Inventions of scientists, engineers and specialists from different countries in the area of nanotechnologies. Part I

Автор: Ivanov L.A., Xu L.D., Bokova E.S., Ishkov A.D., Muminova S.R.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Review of nanotechnological inventions

Статья в выпуске: 1 Vol.13, 2021 года.

Бесплатный доступ

The article provides an abstract review of patents. The results of creative activity of scientists, engineers and specialists, including inventions in the field of nanotechnology and nanomaterials, being implemented, allow achieving a significant effect in construction, housing and community services, and related sectors of the economy. For example, the invention «A method to produce graphene-containing suspensions by means of graphite exfoliation and a device to perform it» refers to chemical and construction industries and can be used in modification of plastic lubricant, epoxy resins and concretes. The technical task of the invention is to increase efficiency of graphite exfoliation, to produce graphene-containing suspensions in continuous mode and to decrease unit labor costs for production of such suspensions. The task is achieved due to the following steps of the method: preparation of mixture of crystal graphite and liquid, graphite concentration is from 10 to 20 mass percent in container for initial suspension, supply of initial suspension into rotor plant, exfoliation of graphite and withdrawal of treated suspension from rotor plant, exfoliation of graphite is performed in several rotor plants one after another, and initial suspension is supplied into the first rotor plant by pump with fixed consumption, after treated suspension has been withdrawn from one of rotor plant, it is supplied into next rotor plant, and from the last rotor plant treated suspension is delivered into centrifugal separator, after separation centrifuge effluent is supplied into container of finish product and precipitate is delivered to a container of initial suspension in which graphite and liquid are added to obtain specified concentration of graphite in initial suspension. The specialists can also be interested in the following inventions in the area of nanotechnologies: Evolution of PV technology from conventional to nano-materials; a composition of coating for colored decoration of building walls; ferroelectric nanocomposite on the basis of porous glass and monopotassium phosphate materials; innovative technology of municipal wastewater treatment for rapid sludge sedimentation and enhancing pollutants removal with nano-material, a method to obtain powder mixture of bidispersed ceramic and metal particles, micro- and nano-plastic pollution: behavior, microbial ecology, and remediation technologies; a method to obtain multilayer wear-resistant diamond like coatings; fuel element with composite protective coating et al.

Nanotechnologies in construction, nanoparticles, nanostructures, nanofibers, nanomaterials

Короткий адрес: https://sciup.org/142226931

IDR: 142226931 | DOI: 10.15828/2075-8545-2021-13-1-23-31

Текст научной статьи Inventions of scientists, engineers and specialists from different countries in the area of nanotechnologies. Part I

Advanced technologies impress people’s imagination demonstrating the latest achievements (materials, methods, systems, technologies, devices etc.) that dra- matically change the world. This, first of all, concerns nanotechnological inventions designed by scientists, engineers and specialists from different countries.

REVIEW OF NANOTECHNOLOGICAL INVENTIONS

MAIN PART

A method to produce graphene-containing suspensions by means of graphite exfoliation and a device to perform it (RU 2737925 С1)

The invention refers to chemical and construction industries and can be used in modification of plastic lubricant, epoxy resins and concretes. The technical task of the invention is to increase efficiency of graphite exfoliation, to produce graphene-containing suspensions in continuous mode and to decrease unit labor costs for production of such suspensions.

The task is achieved due to the following steps of the method: preparation of mixture of crystal graphite and liquid, graphite concentration is from 10 to 20 mass percent in container for initial suspension, supply of initial suspension into rotor plant, exfoliation of graphite and withdrawal of treated suspension from rotor plant, exfoliation of graphite is performed in several rotor plants one after another, and initial suspension is supplied into the first rotor plant by pump with fixed consumption, after treated suspension has been withdrawn from one of rotor plant, it is supplied into next rotor plant, and from the last rotor plant treated suspension is delivered into centrifugal separator, after separation centrifuge effluent is supplied into container of finish product and precipitate is delivered to a container of initial suspension in which graphite and liquid are added to obtain specified concentration of graphite in initial suspension.

