Inventions of scientists, engineers and specialists from different countries in the area of nanotechnologies. Part III

Автор: Ivanov L.A., Xu L.D., Bokova E.S., Demenev A.V., Ivanov V.A.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Review of nanotechnological inventions

Статья в выпуске: 3 Vol.13, 2021 года.

Бесплатный доступ

Introduction. Advanced technologies impress people’s imagination demonstrating the latest achievements (materials, methods, systems, technologies, devices etc.) that dramatically change the world. This, first of all, concerns nanotechnological inventions designed by scientists, engineers and specialists from different countries. Main part. The article provides an abstract review of patents. The results of creative activity of scientists, engineers and specialists, including inventions in the field of nanotechnology and nanomaterials, being implemented, allow achieving a significant effect in construction, housing and community services, and related sectors of the economy. For example, the invention «Composite material with oriented carbon nanotubes» refers to the area of composite materials which consist of polymer matrix and filler that is often presented by carbon nanotubes. The technical result is increased tensile strength of composite material due to formation of structure of oriented carbon nanotubes in polymer matrix. That is performed by means of flat-rate flow of direct current which destroys filler agglomerates. The specialists can also be interested in the following inventions in the area of nanotechnologies: a method to produce powder containing nanocrystalline cubic tungsten carbide; a method to produce porous graphene membranes and the membranes produced with this method; suppressor coating on the basis of polymer matrix with inclusion of carbon nanotubes and a method to produce it; a method to determine location of polyethylene gas pipeline and places of possible illegal tapping of those pipeline; a method to produce biphasic thermoelectric ceramics; electron-beam system of 3D radiant nanomodification for materials and articles; lab-on-fruit skin and lab-on-leaf towards recognition of trifluralin using Ag-citrate/GQDs nanocomposite stabilized on the flexible substrate: A new platform for the electroanalysis of herbicides using direct writing of nano-inks and pen-on paper technology; and others. Conclusion. One of the most challenging tasks the economy of every country face is to increase industrial competitiveness through technological upgrade. From the side of the state and companies the principal object to control in this process are the people and enterprises dealing with introduction of inventions and new technologies.

Nanotechnologies in construction, carbon nanotubes, nanodimensional powders, nanoparticles, nanomodification of materials

Короткий адрес: https://sciup.org/142226902

IDR: 142226902 | DOI: 10.15828/2075-8545-2021-13-3-158-165

Текст научной статьи Inventions of scientists, engineers and specialists from different countries in the area of nanotechnologies. Part III

Advanced technologies impress people’s imagination demonstrating the latest achievements (materials, methods, systems, technologies, devices etc.) that dramatically change the world. This, first of all, concerns nanotechnological inventions designed by scientists, engineers and specialists from different countries.

REVIEW OF NANOTECHNOLOGICAL INVENTIONS

MAIN PART

Composite material with oriented carbon nanotubes (RU 2746103 С1)

It is known that carbon nanotubes possess high strength characteristics and they can be used in production of polymer nanocomposites (PNCM). However, it is also known, large concentration of carbon nanotubes leads to their agglomeration, that decreases strength characteristics of polymer composite materials. To solve this problem different methods are used, for example, application of surface-active agents (SAA), ultrasound treatment et al. One of the ways to resolve this task is to orient carbon nanotubes in polymer matrix.

The invention [1] refers to the area of composite materials which consist of polymer matrix and filler that is often presented by carbon nanotubes (CNT). The composite material possesses increased tensile strength due to formation of structure of oriented carbon nanotubes in polymer matrix. That is performed under uniform constant electric field. The technical result is increased tensile strength of composite material due to formation of structure of oriented carbon nanotubes in polymer matrix. That is performed by means of uniform constant electric field which destroys filler agglomerates. The technical result is achieved because the composite material contains reinforcement which is impregnated with polymer binder which forms matrix and carbon nanotubes oriented in polymer matrix along reinforcement by uniform constant electric field, and the content of carbon nanotubes is chosen within the range 0,05–0,3 vol.%.

