methylene blue molecules. Patent 2782567 RF MPK C1. Bull. 2022; 31.

- Ivanov L.A., Xu L.D., Razumeev K.E., Pisarenko Zh.V., Demenev A.V. Inventions of scientists, engineers and specialists from different countries in the area of nanotechnologies. Part VI. Nanotechnologies in Construction. 2021; 13(6): 370–378. https://doi.org/10.15828/2075-8545-2021-13-6-370-378.

- Ivanova A.V., Abakumov M.A. Method for obtaining nanoparticles of cobalt ferrite. Patent 2787203 RF IPC C1. Bull. 2023; 1.

- Smaev M.P., Glukhenkaya V.B., Lazarenko P.I. et al. Method for forming a periodic pattern on the surface of amorphous thin films of phase-changing chalcogenide materials. Patent 2786788 RF MPK C1. Bull. 2022; 36.

- Minin I.V., Minin O.V. Method for determining superresonance on high-order E modes for a spherical dielectric particle. Patent 2786780 RF MPK C1. Bull. 2022; 36.

- Ivanov L.A., Xu L.D., Bokova E.S., Ishkov A.D., Muminova S.R. Inventions of scientists, engineers and specialists from different countries in the area of nanotechnologies. Part I. Nanotechnologies in Construction. 2021; 13(1): 23–31. Available from: https://doi.org/10.15828/2075-8545-2020-13-1-23-31.

- Zhukova L.V., Salimgareev D.D., Lvov A.E. Terahertz crystalline ceramics of the system. Patent 2786691 RF MPK C1. Bull. 2022; 36.

- Krevchik V.D., Semenov M.B., Razumov A.V. Laser radiation converter based on a quantum molecule in an external electric field. Patent 2786350 RF MPK C1. 2022. Bull. No. 35.

- Drozd D.D., Strokin P.D., Goryacheva O.A. et al. Method for the hydrophilization of quantum dots. Patent 2786239 RF IPC C1. Bull. 2022; 35.

- Ivanov LA., Kapustin I.A., Borisova O.N., Pisarenko Zh.V. Nanotechnologies: a review of inventions and utility models. Part II. Nanotechnologies in Construction. 2020; 12(2): 71–76. Available from: https://doi.org/10.15828/2075-8545-2020-12-2-71-76.

- Cheng Xiaowei, Zuo Tianpeng, Li Mingze et al. Method for producing a slow-release retarder for well cementing. Patent RF 2786170 IPC C1. Bull. 2022; 35.

- Bityurin N.M., Kudryashov A.A. Method of laser-induced creation of nanoparticles of the core-shell type in polymer matrices. Patent 2785991 RF MPK C1. Bull. 2022; 35.

- Vasilyev A.A., Efimov M.N., Muratov D.G., Karpacheva G.P. Method for reprocessing waste polyethylene terephthalate into a porous carbon material (versions). Patent 2785851 RF MPK C1. Bull. 2022; 35.

- Mustafaev A.G., Khasanov A.I., Mustafaev G.A. et al. Method for manufacturing a semiconductor device. Patent 2785083 RF IPC C1. Bull. 2022; 34.

- Ivanov L.A., Xu L.D., Muminova S.R., Ishkov A.D., Demenev A.V. Inventions in the area of nanomaterials and nanotechnologies. Part III. Nanotechnologies in Construction. 2022; 14(6): 466–474. https://doi.org/10.15828/2075-8545-2022-14-6-466-474. – EDN: QGCTUF.

- Plugin I.A., Poznyak A.I., Varezhnikov A.S. Humidity sensor and gas analytical multisensor chip based on two-dimensional molybdenum carbide (maxene) and method for their manufacture. Patent 2784601 RF MPK C1. Bull. 2022; 34.

- Amashaev R.R., Abdulagatov A.I., Abdulagatov I.M. Method for tungsten carbide films forming on a tungstensilicon heterostructure by pyrolysis of a polyamide film obtained by molecular layer deposition. Patent 2784496 RF MPK C1. Bull. 2022; 34.