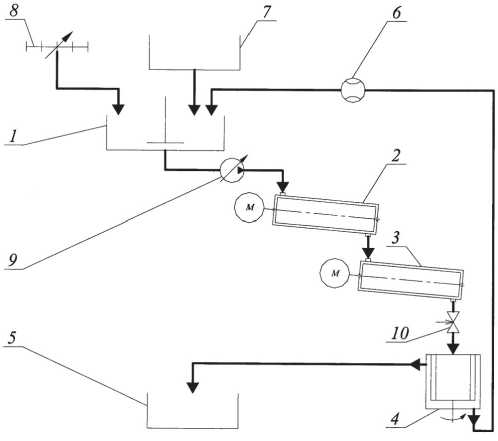

Fig. 1 is a general assembly system. A mixture which contains liquid and 10-20 mass.% of crystalline graphite is prepared in the container for initial suspension. Container 1 comprises a feed unit for liquid from container 7, flow transmitter 6 and a doser of graphite 8. There is a pump 9

Fig. 1. A general assembly system with controlled performance between container 1 and the first rotor plant 2. Due to this pump initial suspension is supplied into exfoliation unit, comprising 5–10 rotor plants, consistently connected in such a way that the suspension withdrawal hole of each previous plant is connected to the suspension supply hole of each follow plant, and suspension withdrawal hole from the last plant 3 is connected to the suspension supplying nozzle into centrifugal separator 4 through controlled valve 10. Each rotor plant contains a stator in the form of cylindrical shell with holes for supply and withdrawal of suspension, rotor with vanes and a rotary drive of rotor. After separation centrifuge effluent is supplied into container of finish graphene-containing suspension 5 and precipitate is delivered to a container of initial suspension 1.

Evolution of PV technology from conventional to nanomaterials

To meet the increasing demand of clean and green energy, solar cells are one of the choices [2]. The advantages of utilizing solar energy is that the solar energy is both sustainable and reliable. In addition to this, this resource is always available throughout the year in most of the regions in the world, which is sunlight. This is accomplished through the use of photovoltaic (PV) solar cells. Conventional solar cells are not efficient enough and are expensive, relatively speaking. Improvement in performance of the solar cell is the challenge we are facing to make solar energy widely usable in our daily life. Until now, a variety of ideas and research have been generated to enhance the performance of the solar cell. In fact, nanotechnology can open the doors for production of cost effective and efficient solar system on a large scale. The main aim of this research is to provide an introduction about the PV cells, its design, parameters, and characteristics. Further, this research explores the evolution of PV technology from conventional to new materials such as nano materials. The paper covers conventional PV cell and photovoltaic cell. A descriptive comparative analysis of different solar cells according to their materials, efficiency, life span, benefits, and limitations associated with them are discussed. Finally, a conclusion of the presented study and future perspectives are provided. It is envisaged that in the future, the carbon nanoparticles and its allotrope forms such as graphene, carbon nanotubes and fullerenes will offer high performance as compared to conventional silicon based cell and thus will help in providing a new outlook for the solar commercial market.

A composition of coating for colored decoration of building walls (RU 2738655 С2)

It is a long time numerous coating systems used for colored decoration of building walls have been known.

REVIEW OF NANOTECHNOLOGICAL INVENTIONS

As an example, they can be based on dispersed paints, silicate paints or dispersed-silicate paints. The use of the coating composition as a coating for building facades or as a coating for inner walls determines the range of their characteristics that should be met. In particularly, the use of coating composition as an interior paint imposes high requirements to gloss grade. For example, it is necessary to reach reproducible required gloss grade, such as matt, medium gloss, also called silk-sparkling and sparkling (for example, it is stated in DIN 13300). However, it is not always achievable.

The task of the invention is to design a coating composition that allows obtaining special coatings with gloss grade matt, medium gloss, also called silk-sparkling and sparkling [3]. The coating composition contains at least one organic binder comprising polyethylene-co-vinyl acetate, copolymer on the basis vinylarene compounds and acrylate or copolymers on the basis of pure acrylates, liquid glass, kieselsol, at least one the first filler and/or at least one the first pigment with particle size D50, less or equal 2 µm. At this, mass content of kieselsol solids is higher than mass content of liquid glass solids, in conversion to total mass of solid of coating composition in each case. The patent also proposes a coating obtained from such composition, and application of coating composition to obtain coating on the surface of underlayment.