Dry sliding wear behavior of Fe–Cr–C–B hardfacing alloy modified with nano-CeO2 and its mechanisms of modification

Wear is one of the most common failure forms of mechanical equipment. Some researchers proposed that wear is a progressive loss of materials due to the mechanical action of two bodies while in contact. The mechanical parts suffering from wear damage lost the original size and increased the downtime of equipment and the cost. And the wear of heavy complicated machines may even lead to production safety accident. To overcome different kinds of wear problems means saving energy and reducing the discharge of CO2 greenhouse gas. For example, the racks on the legs of offshore wind turbine installation platform suffered from serious wear damage during the lifting and descending process because of bearing huge loads. To repair the worn-out racks on the legs of offshore wind turbine installation platform is beneficial for saving steel materials and reducing the cost of exploiting and utilizing offshore wind power which is non-polluting and renewable [2].

In this work, hypereutectic Fe–Cr–C–B hardfac-ing alloy was prepared. Nano-scaled CeO2 was added to improve the wear resistance of the hardfacing alloy. This work was dedicated to studying the dry sliding wear behavior of Fe–Cr–C–B hardfacing alloy modified with nano-CeO2 and revealing the mechanisms of modification of nano-CeO2. WC-Co cemented carbides ball was chosen as the counter body material. Both of the hardfacing alloy and WC-Co cemented carbides were composed of carbide with high hardness and metal matrix with low hardness. The wear rates of the hardfacing specimens under different wear loads were measured. The wear tracks and wear debris were observed to study the wear mechanisms. The rare earth compounds in the hardfacing specimens were studied to reveal the mechanisms of modification of nano-CeO2 in detail. In conclusion, the mechanisms of modification of nano-CeO2 in the Fe–Cr–C–B hardfacing alloy were favorable to sliding wear resistance improvement.

A method to produce porous graphene membranes and the membranes produced with this method (RU 2745631 С2)

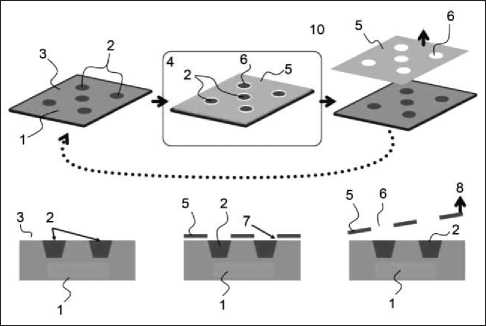

The invention refers to nanotechnology and can be used in production of waterproof and airproof membranes for textile materials, barrier membrane for water, in cell phones and и portable electronic devices, filters and gas-separation membrane [3]. Fig. 1 illustrates direct formation of porous graphene. First, catalytically active substrate (1) is chosen from Cu, Ni, Pt, Ru, Ir, Rh or combination of them. Then catalytically inactive material chosen from molybdenum, wolfram, gold, silver, zirconium, niobium, chrome, or mixture/alloy of them, or oxide systems of them, or aluminum oxide is precipitated on it from vapour phase. After thermal annealing has been completed, active substrate (1) with many catalytically inactive domains (2) which sizes corresponds to sizes of pores (6) in obtained porous graphene layer (5) is produced. Then thermal annealing is performed in medium containing 50–90 vol.% Н2, in gas-carrier with content Ar, Не and Ne or N2, under temperature 900–1200оС and pressure 1–100000 Pa for 30–120 min. The porous graphene layer (5) with thickness less than 100 nm and pores (6), which average size is 5–900 nm and their density is from 0,1 to 100×1010 cm–2 is obtained on the surface (3) of catalytically active substrate (1) by means of chemical precipitation from gas phase, using carbon source, for example, methane, ethane, ethylene, acetylene of mixture of them, volume ratio of them is 1–1000 parts to 1 part of hydrogen, under temperature 300–1200оС for 1–12 hours. Pores (6) in graphene layer (5) are formed in situ due to presence of catalytically inactive domains (2). Obtained porous graphene layer (5) is removed (8) from substrate (3) by means of Van der Waals flaking off, electrochemical demixing, ultrasound and/or thermal impact and is transferred to another substrate chosen

REVIEW OF NANOTECHNOLOGICAL INVENTIONS

Fig 1. Direct formation of porous graphene with pores (or holes)

from woven, nonwoven or knitted structure, metal or ceramic network or foam, fixing it on one or two sides of the substrate, and the substrate (3) is reused for obtaining porous graphene layer (5). The invention makes it possible to facilitate method for obtaining porous graphene membranes, to improve their mechanical properties, to control pore size as well as to set large-scale production of such membranes.