- Fomkin A.A., Shkolin A.V., Tsivadze A.Yu. et al. Method for producing a thermally activated organometallic coordination polymer and a method for producing a composite nanoporous adsorbent based on it. Patent 2782026 RF MPK C2. Bull. 2022; 30.

- Sorokina L.I. Method for manufacturing matrix of chemoresistive sensors. Patent 2784333 RF IPC C1. Bull. 2022; 33.

- Krut U.A., Oleinikova I.I., Kuzubova E.V. et al. Method for obtaining liposomal nanocontainers with immobilized enzyme. Patent 2784321 RF IPC C1. Bull. 2022; 33.

- Voropaev S.A., Dushenko N.V. Method for obtaining ultrafine diamonds and installation for its implementation. Patent 2784236 RF MPK C1. Bull. 2022; 33.

- Savinkina E.V., Karavaev I.A., Buzanov G.A. et al. Method for obtaining nanosized oxides of rare earth elements with acetamide. Patent 2784172 RF IPC C1. Bull. 2022; 33.

- Ivanov L.A., Xu L.D., Bokova E.S., Ishkov A.D., Borisova O.N. Inventions in the area of nanomaterials and nanotechnologies. Part I. Nanotechnologies in Construction. 2022; 14(1): 18–26. https://doi.org/10.15828/2075-8545-2022-14-1-18-26.

- Ovchinnikov O.V., Smirnov M.S., Perepelitsa A.S. et al. Method for obtaining a luminescent medium with laser control. Patent 2783806 RF IPC C1. Bull. 2022; 32.

- Kraft Ya.V., Aduev B.P., Nurmukhametov D.R. et all. Method for producing hydrogen (variants). Patent 2783379 RF IPC C1. Bull. 2022; 32.

- Vasin S.A., Evseev A.V., Pershin V.F. Device for obtaining graphene-containing suspensions by graphite exfoliation. Patent 2783291 RF IPC C1. Bull. 2022; 32.

- Fomkin A.A., Tsivadze A.Yu., Knyazeva M.K. et al. Block composite material for gas accumulation and method of its production. Patent 2782932 RF MPK C1. Bull. 2022; 31.

- Ermakov A.N., Avdeeva Yu.A., Luzhkova I.V. Composite nanopowder based on titanium carbonitride and method for its production. Patent 2782591 RF MPK C1. Bull. 2022; 31.

- Kishchuk P.S., Lyalin N.S. Thermally conductive organosilicon paste. Patent 2782060 RF MPK C1. Bull. 2022; 30.

- Mikhailov M.D., Man’shina A.A., Mamonova D.V. Protective nanomarker with a spectral identification code for marking valuable products and a method for marking valuable products with a protective nanomarker. Patent 2779619 RF MPK C1. Bull. 2022; 26.

- Romashkin A.V., Levin D.D., Polikarpov Yu.A. Method for obtaining a conductive coating based on carbon nanotubes. Patent 2779608 RF MPK C1. Bull. 2022; 26.

- Rozhkova N.N., Rigaeva Yu.L., Rozhkov S.S., Kovalchuk A.A. Nanoscale quartz and method for its production. Patent 2778691 RF MPK C2. Bull. 2022; 24.

- Nozdrina O.V., Melnikov A.G., Tarasov S.Yu. et al. Method of laser surface treatment of steel products. Patent 2777793 RF MPK C1. Bull. 2022; 22.

- Zhizhin E.V., Pudikov D.A., Komolov A.S. Method for producing monolayer silicene. Patent 2777453 RF IPC C1. Bull. 2022; 33.

- Belotelov V.I., Berzhansky V.N., Ignatieva D.O. Method for excitation of standing spin waves in nanostructured epitaxial films of ferrite garnet using femtosecond laser pulses. Patent 2777497 RF MPK C1. Bull. 2022; 22.

- Zheleznov V. V., Saenko N. S. Yu. V. et al. Method for obtaining a layered composite carbon – molybdenum disulfide. Patent 2777083 RF MPK C1. Bull. 2022; 22.

- Nazimov N.A., Vakhin A.V., Nurgaliev D.K. Method for developing a productive low-permeability formation. Patent 2776516 RF MPK C1. Bull. 2022; 21.