One should note, kieselsol are available at the market in the form of aqueous colloid suspensions of molecules of polysilicic acid. Kieselsol is preferably to be alkaline and possess pH > 9. It has been also revealed that it is very profitable, especially if one needs to control desired gloss grade and matte grade, to use fine-dispersed kieselsols. At this, the average size of kieselsol particles is preferably to be 80 nm or less, more preferably – less or equal 40 nm, the most preferably – less or equal 20 nm. The average size of kieselsol particles is even more preferably to be less or equal 10 nm. For each option of invention, the average size of kieselsol particles also can be determined according to DIN ISO 9276-1:2004-09 and ISO 9276-2:2014-05. The invention makes it possible to produce silk-sparkling or sparkling coatings, which are high resistant to wet abrasion, if preservative-free, unchanging in storage place composition is used.

Ferroelectric nanocomposite on the basis of porous glass and monopotassium phosphate materials (RU 2740563 С1)

At present more and more attention is focused on synthetic materials with specified properties, the production of which is based on the influence of nanosized effects on the properties of materials. Leading position among such materials belongs to ferroelectric nanocomposites which properties are highly sensible to nanoeffects. That is due surface or boundary effects. Moreover, possibility to vary parameters of ferroelectric nanocomposites is quite high due to the presence of phase transitions in them, these transitions cause softened structure of nanocomposites and make it particularly transportable.

The invention refers to nanostructured materials with signified ferroelectric activity used as functional materials in the modern micro- and nanoelectronics [4]. Ferroelectric nanocomposite material contains matrix of porous glass and ferroelectric salt of monopotassium phosphate or ammonium dihydrophosphate as a filler. Diameter of transverse pores in matrix of porous glass is 7nm and volume ratio of filler to nanocomposite material is 0,2–0,25. The technical result is ferroelectric nanocomposite material with expanded temperature range of polar phase.

Innovative technology of municipal wastewater treatment for rapid sludge sedimentation and enhancing pollutants removal with nano-material

The rapid development of the economy and the acceleration of urbanization has caused increasingly scarce water supply worldwide. The massive increase of municipal wastewater and low utilization efficiency of municipal infrastructures has seriously affected the operation efficiency of urban system and threatened the ecological environment and human health. In this study, an innovative technique was developed by periodically adding nanofloc®, a commercial nano-type flocculant, to the compact, land-efficient modified SBR for treating municipal wastewater. Firstly, a laboratory-scale SBR was performed under different operation modes and parameters, and an innovative experimental method with adding anoxic reflux and nanofloc® was selected due to the efficient pollutant removal efficiency. And to investigate the effect of reactor size on SBR performance, and further verify the superior overall performance of the modified SBR and provide technical reference for practical applications, the same operation parameters were applied in a pilot-scale SBR. In addition, the mixed liquid suspended solids (MLSS), mixed liquid volatile suspended solids (MLVSS)/MLSS, SVI, and sludge particle size in both laboratory- and pilotscale modified SBRs were tested to investigate the influence of nanofloc® on sludge properties. The nutrients removal mechanism is discussed, and the novel technology was compared with AGS [5].

This study provides an alternative technique by adding nano-type composite flocculant to a modified SBR system. Efficient effluent quality and rapid sludge settling efficiency were obtained in both laboratory-scale and pilot-scale modified SBRs with a low HRT of 8 h, which was due to the electrical neutralization and bridging effects. From the perspectives of settleability of the sludge, the space, stability, and feasibility of this technology in the operation of municipal wastewater treatment plants, it

REVIEW OF NANOTECHNOLOGICAL INVENTIONS could be used as an alternative method for upgrading and reconstructing municipal wastewater treatment plants.

A method to obtain powder mixture of bidispersed ceramic and metal particles (RU 2740495 С1)

The invention refers to powder metallurgy and can be used in technologies aimed at forming nanocomposite materials and alloys. Mixtures are necessary to obtain composite materials on the basis of nanosize ceramic particles and microsize metal particles with evenly distributes in volume particles of matrix, that provides increased mechanical characteristics [6].