A method to produce powder containing nanocrystalline cubic tungsten carbide (RU 2747329 С1)

The invention refers to material science and nanotechnologies, in particularly, to the method to obtain nanopowder containing nanocrystalline cubic tungsten carbide [4]. The method comprises preliminary vacuum pumping of the chamber and filling it with argon under normal atmosphere pressure and room temperature. Tungsten and carbon-containing electric discharge plasma is generated by means of coaxial magnetoplasma accelerator with graphite core and with composite central electrode of nipple made of graphite and steel tang, with electrically fusible strap of pressed mixture of metal tungsten and technical carbon, placed between graphite core and nipple, when charge voltage of 6 mF capacitor is 3,0 кV. The method is performed in three stages. At the first stage electric discharged plasma is generated by means of electrically fusible strap made of pressed mixture of metal tungsten and technical carbon, which ratio W:C is 0,70:0,30. Obtained powder-like material is collected, pressed and used at the second stage as electrically fusible strap. Having placed it between graphite core and nipple, the chamber air is pumped out and the chamber is filled with argon under standard atmosphere pressure and room temperature and electric discharged plasma is generated under charge voltage 2.5 kV of capacitor. Obtained at the previous stage powder material is collected, pressed and used at the third stage as electrically fusible bonding strip, then having placed it between graphite core and nipple, the chamber air is pumped out and the chamber is filled with argon under standard atmosphere pressure and room temperature and electric discharged plasma is generated under charge voltage 2.0 kV of capacitor. The proposed method allows producing the powder, containing nanocrystalline cubic tungsten carbide with particle size up to 10 nm.

A method to produce tungstenless hardalloyed powders from the waste of KNT-16 (КНТ-16) alloy in ethyl alcohol (RU 2747197 С1)

The invention refers to powder metallurgy, in particularly, to the method to obtain powder of tungstenless hard alloy and can be used to produce sintered articles, to apply wear-resistance coatings for restoration and reinforcement of engineering details [5]. The method to produce tungstenless hardalloyed micro- and nanosized globular powders from the wastes of tungstenless hard alloy comprises electroerosive dispergation of hard alloy wastes. The wastes of tungstenless KNT-16 hard alloy are exposed to electroerosive dispergation in ethyl alcohol under pulse repetition rate 95–105 Hz, electrode voltage 195–205 V and capacitor capacity 25,5 µF. Then obtained solution which contains micro-, nano- and macrometric powder is centrifuged to separate macrometric powder from it, after that the solution with micro- and nanopowder is evaporated and obtained micro- and nanopowder is dried. Production of powder material is performed from tungstenless hard alloy by means of electroerosive dispergation, there is no need to sinter the components for further grinding and obtaining final product, that significantly decreases energy consumption and cost of the process. The invention can be used for manufacturing sintered articles, application of wear-resistant coatings for restoration and reinforcement of the parts of engineering equipment in ore mining and smelting industry, automobiles and ships.

Lab-on-fruit skin and lab-on-leaf towards recognition of trifluralin using Ag-citrate/GQDs nanocomposite stabilized on the flexible substrate: A new platform for the electroanalysis of herbicides using direct writing of nanoinks and pen-on paper technology

Pesticides are broadly used as a significant tool in agriculture to control pathogens, weeds, and insects. These chemicals are used to prevent, repel, or eliminate the occurrence or effects of organisms that have the potential to harm agricultural crops. Herbicides are one type of pesticides used for prevention or elimination of weeds. Trifluralin, a pre-emergence and selective herbicide, has been used since 1960s in the cultivation of diverse plants including fruits, vegetables, nuts, and grain crops. This herbicide causes cell death by interfering with the

REVIEW OF NANOTECHNOLOGICAL INVENTIONS polymerization of microtubules. Overuse of it leads to environmental pollution and affect human health. Triflu-ralin leads to physiological changes including changes in the liver and serum parameters, decreased fetal size and weight and increased miscarriage, kidney damage, allergies, etc. Also, trifluralin affects endocrine function and is listed as an endocrine disrupter in the European Union list. In addition to mammalian toxicity, there are concerns about the impact of trifluralin on the environment [6].

In this work, an innovative conductive ink based on Ag-citrate/ GQDs was synthesized and used to produce a three-electrode sensor on the leaf and apple skin. The properties of the synthesized ink were evaluated using FE-SEM, TEM, EDS, XRD, ICP and Raman spectroscopy techniques. According to the results of the ink study, FE-SEM images confirm the presence of graphene quantum dots in the ink sample. The ICP results also confirm the presence of silver in the synthesized ink. TEM images show the presence of graphene quantum dots and the correct arrangement of the polymer plates. After identifying the ink structure, its conductivity and resistance were also investigated. The electrodes were made using ink and direct writing method. Then, trifluralin was evaluated by CV, DPV, and SWV electrochemical techniques. Based on the results, it can be concluded that the proposed three-electrode system has the potential to be used onsite analysis of other herbicides.