The technical result is the method to obtain powder mixture of bidispersed ceramic and metal particles that comprises mixing of powders in liquid-saturated medium in several steps. Mixing of powders in liquid-saturated medium is performed in two steps. Solution of petroleum-ether and stearic acid, mass ratio 199/1, is used as liquid-saturated medium. At the first step ceramic particles are mixed in liquid-saturated medium for not less than 15 minutes. At the second stage metal microparticles are added into the mixture and are mixed for not less than 15 minutes with further removal of liquid in drying oven under the temperature not less than 80оС в for not less than 24 hours. Diameters of ceramic nanoparticles are chosen within the range (30÷140) nm, diameters of metal microparticles - within the range (20÷180) µm, weight parts of powders and liquid are chosen in ratio 1/2, weight parts of nanoparticles and microparticles – in ratio 1/19.

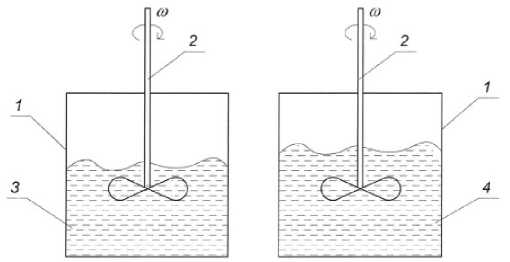

The essence of the invention is shown in figures 2a and 2b.

a) b)

Fig. 2а. The design of device to obtain powder mixture at the first stage: 1 – cylindrical container; 2 – mechanical agitator; 3 – mixture of ceramic nanoparticles with solution petroleum ether/stearic acid

Рис. 2b. The design of device to obtain powder mixture at the second stage: 1 – cylindrical container; 2 – mechanical agitator; 4 – mixture of ceramic nanoparticles and metal microparticles with solution petroleum ether/stearic acid

Micro- and nano-plastic pollution: Behavior, microbial ecology, and remediation technologies

The increase of plastic waste has become one of the most serious global environmental issues, and a variety of strategies have been proposed to control the increasing volume of contaminants caused by plastic waste. Although many studies have been conducted, only a few studies have conducted to investigate the microbial remediation of contaminants using cutting edge nano technology [7]. This study aims at addressing the environmental problems caused by micro-plastic (MP) and nano-plastic (NP) particles in the context of nanoscience such as synthetic nanoparticle plastic integrated research, microbial ecology, and remediation technologies to help elucidate their environmental effects, behavior, transport, eco-toxicity, etc. Interactions between plastic and microbes generally cause biofilm formation, which has biological effects that range from genes by influencing horizontal gene transfer to whole ecosystems by influencing biogeochemical cycling, carbon (C) sequestration, and climate. Plastic waste remediation via chemical and bio-nanotechnologies such as coagulation, membrane bioreactors, biodegradation, and phytoremediation are also studied. In this respect, thermochemical conversion of plastic waste into energy is a promising option. Further, molecular and -omics technologies can also facilitate the microbial biodegradation of MPs/NPs by enhancing enzymatic activity levels.

A method to obtain multilayer wear-resistant diamond like coatings (RU 2740591 С1)

It is known the main cause of wear in heavy-loaded friction nodes (gear and spline systems) is appearance of cracks in its contact zone, which results in shearing distortions and spallings related to fatigue damage and fretting. One of the ways to rise resistant and performance of spline systems with coating is to apply multilayer coatings. The layers with certain thermophysical and mechanical properties inside the coating are capable to slow down processes of crack formation and crack proliferation without decreasing microhardness, to improve thermos-stressed state of splines with coating and rise wear-resistant. One should also note that high rate and high surge of the friction intensify fretting-oxidation processes which cause softening of coating and base material.

The technical result of the invention is a technology to obtain ultra-hard carbon-metal coating with specified properties, namely, improved quality of diamond like films due to the change of their structure and composition, at this, the lower layer should have high adhesion with substrate material, middle layer – high hardness and high wear-resistance, top layer – proper thermal conductivity and heat-resistance with low friction index [8]. The technical result is achieved due to the following condi-

REVIEW OF NANOTECHNOLOGICAL INVENTIONS tion: a surface of the product is preliminary treated before the multilayer diamond like coating application process starts. Preliminary treatment comprises clearing of products with electropulse finishing in aqueous ammonia solution of low concentration (3–6%) for 2–3 min. The duration of finishing is chosen in accordance to degree of pollution and product sizes. After electropulse finishing ultrasound treatment of the products is performed. For this the products are placed into ultrasound bath filled with pure alcohol without contact of cutting edge and clearing is conducted for 2-5 min. The duration of clearing is chosen in accordance to degree of pollution and product sizes. Deposition of nanosize wear-resistant coatings on the products is held by means of vacuum plant BRV600Ф.

The invention can be used in industry or transport to increase performance characteristics of mechanisms, parts of friction nodes and details of precision engineering and to prolong their life-cycle.

A method to obtain nanocomposite magnetic and electrically-conductive material (RU 2739030 С1)

The invention can be used in manufacturing of the parts for electronics, sensors, supercondensers, electromagnetic screens, contrast materials applied in magnetic resonance imaging, in the information magnetic record systems, as materials absorbing electromagnetic radiation, etc. Hybrid metal-polymer nanocomposites on the basis of polymers with interface system are materials of new generation with wide range of functional characteristics [9]. Special place among these hybrid materials belongs to magnetic nanocomposites. Functional properties of such nanocomposites are determined by specific electronic structure of polyconjugated system as well as by nature of magnetic nanoparticles, that provides combination of magnetic, electric, electrochemical and other physicochemical characteristics in one material. The aim of the invention is to create nanocomposite magnetic material possessing simultaneously electric (electrically conductive) and superparamagnetic properties, high saturation magnetization and thermal stability, high electric conductivity, and to develop simple and efficient method to produce it.

The imposed task is solved due to proposed method of obtaining nanocomposite magnetic and electrically conductive material by joint dissolving Со (II) and Fe (III) salts in organic dissolvent and polymer matrix – polyphenoxazine (PPOA), removing dissolvent with precursor formation and further IR-heating of obtained precursor, characterized in that joint dissolving is performed simultaneously with single wall carbon nanotubes (SCNT) additionally added in solution, removal of dissolvent in conducted under temperature60–85оС, and IR-heating is performed in argon atmosphere under

350–600оС for 2–10 min till formation of nanocomposite material which contains 5–10 mass.% of weight of polymer of SCNT on which Co–Fe particles are fixed, the total content of Co–Fe particles in material is 2–45 mass. %.

Fuel element with composite protective coating (RU 2740701 С2)

After breakdown at APS “Fukushima-1” (Japan) in 2011 and the loss of fuel element, the world witnessed the start of the program on creation of “tolerant” fuel (Accident Tolerant Fuel, ATF), which eliminates production of hydrogen evolving in zirconium oxidation (zirconium-steam reaction Zr + 2H2O –> ZrO2 + 2H2↑) and causing formation of explosive hydrogen mixture in the top part of reactor. Hydrogen explosion is the most dangerous phenomenon in the course of radiation emergency and it results in spreading of radioactive matters at distance more than 100 km. The technical task being solved in this invention is to prevent both ballooning and leakage of fuel elements at early stage of heavy accident with loss of heat carrier medium and evolving of zirconium-steam reaction.

The technical task is solved due to the following steps: a multilayer protective coating is created on fuel-element cladding; one or several barrier layers in the protective coating are made of materials selected from the group comprising tantalum, molybdenus, wolfram, niobium, vanadium, hafnium (refractory body-centered cubic metals which form continuous series of solid solutions in connection with Ti) and outer layer is made of alloy on the basis of Cr–Al, characterized in that coating contains a composite layer consisting of bundles of nanotubes placed in plastic matrix of titanium alloy [10].

The new technical result of the invention is that carbon-containing material, in particularly, nanotubes with high specific strength that weakly depends on temperature up to 2500оС, convoluted on fuel element, provide “abdominal support” which stops ballooning and explosion of shells at the initial stage of accident accompanied with loss of heat carrier agent. Outer corrosion-resistant layer on the basis of Cr–Al alloy slows down oxidation of zirconium and hydrogen formation. Theoretical evaluations showed that fuel-element cladding’s radial rift strength under temperature 1000оС and corrosion resistance under 1400оС increase by more than one order when the proposed composite coating is applied. Stripping under radiation exposure is not expected due to hardness of composite layer. It is possible to choose such a final thickness of the proposed composite coating (for example, not more than 30 µm) that the invention won’t cause significant changes in fuel-air composition production technology and that is obvious advantage of the present invention.