A method to determine location of polyethylene gas pipeline and places of possible illegal tapping of those pipeline (RU 2745048 С1)

The invention refers to construction, gas pipeline transport in gas industry and can be used to determine position of polyethylene gas pipelines and places of possible illegal tapping of pipeline [7]. The essence of the invention is that natural gas is marked with ferrous particles pumped into distribution polyethylene pipeline prior to sector of possible illegal tapping (Fig. 2). Then subsurface

Injection of nanoparticles into gas

Fig. 2. An example of how method to determine location of polyethylene gas pipeline and places of possible illegal tapping of those pipeline can be performed exploration of streamline of gas flow with suspended particles is performed. Ferrous nanoparticles are pumped into distribution pipeline by portions of different volumes with specified period of supply. This technical solution expands functionalities and makes it possible to use this method for polymer unreinforced tubes or tubes reinforced with synthetic fibers, enhances engineering applicability and decreases cost of its production.

Suppressor coating on the basis of polymer matrix with inclusion of carbon nanotubes and a method to produce it (RU 2745976 С1)

The invention refers to composite materials which can be applied on the surface of different parts to create suppressor coatings [8]. A suppressor coating formed on the surface of detail is characterized by the presence of carbon nanotubes, at this, it comprises, at least, the first layer of composite material which is polymer matrix with inclusion of multi-wall oriented carbon nanotubes with diameter from 8 nm to 250 nm. The thickness of the layer is from 0.1 to 1mm, its density of oriented carbon nanotubes is from 0.5 to 1 g/cm3, the quantity of oriented carbon nanotubes is from 5 to 20 mass.% of composite material mass. A method to produce the mentioned coating has been applied too. The invention provides obtaining high-quality suppressor coating on the details with complex shape and enhanced method to apply this coating as it does not require to use high-temperature processing of the detail.

A method to produce biphasic thermoelectric ceramics (RU 2745910 С1)

The invention refers to nanotechnologies, in particularly, to the methods of obtaining new biphasic ceramic materials used in thermal power generation [9]. A method to produce biphasic thermoelectric ceramics comprises preparation of powder system of initial strontium carbonate SrCO3 and titanium dioxide TiO2 powders by joint high-energy grinding them in ethanol, annealing and drying, after that obtained material is sintered under mechanical load. Powder system is formed from submicron strontium carbonate SrCO3 powder and nanosized titanium dioxide TiO2 powder taken in quantity that provides ratio of formed after sintering phases of strontium titanate SrTiO3 and titanium dioxide TiO2 in rutile shape by volume 1:1. Drying is performed under the temperature 60–80оС for 24–48 hours with further granulation of powder system through grading screen with efficient size of combs 75 µm and with further air annealing under 600–800оС for 2–4 hours. Obtained material is exposed to reaction spark plasma sintering under outer pressure 21,5 MPa with heating rate 55оС/min up to 1200–1250оС is kept under this temperature for 5 min. It is not neces-

REVIEW OF NANOTECHNOLOGICAL INVENTIONS sary to perform annealing after sintering. The technical result is production of biphasic thermoelectric ceramics SrTiO3/TiO2 with evenly distributed phases in the volume, rich in boundaries between two phases, in which it is possible to form two-dimensional electronic gas.

Avidin-biotin technology to synthesize multi-arm nanoconstruct for drug delivery

Targeted drug delivery to joint tissues like cartilage remains a challenge that has prevented clinical translation of promising osteoarthritis (OA) drugs. Local intra-articular (IA) injection of drugs suffers from rapid clearance from the joint space and slow diffusive transport through the dense, avascular cartilage matrix comprising of negatively charged aggrecan-glycosaminoglycans (GAGs). The high negative fixed charge density (FCD) of cartilage provides a unique opportunity to use electrostatic interactions for enhancing transport, uptake, and retention of cationic drug carriers [10].