REVIEW OF NANOTECHNOLOGICAL INVENTIONS

The science and technology of using nano-materials in engine oil as a lubricant additives

Nano technology is a developing field. The understanding of structures and procedures at the nuclear and sub-atomic scale (nanoscience) and the usage and control of nano scale phenomenon for particular purposes (nanotechnology), have advanced in recent years. The intersection of nanotechnology with many fields will increase human capability at various levels [11].

This study concentrates on the new application patterns for nanofluids notwithstanding the heat transfer characteristics of fluids at nano scale. This study describes the impact of adding lubricant additives on the viscoelastic and thermo-physical properties of engine oils. The engine oils used in automotive industry are one of the most widely used consumable entities. There has been an increasing demand to improve the performance of engine oil lubricants. For that purpose, performance enhancing additives have been added to engine oil lubricants. Subsequently, there is an increasing need to show the contribution lubricant additives make towards the automotive industry, the consumer, and the impact on the environment. Such additives encompass applications for lubrication of passenger car (diesel and gasoline engine) lubricants, truck, coach and bus diesel engine lubricants, heavy duty engine oil etc. This study demonstrates the contribution made by lubricant additives in these applications to the consumer, industry, and the environment, through their ability to optimise desirable lubricant properties while suppressing unwanted ones. The study was conducted in perspectives of nanotechnology.

A method to produce hollow microspheres from aluminium oxide (RU 2740748 С1)

The invention refers to the methods used to produce non-organic fillers from hollow nanospheres of aluminium oxide, used as the basis for sorbents, catalyst carriers, fillers for heat-resistant and thermal insulating coatings and other functional materials [12].

The task of the technical solution was to develop a method for manufacturing of hollow microspheres from aluminium oxide as it is aluminium that provides average size of microsphere in the range from 40 to 100 nm and at the same time facilitates manufacturing process. The imposed task is solved in the following way. The method to produce hollow microspheres from aluminium oxide comprises: hydrothermal treatment of aqueous solution of aluminium nitrate and monosaccharide, washing-out of the product of hydrothermal treatment in the form of carbon core with aluminium oxide coating in distilled water, its drying and annealing in air till obtaining hollow microspheres of aluminium oxide. The novelty of the method is that hydrothermal treatment of aque- ous solution (0,001–0,050) mol/l of aluminium nitrate and (0,01–0,50) mol/l of fructose is performed under the temperature (100–125)оС and pressure (0,5–1,0) MPа for (1–4) hours to create large amount of nucleating seeds of new phase in the volume of reaction solution and then under (175–200)оС and pressure (3–5) MPа for (5–25) hours to provide growth of these nucleating seeds up to the sizes of several tens of nanometers.

Annealing of the product of hydrothermal treatment can be performed under temperature (600–800)оС. Hydrothermal treatment of the initial solution of aluminium nitrate and fructose in two-stage mode makes it possible to specify precisely functional parameters of the final product due to control of crystal nucleation process (the first stage) and growth process (the second stage) which antecede the main product of composite spheres with the structure “carbon nuclear – oxide coating”. At the first stage of hydrothermal treatment of solution comparatively soft temperature and time conditions provide appearance of large number of new phase nucleating seeds in reaction volume. At the second stage, more rigid conditions of hydrothermal treatment cause rapid growth of nucleating seeds up to size of several tens of nanometers and formation of their composition structure “carbon nuclear – oxide shell” which further determines values of specific surface and porosity of the product – hollow spheres Al2O3 – obtained in future thermal treatment.

A method to obtain powders of high-borated diamond (RU 2740933 С1)

The invention refers to diamond synthesis and, in particularly, to the methods of synthesis of diamond powders alloyed with boron in concentration more than 1021 atom/cm–3. The particular characteristic of the material is metal type of conductivity and hyper conductivity under low temperatures, that makes it to be used in such areas as electrochemistry, biochemistry, electroanalysis, electronic and electromechanical devices. The need in micronic and submicronic powders of high boron-doped diamond is caused by the fact that they can be used to produce conducting and hyper conducting composites with extraordinary hardness [13].

The aim of the given technical solution is to eliminate some drawbacks, and in particularly, to eliminate application of hydrogenous material and to obtain diamond powders of micron approximately 1–10 µm and submicron 0.1–1 µm sizes, containing alloying boron additive in concentration not less than 1021 atom/cm–3. Moreover, the task to obtain diamond powders of specified size of grain in micron and submicron ranges is also considered.

The study of the proposed solution revealed that dispersiveness and boron impurity level of the obtained diamond powders is determined by the state of initial

REVIEW OF NANOTECHNOLOGICAL INVENTIONS carbon material and, in particular, by its dispersiveness and its boron impurity level. It was determined that initial carbon material can be borated graphite which can be obtained from the mixture of nanoglobular carbon and X-ray amorphous boron under the impact of high pressure and temperature, at this the pressure must be lower than the pressure for diamond synthesis. It was also determined that variation of atomic ratio of boron and carbon in the mixture of nanoglobular carbon and X-ray amorphous boron as well as variation of parameters of thermobaric treatment makes it possible to obtain boron-doped graphite powders of different grain size and crystalline perfection. The imposed aim is achieved due to the following consequence of stages: nanoglobular carbon and X-ray amorphous boron are taken according to boron-to-carbon atom ratio from 1/10 to 1/20, are mixed and are treated under the pressure within the range 3–6 GPа and temperature within the range 1400–1700оС, that allows obtaining borated graphite powders which further will be treated under the pressure 8 GPа and temperature 1600–1800оС.

The specialists can also be interested in the following inventions related to nanotechnologies:

-

• A method to produce dry construction mixtures [14].

-

• A method to produce nanostructured hollow microspheres of vanadium oxide [15].

-

• A method to produce water suspensions of nanocomposite material on the basis of graphene oxide and

zirconium trisulfides with antibacterial properties [16].

-

• A method to produce ferrum-based composite material strengthened with metal nanopowder oxides [17].

-

• A method to produce metal ferrites of eighth group fourth period [18].

-

• A method to form contact surface of lithium-ion anode battery [19].

-

• Broadband radiant of infrared and THz-bands of wave length [20].

-

• A method to produce metal-polymer nanocomposite materials with metal nanoparticles [21].

-

• A method to obtain modified magnetite nanoparticles gadolinium-doped [22].

-

• Hybride magnetic and electric conductive material on the basis of polymer, bimetal nanoparticles and carbon nanotubes and a method to produce it [23].

-

• A method to form micro- and nanofiber material [24].

CONCLUSION

One of the most challenging tasks the economy of every country face is to increase industrial competitiveness through technological upgrade. From the side of the state and companies the principal object to control in this process are the people and enterprises dealing with introduction of inventions and new technologies.

Therefore, we hope that the information published in this section will be in demand and useful for specialists.

Список литературы Inventions of scientists, engineers and specialists from different countries in the area of nanotechnologies. Part I

- Pershin V.F., Al-Jakhar R.А., Mansur V. et al. A method to produce graphene-containing suspensions by means of graphite exfoliation and a device to perform it. Russian Federation Patent 2737925. 04.12.2020.

- Sharma P., Goyal, P. (2020). Evolution of PV technology from conventional to nano-materials. Materials Today: Proceedings, 28, 1593-1597.

- Gengenbach P., Brenner T., Befurt U. A composition of coating for colored decoration of building walls. Russian Federation Patent 2738655. 15.12.2020.

- Tarnavich V.V., Sidorkin А.S., Korotkova Т.N. et al. Ferroelectric nanocomposite on the basis of porous glass and monopotassium phosphate materials. Russian Federation Patent 2740563. 15.01.2021.

- He W., Wang Q., Zhu Y., Wang K., Mao J., Xue X., Shi Y. Innovative technology of municipal wastewater treatment for rapid sludge sedimentation and enhancing pollutants removal with nano-material. Bioresource Technology. 124675.

- Vorozhtsov А.B., Arkhipov V.А., Chrustalev А.P., Danilov P.А. A method to obtain powder mixture of bidispersed ceramic and metal particles. Russian Federation Patent 2740495. 14.01.2021.