This paper presents a protocol for synthesizing cartilage penetrating cationic multi-arm Avidin (mAv) nanoconstruct that provides multiple sites for covalent loading of Dex using hydrolysable ester linkers. A method was developed for designing more stable ester linkers by increasing carbon spacer length between the ester and adjacent amide bond by replacing SA with GA or PA. The controlled release mAv-Dex formulation containing ester derivatives from SA, GA and PA in 2:1:1 molar ratio showed a release half-life of 38.5±1.5 h providing sustained drug release over at least 10 days. This cationic multi-arm Avidin (mAv) nano-construct can enable intra-cartilage delivery of a broad array of small molecule OA drugs and their combinations to chondrocytes. Drug release rates can be modulated by using a combination of ester linkers with different rates of hydrolysis based on the type of drug, its target sites and state of disease. Avidin-biotin technology provides the flexibility for biotinylating other similar sized drugs as Dex that can then be conjugated with Avidin by simple mixing at room temperature, which can be conducted at the clinic prior to use.

Electron-beam system of 3D radiant nanomodification for materials and articles in reverse-micellar solutions (RU 2746263 С1)

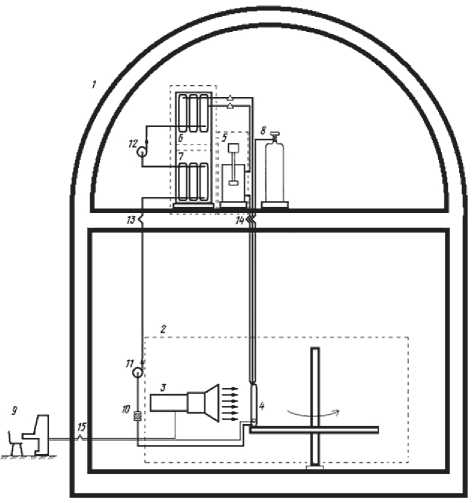

The invention refers to the means of production in the area of nanocomposite materials, catalysts, adsorbents, nanofunctionalization of coatings as well as in the area of radio electronics, electrical engineering, medicine, agriculture, agri- and biotechnologies [11]. Electron-beam system of 3D radiant nanomodification for materials and articles in reverse-micellar solutions contains two-level production-technological unit with biological radiation- proof protection and a system control panel, placed out of two-level production-technological unit, and connected to it by electric cables (Fig. 3). The top level of two-level production-technological unit comprises a container for preparation of reverse-micellar solution, a unit of reactor washing, a unit of reagent regeneration and a cylinder with inert gas, the bottom level of the unit comprises electron accelerator and a system of reactors. The technical result is the increased efficiency and safety of the processes concerned radiation-chemical modification of the objects.

Fig. 3. The scheme of 3D radiant nanomodification for materials and articles in reverse-micellar solutions, where:

-

1 – two-level production-technological unit;

-

2 – unit of dynamic modification in situ;

-

3 – electron accelerator;

-

4 – system of reactors;

-

5 – container for preparation of reverse-micellar solution;

-

6 – unit of reactor washing;

-

7 – unit of reagent regeneration;

-

8 – cylinder with inert gas;

-

9 – system control panel;

-

10 – adsorber;

-

11 – pump for mixture pumping;

-

12 – backing pump;

-

13 – labyrinth of radiation protection of regeneration supply line;

-

14 – labyrinth of radiation protection of the lines supplying reagents and gases into reactor;

-

15 – labyrinth of radiation protection of electric cables of the system.

REVIEW OF NANOTECHNOLOGICAL INVENTIONS

Nano-fertilizers and their impact on vegetables: Contribution of Nano-chelate Super Plus ZFM and Lithovit®-standard to improve salt-tolerance of pepper