- Rai P. K., Lee J., Brown R. J., Kim K. H. Micro-and Nanoplastic Pollution: Behavior, Microbial Ecology, and Remediation Technologies. Journal of Cleaner Production, 2020; 125240.

- Kolesnikov V.I., Sychev А.P., Kolesnikov I.V. et al. A method to obtain nanocomposite magnetic and electricallyconductive material. Russian Federation Patent 2740591. 15.01.2021.

- Ozkan S.Zh., Karpacheva G.P. A method to obtain nanocomposite magnetic and electrically-conductive material. Russian Federation Patent 2739030. 21.12.2020.

- Yakushkin А.А., Borisov V.М., Trofimov V.N. Fuel element with composite protective coating. Russian Federation Patent 2740701. 19.01.2021.

- Tonk R. The science and technology of using nano-materials in engine oil as a lubricant additives. Materials Today: Proceedings. 2020. Available from: doi: 10.1016/j.matpr.2020.09.384.

- Martinson К.D., Popkov V.I., Bachina А.К. et al. A method to produce hollow microspheres from aluminium oxide. Russian Federation Patent 2740748. 20.01.2021.

- Brazhkin V.V., Bagramov R.Kh., Filonenko V.P., Zibrov I.P. A method to obtain powders of high-borated diamond. Russian Federation Patent 2740933. 21.01.2021.

- Ivanov L.A., Xu L.D., Bokova E.S., Ishkov A.D., Muminova S.R. Nanotechnologies: are view of inventions and utility models. Part V. Nanotechnologies in Construction. 2020; 12(6): 331–338. Available from: doi: 10.15828/2075-8545-2020-12-6-331-338.

- Vladimirova Е.V., Gyrdasova О.I., Dmitriev А.V. A method to produce nanostructured hollow microspheres of vanadium oxide. Russian Federation Patent 2739773. 28.12.2020.

- Gusev А.А., Zaharova О.V., Muratov D.S. A method to produce water suspensions of nanocomposite material on the basis of graphene oxide and zirconium trisulfides with antibacterial properties. Russian Federation Patent 2739922. 29.12.2020.

- Ivanov L.A., Bokova E.S., Muminova S.R., Katuhin L.F. Nanotechnologies: a review of inventions and utility models. Part I. Nanotechnologies in Construction. 2020; 12(1): 27–33. Available from: doi: 10.15828/2075-8545-2020-12-1-27-33.

- Belaya Е.А., Kovalev I.А., Viktorov V.V. A method to produce metal ferrites of eighth group fourth period. Russian Federation Patent 2738940. 18.12.2020.

- Povoroznyuk S.N., Nesov S.N., Korusenko P.M., Bolotov V.V. A method to form contact surface of lithium-ion anode battery. Russian Federation Patent 2739574. 28.12.2020.

- Bagraev N.Т., Klyachkin L.Е., Kukushkin S.А. et al. Broadband radiant of infrared and THz-bands of wave length. Russian Federation Patent 2739541. 25.12.2020.

- Ivanov LA., Kapustin I.A., Borisova O.N., Pisarenko Zh.V. Nanotechnologies: a review of inventions and utility models. Part II. Nanotechnologies in Construction. 2020; 12(2): 71–76. Available from: doi: 10.15828/2075-8545-2020-12-2-71-76.

- Tsareva Ya.О., Petukhova А.Yu., Nizamov Т.R. et al. A method to obtain modified magnetite nanoparticles gadolinium-doped. Russian Federation Patent 2738118. 08.12.2020.

- Ozkan S.Zh., Karpacheva G.P. Hybride magnetic and electric conductive material on the basis of polymer, bimetal nanoparticles and carbon nanotubes and a method to produce it. Russian Federation Patent 2737184. 25.11.2020.

- Bokova E.S, Kovalenko G.M, Pawlova M., Kapustin I.A., Evsyukova N.V., Ivanov L. Electrospinning of Fibres Using Mixed Compositions Based on Polyetherurethane and Hydrophylic Polymers for the Production of Membrane Materials. FIBRES & TEXTILES in Eastern Europe. 2020; 28, 4(142): 49-51. Available from: doi: 10.5604/01.3001.0014.0933.