Global warming, desertification and soil salinization are currently occurring globally and affecting food production by reducing the land capacity of cultivated soil. Land salinization is happening mainly in irrigated soils, where >45 million ha are salt affected. If no mitigation measures are taken, it is estimated that 50% of agricultural lands will be similarly affected by 2050. The implementation of nanotechnology for the amelioration of plant tolerance against abiotic stress has been widely reported in last years. In this study, the separate and combined effects of Nano-chelate Super Plus ZFM (A) and Lithovit®-standard (B) on salt-stressed chili pepper were evaluated. Two different concentrations of each products were tested (A1, 2.5 g L-1, A2, 5 g L-1; B1, 3 g L-1 and B2, 5 g L-1) on pepper irrigated by three NaCl solutions (1.5dS m-1, 3dS m-1 and 6dS m-1. The control (no treatment) experiments were only irrigated with the three NaCl solutions. Spraying Nano-chelate Super Plus ZFM in low concentration (A1) enhanced significantly iron, zinc and manganese content in shoots and fruits. The application of Lithovit®- standard at high concentration ameliorated calcium and magnesium content in plant parts. A1B2 caused the highest enhancement in leaf number, fresh and dry weights of plant parts. It also improved fruit number significantly, fruit fresh and dry weight, yield plant-1 and fruit dimension compared to control under all NaCl solutions. All treatments improved carotenoids content and reduced cellular electrolyte leakage and sodium content, as compared to control. Low concentration of Nano-chelate Super Plus ZFM improved chlorophyll a (Chl a), b (Chl b) and total chlorophyll (TChl) more than the high concentration (A2). Photosynthetic pigments were maximized by A1B2. Treating plants with A1B2 and A1B1 improved the most nitrogen and potassium content respectively in shoots and fruits compared to control at all EC levels. Combining both products would be an efficient method inducing salt-tolerance of pepper [12].

A method to produce an alloying composition for preparing composite materials on the basis of aluminum or aluminum alloys (options) (RU 2746701 С1)

Composite materials on the basis of aluminum are known to be attractive due to their characteristics: specific strength, resistance to friction and high temperatures. The properties of aluminum composite materials depend on size of the filler dispersed in it. Finer filler, for example, carbon nanotubes provide better material properties, but it is very difficult to disperse evenly such filler as its size is extremely small.

The invention [13] refers to metallurgy and can be used to produce strengthened aluminum materials by moulding technologies. Alloying composition is obtained by placing carbon nanotubes into gas-tight aluminum envelope, then by providing vacuum in gas-tight aluminum envelope and heating it adsorbed gases are partially removed from the surface of carbon nanotubes and provide mass ratio between nanotubes and adsorbed gases to be not less than 100. Then gas-tight aluminum envelope with carbon nanotubes in it is deformed until incorporation of carbon nanotubes into envelope material or mixture of carbon nanotubes and metal powder is placed into gas-tight aluminum envelope, after that vacuum is provided gas-tight aluminum envelope. Gas-tight aluminum envelope with mixture is heated and deformed in such a way to obtain alloying composition in the form of half-finished product in which one part of nanotubes has no contact with outer surface of the product and the pores linked with outer surface of the product.

The specialists can also be interested in the following inventions related to nanotechnologies:

-

• Ferroelectric nanocomposite on the basis of porous glass and monopotassium phosphate materials [14].

-

• Ceramic material and a method to produce it [15].

-

• A method to disperse flash-resistant nanoparticles [16].

-

• A self-hardening composition based on polydimethylsiloxane [17].

-

• Metal pigments with anticorrosion coatings on the basis of aluminum and/or alloys of it [18].

-

• Nanosize logical inverter for digital devices [19].

-

• A method to modify carbon nanotubes for hydrophilic or hydrophobic surfaces [20].

-

• A method to produce composite metal-dispersed coating, a dispersed system for precipitation of composite metal-dispersed coating and a method to obtain it [21].

-

• A method of adsorbtion refining for wastewater with content of aromatic compounds of benzene series [22].

-

• A method to obtain multiferroic on the basis of ferromagnetic glass matrix [23].

CONCLUSION

One of the most challenging tasks the economy of every country face is to increase industrial competitiveness through technological upgrade. From the side of the state and companies the principal object to control in this process are the people and enterprises dealing with introduction of inventions and new technologies.

Therefore, we hope that the information published in this section will be in demand and useful for specialists.

REVIEW OF NANOTECHNOLOGICAL INVENTIONS

Список литературы Inventions of scientists, engineers and specialists from different countries in the area of nanotechnologies. Part III

- Krasnovsky A.N., Kischuk P.S. Composite material with oriented carbon nanotubes. RF Patent 2746103 C1. 2021-04-07.

- Gou J., Wang Y., Zhang Y., Wang C., Wan, G. Dry sliding wear behavior of Fe–Cr–C–B hardfacing alloy modified with nano-CeO2 and its mechanisms of modification. Wear. 2021; 203756.

- Khait M., Park H.G., Choi К. A method to produce porous graphene membranes and the membranes produced with this method. RF Patent 2745631. 2021-03-29.

- Sivkov А.А., Nasyrbaev А.R., Nikitin D.S., Shanenkov I.I. A method to produce powder containing nanocrystalline cubic tungsten carbide. RF Patent 2747329. 2021-05-04.

- Ageeva E.V., Ageev E.V., Sabelnikov B.N. A method to produce tungstenless hardalloyed powders from the waste of KNT-16 (КНТ-16) alloy in ethyl alcohol. RF Patent 2747197. 2021-04-29.

- Saadati, A., Hassanpour, S., & Hasanzadeh, M. (2020). Lab-on-fruit skin and lab-on-leaf towards recognition of trifluralin using Ag-citrate/GQDs nanocomposite stabilized on the flexible substrate: A new platform for the electroanalysis of herbicides using direct writing of nano-inks and pen-on paper technology. Heliyon. 6(12): e05779.

- Belyaeva N.V. A method to determine location of polyethylene gas pipeline and places of possible illegal tapping of those pipeline. RF Patent 2745048. 2021-03-18.

- Shemukhin А.А., Tatarintsev А.А., Vorobieva Е.А., Chechenin N.G. Suppressor coating on the basis of polymer matrix with inclusion carbon nanotubes and a method to produce it. RF Patent 2745976. 2021-04-05.

- Kosianov D.Yu., Zavialov A.P. A method to produce biphasic thermoelectric ceramics. RF Patent 2745910. 2021-04-02.

- Zhang C., He T., Vedadghavami A., Bajpayee A. G. Avidin-biotin technology to synthesize multi-arm nanoconstruct for drug delivery. MethodsX. 2020; 7: 100882.

- Suvorova О.V., Bystrov P.A., Pavlov Yu.S., Revina A.A. Electron-beam system of 3D radiant nanomodification for materials and articles in reverse-micellar solutions. RF Patent 2746263. 2021-04-12.

- Sajyan T.K., Alturki S.M., Sassine Y.N. Nano-fertilizers and their impact on vegetables: Contribution of Nano-chelate Super Plus ZFM and LithovitR-standard to improve salt-tolerance of pepper. Annals of Agricultural Sciences. 2020; 65(2): 200–208.

- Predtechensky M.R., Khasin A.A., Alekseev A.V. A method to produce an alloying composition for preparing composite materials on the basis of aluminum or aluminum alloys (options). RF Patent 2746701. 2021-04-19.

- Ivanov L.A., Xu L.D., Bokova E.S., Ishkov A.D., Muminova S.R. Inventions of scientists, engineers and specialists from different countries in the area of nanotechnologies. Part I. Nanotechnologies in Construction. 2021; 13(1): 23–31. Available from: doi: 10.15828/2075-8545-2021-13-1-23-31.

- Podzorova L.I., Ilycheva А.А., Kutuzova V.Е. et al. Ceramic material and a method to produce it. RF Patent 2744546. 2021-03-11.

- Kuleshov P.S. A method to disperse flash-resistant nanoparticles. RF Patent 2744462. 2021-03-09.

- Ivanov LA., Kapustin I.A., Borisova O.N., Pisarenko Zh.V. Nanotechnologies: a review of inventions and utility models. Part II. Nanotechnologies in Construction. 2020; 12(2): 71–76. Available from: doi 10.15828/2075-8545-2020-12-2-71-76.

- Garshev А.V., Putlyaev V.I., Evdokimov P.V. et al. Metal pigments with anticorrosion coatings on the basis of aluminum and/or alloys of it. RF Patent 2746989. 2021-04-23.

- Gurovich B.А., Prikhodko К.Е., Kuleshova Е.А., Kutuzov L.V. Nanosize logical inverter for digital devices. RF Patent 2744161. 2021-03-03.

- Ivanov L.A., Bokova E.S., Muminova S.R., Katuhin L.F. Nanotechnologies: a review of inventions and utility models. Part I. Nanotechnologies in Construction. 2020; 12(1): 27–33. Available from: doi: 10.15828/2075-8545-2020-12-1-27-33.

- Esaulov S.К., Esaulova Ts.V. A method to produce composite metal-dispersed coating, a dispersed system for precipitation of composite metal-dispersed coating and a method to obtain it. RF Patent 2746863. 2021-04-21.

- Koshelev A.V., Atamanova О.V., Tikhomirova E.I. et al. A method of adsorbtion refining for wastewater with content of aromatic compounds of benzene series. RF Patent 2747540. 2021-05-06.

- Tumarkin A.V., Sinelschikova O.Yu., Tyurnina N.G. et al. A method to obtain multiferroic on the basis of ferromagnetic glass matrix. RF Patent 2747496. 2021-05-05.